Optimizing method of simplified model cooling structure of transition section

A technology that simplifies the model and cooling structure. It is used in special data processing applications, instruments, electrical and digital data processing, etc. It can solve the problems of the lack of impact cooling methods in the transition section structure of the impact hole and the lack of research, so as to achieve rapid performance evaluation and Quick modification, shorten design cycle, and enhance the effect of heat transfer intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0032] In order to solve the problems of the technologies described above, the present invention is achieved by adopting the following technical solutions:

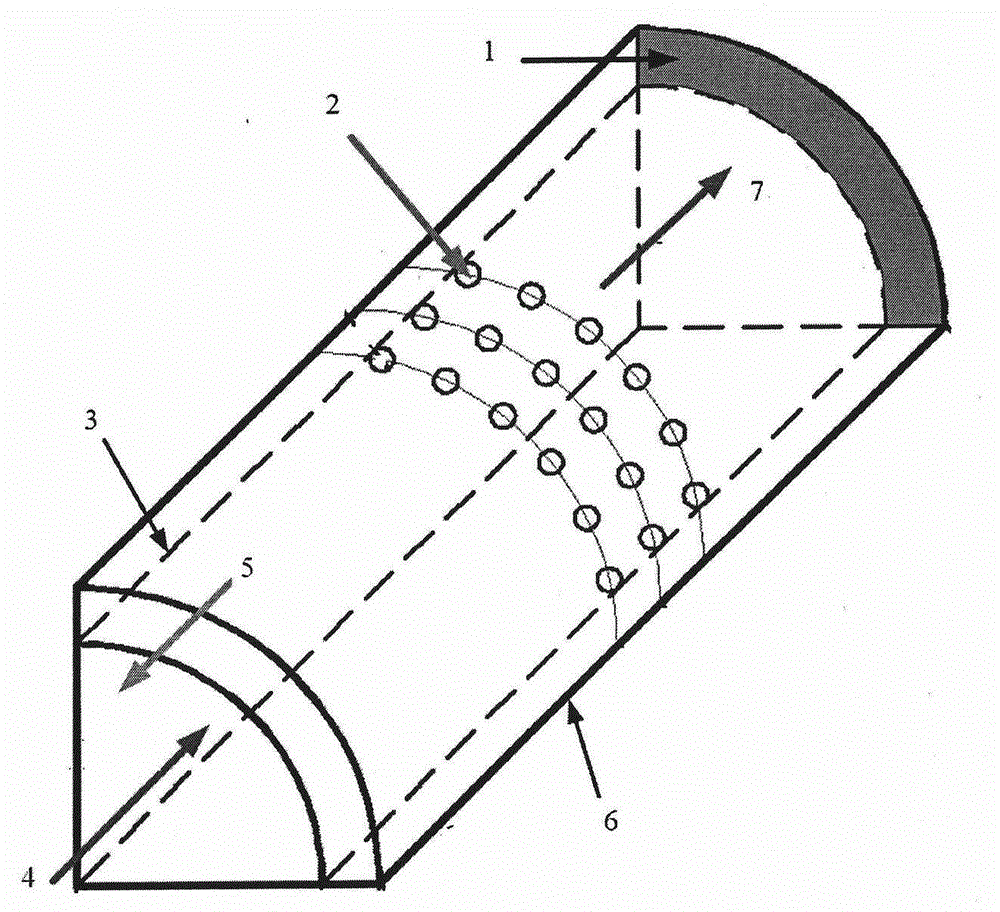

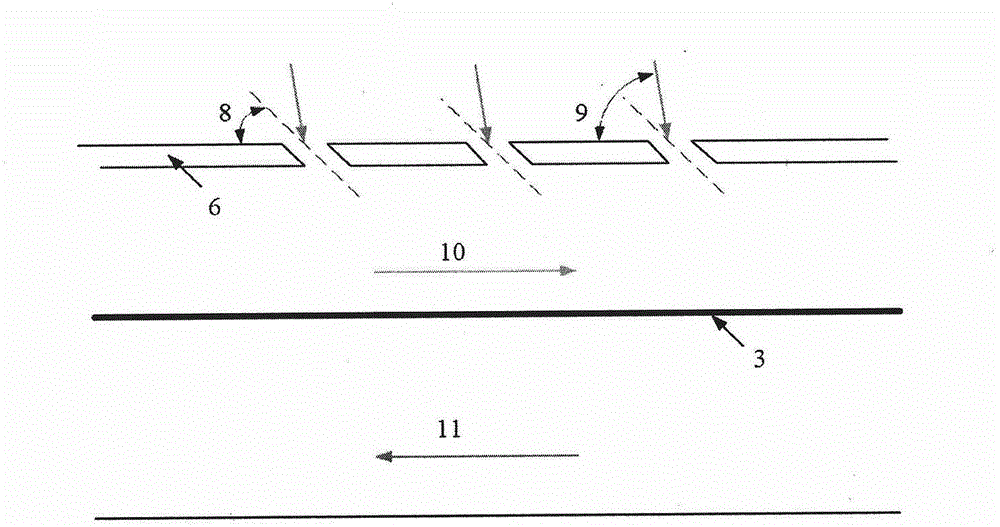

[0033] Step a, constructing a simplified model of the double chamber according to the function and structural characteristics of the gas turbine combustor transition section, including: simplified model size, structure, appearance, function, impact hole size, arrangement, impact angle, and airflow jet angle;

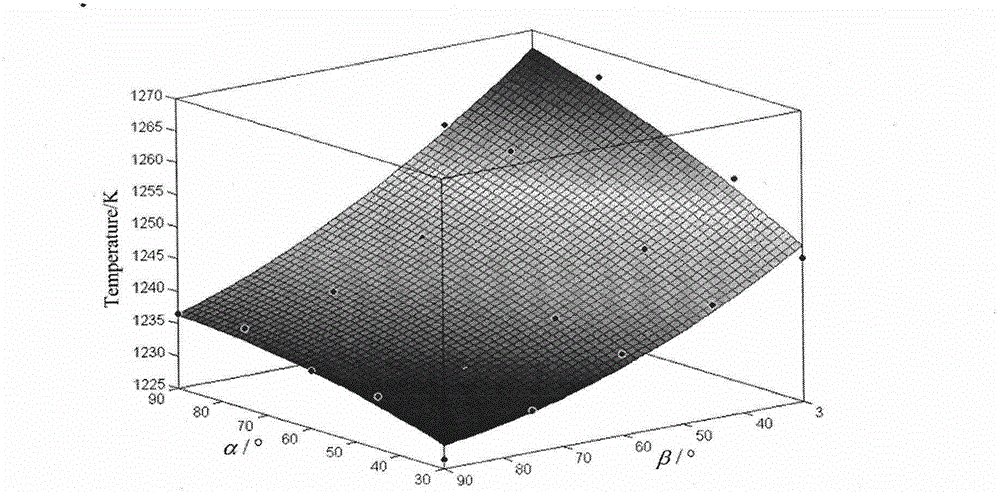

[0034] Step b, using the commonly used orthogonal test design in engineering applications to provide an initial approximate model for optimal design modeling, including: when calculating different impact angles and airflow jet angles, simplify the model's inner wall surface temperature distribution and outlet pressure values;

[0035] Step c, ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com