Fuel oil (gas) vertical radiation jet heat pipe heat-blast stove

A heat pipe hot blast stove and heat pipe heat exchanger technology, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of flue gas series mixing, tube sheet cracking, and low gas-air heat transfer coefficient. , to achieve the effect of ensuring heat exchange intensity, improving heat exchange intensity and reducing heat transfer thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

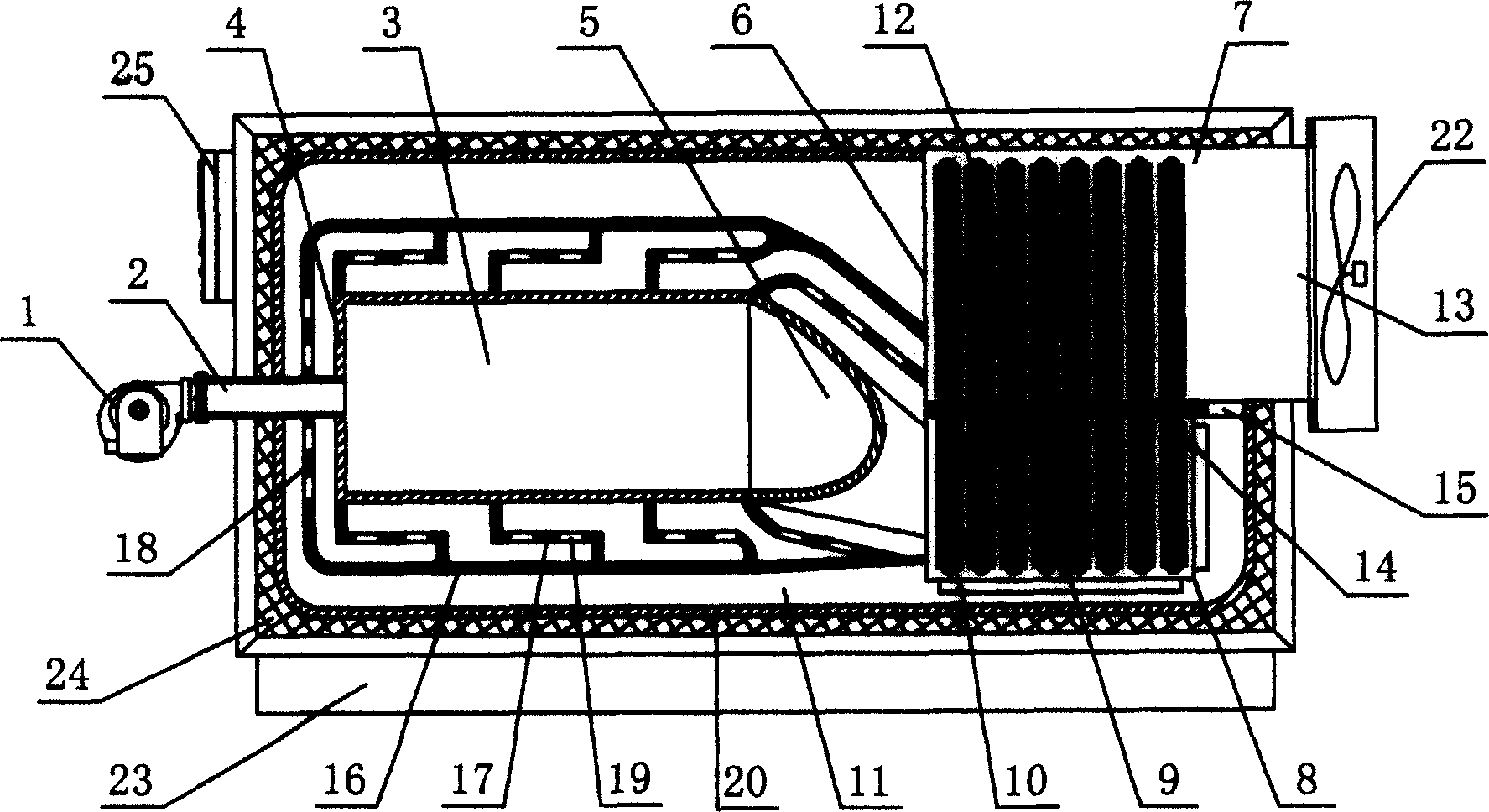

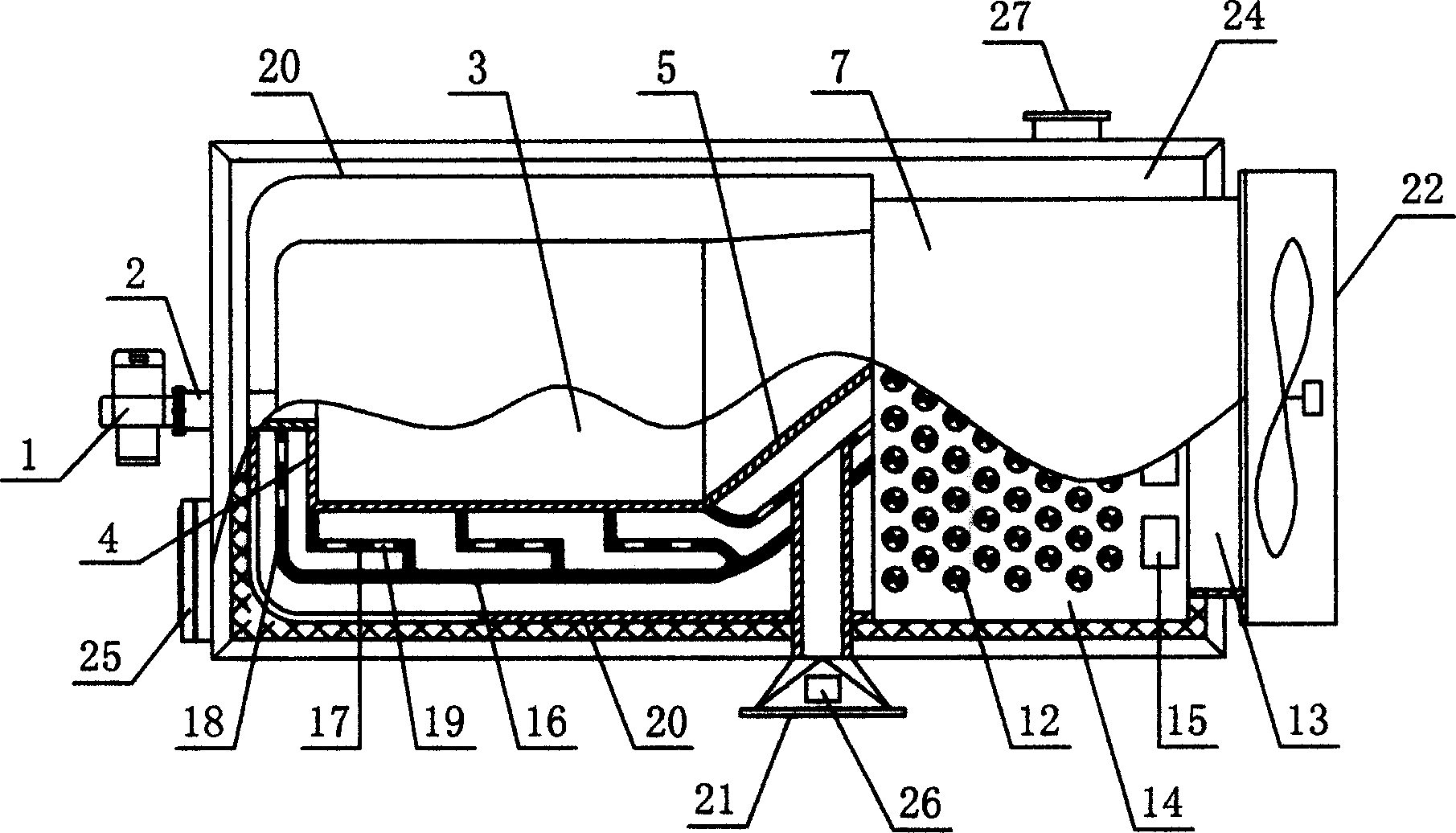

[0015] Referring to Fig. 1 and Fig. 2, the implementation of the present invention mainly includes: burner 1, burner connecting pipe 2, furnace 3, front end cover 4, inclined fire channel 5, heat pipe heat exchanger 6, hot air generating chamber 7, flue 8 , flue partition 9, fins 10, lower air passage 11, heat pipe 12, air inlet and outlet 13, tube plate 14, air inlet 15, air collector 16, spray tube 17, front spray plate 18, spray holes 19, heating Tube 20, hot air outlet 21, fan 22, frame 23, insulation layer 24, automatic control box 25, temperature sensor 26, smoke outlet (27).

[0016] In the implementation of the present invention, the burner connecting pipe (2) is installed on the front end cover (4) of the furnace (3), and the combustion flame of the burner (1) burns in the furnace (3) and enters the flue (8) through the inclined flue (5). ) is formed by a flue partition (9) into a U-shaped flue, which absorbs heat through the heat-absorbing sections of heat pipes (10)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com