A device and method for preparing titanium tetrachloride by vibrating internal circulation fluidization

A technology of titanium tetrachloride and internal circulation, applied in the direction of titanium halide, etc., can solve the problems of complex reactor structure, low energy efficiency, and large equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

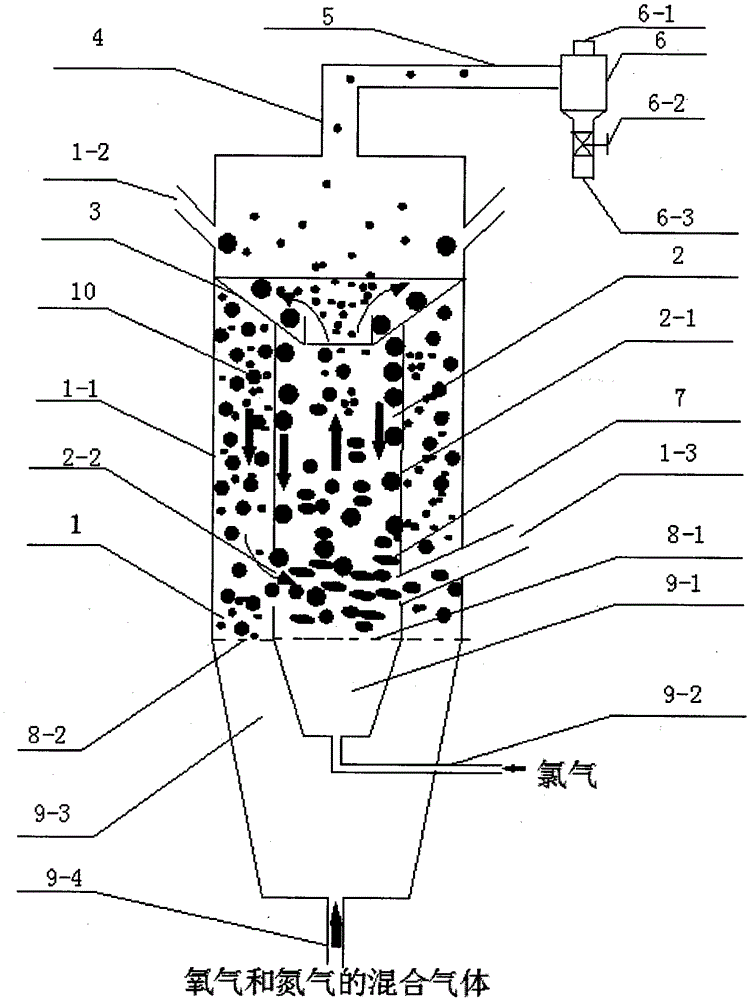

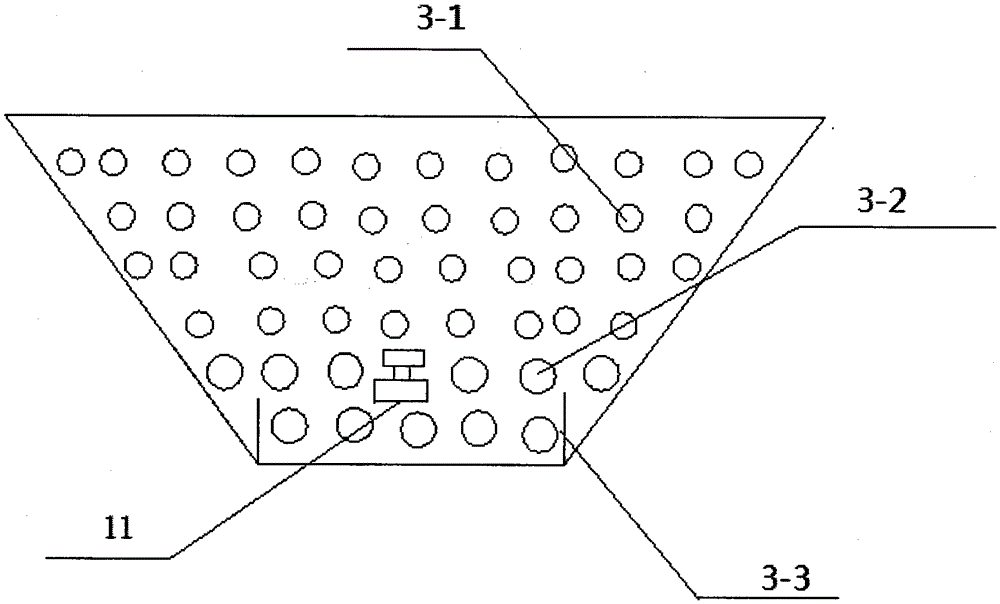

[0033] Such as figure 1 , 2Shown, a vibratory internal circulation fluidization device for preparing titanium tetrachloride. It mainly includes external circulating fluidized bed, internal fluidized bed reactor, vibration distribution plate and vibrator, cyclone separator, gas buffer tank and gas distribution plate, etc. Its characteristics are:

[0034] The materials of the external circulating fluidized bed, the internal fluidized bed reactor, the vibration distribution plate, the gas buffer tank, the baffle plate, the discharge pipe, the straight pipe and the feed pipe are all stainless steel.

[0035] The shape of the external circulating fluidized bed 1 is a cylindrical shell with a closed top, and the inner diameter of the cylindrical shell is 1800mm, the length is 3000mm, and the thickness is 5mm. The upper part of the cylindrical shell with a height of 1700mm is a free airspace, which is used for feeding coke solid raw materials and settling solid particles flowing ...

Embodiment 2

[0041] A kind of vibrating type internal circulation fluidization prepares the device of titanium tetrachloride, with embodiment 1, wherein:

[0042] The inner diameter of the external circulating fluidized bed 1 is 500mm, the length is 1000mm, and the thickness is 3mm. The height of the upper part of the free space in the cylindrical shell is 400mm. Two through holes ( That is, the aperture of the coke solid raw material inlet) is 50 mm. Weld a coke particle feeder with a length of 500mm, an angle of 30° with the shell of the external circulating fluidized bed 1, and an inner diameter matching the inlet of the coke solid raw material outside the inlet of the coke solid raw material. Tube 1-2. The aperture of the through hole (i.e. the discharge port) at the center of the top surface of the cylindrical housing is 50mm, and a length of 1500mm is welded at the discharge port, and the inner diameter is the same as that of the discharge port. Matching discharge pipe 4, and weldi...

Embodiment 3

[0047] A kind of vibrating type internal circulation fluidization prepares the device of titanium tetrachloride, with embodiment 1, wherein:

[0048] The materials of the external circulating fluidized bed, the internal fluidized bed reactor, the vibration distribution plate, the gas buffer tank, the baffle, the discharge pipe, the straight pipe and the feed pipe are all made of titanium alloy.

[0049] The inner diameter of the external circulating fluidized bed 1 is 3000mm, the length is 5000mm, and the thickness is 8mm. The height of the upper free space in the cylindrical shell is 3000mm. The aperture of the solid raw material inlet) is 150mm, and a length of 1500mm is respectively welded outside the coke solid raw material inlet, and a coke particle feed pipe 1 having an angle of 70° with the shell of the outer circulating fluidized bed 1 -2. At the center of circle of the top end face of the cylindrical housing, a through hole (i.e. a discharge port) with a diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com