Through seam type half-split seam trailing edge cooling structure and turbine blade

A technology for cooling structure and turbine blades, applied in the direction of supporting elements of blades, machines/engines, mechanical equipment, etc., can solve the problems of low cooling efficiency on the surface of the partition rib, insufficient cooling, neglect of the cooling of the surface of the partition rib, etc., to improve the comprehensive Cooling effect, good implementability, enhanced internal heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

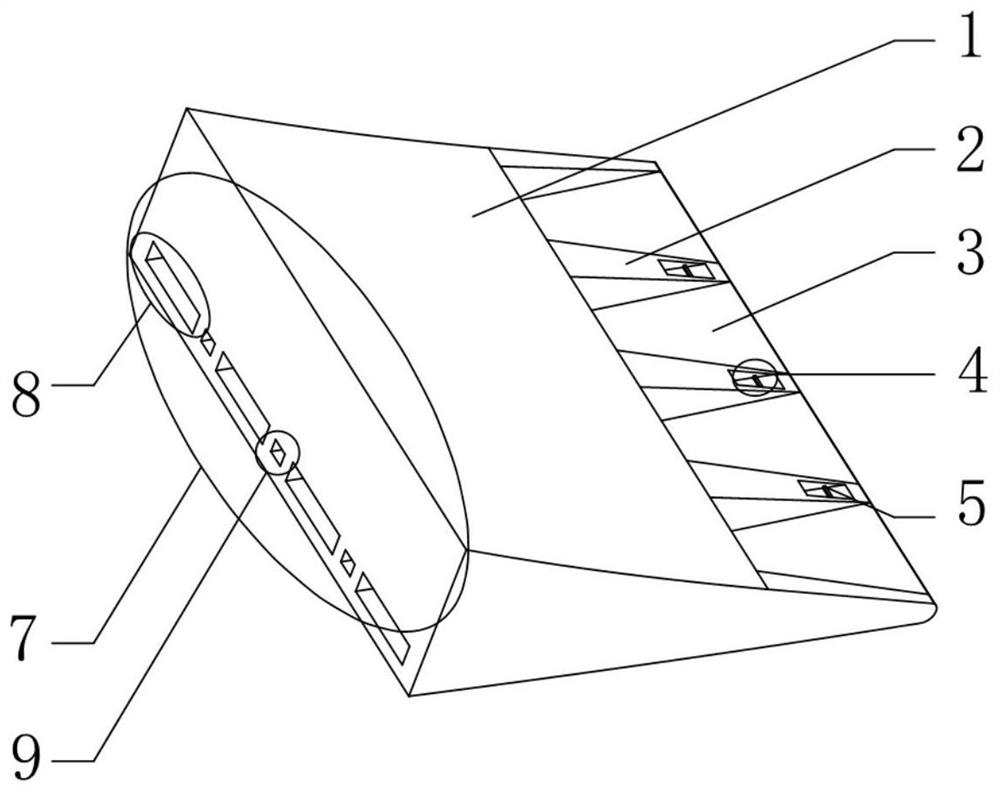

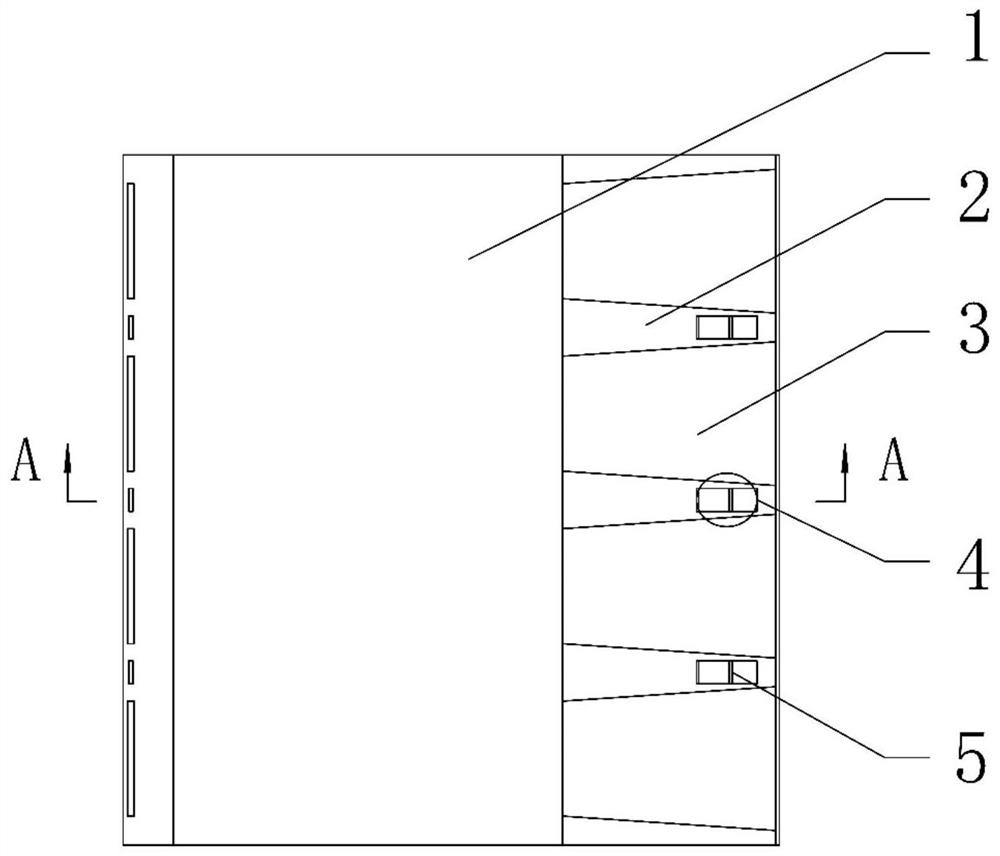

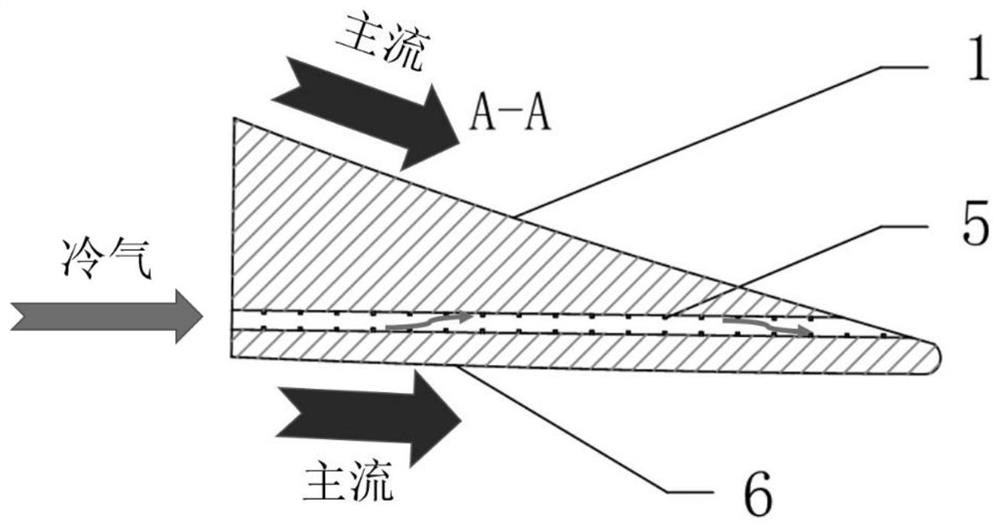

Embodiment 1

[0030] This embodiment is a through-slit half-slit trailing edge cooling structure on a certain type of turbine working blade. Slit cold air intake chamber 8 and the entrance of the two cooling airflows of partition rib rectangular cooling hole inlet 9, the cooling airflow entering the trailing edge cold air intake chamber 8 sprays out and covers the half split surface 3 of the trailing edge to form a cooling air film, thereby Cool the pressure surface 1 of the trailing edge of the blade, and part of the cooling air flow flows into the inlet 9 of the rectangular cooling hole of the partition rib, and cool the partition rib 2 through the internal heat exchange between the cooling air flow and the partition rib, and also enhance the internal exchange with the suction surface 6 of the trailing edge. Heat, enhance the heat exchange intensity between the position of the partition rib 2 and the suction surface 6, and export the heat from the trailing edge suction surface 6 and the pa...

Embodiment 2

[0033] This embodiment is a through-slit half-slit trailing edge cooling structure on a certain type of turbine working blade. Slit cold air intake cavity 8 and partition rib cooling hole inlet 9 are two inlets of cooling air flow, and the cooling air flow entering the trailing edge cold air intake cavity 8 is sprayed out and covered on the trailing edge half-slit surface 3 to form a cooling air film, thereby cooling The pressure surface 1 of the trailing edge of the blade, and part of the cooling air flow flows into the inlet 9 of the cooling hole of the partition rib, and the partition rib 2 is cooled by the internal heat exchange between the cooling air flow and the partition rib, and the internal heat exchange with the suction surface 6 of the trailing edge can also be enhanced. The heat exchange intensity between the position of the partition rib 2 and the suction surface 6 is enhanced, and the heat from the trailing edge suction surface 6 and the partition rib 2 is export...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com