Method of producing gasoline by fluidized bed process methanol

A technology using flow and fluidized bed reactors, applied in the petroleum industry, biological raw materials, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of high energy consumption, large investment, complicated process, etc., and achieve low investment and high heat exchange intensity High, constant catalyst properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

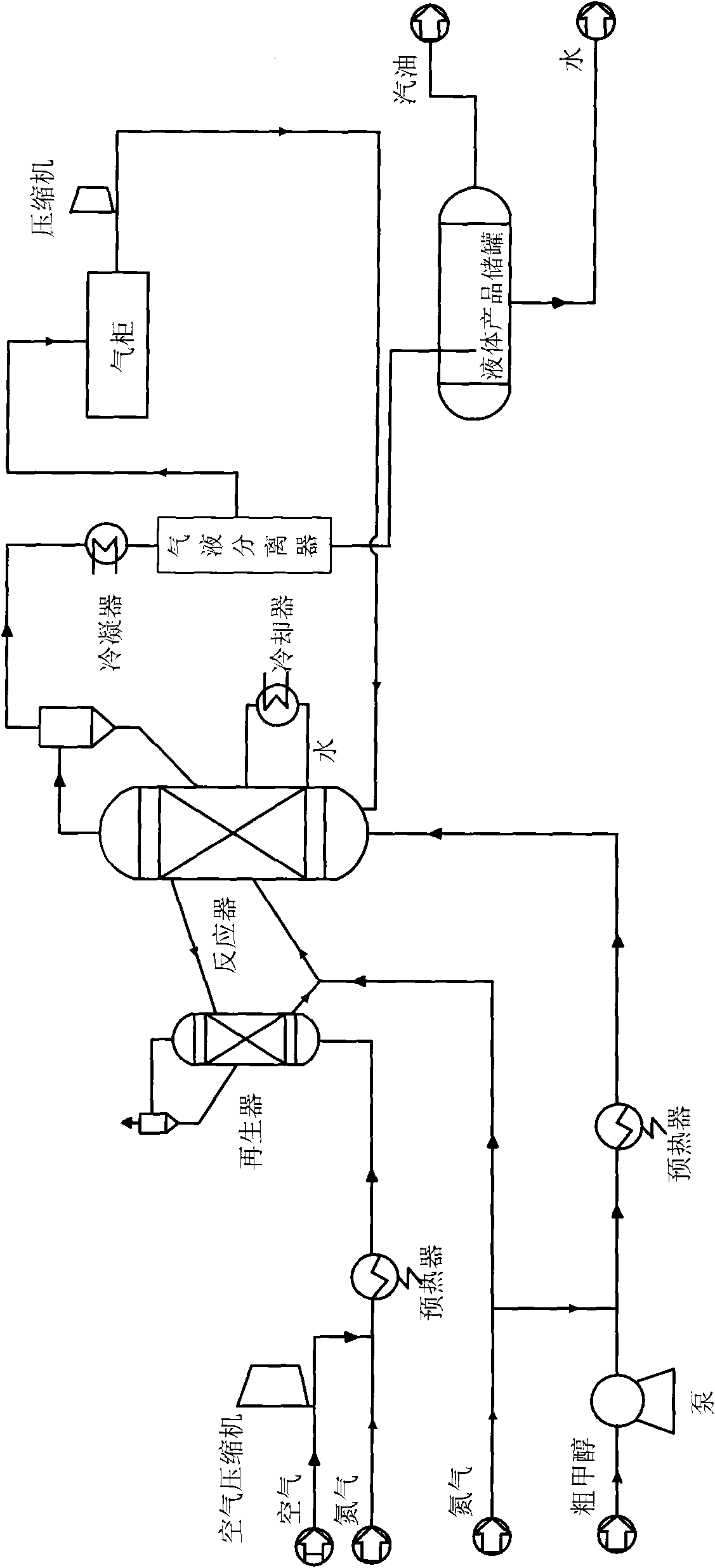

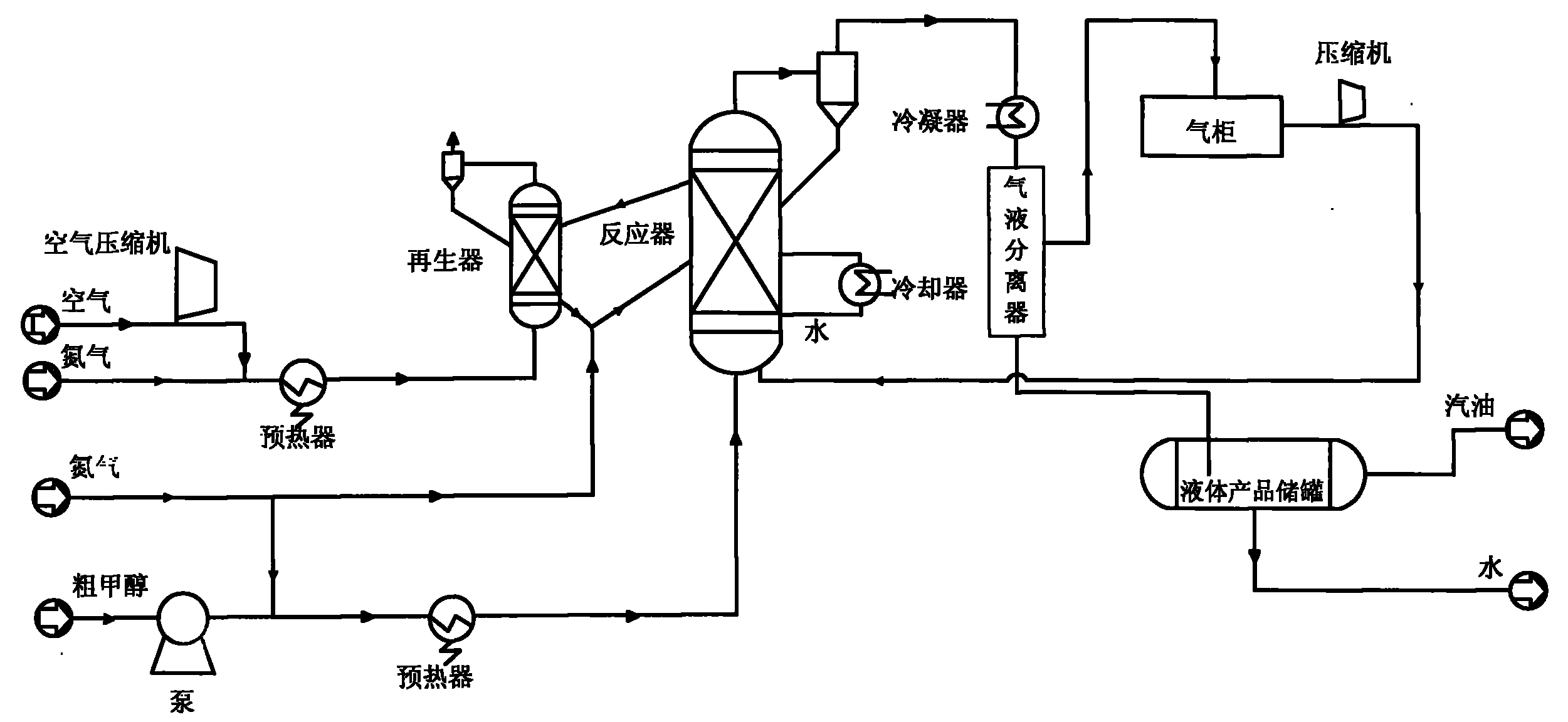

Method used

Image

Examples

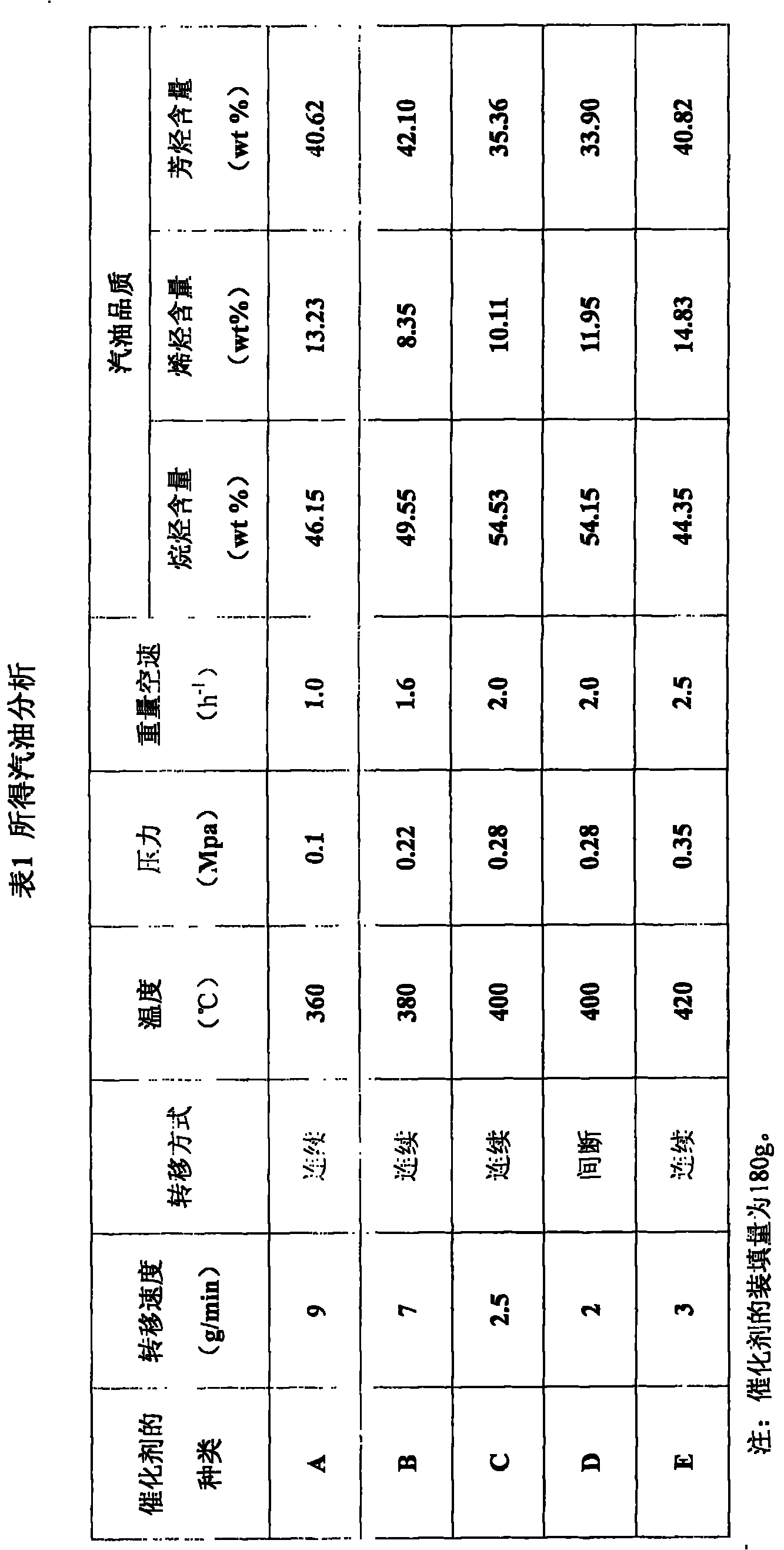

Embodiment 1

[0021] Crude methanol is pumped into the preheater from the methanol storage tank through the methanol metering pump, preheated and vaporized in the preheater, and then enters the tank equipped with zirconium-containing ZSM-5 molecular sieve catalyst A with a silicon-aluminum ratio of 80 produced by the Shanxi Coal Chemical Industry Institute of the Chinese Academy of Sciences. Fluidized bed reactor, the reactor temperature is controlled by a program temperature controller to 360°C, the pressure is 0.1MPa, and the space velocity is 1.0h -1 React with the catalyst in the reactor. The catalyst is continuously or intermittently removed from the reactor at a certain speed, and then replenished by the regenerator at the same speed, and the cycle is repeated. The catalyst regeneration conditions are: temperature 500°C; pressure 0.1MPa; regeneration gas is air and N 2 Mixed gas, gravimetric space velocity: 3h -1 , the regeneration time is 2 hours. The reaction product flows out fr...

Embodiment 2

[0023] Crude methanol is pumped into the preheater from the methanol storage tank through the methanol metering pump. After preheating and vaporizing in the preheater, it enters the fluidized bed reactor equipped with catalyst B with a silicon-aluminum ratio of 38 produced by Nankai University. The reactor The temperature is controlled by a program temperature controller to 380°C, at a pressure of 0.22MPa and a space velocity of 1.6h -1 React with the catalyst in the reactor, and others are the same as in Example 1. The regeneration conditions of the catalyst are: temperature 550°C; pressure 0.2MPa; regeneration gas is O 2 with N 2 Mixed gas, weight space velocity: 5h -1 , the regeneration time is 4 hours.

Embodiment 3

[0025] Crude methanol is metered by the methanol metering pump according to the amount required by the test and injected into the preheater from the methanol storage tank. After preheating and vaporizing in the preheater, it enters a certain amount of catalyst C with a silicon-aluminum ratio of 50 produced by Nankai University. The fluidized bed reactor, the reactor temperature is controlled by the program temperature controller to 400 ℃, the pressure is 0.28MPa, the space velocity is 2.0h -1 React with the catalyst in the reactor, and others are the same as in Example 1. The regeneration conditions of the catalyst are: temperature 600°C; pressure 0.2MPa; regeneration gas is O 2 with N 2 Mixed gas, gravimetric space velocity: 10h -1 , the regeneration time is 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com