Regenerative throttling assembly, combined microchannel throttling refrigerator and device

A technology of throttling components and throttling channels, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increasing the axial heat conduction of the channel wall, reducing the pressure bearing capacity, and small cooling capacity, so as to achieve enhanced heat transfer The effect of improving efficiency, improving heat exchange intensity, and increasing cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

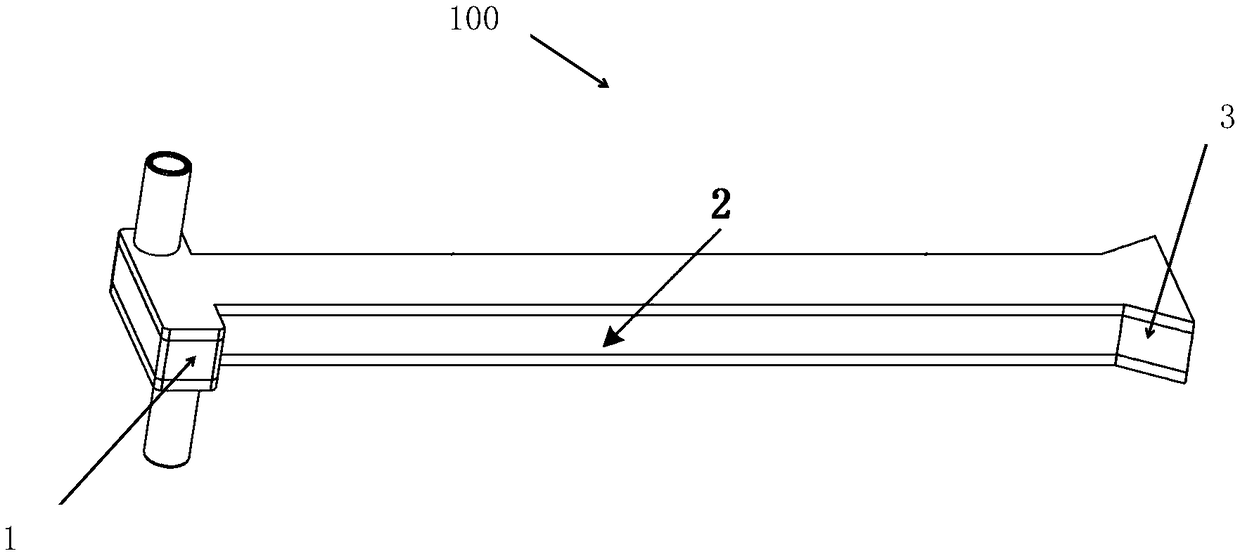

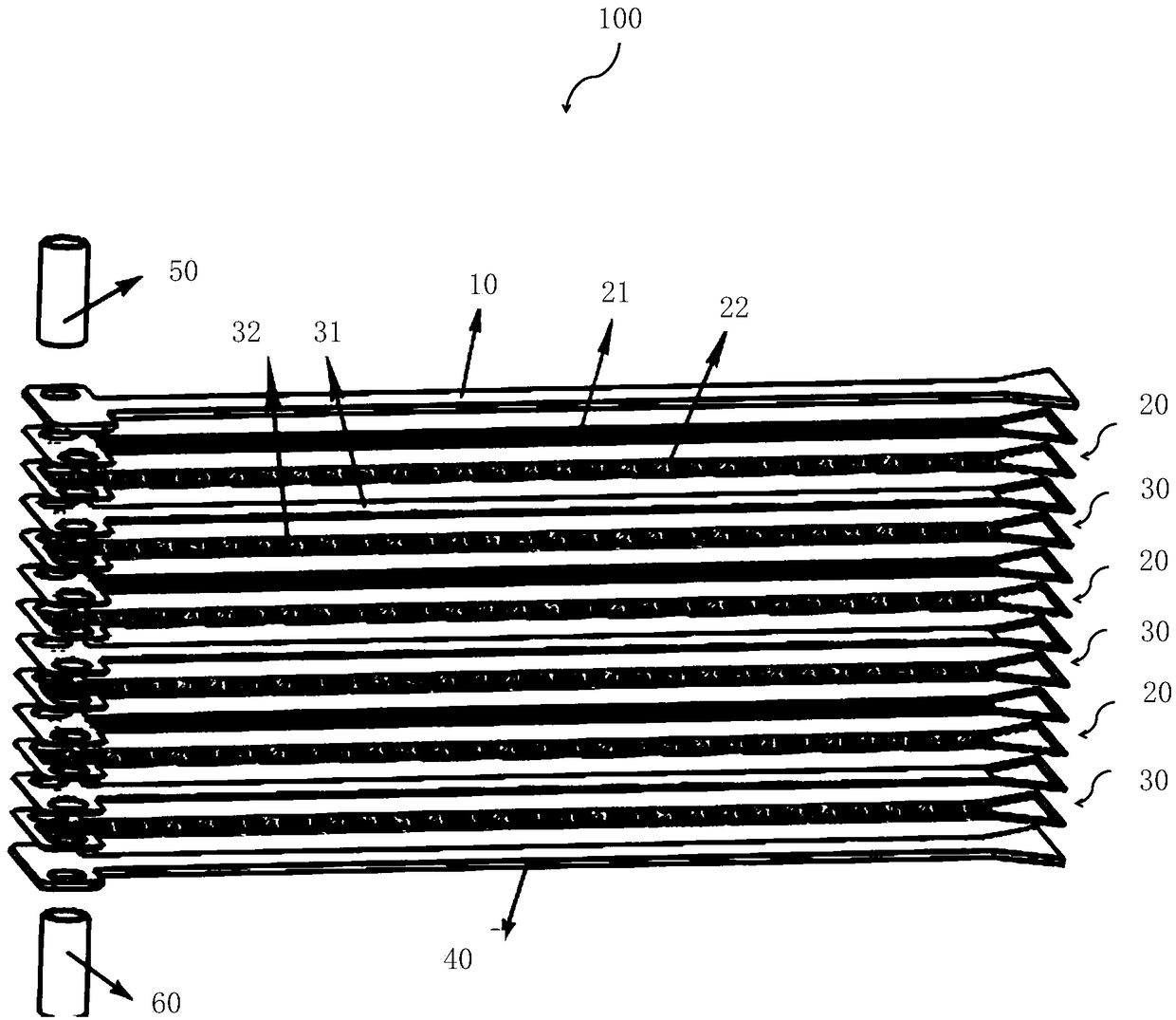

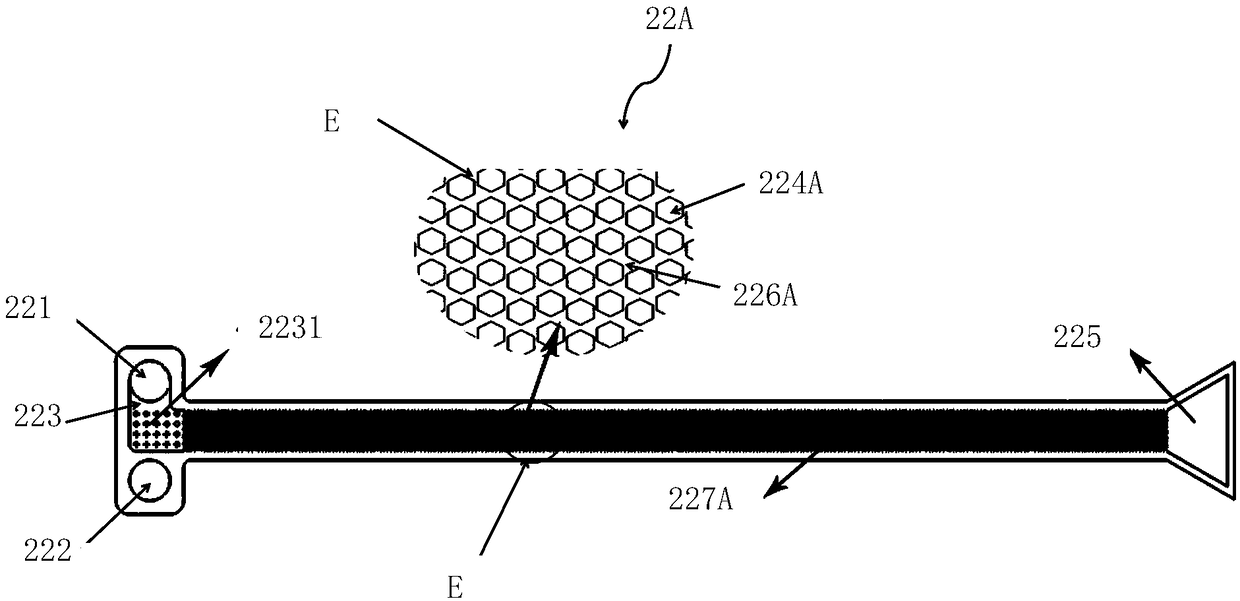

[0028] figure 1It is the overall appearance diagram of a stacked chute-shaped and wavy combined micro-channel throttling refrigerator. The stacked chute-shaped and wavy-shaped combined micro-channel throttling refrigerator 100 includes an inlet section 1, a regenerative throttling section 2 and a capacity expansion paragraph 3. The high-pressure and normal-temperature gas enters the regenerative throttling area from the inlet section 1 of the refrigerator, and is pre-cooled by the low-pressure and low-temperature recirculation gas in the adjacent components. During this flow process, the high-pressure fluid has both the Bernoulli effect and the charred throttling effect The multi-layer low-temperature and low-pressure gas after regenerative throttling gathers in the expansion section 3 to expand and cool down. At the same time, it absorbs the heat from the external heat source in the expansion section 3, then enters the low-pressure channel, and finally flows out through the l...

Embodiment 2

[0118] The other structures of this embodiment are the same as those of the first embodiment, except that the high-pressure channel assembly 20 adopts a high-pressure channel assembly 20C3, and the low-pressure channel assembly 30 adopts a low-pressure channel assembly 30C3.

Embodiment 3

[0120] The other structure of this embodiment is the same as that of the first embodiment, except that the high-pressure channel assembly 20 adopts the high-pressure channel assembly 20A3, and the low-pressure channel assembly 30 adopts the low-pressure channel assembly 30C4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com