Forced cooling device based on latent heat exchanging

A forced cooling and latent heat technology, applied in the field of heat transfer and heat exchange, can solve the problems of high power consumption, complex structure, and unsafety of radiators, and achieve the effects of high heat exchange intensity, small flow rate of working fluid, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

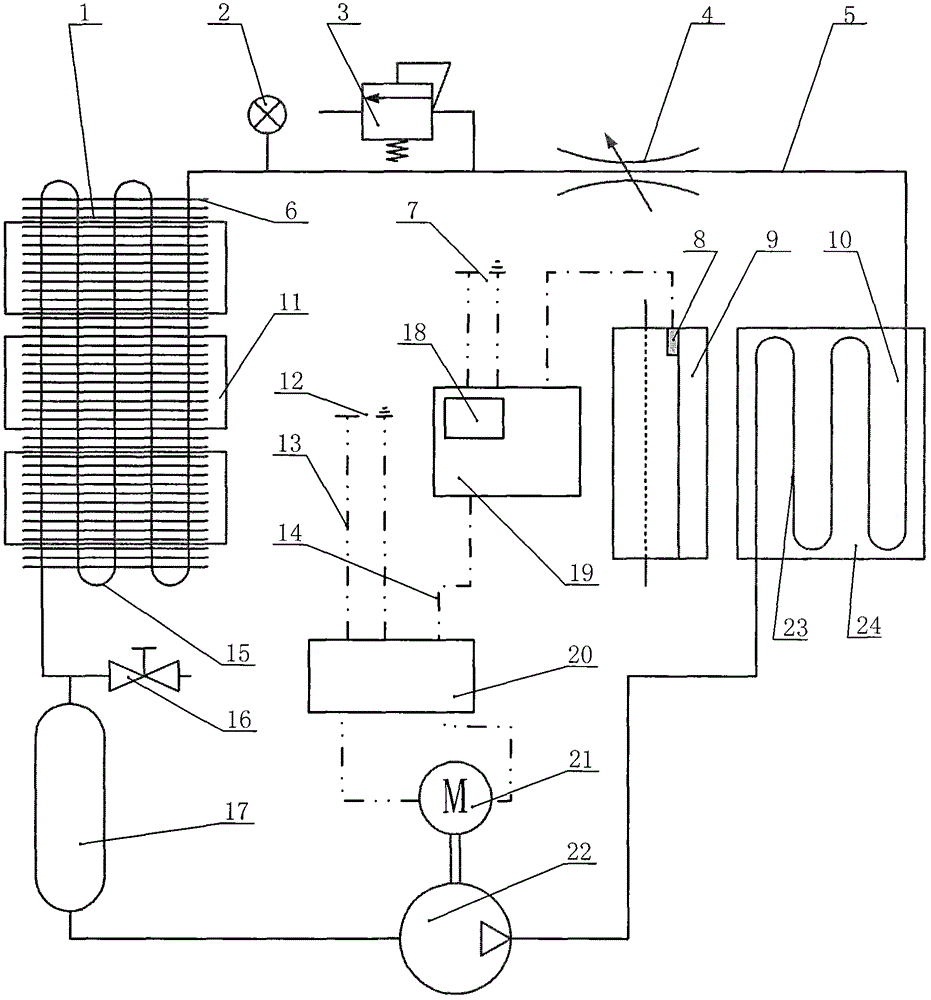

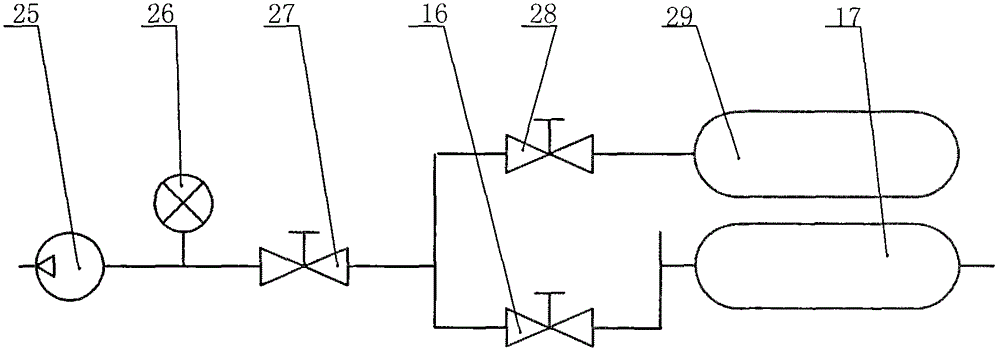

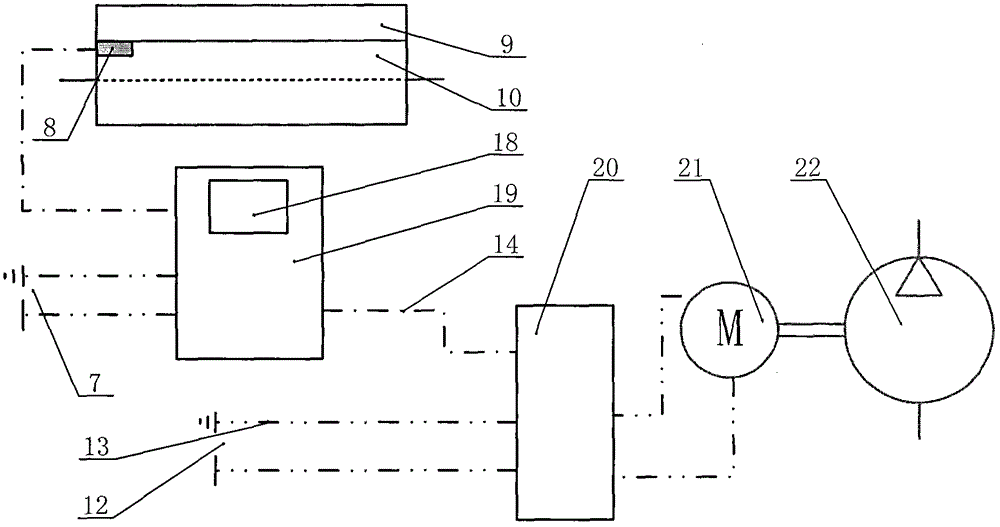

[0019] This embodiment is a forced cooling device based on latent heat exchange.

[0020] refer to Figure 1~3 In this embodiment, a forced cooling device based on latent heat exchange consists of a condenser 1, a pressure gauge 2, a safety valve 3, a restrictor 4, a hose 5, a fin set 6, a 5V DC power supply 7, a temperature sensor 8, Heating unit 9, heat conduction block 10, fan 11, 24V DC power supply 12, wire 13, signal line 14, first S-shaped copper tube 15, first stop valve 16, liquid collector 17, MCU 18, main control unit 19, motor Controller 20, DC motor 21, diaphragm pump 22, second S-shaped copper tube 23, evaporator 24, vacuum pump 25, vacuum gauge 26, second shut-off valve 27, third shut-off valve 28, working fluid storage tank 29. The hoses 5 are DN8mm polytetrafluoroethylene high-pressure hoses, and the adapters of the pipelines 5 are quick-plug connectors; the opening pressure of the safety valve 3 is 1.0Mpa, the range of the pressure gauge 2 is 1.2Mpa, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com