Low-temperature flash evaporation and light hydrocarbon recovery system and method used for oilfield associated gas

A technology for recovery of associated gas and light hydrocarbons in oilfields, which is applied in the direction of flash evaporation, separation methods, chemical instruments and methods, etc., can solve problems that do not meet national security and environmental protection requirements, affect the economic benefits of enterprises, and are difficult to control associated gas. Reduced emissions, improved efficiency, and reduced adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0042] Example.

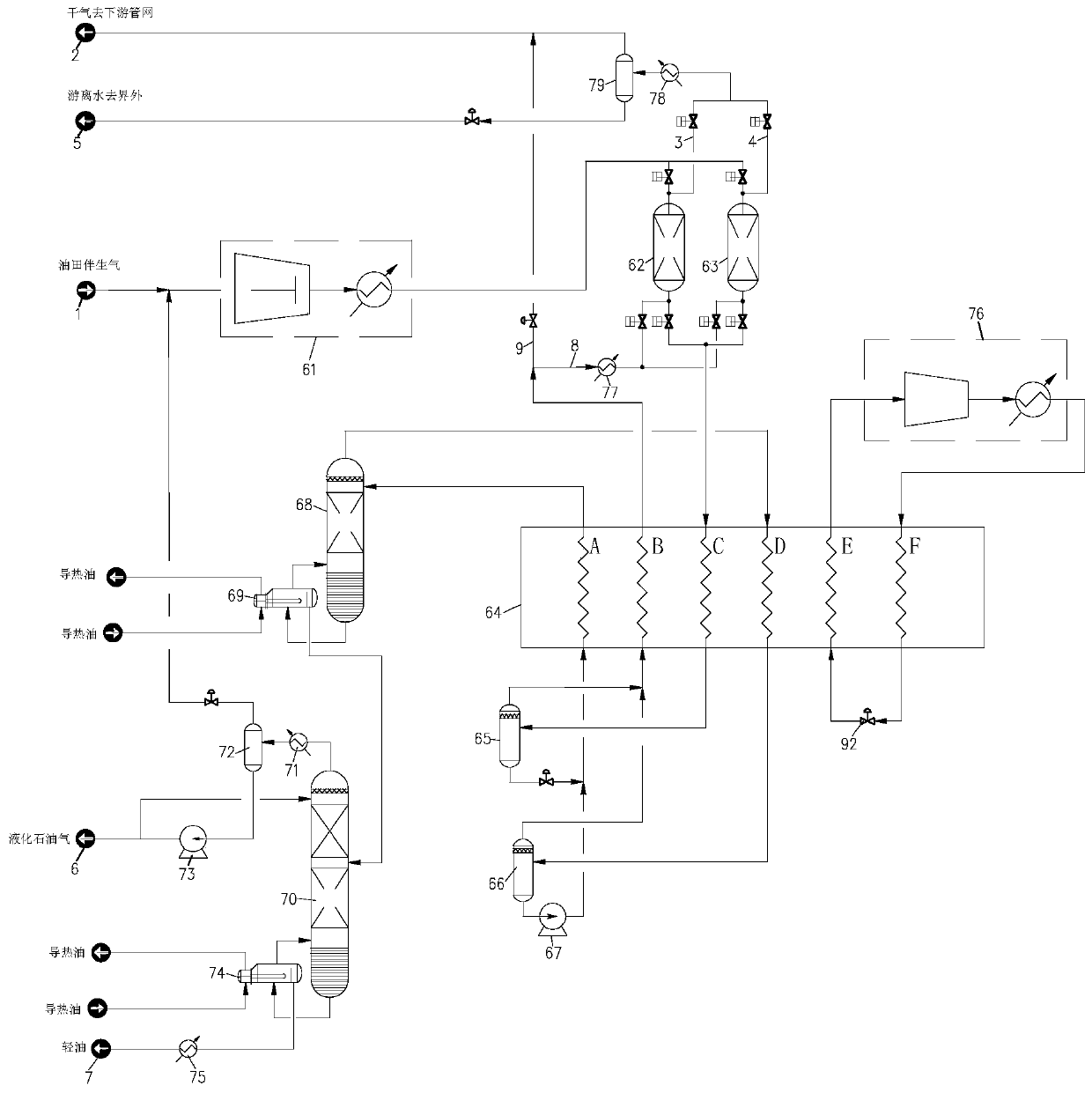

[0043] see figure 1 , this embodiment discloses a low-temperature flash light hydrocarbon recovery system for oilfield associated gas, including a feed gas compressor 61, No. 1 adsorption tower 62, No. 2 adsorption tower 63, low-temperature heat exchanger 64, a first-stage Flash separator 65 , secondary flash separator 66 , deethanizer 68 , deethanizer reboiler 69 , liquefied gas tower 70 , reflux tank 72 and liquefied gas tower reboiler 74 .

[0044] In this embodiment, the low-temperature heat exchanger 64 is an aluminum plate-fin heat exchanger, and channels A, B, C, D, E and F are arranged inside. The cooling capacity of the low-temperature heat exchanger 64 is provided by a mixed refrigerant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com