Method for producing balance together negative-positive plate of battery

A technology of cathode, anode and storage battery, which is applied in the field of balanced production of battery cathode and anode plates, can solve unreasonable and unscientific problems, and achieve the effect of balanced matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

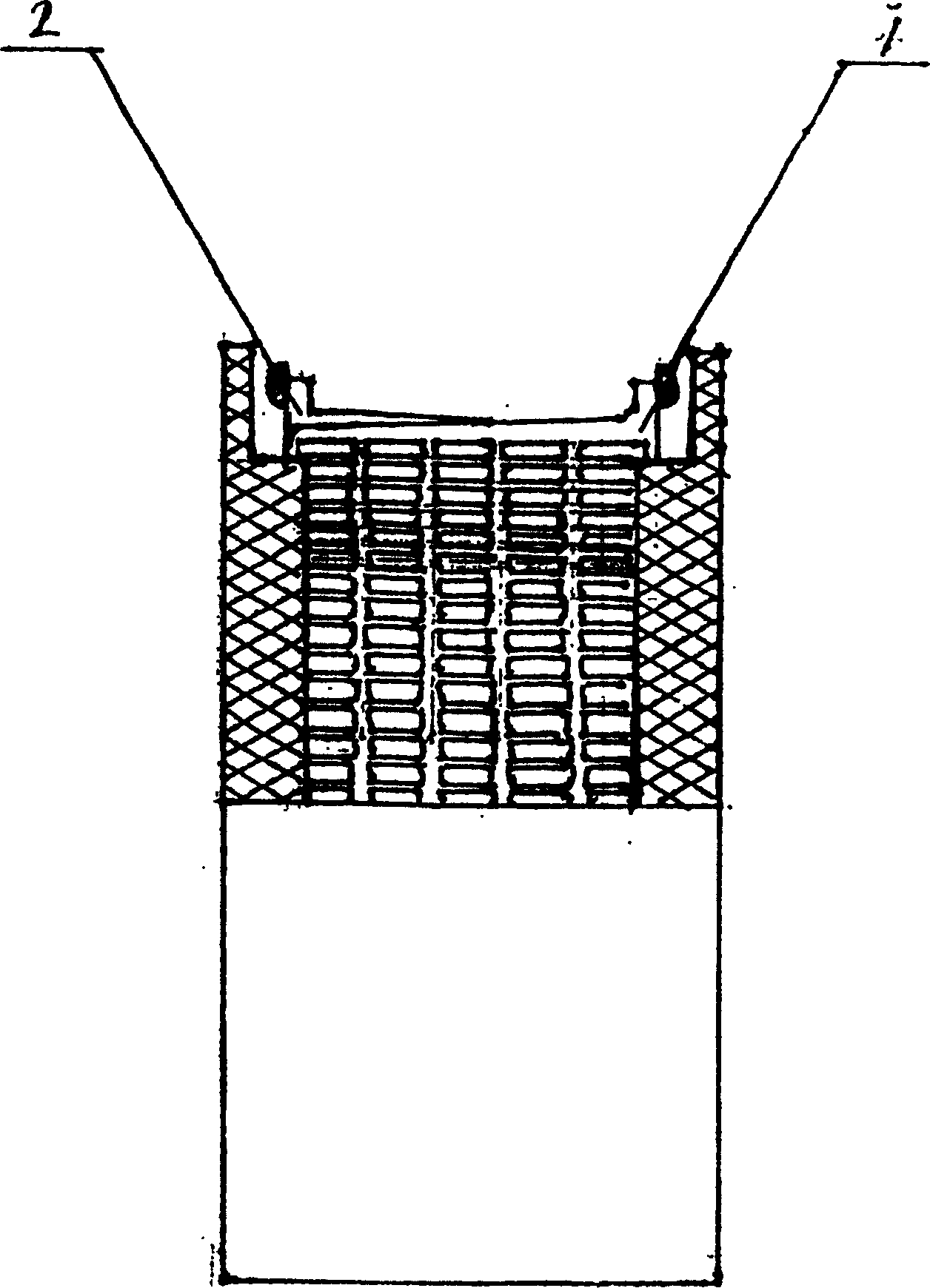

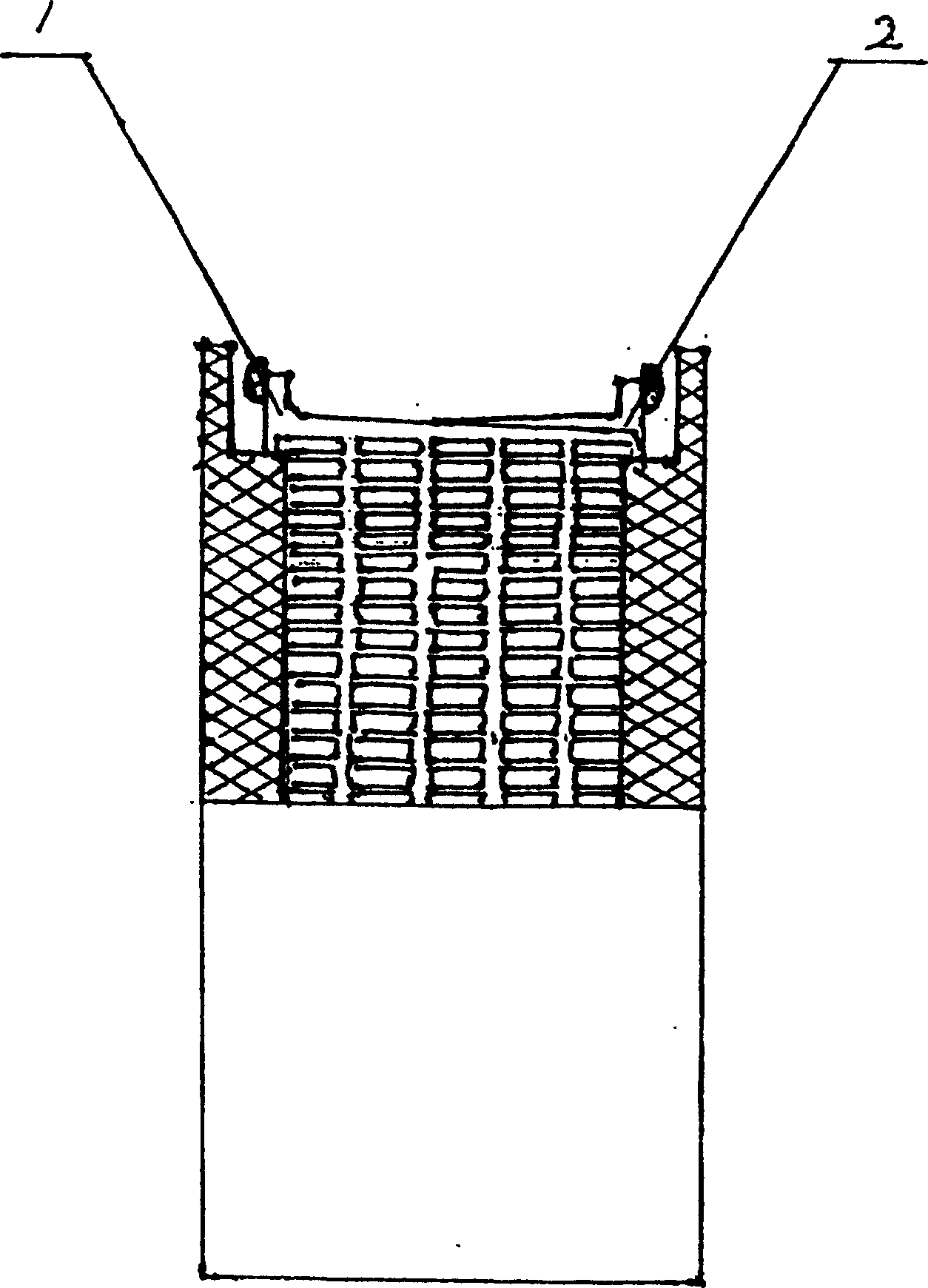

Image

Examples

Embodiment 1

[0031] Example 1: replace the anode plate with the grid to install the tank, the cathode is the cathode plate, the density of the electrolyte used is 1.05±0.005 at 15°C, and the formation current is 2.5A / single chip based on the positive plate. The formation voltage is ≤155V, the formation time is 28 hours, the negative plate is rinsed with clean water for 2 hours, soaked in 5% glycerin for 15-20 minutes, and the drying temperature is 90-95°C. Lower than the internal control standard with PbO≤9%, the formation cost is 0.26 yuan / single piece.

Embodiment 2

[0032] Embodiment 2: Replace the anode plate with the grid to fill the tank, and the cathode is the cathode plate, which is formed according to the chemical conversion conditions of Example 1, and the cathode plate is produced separately to contain PbO5.72%, which is lower than that containing PbO≤9%. Internal control standards, the formation cost is 0.27 yuan / single chip.

Embodiment 3

[0033] Embodiment 3: Replace the anode plate with the grid to fill the tank, and the cathode is the cathode plate, which is formed according to the chemical conversion conditions of Example 1, and the cathode plate is produced separately containing PbO4.33%, which is lower than that containing PbO≤9%. Internal control standards, the formation cost is 0.30 yuan / single chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com