Pulsation combustion type ultrasonic-assisted reinforced heat transfer boiler

A technology of pulsating combustion and heat transfer enhancement, applied in the field of heat transfer, can solve the problems of boiler scaling, overheating drum bulging, etc., and achieve the effects of saving energy, improving the degree of turbulence, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

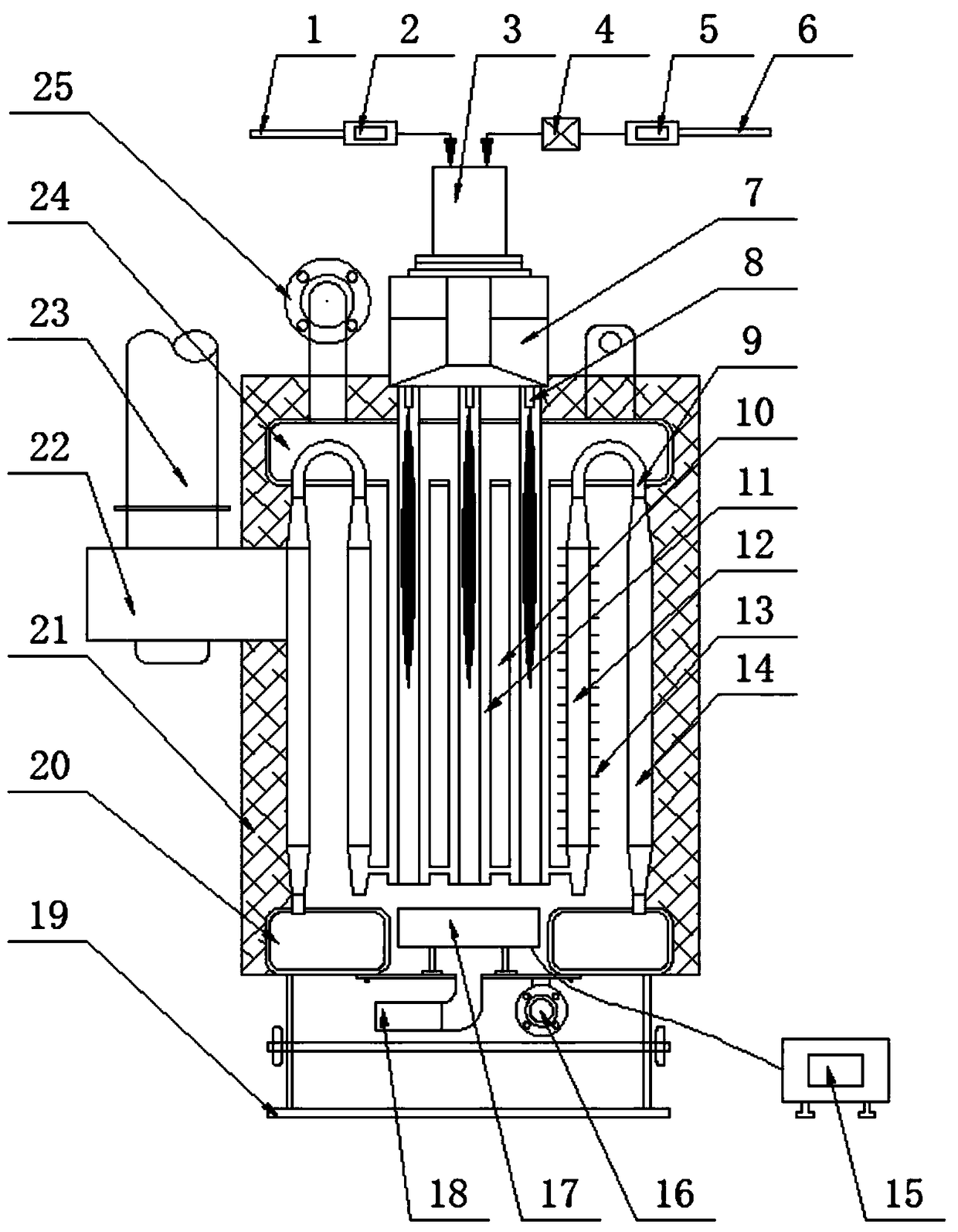

[0030] A pulsating combustion type ultrasonic-assisted enhanced heat transfer boiler, its innovation lies in: including a support 19 and a pulsating combustion system installed on the support, a heat exchanger 24 and an ultrasonic-assisted enhanced heat transfer system, the pulsating combustion system includes a gas mixing chamber 3 and the pulsation burner 7, the air inlet pipe 6 and the natural gas inlet pipe 1 are respectively connected to the gas mixing chamber; a number of straight pipe heat exchange pipes 11, liquid inlet 16, liquid outlet 25, mixed gas inlet, Mixed gas outlet 22, liquid inlet tube sheet 20 and condensate water outlet 18, the liquid inlet is connected to the liquid inlet tube sheet, and several straight tube heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com