Airtight removing method for harmful gas in drilling fluid

A harmful gas and drilling fluid technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problems that affect the effect and efficiency of hydrogen sulfide removal, and can not remove hydrogen sulfide well, so as to meet the requirements of The effect of safety and environmental protection, improving safety and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

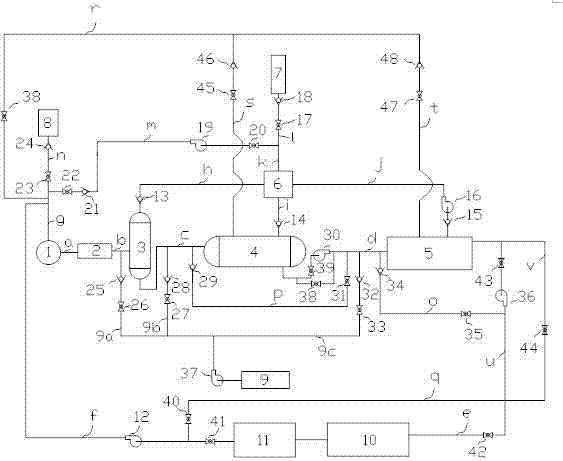

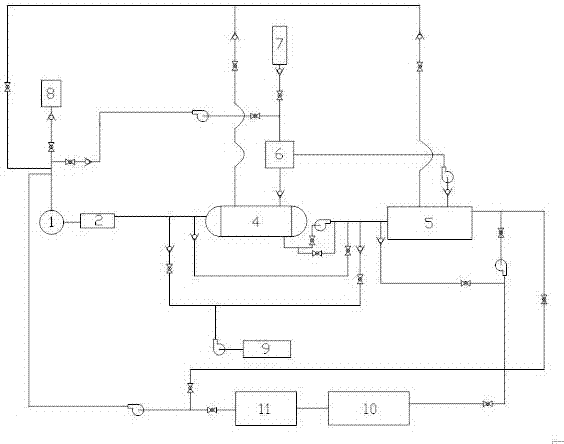

[0028] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

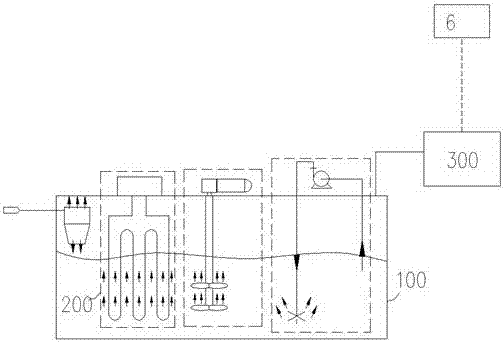

[0029] The method of airtight removal of harmful gas in drilling fluid, the drilling fluid containing harmful gas returns to the ground from the well, and enters the surface drilling fluid airtight treatment system, the drilling fluid containing harmful gas returns from the well, and enters the primary separator after depressurization, The drilling fluid separated by the primary separator is directly introduced into the secondary separator for secondary separation. The working pressure of the secondary separator is lower than that of the primary separator; the drilling fluid separated by the secondary separator is pumped by a centrifugal pump Into the third-level separation system, in the third-level separation system, the participating gases are separated by the combination of negative pressure extraction, submerged turbulence, and fluid temperature c...

Embodiment 2

[0031] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0032] The method of airtight removal of harmful gas in drilling fluid, the drilling fluid containing harmful gas returns to the ground from the well, and enters the surface drilling fluid airtight treatment system, the drilling fluid containing harmful gas returns from the well, and enters the primary separator after depressurization, The drilling fluid separated by the primary separator is directly introduced into the secondary separator for secondary separation. The working pressure of the secondary separator is lower than that of the primary separator; the drilling fluid separated by the secondary separator is pumped by a centrifugal pump Into the third-level separation system, in the third-level separation system, the participating gases are separated by the combination of negative pressure extraction, submerged turbulence, and fluid tempera...

Embodiment 3

[0038] As another preferred embodiment of the present invention, this embodiment discloses:

[0039] The method of airtight removal of harmful gas in drilling fluid, the drilling fluid containing harmful gas returns to the ground from the well, and enters the surface drilling fluid airtight treatment system, the drilling fluid containing harmful gas returns from the well, and enters the primary separator after depressurization, The drilling fluid separated by the primary separator is directly introduced into the secondary separator for secondary separation. The working pressure of the secondary separator is lower than that of the primary separator; the drilling fluid separated by the secondary separator is pumped by a centrifugal pump Into the third-level separation system, in the third-level separation system, the participating gases are separated by the combination of negative pressure extraction, submerged turbulence, and fluid temperature control; The output gas is introdu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com