Industrial pulverized coal boiler boiler-inside denitration combustion device with reducing agent being sprayed to main combustion area of combustor

A pulverized coal boiler and combustion device technology, which is applied in the direction of burning powder fuel burners, burners, block fuel and powder fuel combustion, etc., can solve the problems of poor load adaptability and high NOx emissions, and achieve enhanced The effect of graded combustion degree, reduction of NOx emission and avoidance of flue gas corridor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

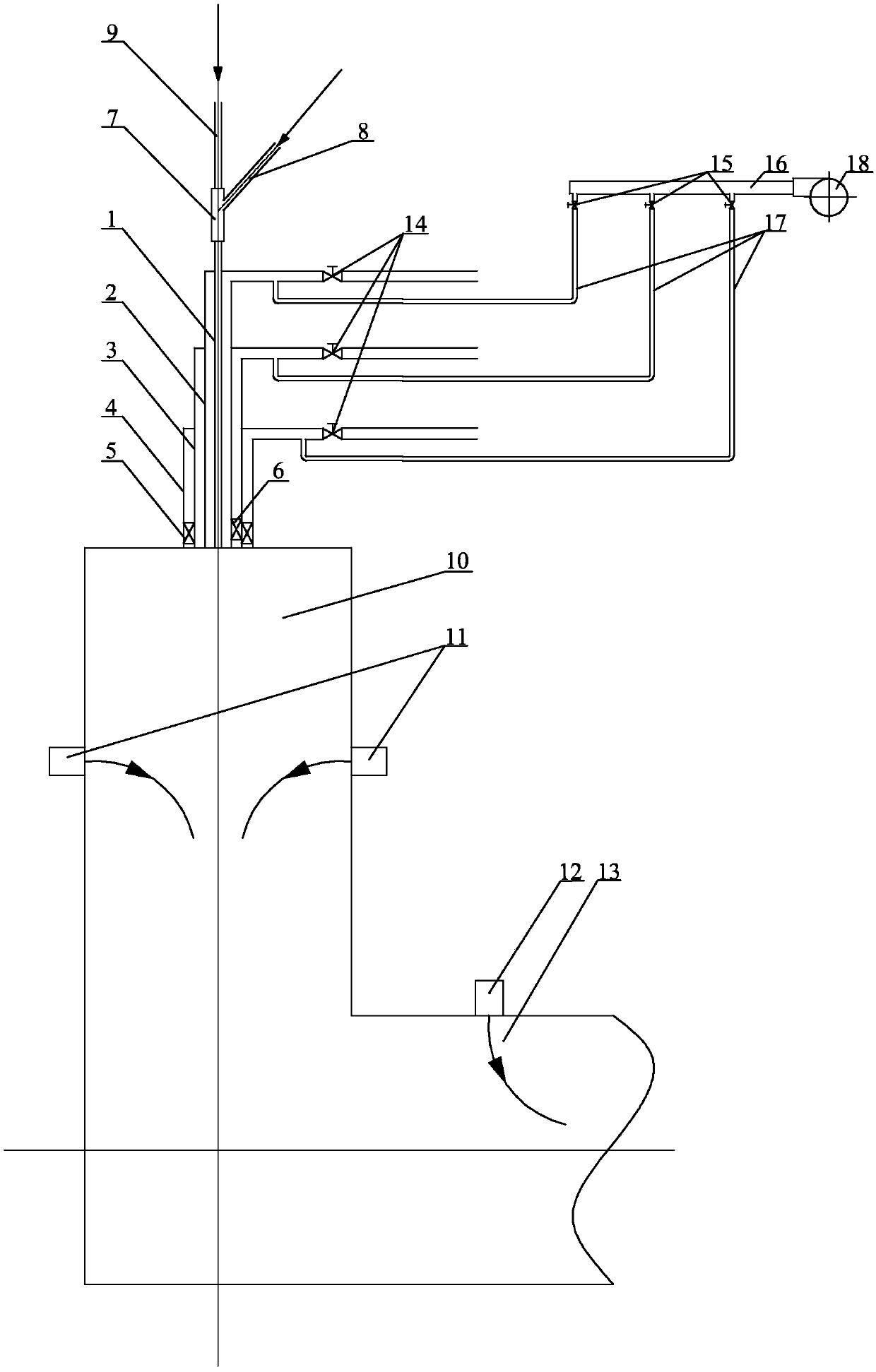

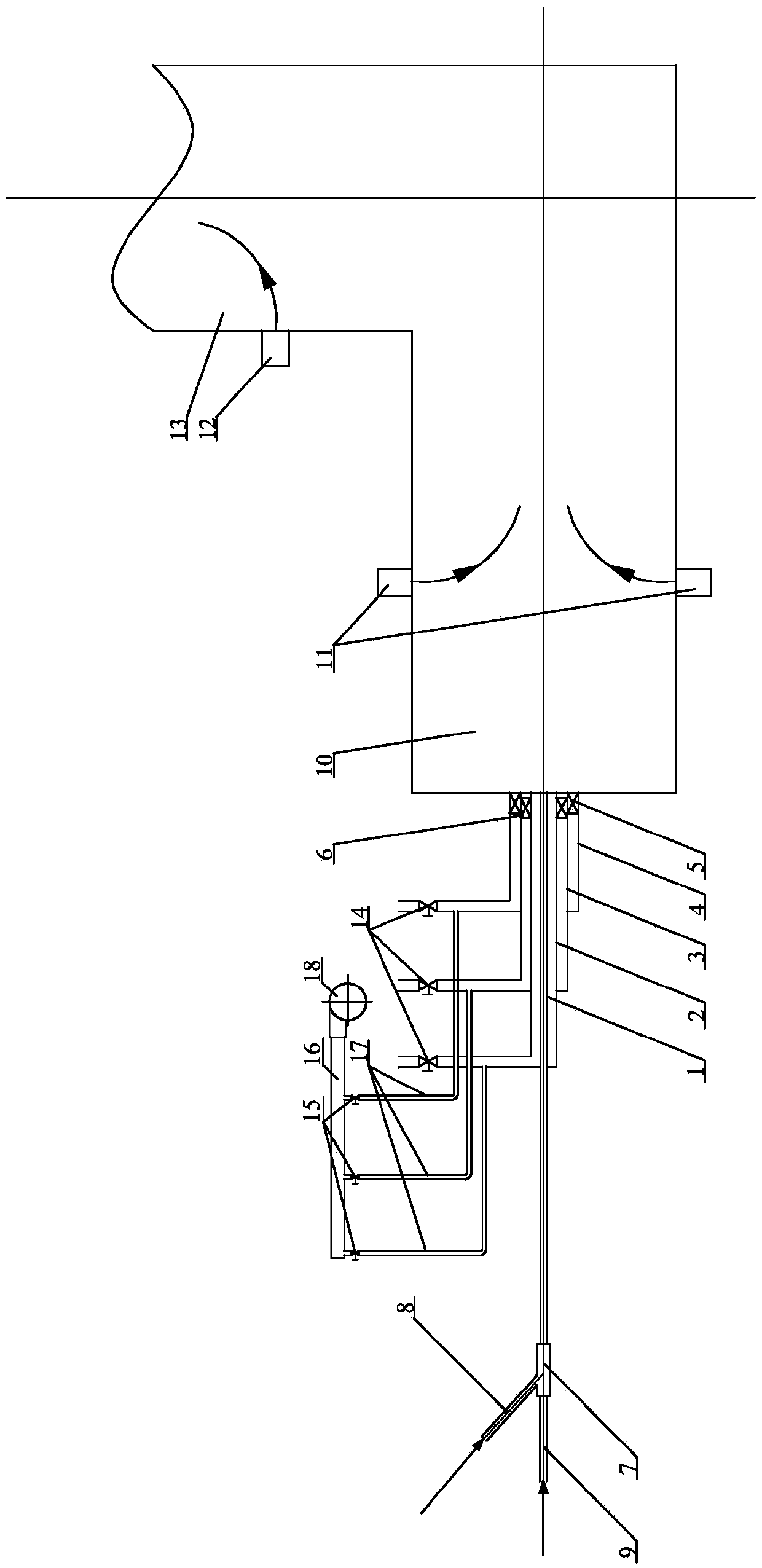

[0019] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, the industrial pulverized coal boiler burner main combustion zone of the industrial pulverized coal boiler burner sprays the denitrification combustion device in the furnace, which includes a burner, a recirculation flue gas pipeline 16 and an induced draft fan 18, and the burner includes a primary air duct 1. DC secondary air duct 2, swirl inner secondary air duct 3, swirl outer secondary air duct 4, first axial swirl vane 5 and second axial swirl vane 6; it also includes a mixer 7. Amino reducing agent delivery pipe 8, concentrated pulverized coal delivery pipe 9, three secondary air air pipes, three secondary air air pipe valves 14, three recirculation flue gas pipe valves 15, three recirculation flue gas Branch pipes 17, four first-level overburning air nozzles 11 and multiple second-level overburning air nozzles 12; primary air duct 1, DC secondary air duct 2, swirling inner seco...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, the industrial pulverized coal boiler burner main combustion area of the industrial pulverized coal boiler burner in this embodiment sprays the denitrification combustion device in the furnace, the primary air pipe 1 passes through the direct current secondary air pipe 2 and is connected to the outlet of the mixer 7 . Other methods are the same as in the first embodiment.

specific Embodiment approach 3

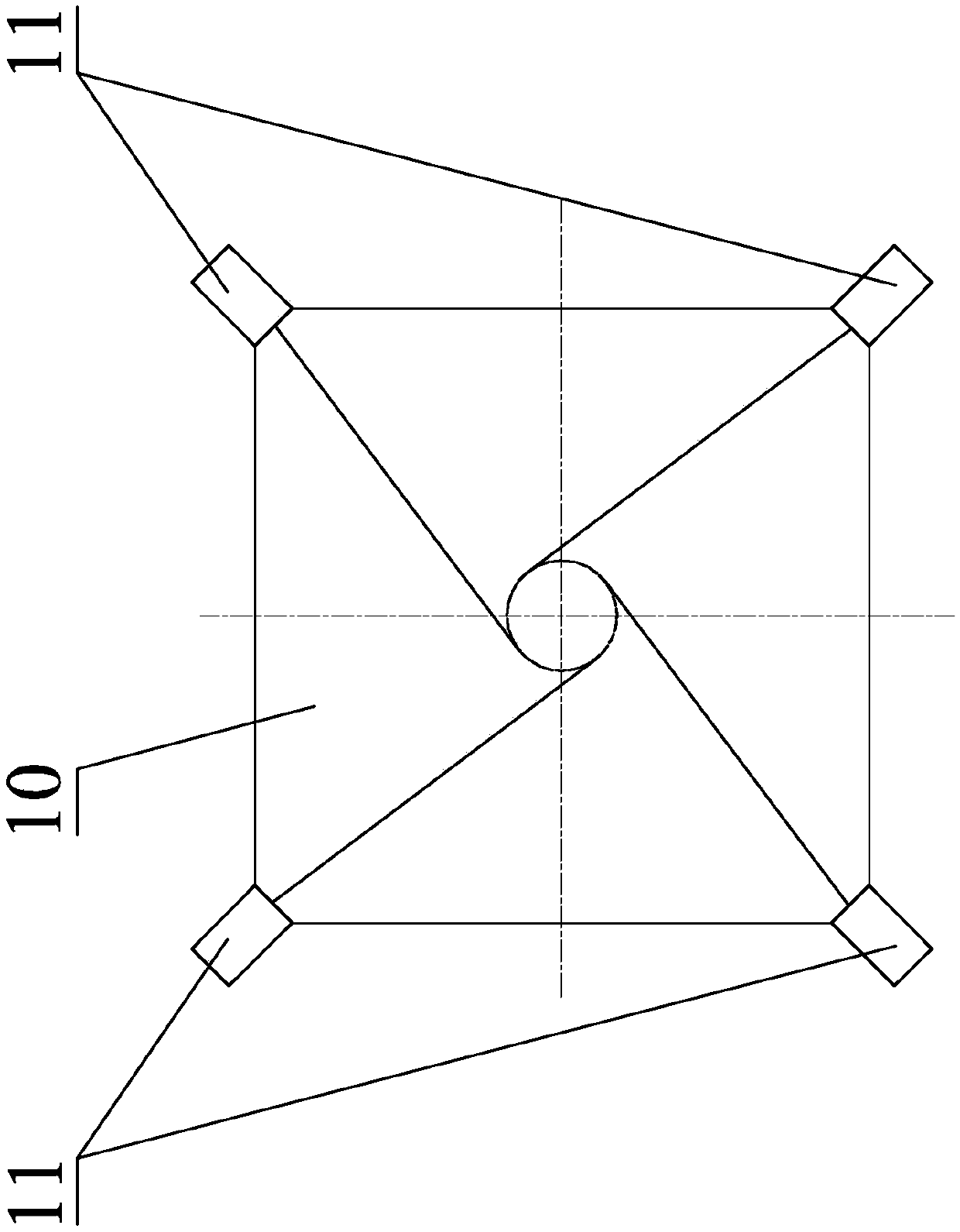

[0021] Specific implementation mode three: combination image 3 To illustrate this embodiment, the industrial pulverized coal boiler burner main combustion area of the industrial pulverized coal boiler burner sprays the denitrification combustion device in the furnace, each primary burn-off air nozzle 11 is set toward the center of the boiler furnace 10, and the four primary burn-off air The center line of the air spout 11 is tangent to the circle where the center line of the boiler furnace 10 is located. Other methods are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com