Aging oil dehydration device and method

A dehydration device and aging oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, and only multi-stage serial refining process treatment, etc., can solve the problem that the water content of aging oil cannot meet the requirements of crude oil, and achieve low cost and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

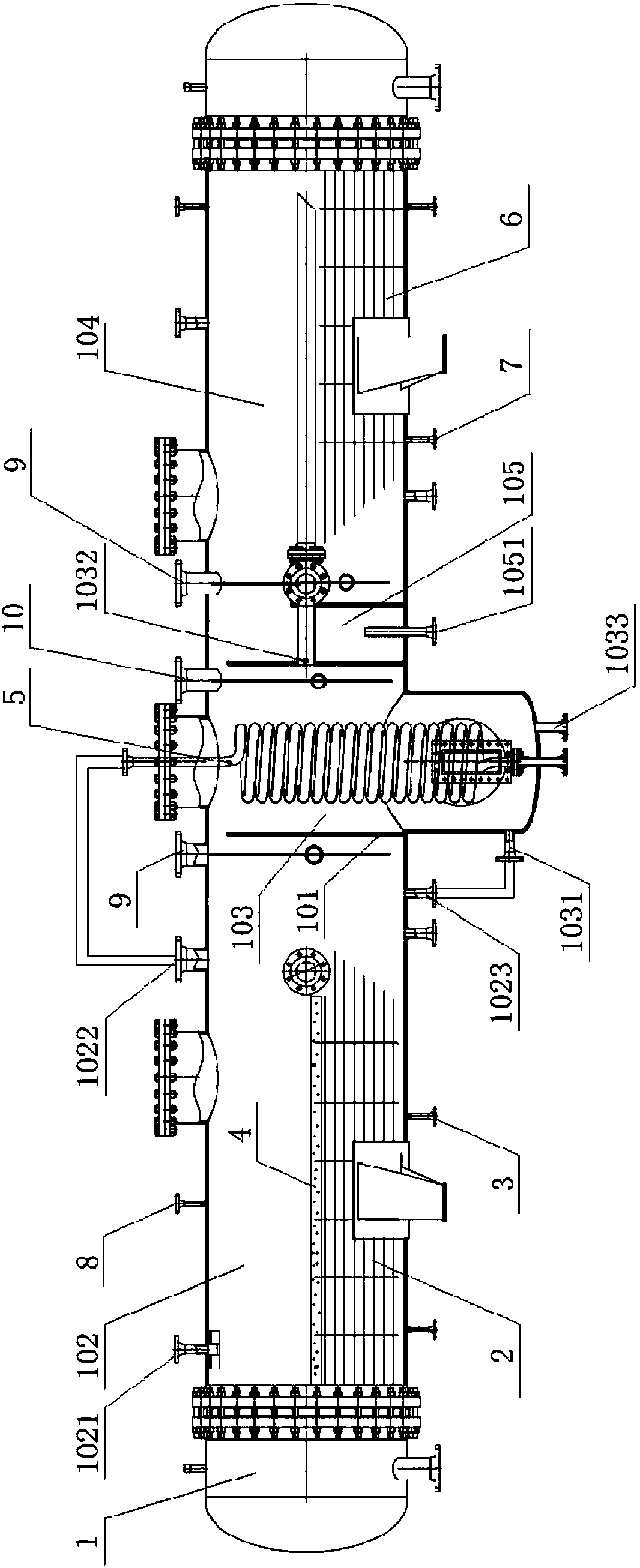

[0057] In the first aspect, the embodiment of the present invention provides an aging oil dehydration device, such as the attached figure 1As shown, the device includes: a shell 1, the inner cavity is divided into a heated demulsification zone 102, a sedimentation and dehydration zone 103, a selection and standardization zone 104, and a selection and standardization zone 104 through the overflow port through a partition 101. Connected outer drain oil area 105.

[0058] The first heat transfer oil pipe 2 connected to the heat conduction oil furnace is arranged in the heating demulsification area 102 , an aging oil inlet 1021 and a water vapor outlet 1022 are arranged at the top, and a first oil outlet 1023 is arranged at the bottom.

[0059] Settling and dehydrating area 103 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com