Evaporating pipe and evaporating pipe type heat storage boiler heat exchange system

A technology of heat exchange system and heat storage boiler, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., and can solve problems such as secondary pollution, high noise, and difficulty in realizing the characteristics of extremely cold and rapid heating of materials, etc. Achieve the effect of restoring the inlet water temperature and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

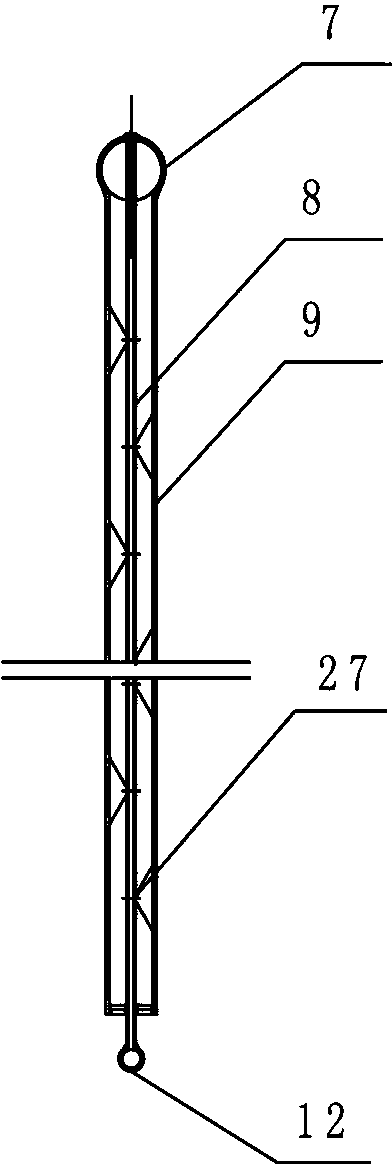

[0014] Such as figure 1 As shown, a kind of evaporating pipe comprises heat pipe 9, the upper end of heat pipe 9 is open, the lower end of heat pipe 9 is closed, and the inside of heat pipe 9 is longitudinally pierced with water spray pipe 8, and the upper end of water spray pipe 8 is closed, and the water spray pipe The lower end of 8 is open and stretches in the outside of heat pipe 9, and on the pipe wall of spray pipe 8, several pipe water holes 27 are evenly distributed.

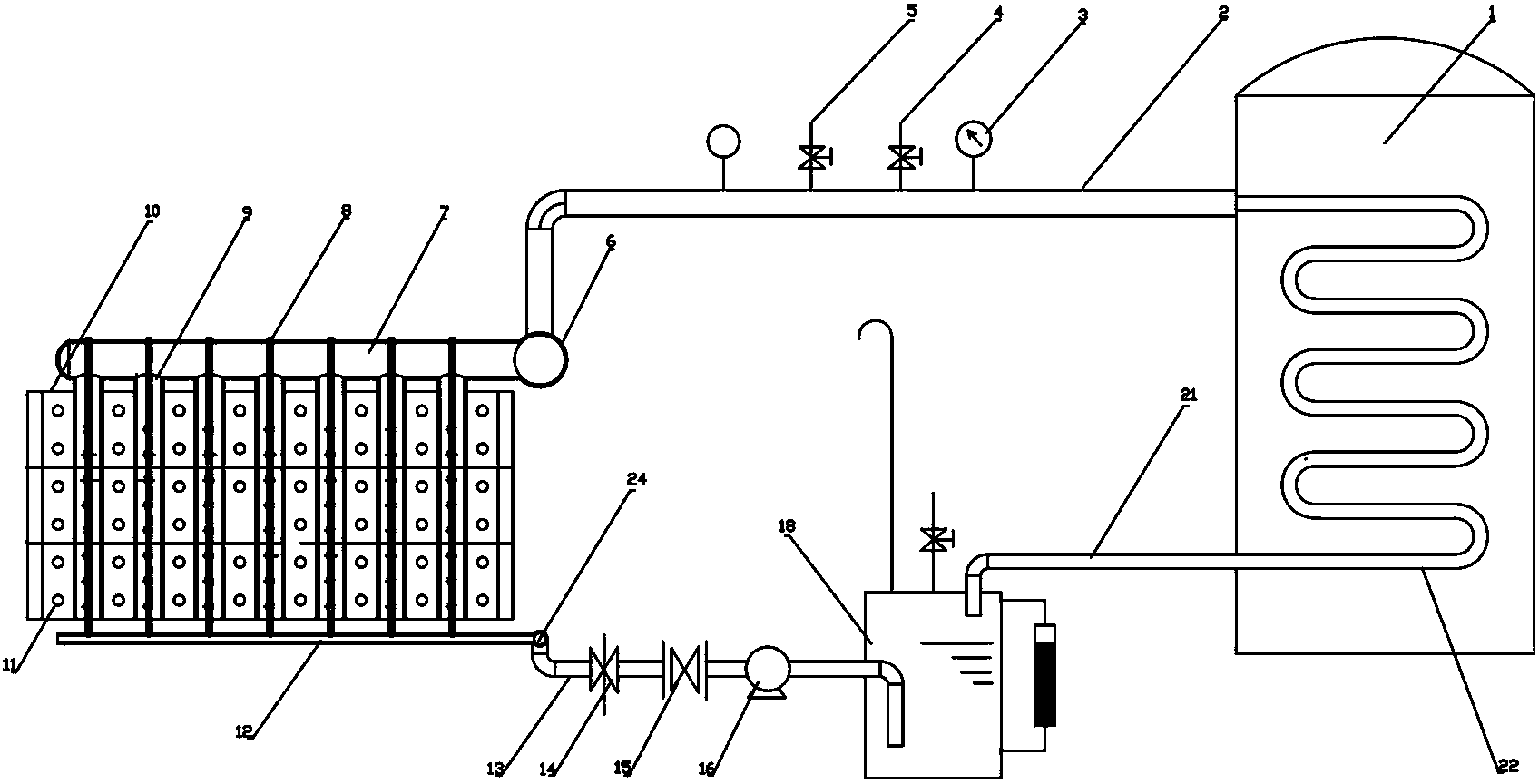

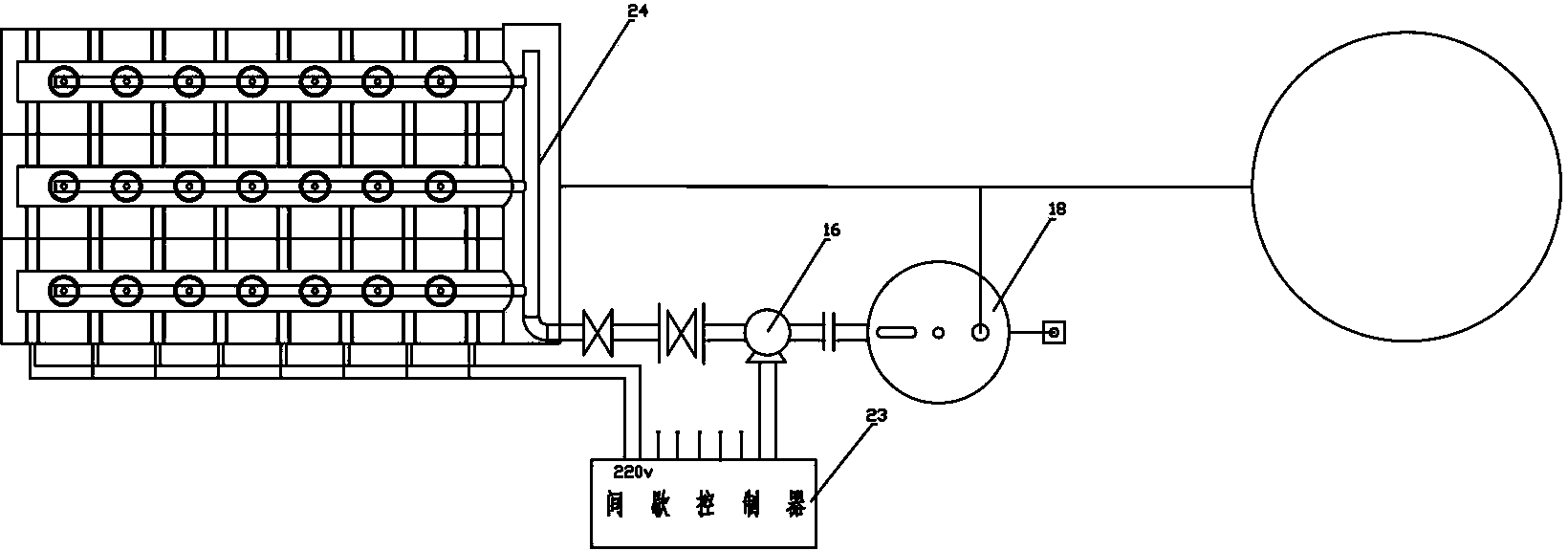

[0015] Such as figure 2 with image 3 As shown, a heat storage boiler heat exchange system adopts the above-mentioned evaporation tube. The system includes five parts: heat accumulator, water inlet, return water, heat exchange and control. The heat accumulator adopts several heat accumulators 10 and several evaporation tubes, and all heat accumulators 10 are neatly placed in rows and columns. An electric heating tube 11 is provided in the heat storage body 10, and the evaporation tube is vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com