Ball-throwing type layered sand control process pipe column and method thereof

A process pipe string and ball-throwing technology, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of high implementation risk, complex pipe string structure, and complicated implementation process, so as to ensure the safety of well control. , Reduce the construction process, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

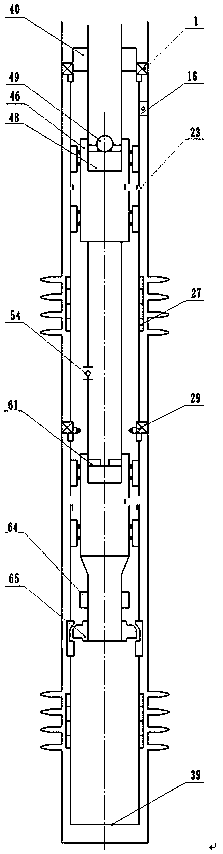

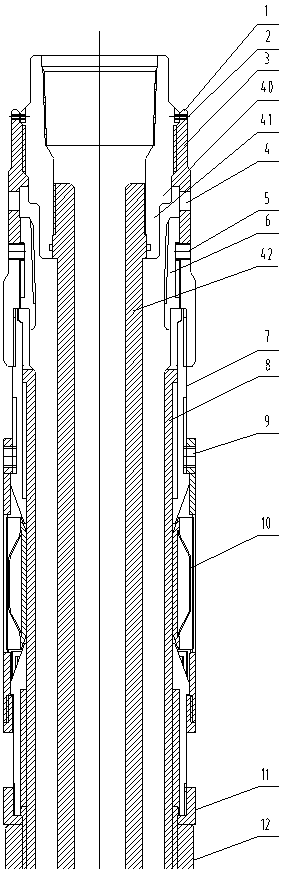

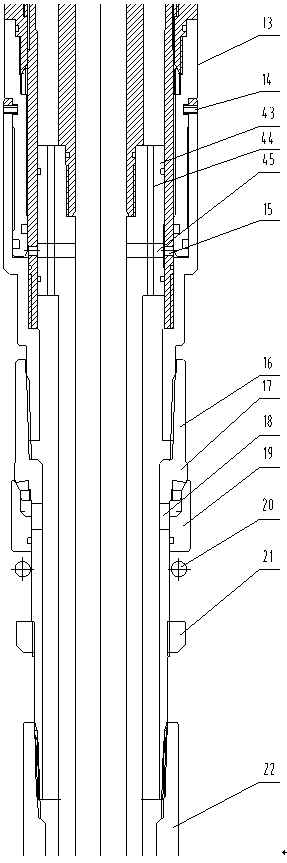

[0037] according to figure 1 as well as Figure 2 to Figure 11 , the ball-pitching layered sand control process string, mainly consists of two layers of sand control outer pipe and sand control inner pipe, the sand control outer pipe is mainly composed of top hanging setting mechanism 1, backwashing device 16, outer filling device 23, and upper screen pipe 27. The interlayer isolation device 29 and the plug 39 are composed; the inner pipe string is mainly composed of the hand release mechanism 40, the inner well flushing valve 54, the setting slider opening device 56, the switch mechanism 63, the upper inner filling device 46, and the stratified Unit slider device 47, steel ball 49 and bottom positioning device 59 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com