Lithium battery thermal safety management system and management and control method

A battery management system and safety management technology, applied in the field of lithium battery thermal-safety management system and management and control, can solve the problems of reducing the overall performance of the battery system, reducing the lifespan, not considering the heating and/or cooling requirements of the battery module, etc. Consistency and performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

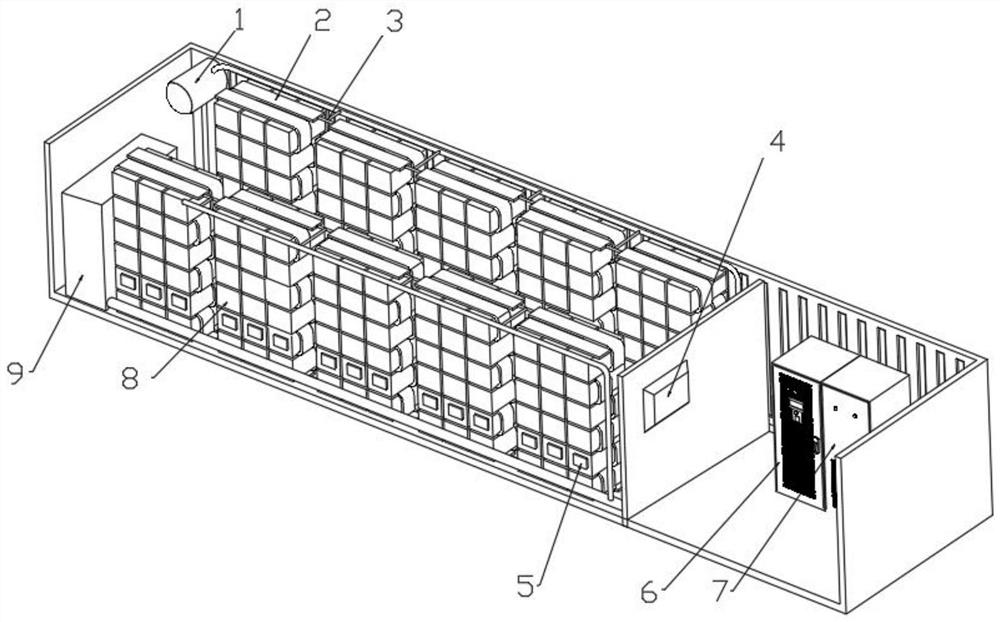

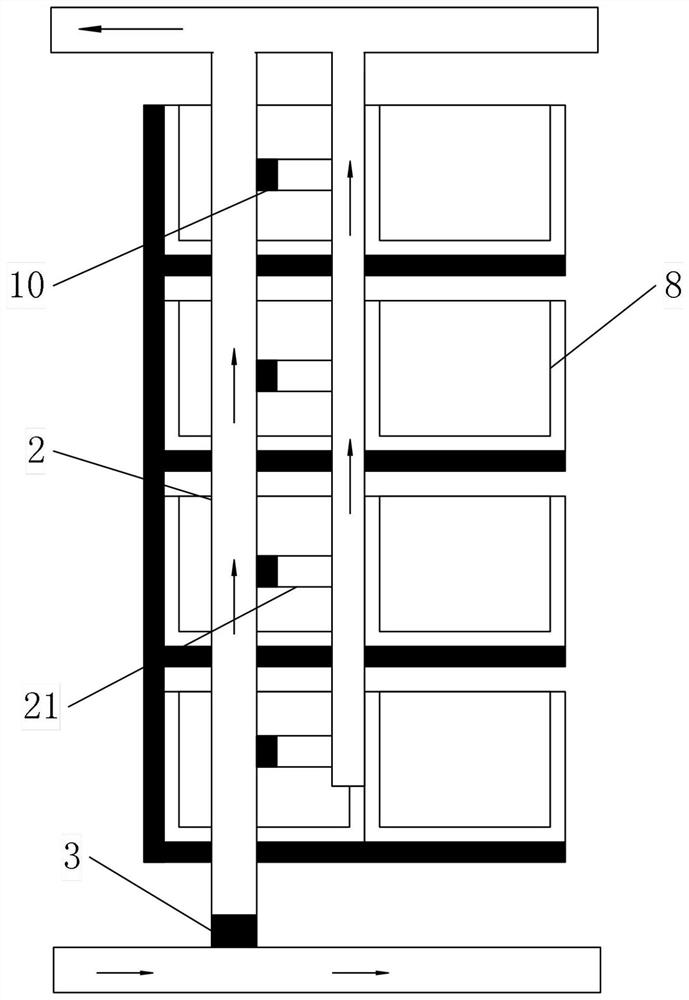

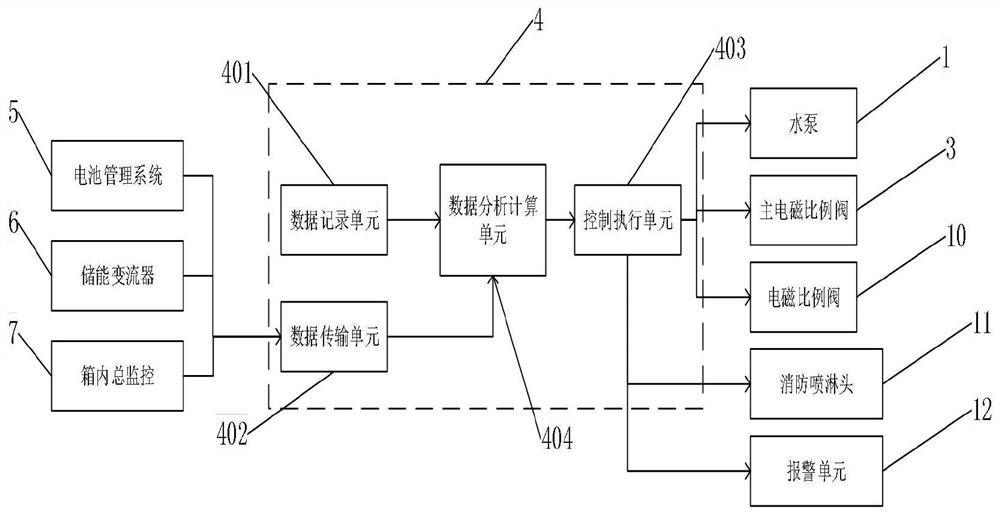

[0039] see Figure 1 to Figure 3 , a thermal-safety management system for a lithium battery, comprising a thermal-safety management controller 4, a battery management system 5, an energy storage converter 6, a total monitor 7 in the box, several battery modules 8 and a cooling system; the thermal- The safety management controller 4 is used for thermal management and control of the battery module 8; the battery module 8 is composed of several single batteries; the cooling system includes a liquid cooling channel 2 arranged on the heat dissipation surface of the battery module 8 The branches of the liquid cooling passage 2 form several liquid cooling pipes 21, and the liquid cooling pipes 21 cover the heat dissipation surface of each group of the battery modules 8; the liquid cooling passage 2 and the liquid cooling The pipe 21 is respectively provided with a main electromagnetic proportional valve 3 and a sub electromagnetic proportional valve 10; the thermal-safety management ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com