Method and device for concentrating and coupled-drying catalyst in quenched wastewater in process of using methanol to prepare olefin

A methanol-to-olefins and catalyst technology, applied in the field of coal chemical industry, can solve the problems of undeveloped energy consumption and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

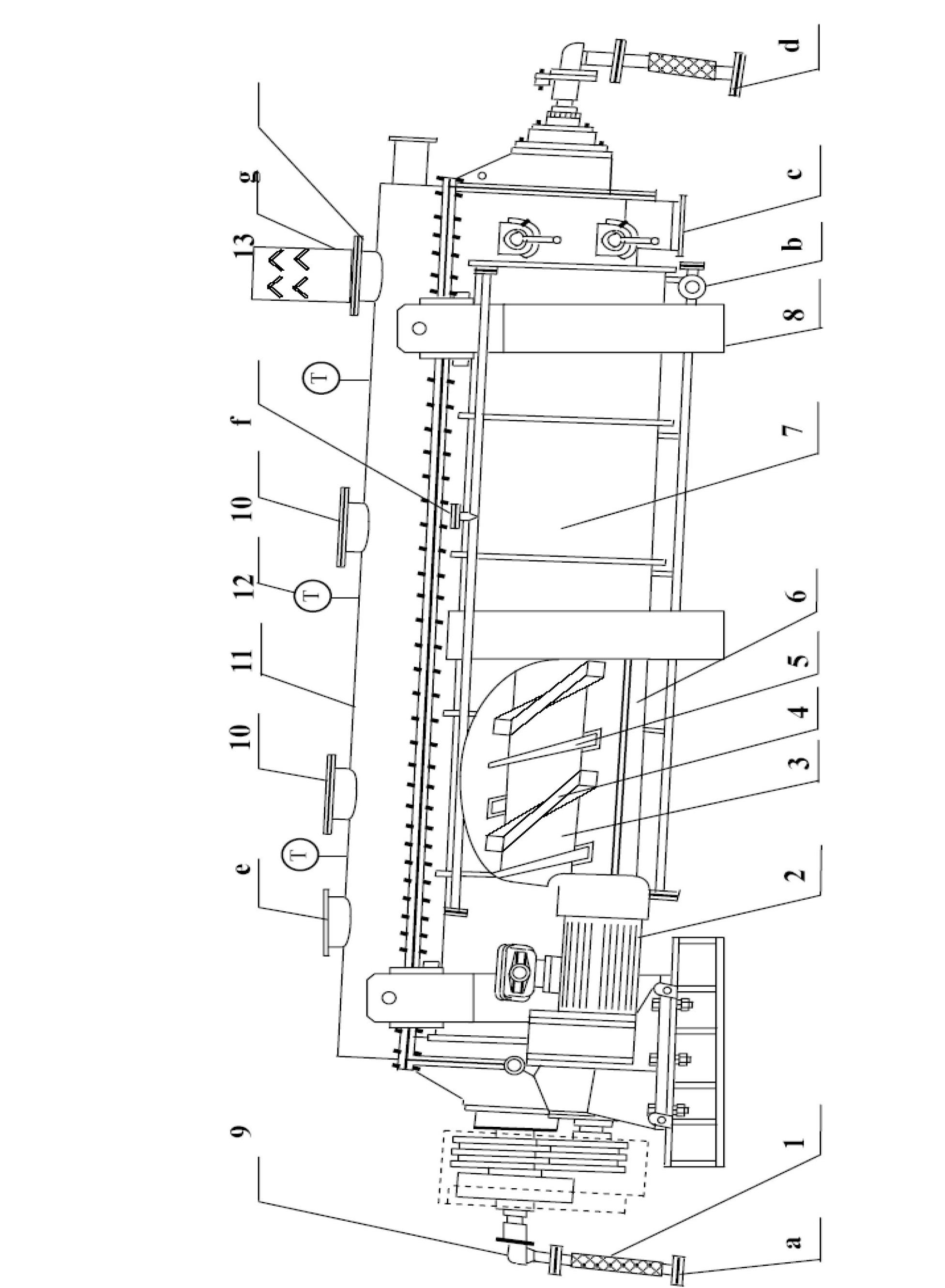

Method used

Image

Examples

Embodiment 1

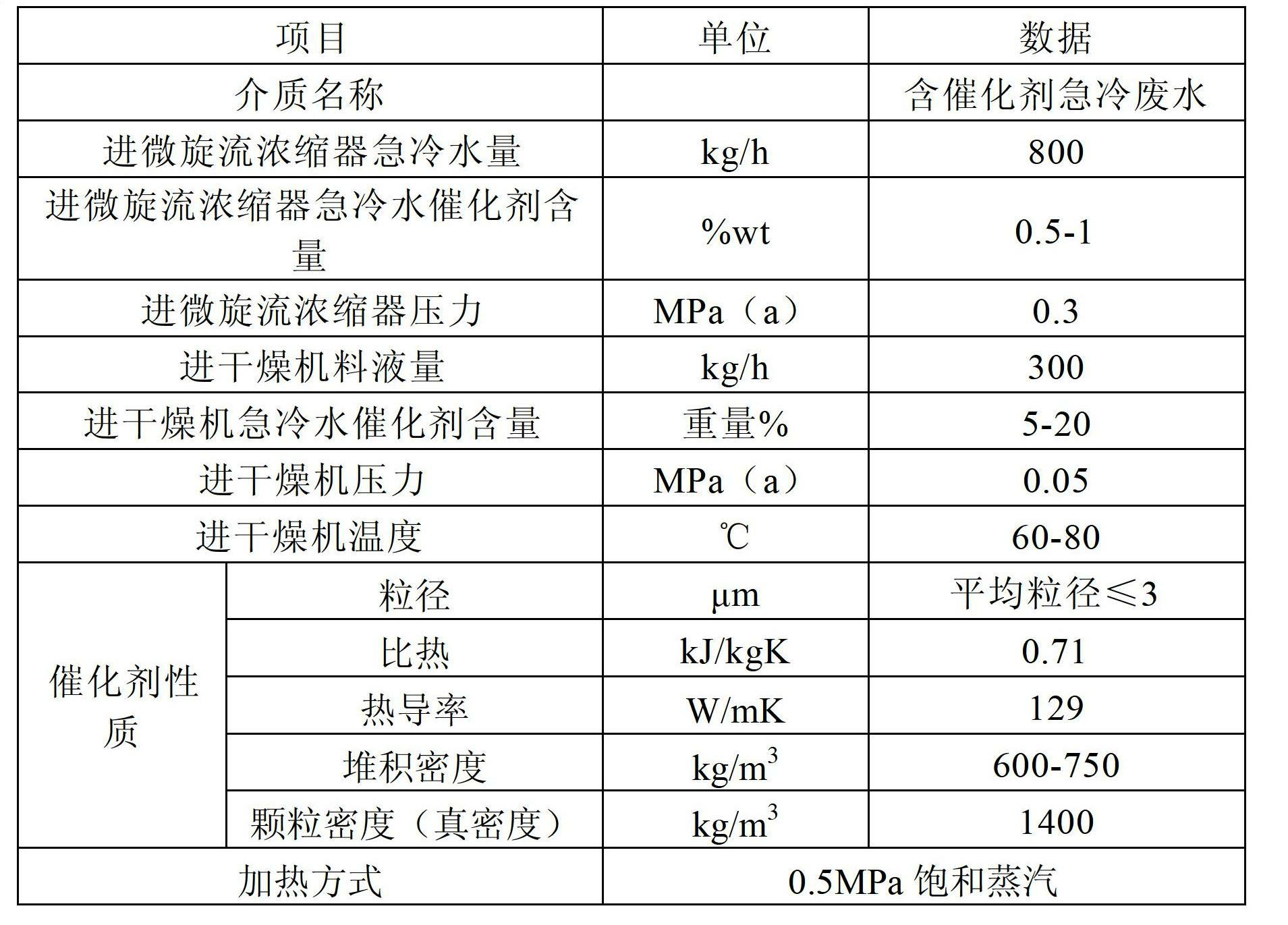

[0052] The catalyst-containing quenching wastewater treatment system of a methanol-to-olefins plant in a factory uses the method and device of the present invention to concentrate and dry the catalyst-containing quenching water that has passed through two-stage swirls. The properties and parameters of the materials are shown in the following table:

[0053]

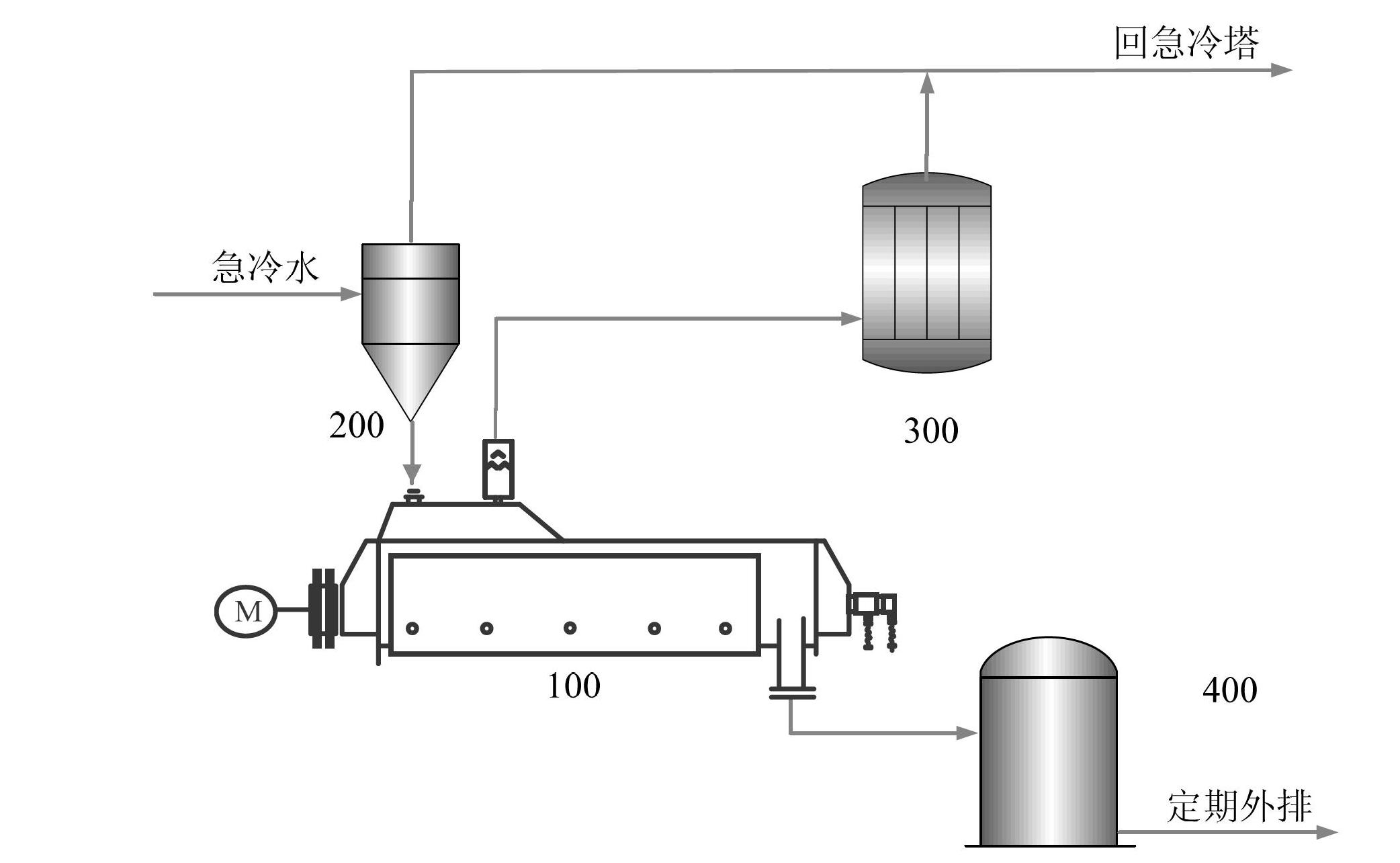

[0054] Process flow:

[0055] The used methanol-to-olefins catalyst-containing quenching wastewater treatment system such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com