Preparation method of amphoteric comb-shape polyacrylamide by synthesis of quaternary ammonium salt functional monomer

A technology of functional monomer and polyacrylamide is applied in the field of compound synthesis and preparation to achieve the effects of uniform reaction temperature distribution, high viscoelasticity and easy heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 100ml of acetone to a 250ml four-neck flask, then add equimolar dimethylaminoethyl methacrylate (DM) 7.85g, 1-bromododecane 12.45g, blow nitrogen for 0.5 hours, add 0.02g of Hydroquinone, heated to 35 ° C for 7 hours to obtain a uniform and transparent solution;

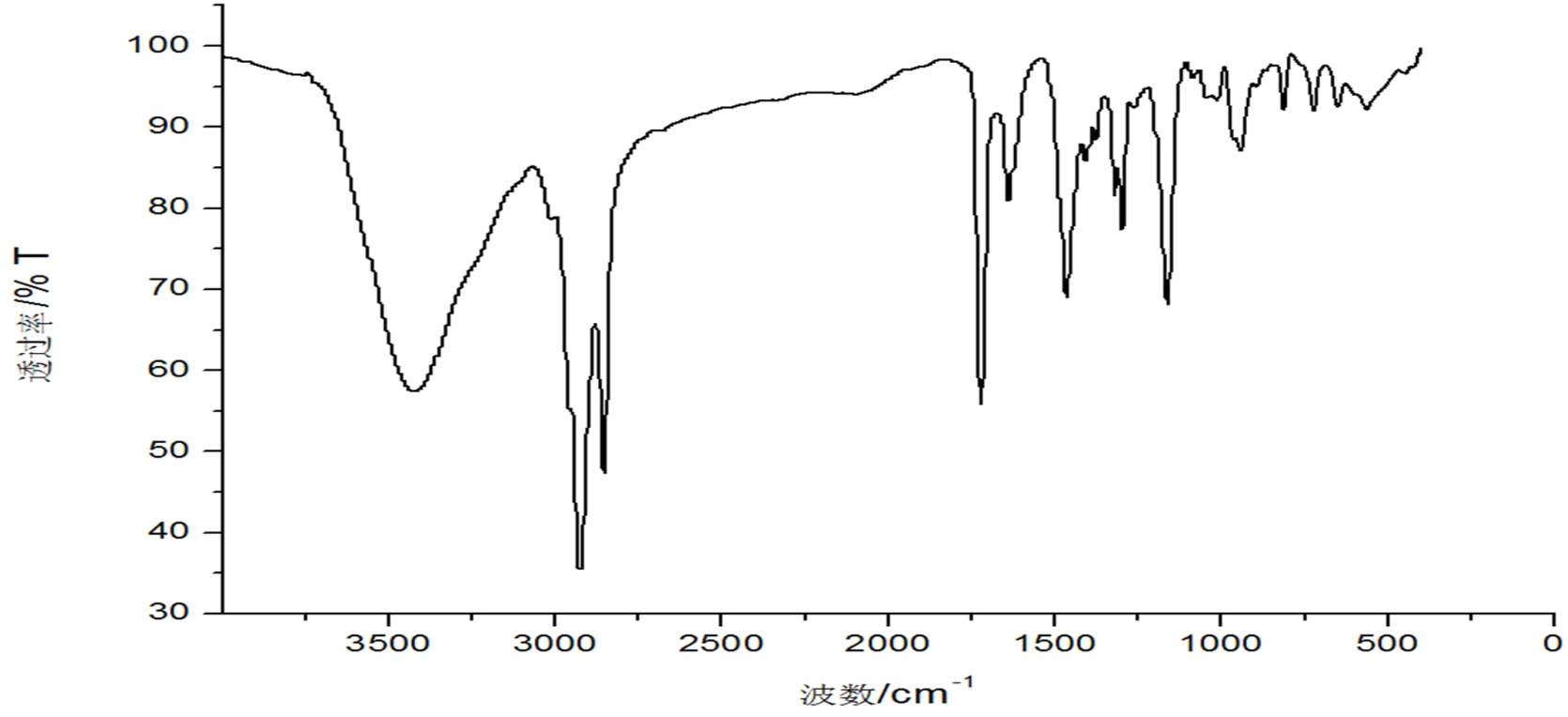

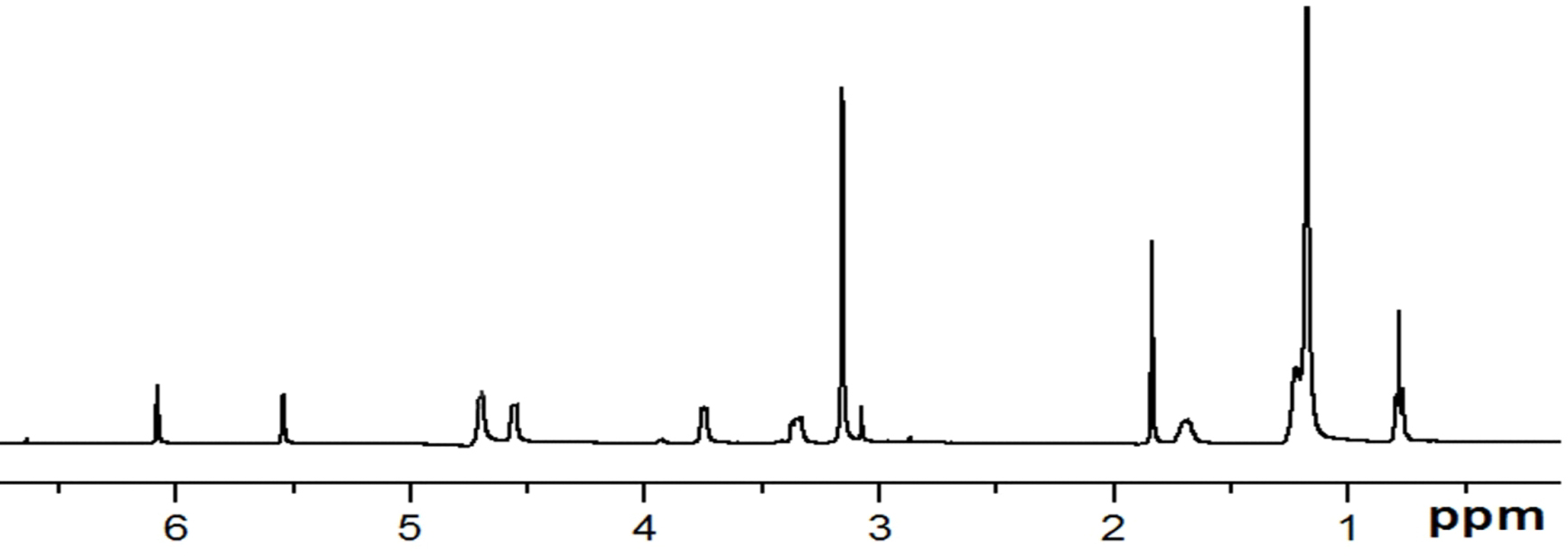

[0033] The transparent solution was evaporated at low temperature to remove acetone, then washed with petroleum ether until clarified, dried in a vacuum oven at 30°C for 24 hours, then taken out and placed in a vacuum oven to obtain quaternary ammonium salt I, whose infrared spectrum is shown in figure 1 , see the NMR spectrum figure 2 .

Embodiment 2

[0035] Add 100ml of acetone to a 250ml four-necked flask, then add 7.85g of dimethylaminoethyl methacrylate (DM) in equimolarity, 8.25g of 1-bromohexane, blow nitrogen for 0.5 hours, and add 0.02g of p-benzene Diphenol, heated to 35 ° C for 7 hours to obtain a uniform and transparent solution;

[0036] The transparent solution was evaporated at low temperature to remove acetone, then washed with petroleum ether until clear, dried in a vacuum oven at 30°C for 24 hours, then taken out and put into a vacuum oven to obtain quaternary ammonium salt II.

Embodiment 3

[0038] Add 100ml of acetone to a 250ml four-neck flask, then add equimolar dimethylaminoethyl methacrylate (DM) 7.85g, 1-bromohexadecane 15.25g, nitrogen exhaust oxygen for 0.5 hours, add 0.02g Hydroquinone, heated to 35 ° C for 7 hours to obtain a uniform and transparent solution;

[0039] The transparent solution was evaporated at low temperature to remove acetone, then washed with petroleum ether until clear, dried in a vacuum oven at 30°C for 24 hours, then taken out and put into a vacuum drying oven to obtain quaternary ammonium salt III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com