Method for preparing pre-vulcanized natural latex based slow release fertilizer

A technology of natural rubber latex, slow-release fertilizer, applied in the direction of fertilizer mixture, fertilization device, application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

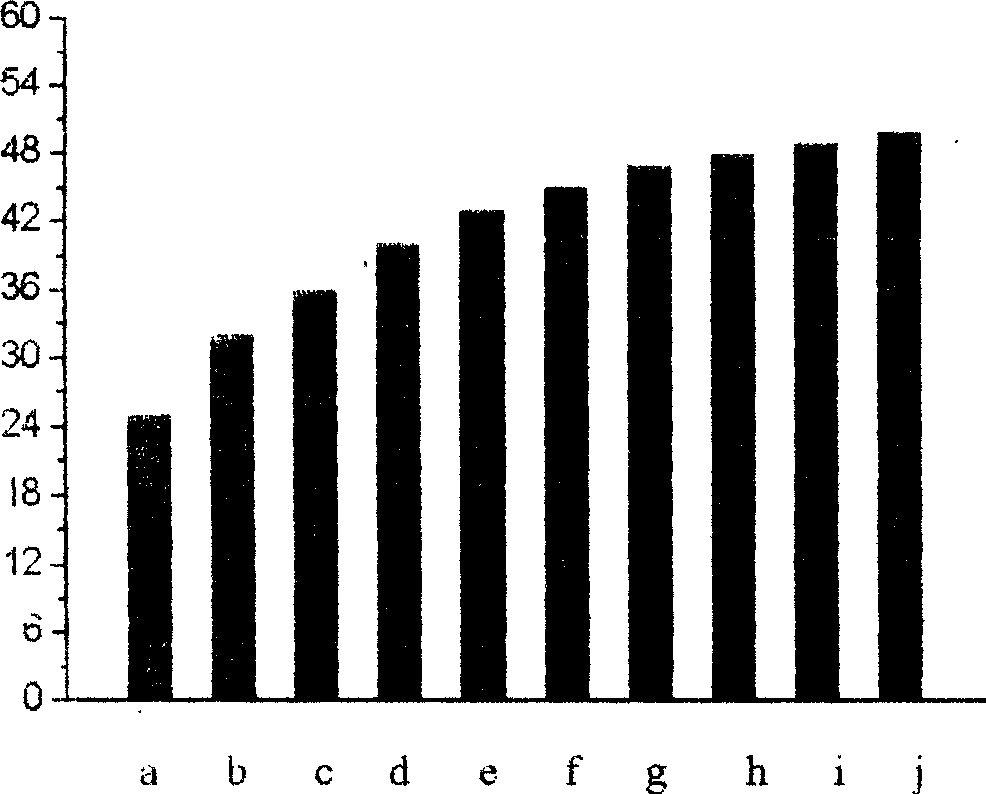

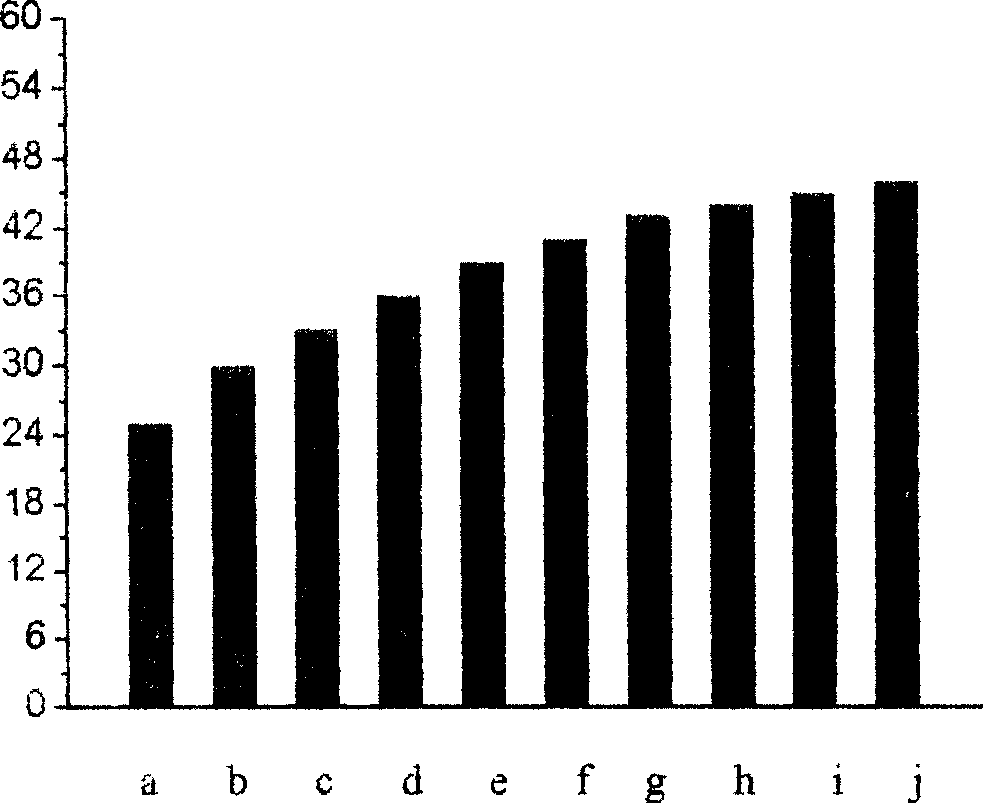

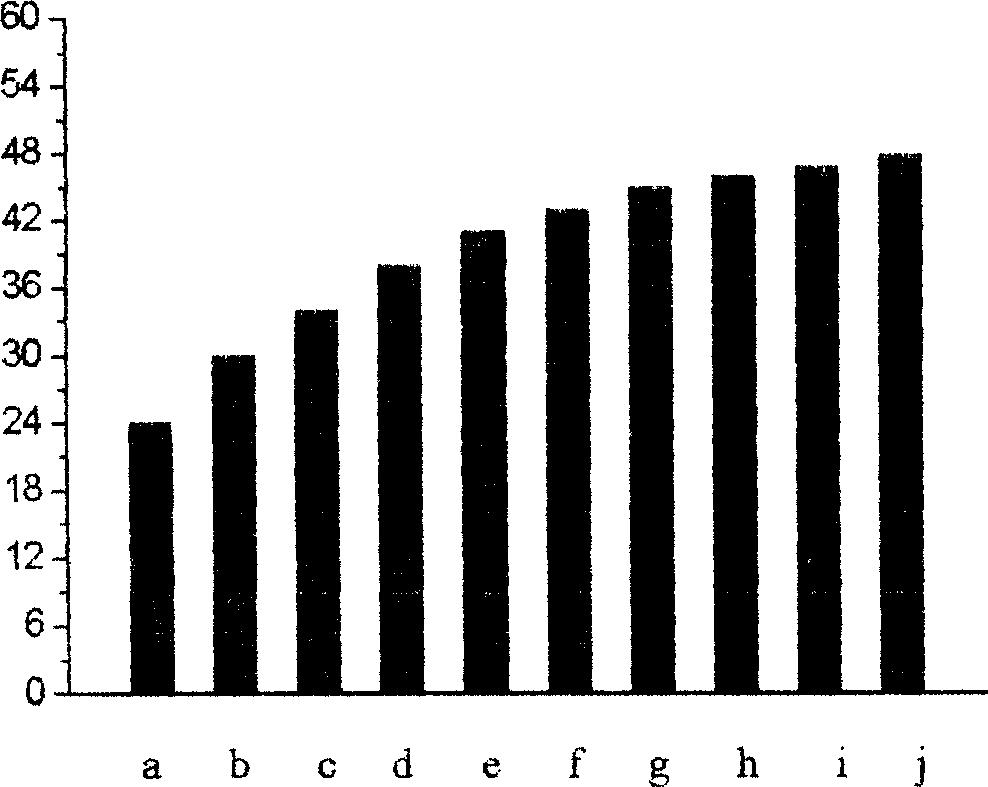

Image

Examples

preparation example Construction

[0012] 1 Preparation of prevulcanized latex:

[0013] ① Vulcanization formula: 166.67 parts of natural rubber latex with a mass percentage concentration of 60%, 14.46 parts of casein with a mass percentage concentration of 10%, 3.86 parts of KOH with a mass percentage concentration of 25%, 8-12.05 parts of sulfur, and 8-8 parts of accelerator PX 12.05 parts, anti-aging agent 264 6.03 parts, zinc oxide 4.82 parts, soft water 143.24 parts, wherein, sulfur, accelerator PX, anti-aging agent 264 and zinc oxide all adopt colloid mill or sand mill to carry out grinding 24-48 hours before use, make Component dispersion, its mass percent concentration is respectively 40%, 40%, 40% and 50%.

[0014] ②Adding order: natural latex---→soft water---→casein---→KOH---→sulfur---→accelerator PX---→antiaging agent 264---→zinc oxide.

[0015] ③ Pre-vulcanization: heat the latex, raise the temperature to 55°C within 50 minutes, and stir slowly under the condition of 55±3°C, and control the natural...

Embodiment 1

[0022] Get 100kg urea, join in the chitosan acetic acid solution, stir until completely dissolving, control the mass percent concentration of urea between 8%-10%, the mass percent concentration of chitosan is 1.00%, obtain solution A. Then add glutaraldehyde solution and urea in the sodium alginate solution, and supplement a certain amount of water, stir until dissolving evenly, control the mass percentage concentration of urea between 8%-10%, the mass percentage concentration of glutaraldehyde is at 3 Between -5%, the mass percentage concentration of sodium alginate is 3%, and solution B is obtained. Use a water pump to pump a small amount of solution A onto a disc with many small holes at the bottom, let solution A drop into solution B through the small holes (hole diameter 4 to 6 mm), and after solution A drops into solution B, Immediately solidify into a ball. Continue dripping the solution for about 5-10 minutes, stop dripping solution A, let it stand still for about 20 ...

Embodiment 2

[0025] Get 100kg potassium chloride, join in chitosan acetic acid solution, stir until completely dissolving, control the mass percentage concentration of potassium chloride between 5%-10%, chitosan mass percentage concentration is 1.0%, obtain solution A . Then add glutaraldehyde solution and potassium chloride in the sodium alginate solution, and supplement a certain amount of water, stir until dissolving evenly, control the mass percentage concentration of potassium chloride between 5%-10%, the mass percentage of glutaraldehyde The percentage concentration is between 3-5%, the mass percentage concentration of sodium alginate is 3%, and the solution B is obtained. Use a water pump to pump a small amount of solution A onto a disc with many small holes at the bottom, let solution A drop into solution B through the small holes (hole diameter 4 to 6 mm), and after solution A drops into solution B, Immediately solidify into a ball. Continue dripping the solution for about 5-10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com