Waterborne bicomponent epoxy iron red shop primer and preparation method thereof

A technology of epoxy iron red primer and water-based epoxy resin, used in primers, epoxy resin coatings, coatings, etc., can solve the problem that the hardness of the primer coating cannot meet the requirements, and the compressive strength and impact resistance are not enough. , poor mixing effect and other problems, to achieve mild activity, improve wear resistance and durability, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

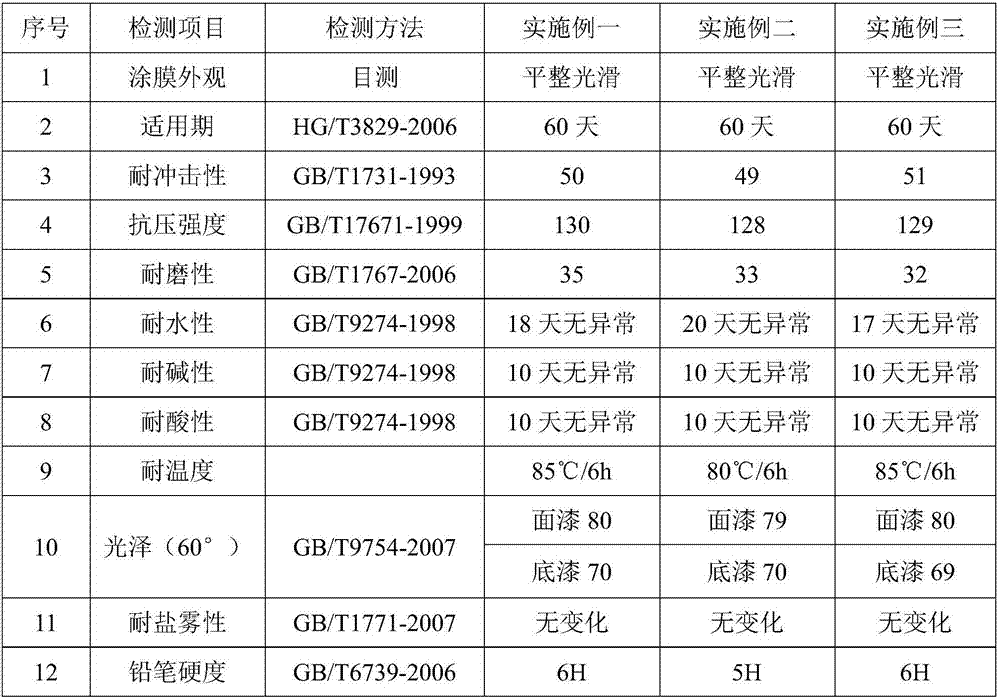

Examples

Embodiment 1

[0038] (1) Add 250kg of deionized distilled water, 400kg of water-based epoxy resin, 10kg of iron red pigment, and 2kg of water-based dispersant into the grinding container, and turn on the mixer to stir evenly. After 0.5 hours, add 10kg of defoamer, and then continue Stir well.

[0039] (2) After reacting for 1 hour, add 10kg of nano-alumina, 70kg of filler barium sulfate, and 10kg of preservative benzoic acid in sequence, and continue to stir and react for 0.5 minutes.

[0040] (3) Under the condition of uniform stirring, add 8kg of water-based amine curing agent into the container, and raise the temperature to 70°C at the same time, and perform high-speed dispersion mixing for 0.5 hours after it reacts for 2 hours.

[0041] (4) After dispersing and mixing for 0.5 hours, lower the temperature to 40°C, and then carry out sand grinding process, and control the fineness within 55um after toning.

[0042] (5) filter and obtain the slurry with a 130 mesh stainless steel filter s...

Embodiment 2

[0046] (1) Add 260kg of deionized distilled water, 430kg of water-based epoxy resin, 11kg of iron red pigment, and 4kg of water-based dispersant into the grinding container, and turn on the mixer for uniform stirring. After 0.5 hours, add 8kg of defoamer, and then continue Stir well.

[0047] (2) After reacting for 1 hour, add 12kg of nano-alumina, 80kg of filler barium sulfate, and 12kg of preservative benzoic acid in sequence, and continue to stir and react for 0.5 minutes.

[0048] (3) Under the condition of uniform stirring, add 7.5kg of water-based amine curing agent into the container, and raise the temperature to 70°C at the same time, and perform high-speed dispersion mixing for 0.5 hours after it reacts for 2 hours.

[0049] (4) After dispersing and mixing for 0.5 hours, then carry out sand grinding process, and control the fineness within 55um after toning.

[0050] (5) filter and obtain the slurry with a 130 mesh stainless steel filter screen, namely obtain the fir...

Embodiment 3

[0054] (1) Add 280kg of deionized distilled water, 450kg of water-based epoxy resin, 14kg of iron red pigment, and 5kg of water-based dispersant into the grinding container, and turn on the mixer to stir evenly. After 0.5 hours, add 11kg of defoamer, and then continue Stir well.

[0055] (2) After reacting for 1 hour, add 13kg of nano-alumina, 100kg of filler barium sulfate, and 12kg of preservative benzoic acid in sequence, and continue to stir and react for 0.5 minutes.

[0056] (3) Under the condition of uniform stirring, add 9kg of water-based amine curing agent into the container, and raise the temperature to 70°C at the same time, and perform high-speed dispersion mixing for 0.5 hours after it reacts for 2 hours.

[0057] (4) After dispersing and mixing for 0.5 hours, lower the temperature to 40°C, and then carry out sand grinding process, and control the fineness within 55um after toning.

[0058] (5) filter and obtain the slurry with a 130 mesh stainless steel filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com