Patents

Literature

77results about How to "No metal residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetradentate schiff base metal complexes, metal porphyrin complexes and preparing method of polycarbonate

ActiveCN102558199AHigh catalytic activityPrevent the problem of excessive toxic metal contentGroup 5/15 element organic compoundsMagnesium organic compoundsQuaternary ammonium cationPorphyrin

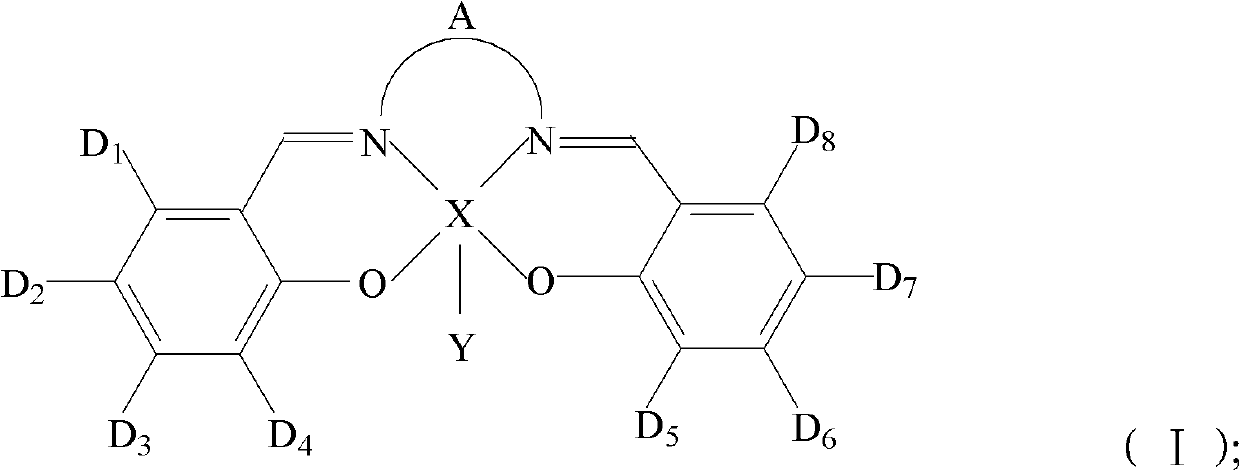

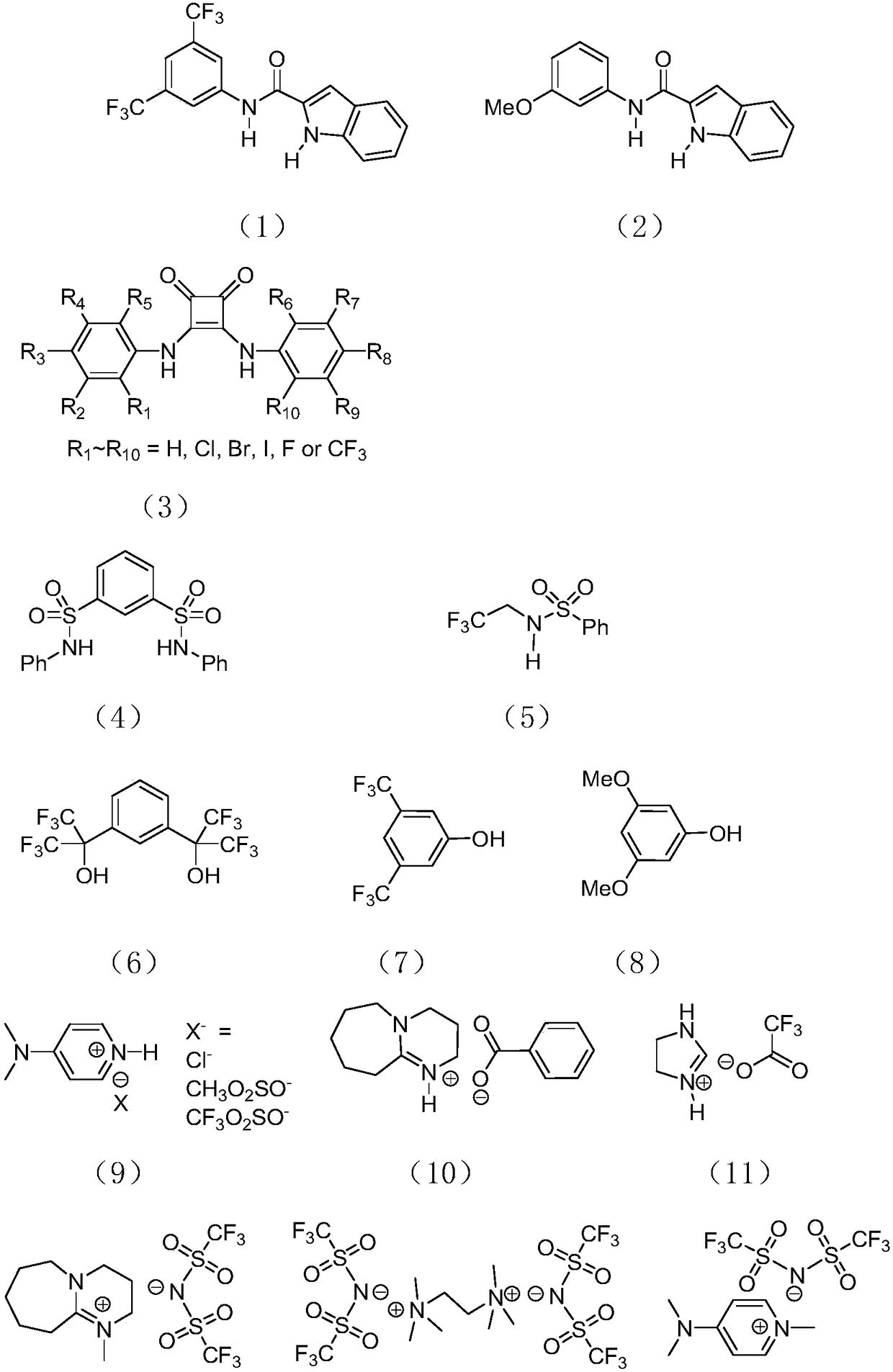

The invention provides tetradentate schiff base metal complexes with formula (I) and metal porphyrin complexes with formula (II). The active centers of the two complexes are non-toxic zinc, magnesium, manganese or iron. The invention also provides a method for preparing polycarbonate by using the complexes as a catalyzer. The ligand of the two complexes contain at least one or more quaternary ammonium salt or strong sterically hindered organic base group, so the two complexes have higher catalytic activity, meanwhile the complexes have non-toxic active center metal like zinc, magnesium, manganese or iron, can effectively prevent the problem of the exceeding content of toxic metals in polycarbonate and ensure that the product does not contain toxic metal residues.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

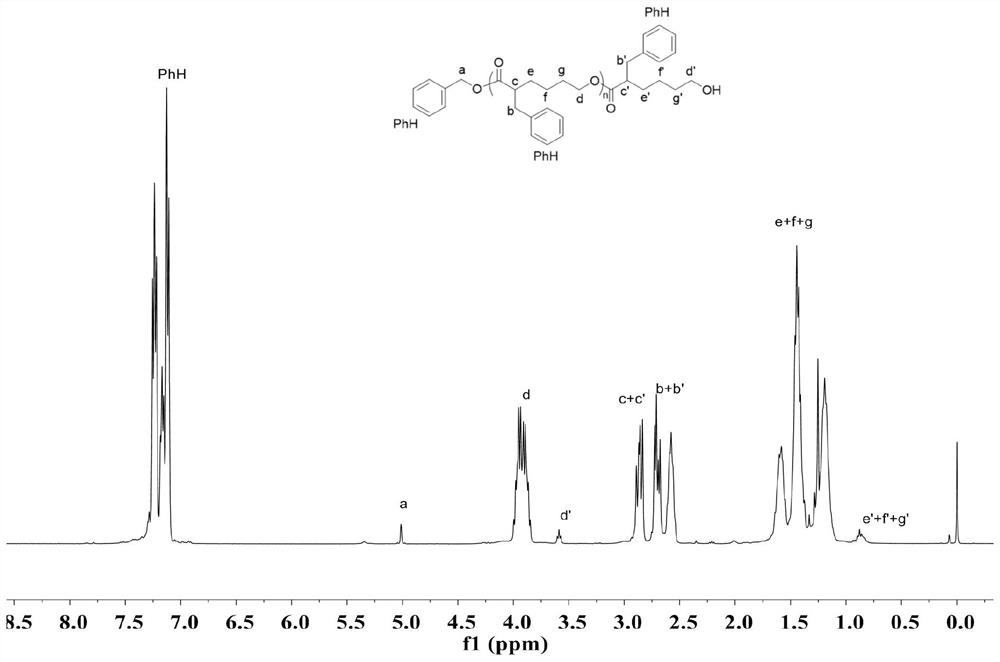

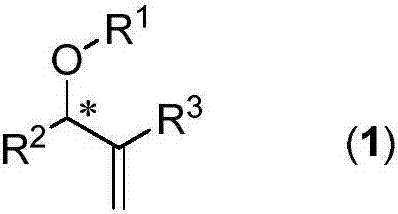

Polyene ether compounds and preparation method thereof

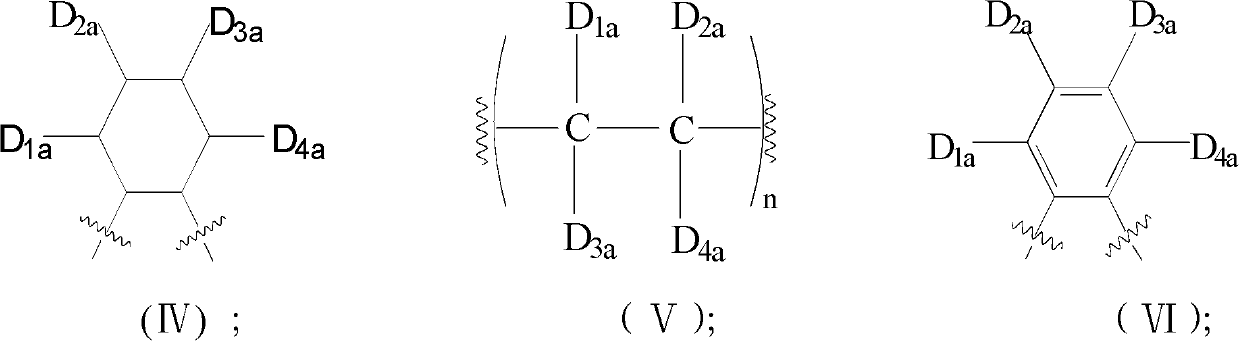

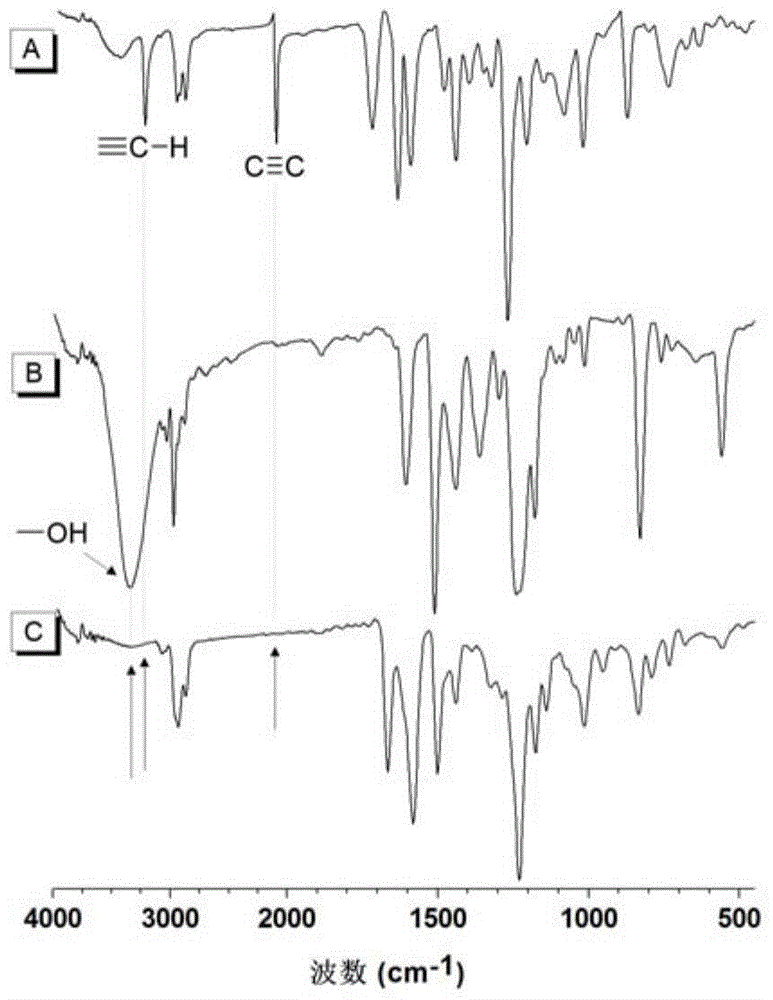

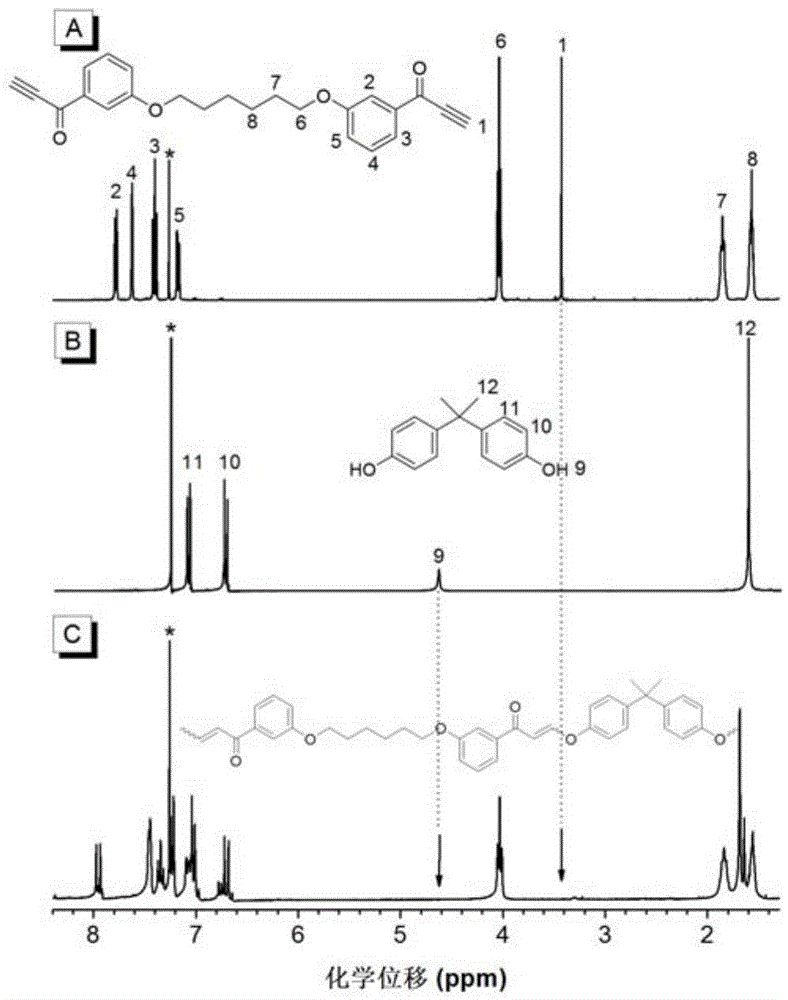

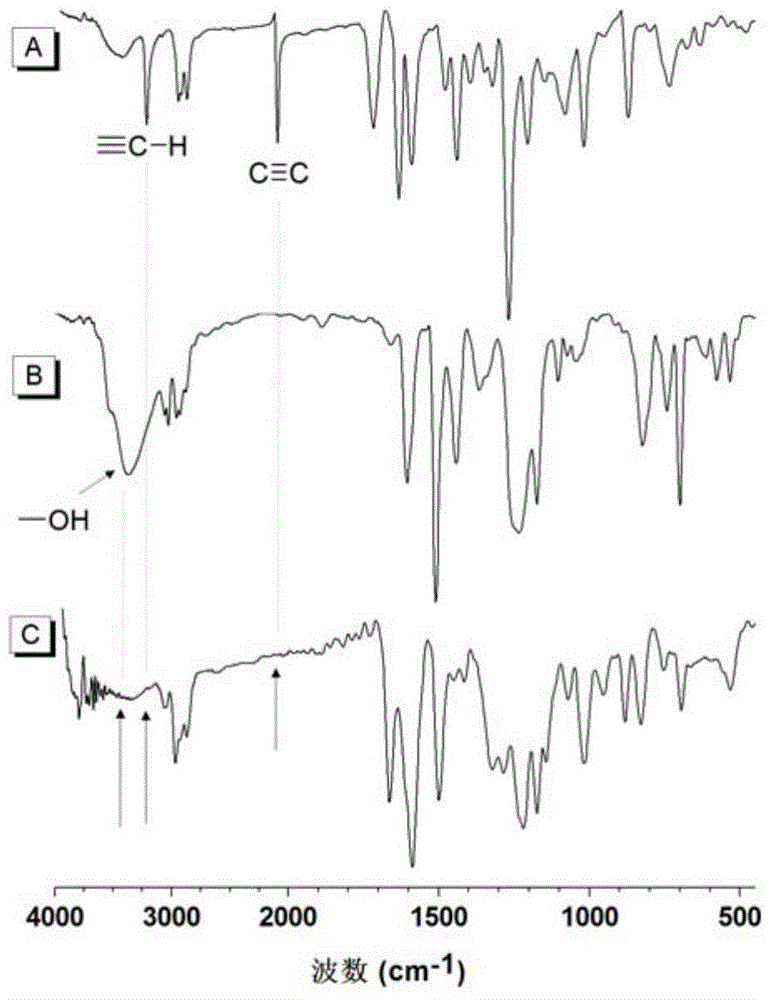

The invention discloses a preparation method of polyene ether compounds. The method includes: organic small-molecule 4-dimethylamino pyridine (DMAP) is used as the catalyst, binary alkynyl compounds and binary hydroxy compounds are mixed with organic solvent, and the polyene ether compounds are obtained by using the click polymerization reaction of alkynyl-hydroxy. The polyene ether compounds comprise an inner unit indicated by formula (I). The polymerization step is showed in the formula (V), wherein n is larger than 1, and R1 and R2 are selected from organic groups. The method has the advantages that water and oxygen do not need to be removed during reaction, polymerization temperature is low, polymerization efficiency is high, and no metal residues exist in products; the prepared polyene ether compounds are high in steric regularity, good in machinability, and high in heat stability, degradability and aggregation-induced emission performance.

Owner:ZHEJIANG UNIV

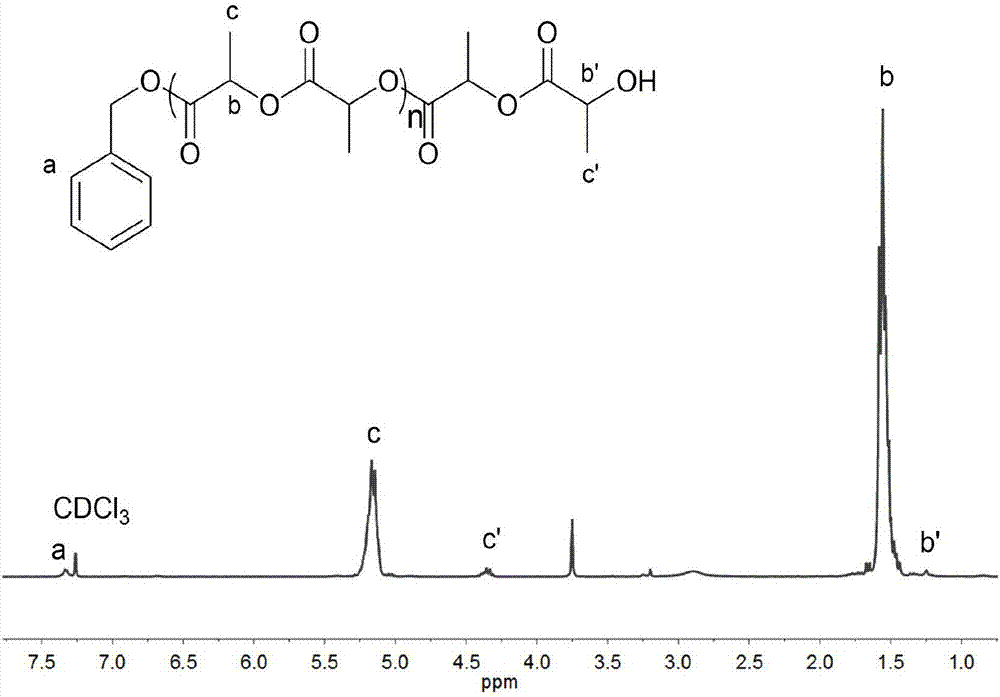

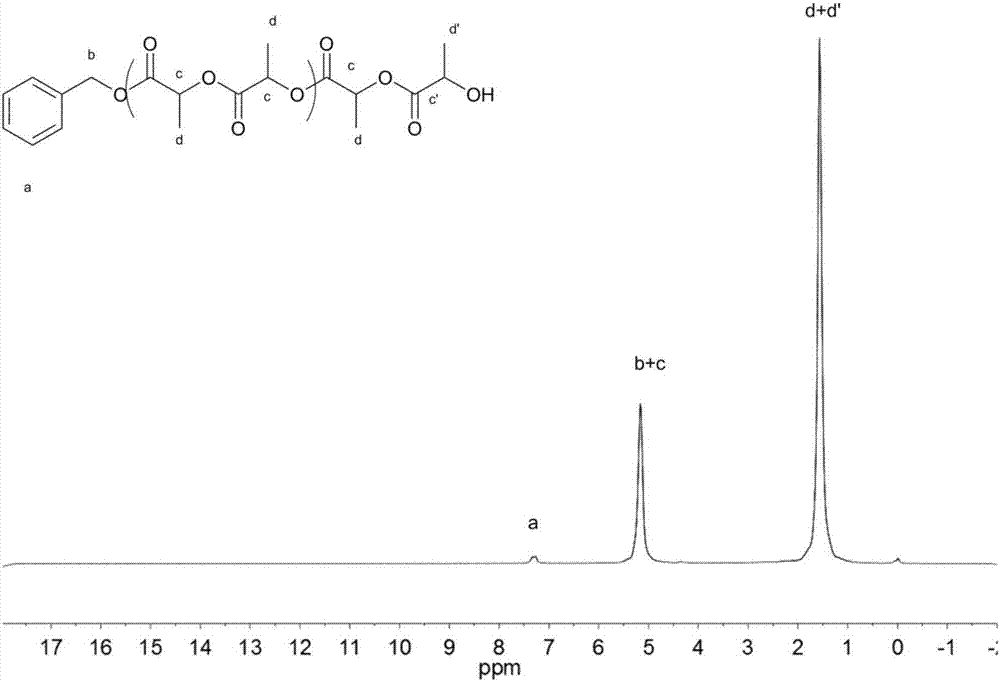

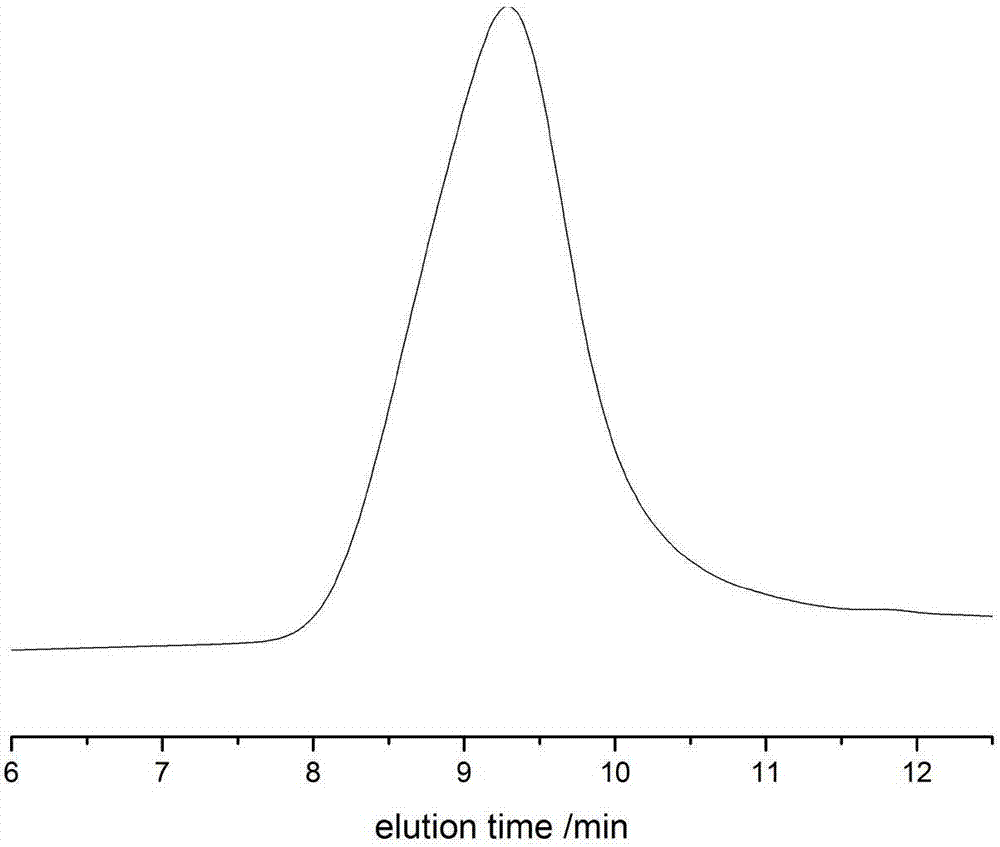

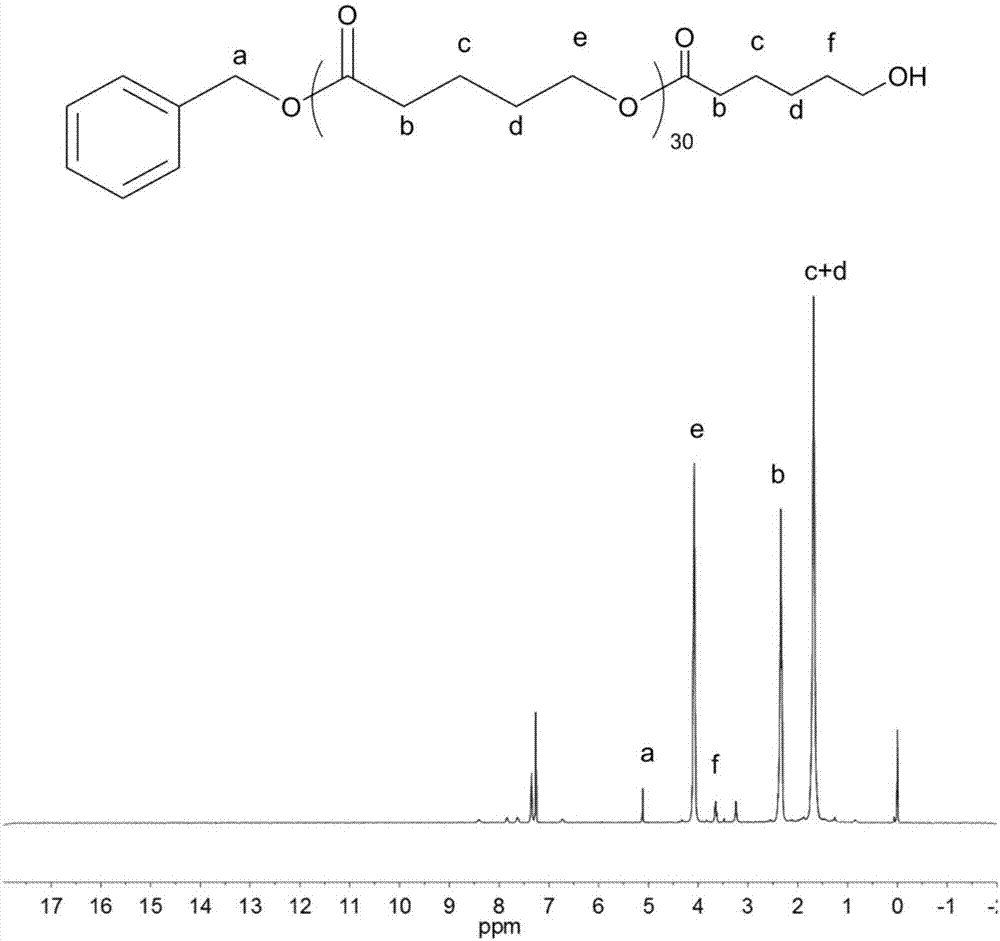

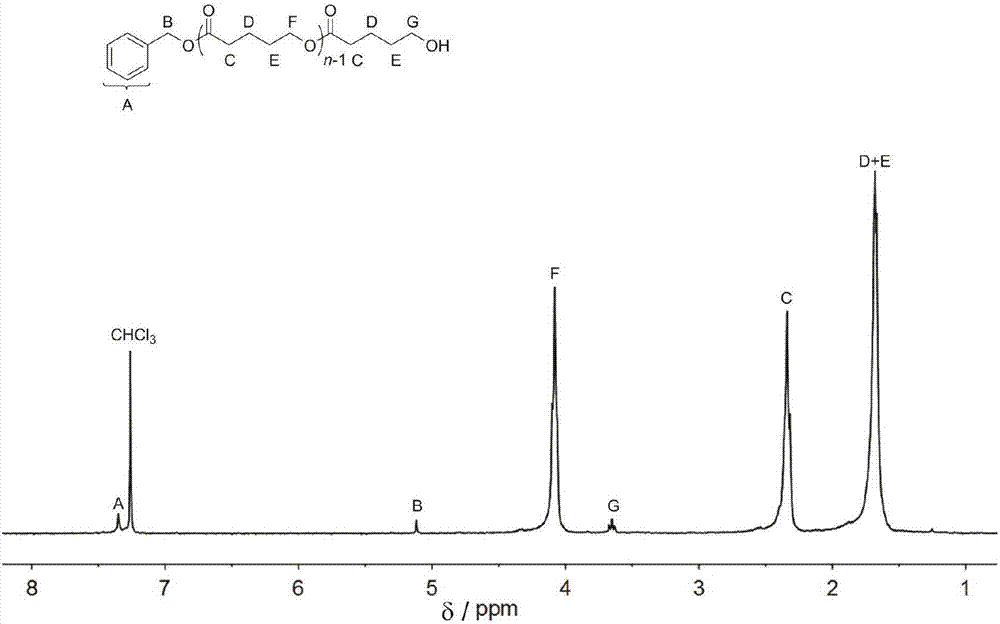

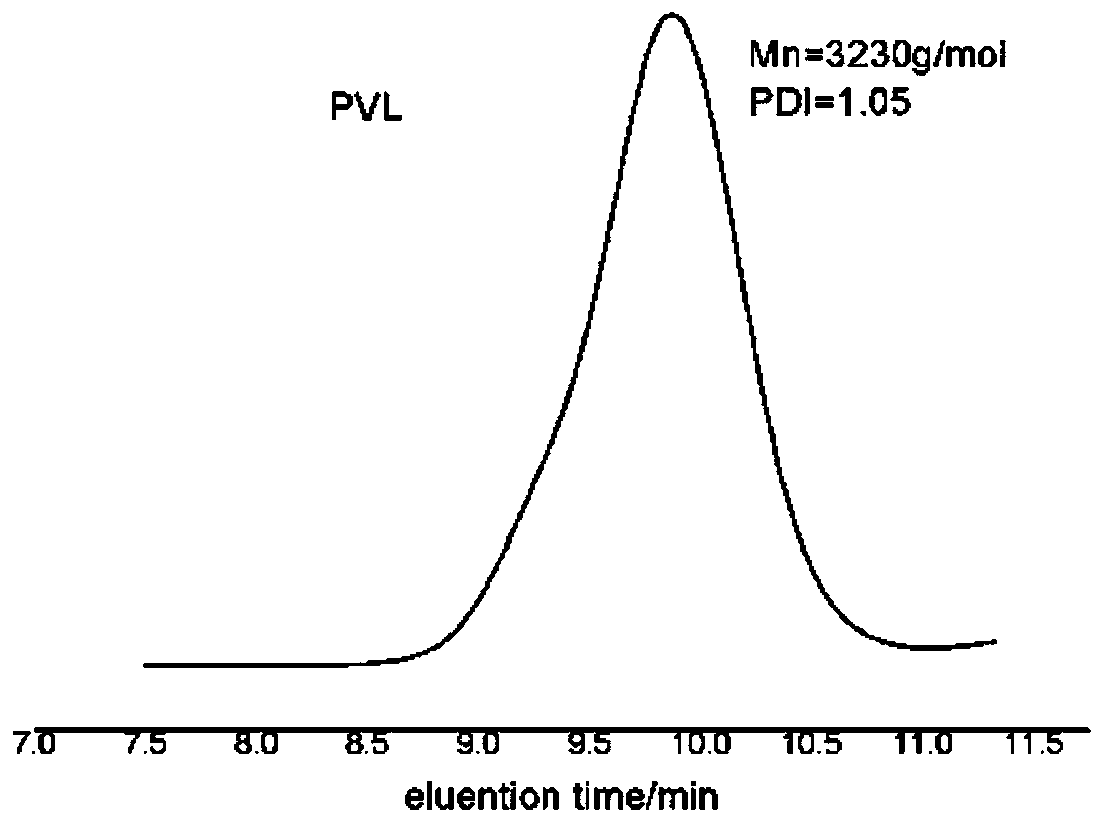

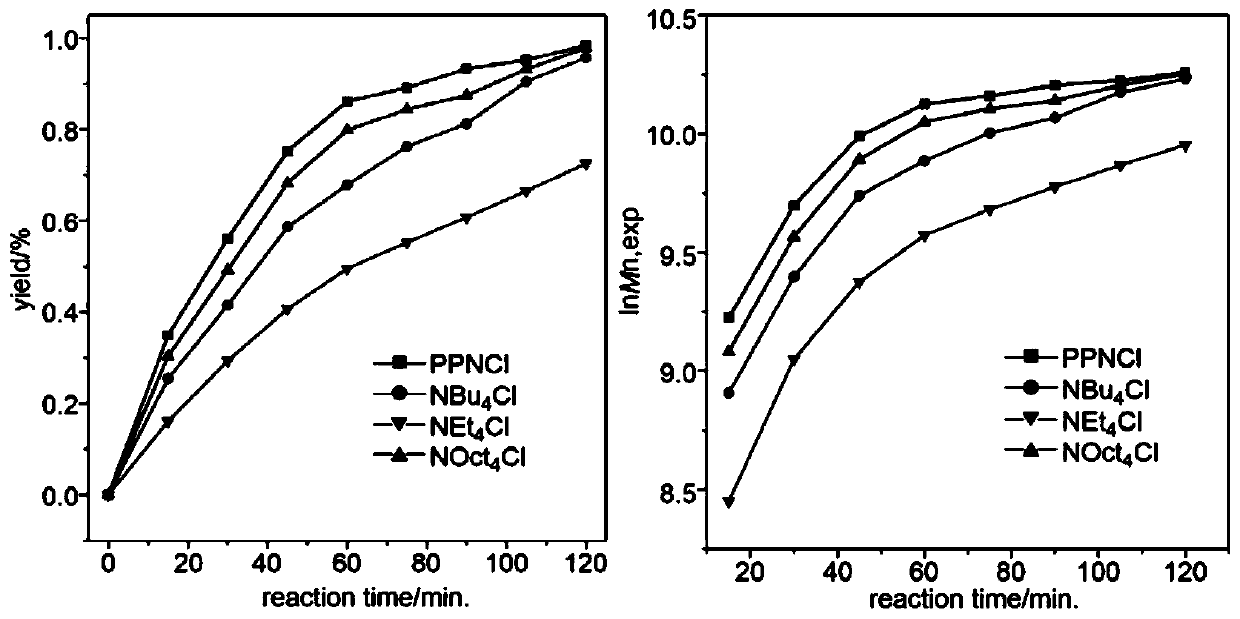

Method for preparing polylactone through ring opening

ActiveCN107141457ANon-toxic reactionSimple conditionsOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholTransesterification

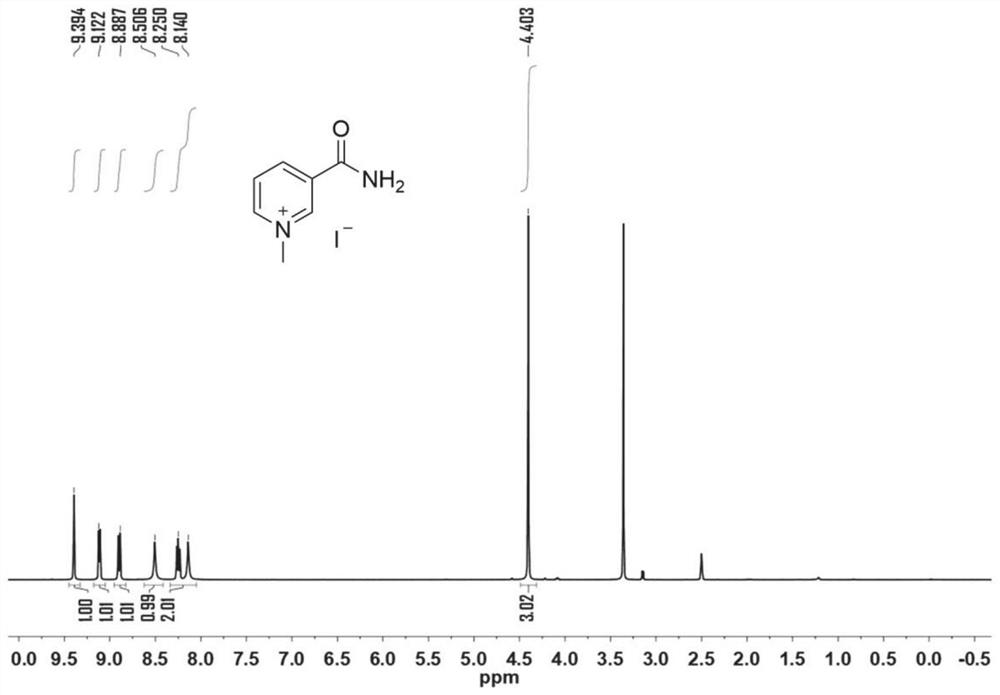

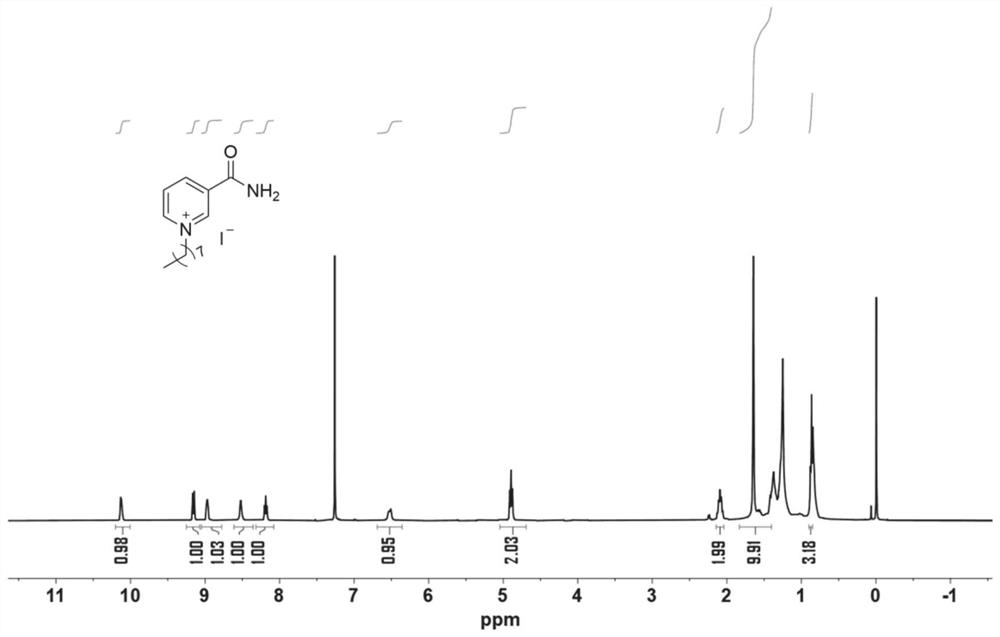

The invention discloses a method for preparing polylactone through ring opening, and belongs to the technical field of organic catalysis and high polymer materials. A novel catalytic mechanism is put forward, organic alcohol is adopted as an initiator, under the catalysis of an organic catalyst, ring opening polymerization of a cyclic monomer is initiated, and polylactone is obtained; the catalyst is pyridine salt, the method has the advantages that no toxin is generated during the reaction, conditions are simple, and the process is controllable, compared with 4-(N,N-dimethyl amino) pyridine catalysis, during solvent-free polymerization, narrow molecular distribution can be obtained, and the transesterification can be effectively restrained.

Owner:NANJING TECH UNIV

Etching solution, additive and manufacturing method for metal layout wires

InactiveCN111155091AModerate etch rateSuitable etching anglePrinted circuit manufactureActive agentPhysical chemistry

The invention discloses an etching solution, an additive and a manufacturing method for metal layout wires. The etching solution is prepared from the following main components in percentage by weight:5-30% of hydrogen peroxide, 0.1-5% of a hydrogen peroxide stabilizer, 5-25% of a chelating agent, 0.1-1% of a surfactant, 0.1-5% of an inorganic acid oxidant, and the balance of deionized water, wherein the additive is added into the etching solution while the etching solution is repeatedly used. The etching solution is free of fluorides, is environmentally friendly, and has the advantages of being moderate in etching rate, proper in etching angle, small in line width loss, free of metal residues, and the like. The additive and the etching solution are combined for use, so that the service life of the etching solution can be greatly prolonged.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Fluid for removing vacuum metallic coated nickel layer for decorating nonmetallic surface

This invention relates to a coating stripping solution for metal surface vacuum-coated with nickel. The coating stripping solution comprises: FeCl3 0.01 mol / L, HNO3 0.02 mol / L, HCl 0.08 mol / L, and NaCl 0.02 mol / L. The coating stripping solution has such advantages as rapid reaction, high stability, and uniform coating stripping, no metal residue, no side corrosion, low cost, high production efficiency, and easy control of the product quality.

Owner:TIANJIN ZHONGHUAN HI TECH

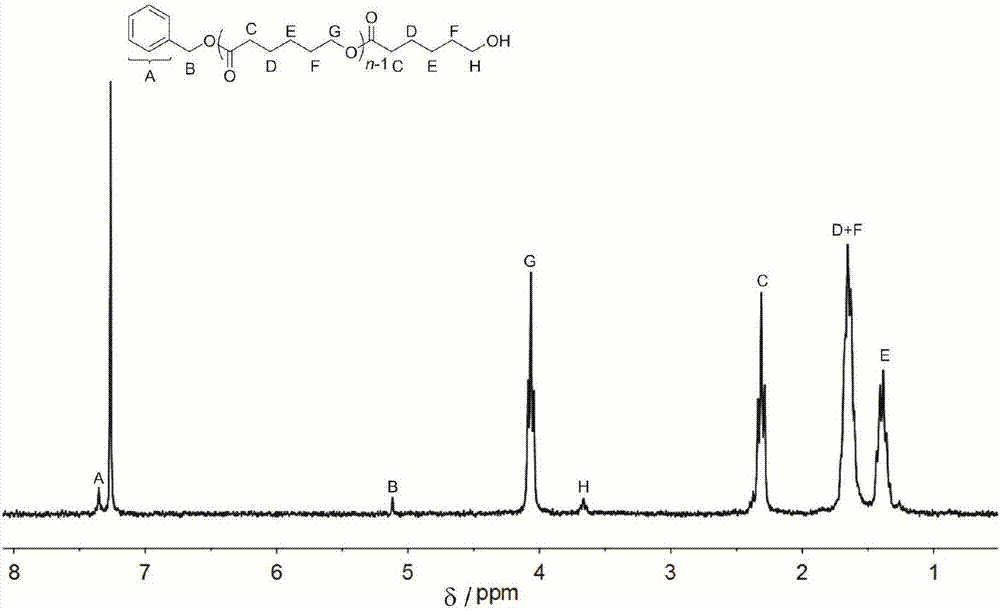

Preparation method of polyester

The invention discloses a preparation method of polyester. The preparation method of the polyester belongs to the technical field of organocatalysis and high polymer materials. The preparation method comprises the steps of (1) preparing pyridine saccharin salt through adding pyridine and saccharin (1:1) in tetrahydrofuran at the temperature of 60 DEG C, and separating out from methyl alcohol and hexane;(2) separating a little pyridine out of the pyridine saccharin salt at a heating state, and jointly catalyzing cyclic lactone or carbonic ester ring opening polymerization to form a polyester, wherein no other compound residual exists in a system; (3) in the presence of an alcohol initiator, catalyzing cyclic lactone ring opening polymerization through the pyridine saccharin salt to obtain the polyester. The accurate polylactone can be efficiently synthesized through the catalytic system, and compared with a synthesized polymer containing a metal catalyst in the prior art, the polymer is widely applied, has no metal residue, is narrow in molecular weight distribution, has no chain transesterification reaction, and has a great business application potential in a biological medicine field and a microelectronic field.

Owner:NANJING TECH UNIV

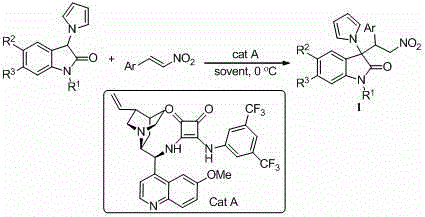

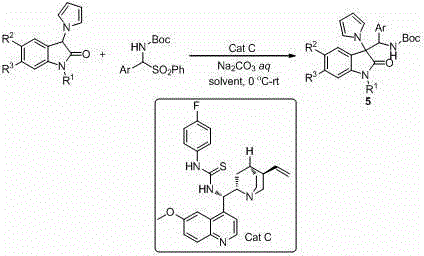

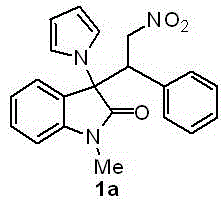

3, 3'-disubstituted 3-pyrrole oxoindole compound and asymmetric synthetic method thereof

ActiveCN104086535AMild reaction conditionsNo metal residueOrganic chemistryPtru catalystPharmaceutical Substances

The invention discloses a 3, 3'-disubstituted 3-pyrrole oxoindole compound and an asymmetric synthetic method thereof and belongs to the fields of organic chemistry and medicines. The structure of the compound takes the 3, 3'-disubstituted 3-pyrrole oxoindole compound as a framework, and the type of indole alkaloid is enriched so as to provide a sufficient compound source for screening pharmaceutical activity. Meanwhile, a synthetic method of the compound is provided. The asymmetric synthetic method comprises the following steps: dissolving 3-pyrrole oxoindole, an electrophilic reagent and a chiral catalyst in an organic solvent; carrying out a reaction at (-20)-25 DEG C; after reaction, separating and purifying to obtain the compound. The method is mild in reaction condition, easy in obtaining of raw materials and catalyst, free from metal residues, simple to operate, high in yield and further high in stereoselectivity.

Owner:CHENGDU LIKAI CHIRAL TECH

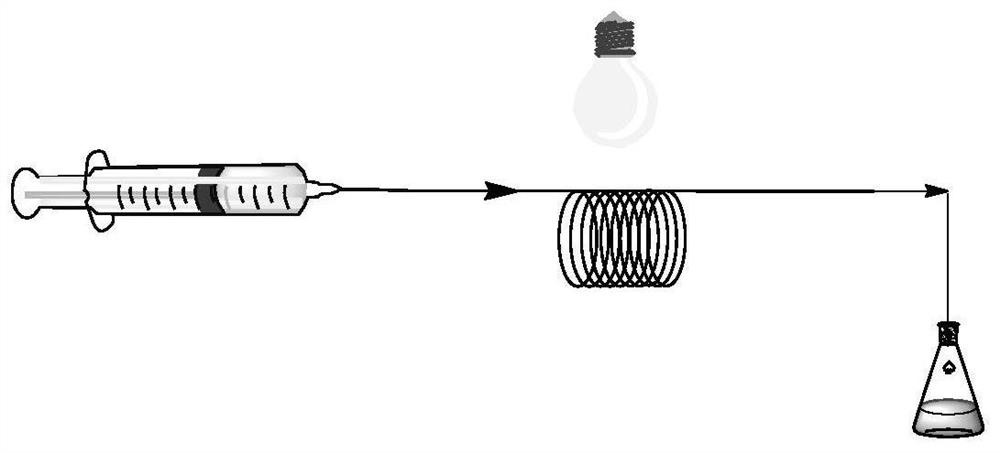

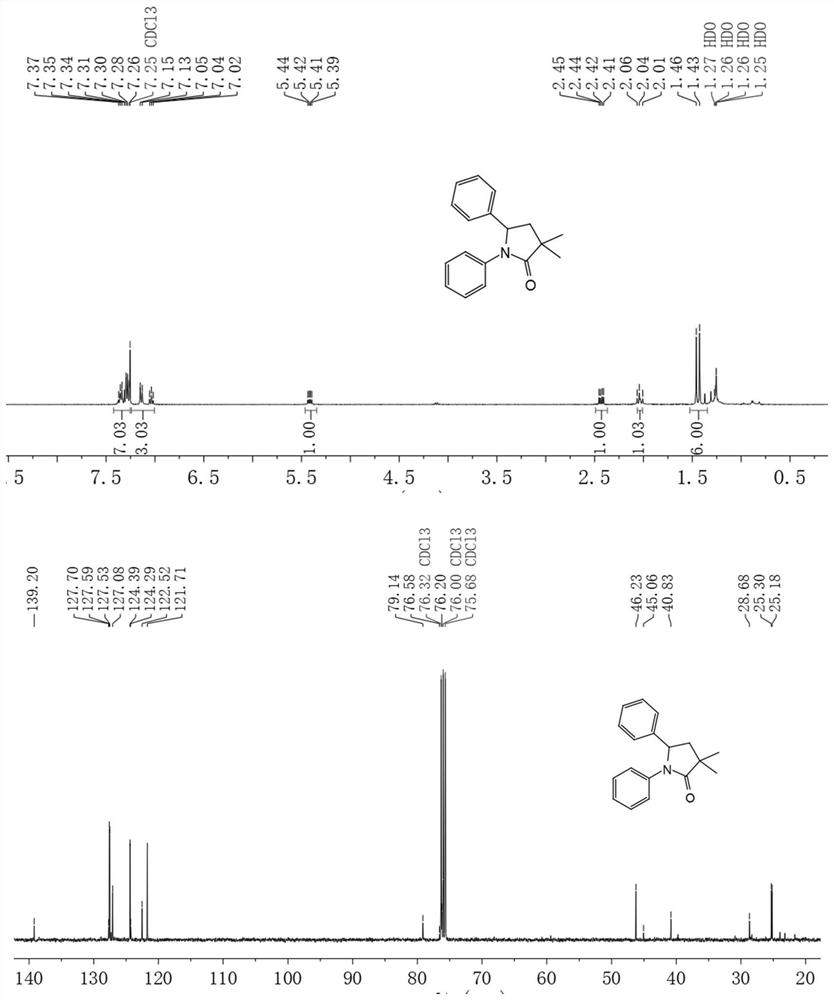

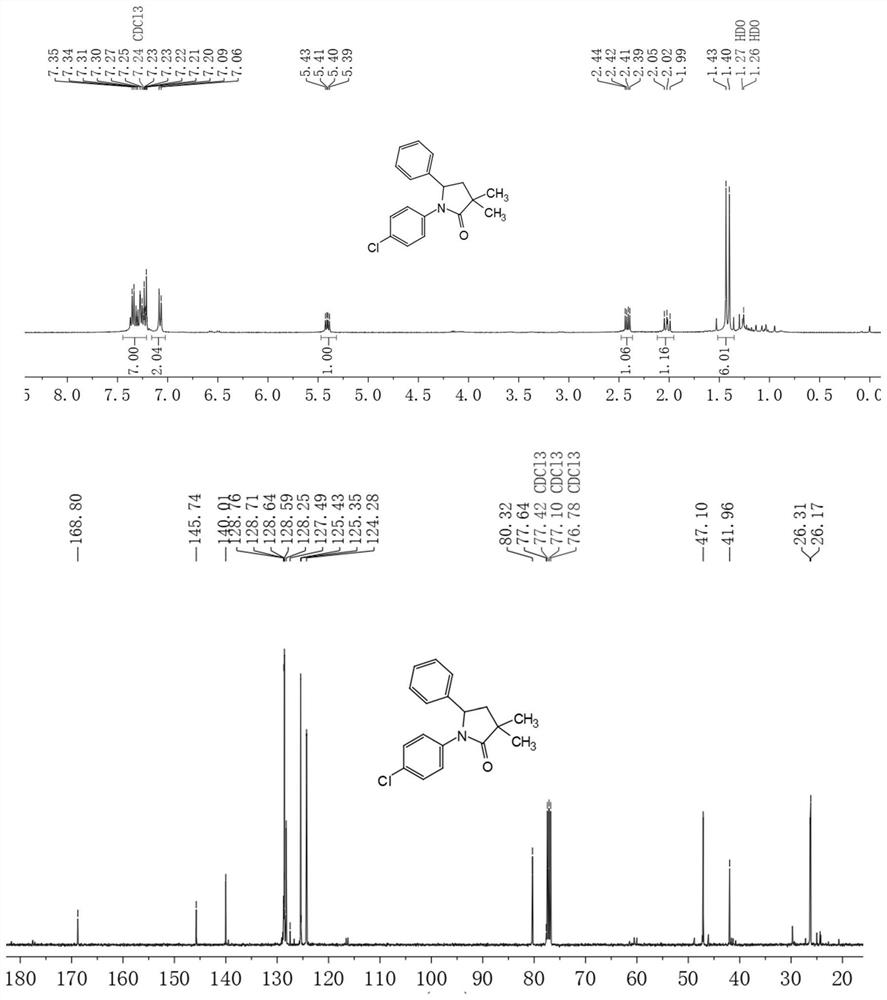

Method for synthesizing pyrrolidone compound through continuous light-induced catalysis

ActiveCN111777540AHigh yieldNo metal residueOrganic chemistryChemical/physical/physico-chemical microreactorsContinuous lightPtru catalyst

The invention discloses a method for synthesizing a pyrrolidone compound by continuous light-induced catalysis. The method comprises the following steps: dissolving an organic catalyst, an olefin organic compound, a bromo-acetate compound and an amine compound in a solvent to obtain a homogeneous solution; pumping the homogeneous solution into a micro-channel reaction device provided with a lightsource for reaction to obtain a reaction solution containing the pyrrolidone compound. Compared with the prior art, a catalyst is replaced by organic photocatalysis, so that the method is green, efficient and free of metal residues, and has a wide application prospect in the aspect of synthesizing medical products.

Owner:NANJING UNIV OF TECH

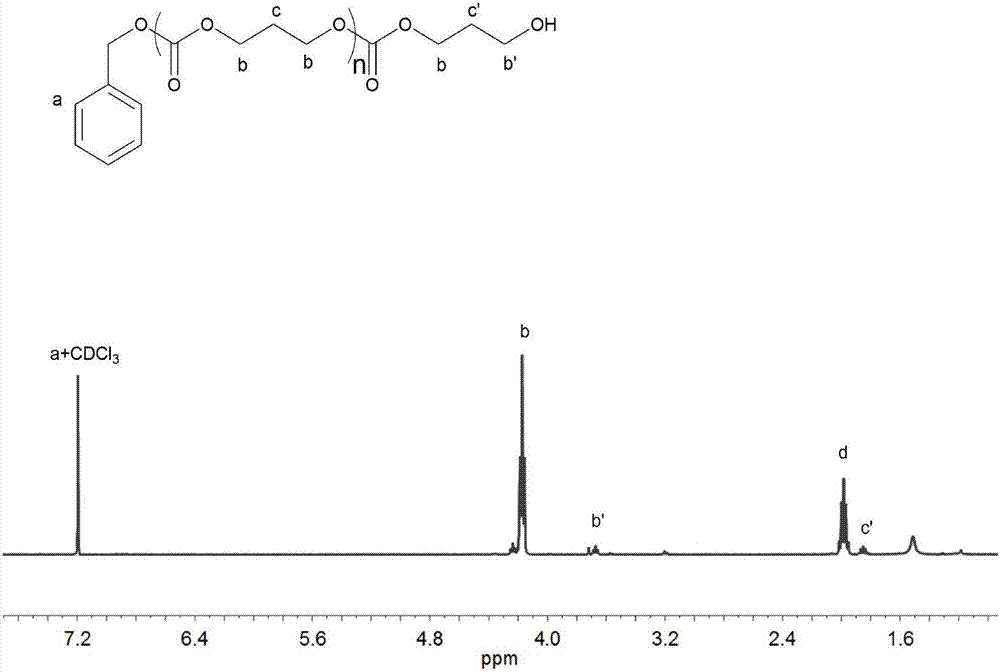

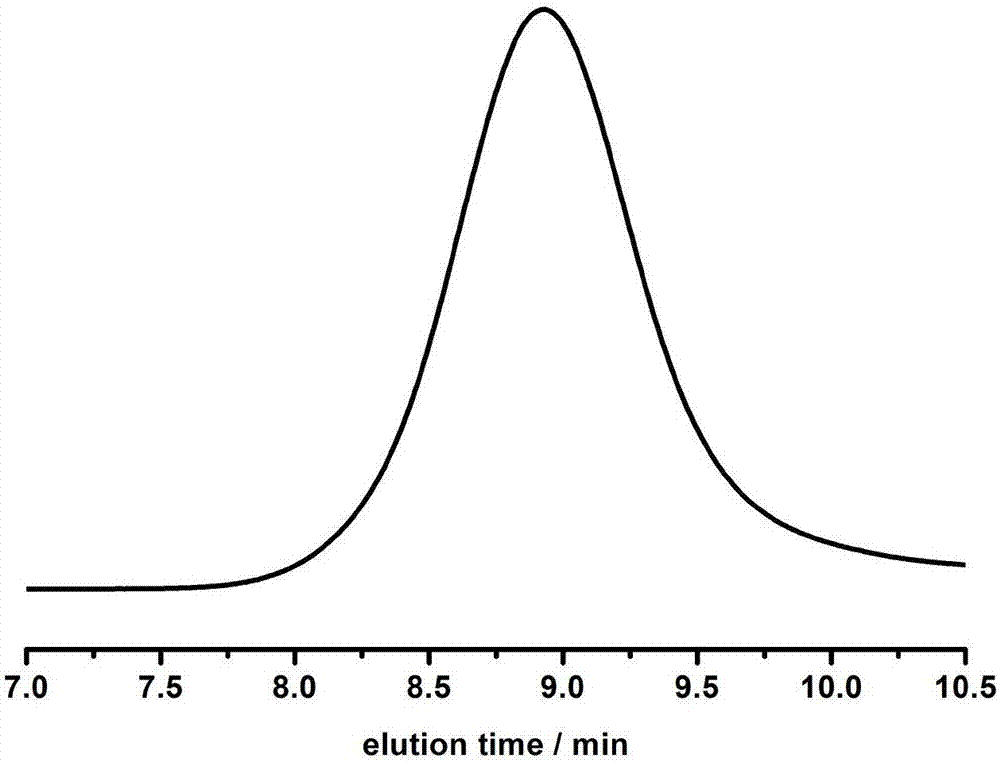

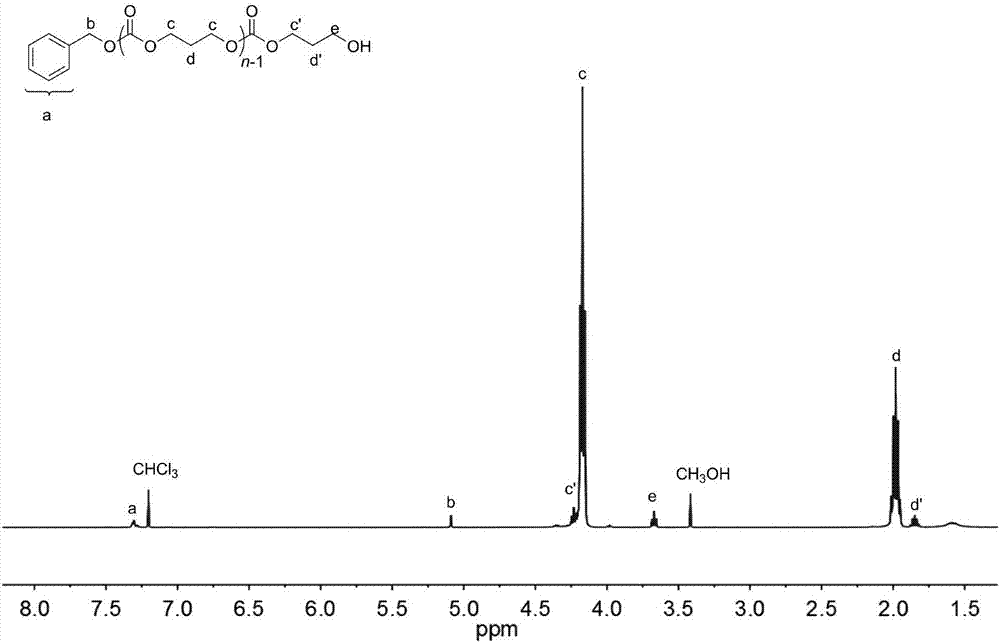

Method for cyclic compound ring opening polymerization

The invention discloses a method for cyclic compound ring opening polymerization and belongs to the technical field of organic catalytic and high polymer materials. According to the method disclosed by the invention, a cyclopropene salt is utilized to catalyze cyclic compound ring opening polymerization in the presence of an initiator to obtain polyester compounds. By means of the method disclosed by the invention, a macromolecular biodegradable material with large molecular weight, narrow dispersity and no metallic impurities can be obtained. A novel catalyst system is stable and general and is effective for a long time in a storage aspect. The macromolecular material prepared by the method can be applied to aspects of medicine carriers, nano reactors, films, material connectors and the like, further has biodegradability and is an environment-friendly material.

Owner:NANJING UNIV OF TECH

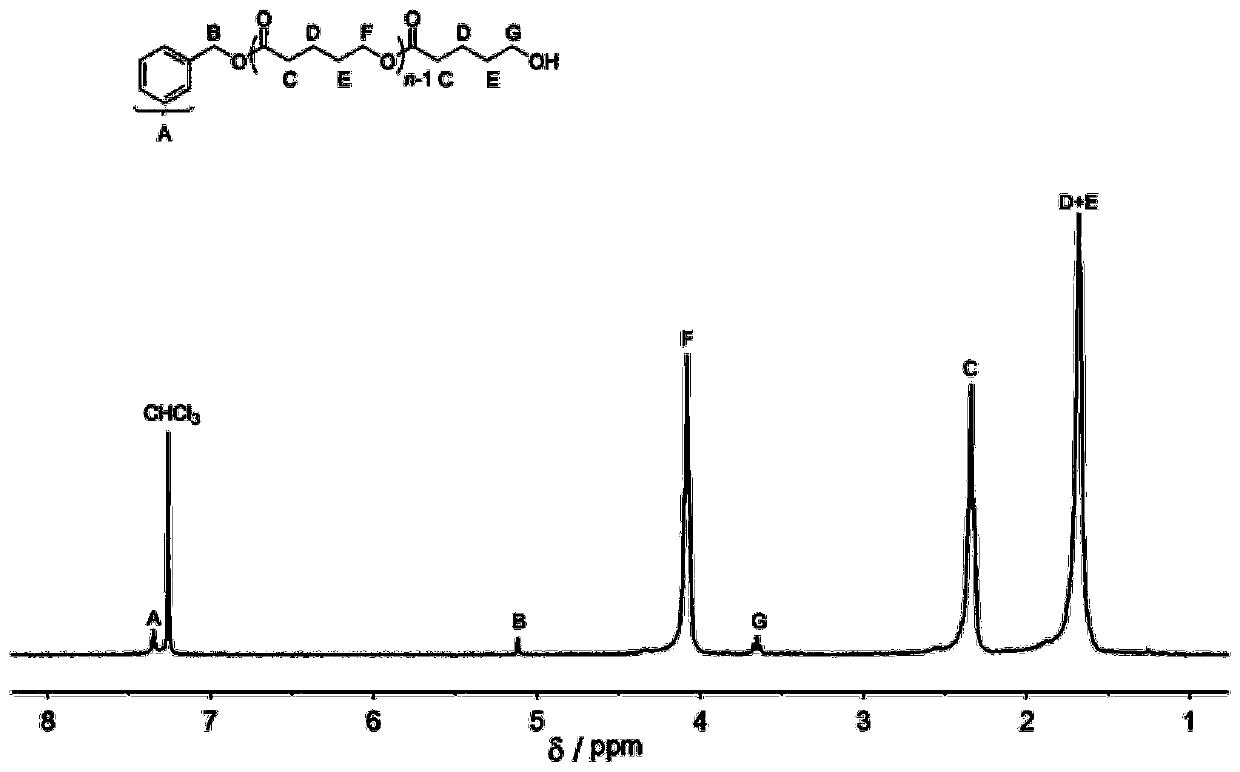

Preparation method of polylactone

The invention discloses a preparation method of a polylactone, and relates to the technical field of macromolecule materials. The method uses an initiator alcohol or amine to initiate the ring openingof a cyclic lactone monomer or a cyclic lactide monomer or a cyclic carbonate monomer, and uses a stable carbon cationic salt as an organic catalyst to initiate the ring-opening polymerization of a small molecular monomer to obtain the polylactone. By adopting the technical scheme of the method, the catalyst has the beneficial effects of low load and high efficiency, plays the role of controllingmolecular weight and / or stereochemistry of the polymer, and shows high reactivity. In particular, the new catalyst has better practicability than a catalyst used in the prior art, has less catalyst consumption, has a wide range of catalytic monomers, and has no metal residue.

Owner:NANJING TECH UNIV

Method for preparing polylactone

ActiveCN109880073AWide applicationNarrow molecular weight distributionWeight distributionCatalytic efficiency

The invention discloses a method for preparing polylactone, and relates to the technical field of polymer materials. An initiator alcohol or amine is used to initiate ring opening of a cyclic lactonemonomer or a cyclic lactide monomer or a cyclic carbonate monomer, ring-opening polymerization of a small molecule monomer is initiated under the catalysis of an organic catalyst to obtain polylactone, and the organic catalyst is a hydantoin derivative and tertiary amine catalyst system. The method has the advantages of high catalytic efficiency, mild reaction, and high-efficiency synthesis of pure polylactone, and the product has the advantages of no metal residue, narrow molecular weight distribution, high product yield, no monomer residue and white color.

Owner:NANJING UNIV OF TECH

Preparation method of cyclic carbonate

InactiveCN111253360AHigh activityImprove hydrogen supply capacityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCarbonate ester

The invention belongs to the technical field of green catalytic synthesis, and particularly relates to a preparation method of cyclic carbonate. Epoxide and carbon dioxide are catalyzed by using a catalyst provided by the invention to obtain the cyclic carbonate. According to the invention, the synthesis method is simple, cost is low, the catalyst has high activity and high selectivity, a reactioncondition is mild, and good reusability is realized.

Owner:NANJING UNIV OF TECH

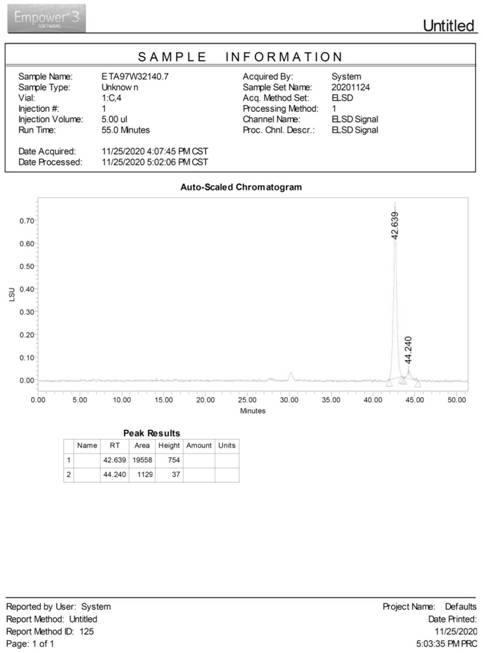

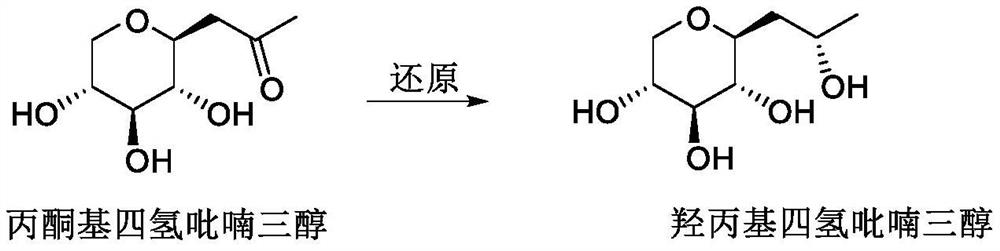

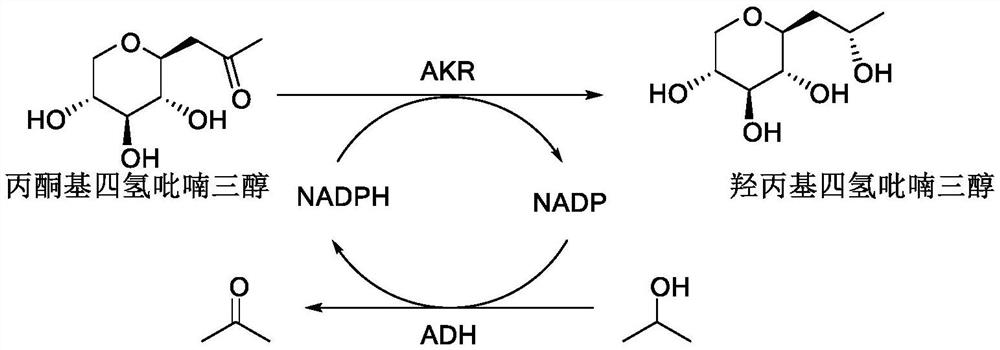

Synthetic method of hydroxypropyl tetrahydropyrantriol catalyzed by biological enzyme

PendingCN113416756AHigh puritySuitable for synthesisOxidoreductasesGenetic engineeringEthanol dehydrogenaseOrganic synthesis

The invention belongs to the field of organic synthesis, fine chemicals and daily chemicals, and particularly relates to a synthetic method of hydroxypropyl tetrahydropyrantriol catalyzed by a biological enzyme. According to the method, a double-enzyme circulating catalysis system containing aldoketo reductase (AKR) and ethanol dehydrogenase (ADH) is used, and in the presence of oxidized coenzyme II (NADP), isopropanol is used as a reducing agent, so that the synthesis of the hydroxypropyl tetrahydropyrantriol is realized. As biological enzyme catalysis is adopted, the method is mild in condition, simple and convenient to operate, small in pollution, green, safe, free of metal residues and high in product purity, and is particularly suitable for synthesis of active matters of medicines and cosmetics.

Owner:SHANGHAI COACHCHEM TECH

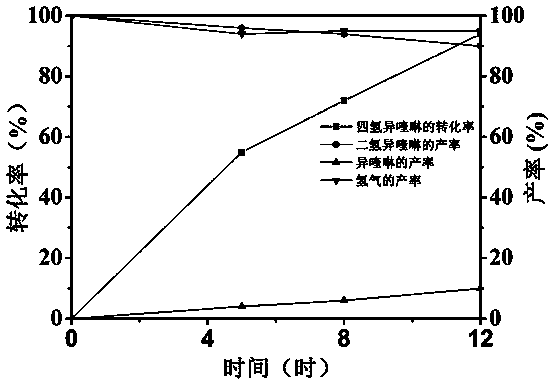

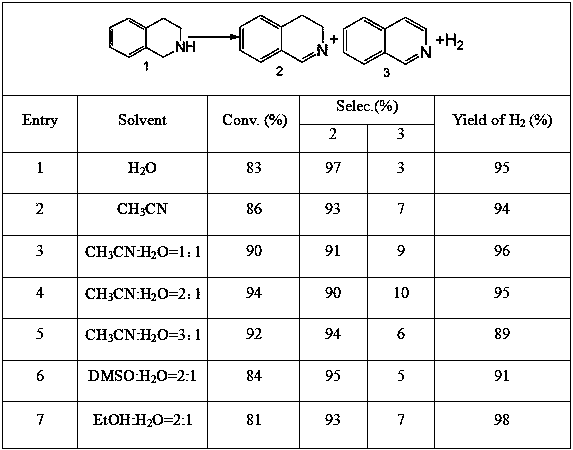

Method for synthesizing 3,4-dihydroisoquinoline by semi-dehydrogenation oxidation of 1,2,3,4-tetrahydroisoquinoline

ActiveCN109134368AHigh selectivityEasy to prepareOrganic chemistryPhysical/chemical process catalystsPhotocatalysisPhotochemistry

The invention belongs to the technical field of organic chemistry and photocatalysis and discloses a method for synthesizing 3,4-dihydroisoquinoline by semi-dehydrogenation oxidation of 1,2,3,4-tetrahydroisoquinoline. According to the method, by adoption of MoS2 / ZnIn2S4 as a photocatalyst, semi-dehydrogenation oxidation of 1,2,3,4-tetrahydroisoquinoline is realized in an N2 atmosphere under the visible light condition to obtain a product namely 3,4-dihydroisoquinoline, and high conversion rate and selectivity are achieved. In addition, the method is simple, convenient and feasible and is beneficial to large-scale industrial popularization.

Owner:FUZHOU UNIVERSITY

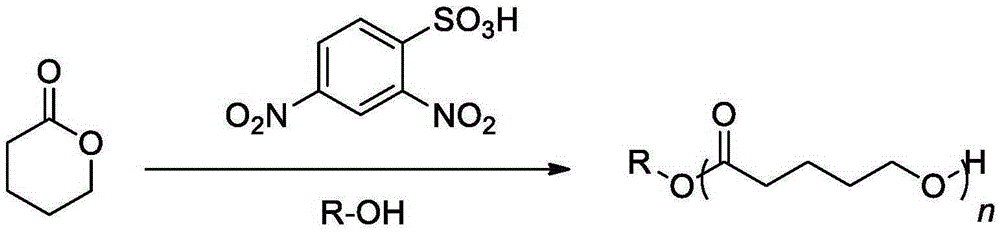

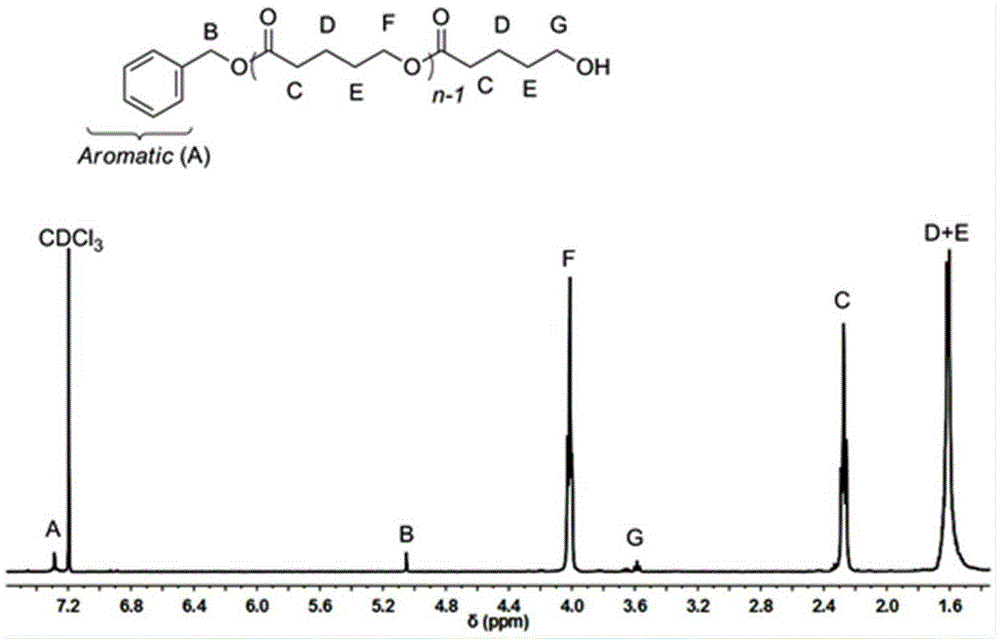

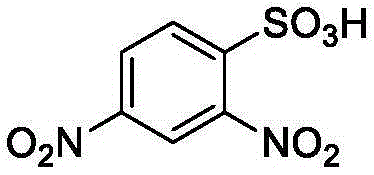

Method for preparing polylactone through ring-opening polymerization

InactiveCN105399932ANo metal residueAvoid application restrictionsSolution polymerizationOrganic solvent

The invention discloses a method for preparing polylactone through ring-opening polymerization and belongs to the high-molecular material synthesis field. The preparation method is as follows: in presence of an organic sulfonic acid catalyst in an organic solvent, lactone is employed as reaction monomers, a reaction is carried out with organic alcohol as an initiator, the monomers are subjected to ring-opening polymerization, and polylactone prepared. The organic sulfonic acid is 2,4-Dinitrobenzenesulfonic acid. The polylactone prepared through catalysis of organic sulfonic acid has no metal residues, restriction of medical material aspect applications is avoided, and the high-efficiency polymerization reaction without high temperature shows green low energy consumption.

Owner:NANJING UNIV OF TECH

Catalyst for preparing polypeptide through ring-opening polymerization of amino acid N-carboxy anhydride, and method for preparing polypeptide by catalyst

ActiveCN109503827APrecise and controllable structureIncrease dosagePeptide preparation methodsFiltrationReaction rate

Disclosed are a catalyst for preparing polypeptide through ring-opening polymerization of amino acid N-carboxy anhydride, and a method for preparing the polypeptide by the catalyst. The catalyst comprises a component A and a component B, both of which are non-metal compounds; the component A is used for initiating ring-opening polymerization of an amino acid N-carboxy anhydride monomer, the molecular weight of the obtained polypeptide is controlled, the component B is used for activating the amino acid N-carboxy anhydride monomer, the polymerization reaction rate is controlled, and the component B can greatly reduce the reaction activation energy and accelerate the polymerization reaction. The method includes the steps of adding the component A and the component B of the catalyst and an organic solvent into an anhydrously treated polymerization bottle at the room temperature, adding the amino acid N-carboxy anhydride monomer after stirring, carrying out a polymerization reaction at theroom temperature, adding a hydrochloric acid alcohol solution to stop the reaction, pouring reaction liquid into ethyl alcohol for precipitation, performing filtration to obtain white solids, and drying the white solids to obtain the polypeptide. The method has the advantages of environment protection, high efficiency and accuracy.

Owner:SHAANXI UNIV OF SCI & TECH

Method for synthesizing cyclic carbonate and derivatives thereof

ActiveCN112409317AHigh activityLow costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOrganic synthesisEpoxide Compound

The invention belongs to the field of organic synthesis, and particularly relates to a method for synthesizing cyclic carbonate and derivatives thereof, which comprises the following step of: reactingan epoxy compound shown in a formula I with carbon dioxide under the catalysis of a catalyst shown in a formula II to obtain a target product. The product prepared by the method has the advantages ofhigh yield, high purity, low catalyst cost and mild synthesis conditions, and the obtained product has no metal residue.

Owner:NANJING UNIV OF TECH

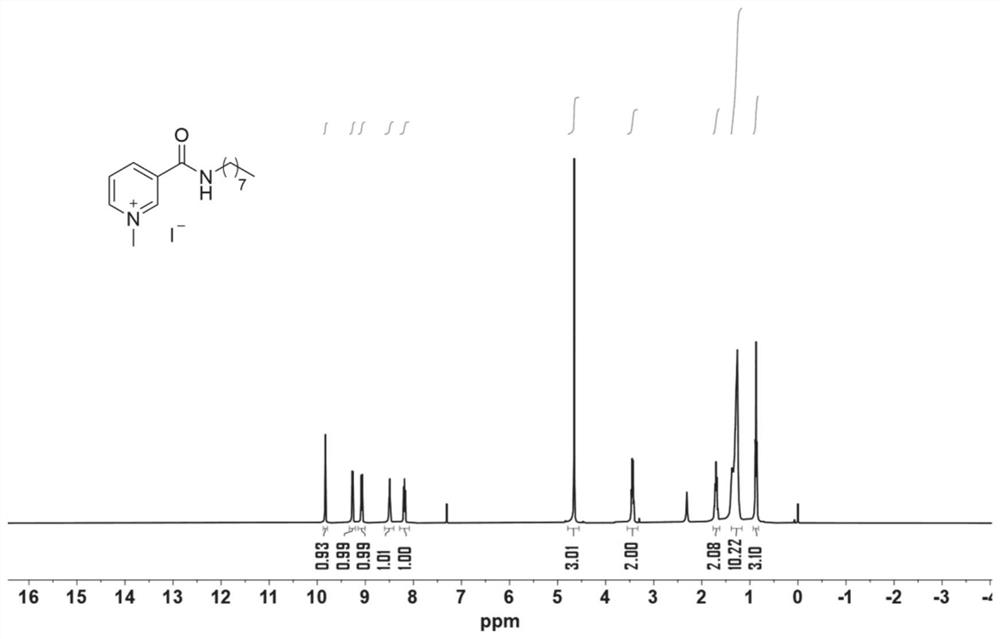

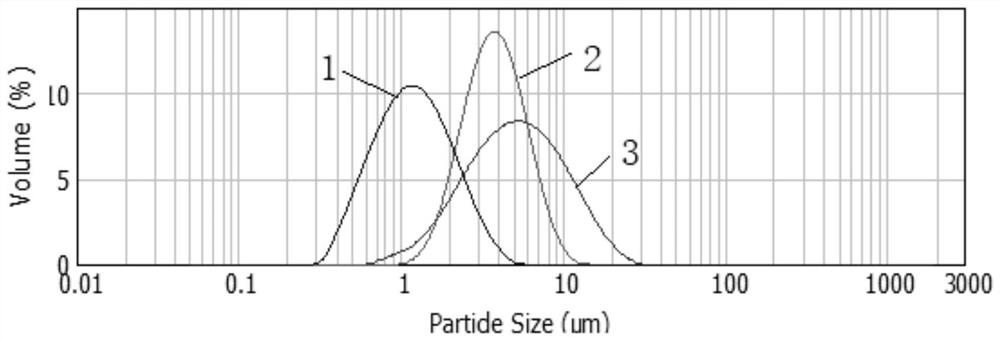

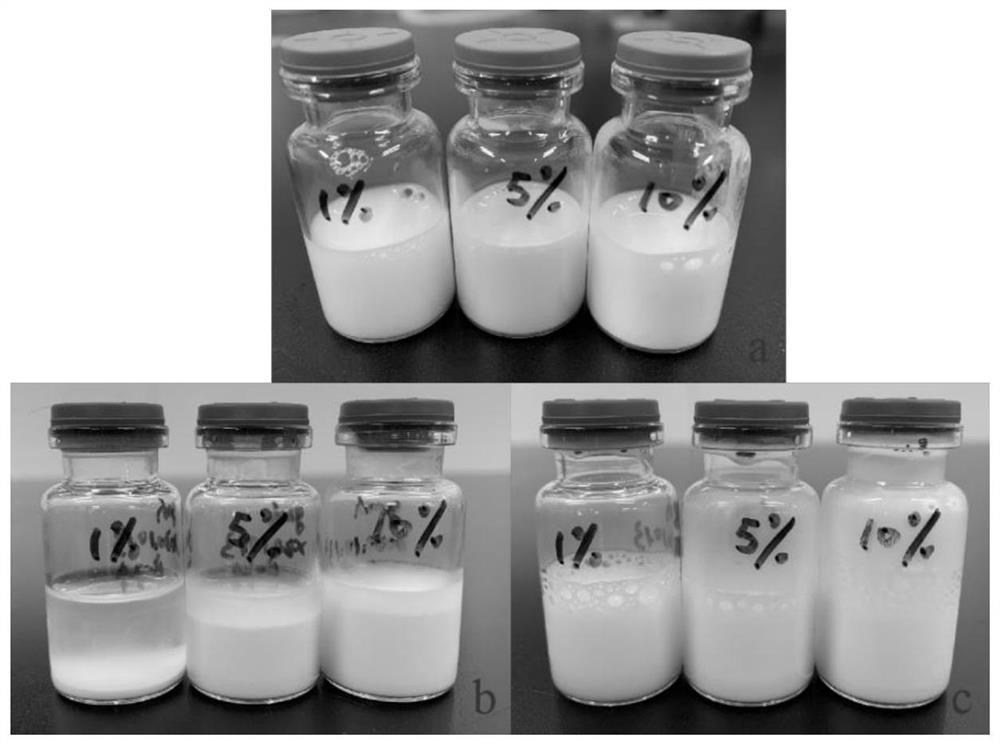

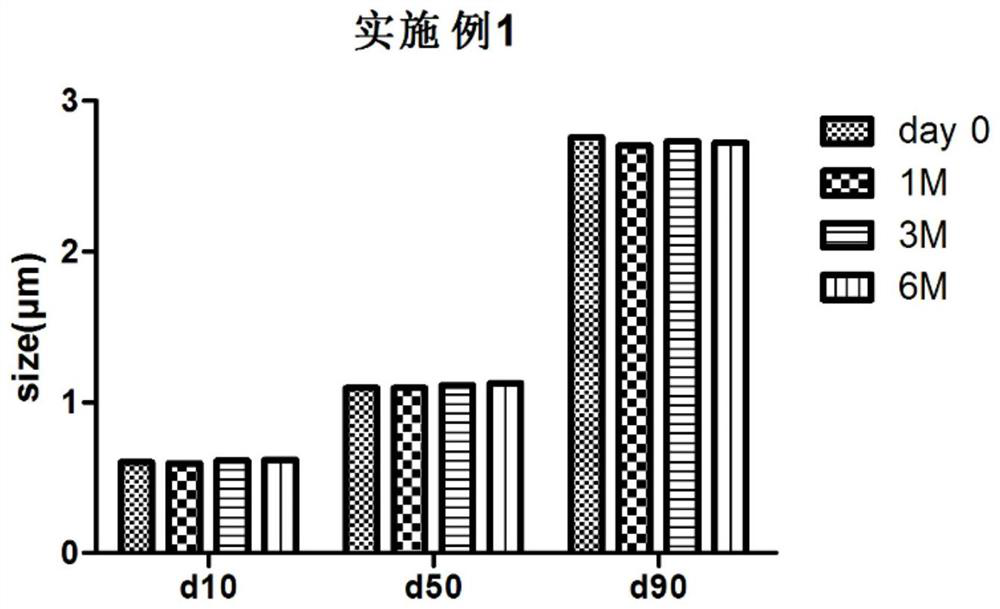

Preparation method of paliperidone palmitate suspension

ActiveCN112451483AUniform particle size distributionImprove stabilityOrganic active ingredientsNervous disorderDrugs solutionActive agent

The invention discloses a preparation method of a paliperidone palmitate suspension. The preparation method comprises the following steps of (1) dispersing and dissolving paliperidone palmitate drug particles in a first water-soluble good solvent containing a surfactant to obtain a drug solution; and (2) slowly adding the drug solution into a second water-soluble solvent, simultaneously adding energy to enable the drug particles to be rapidly precipitated, and performing resuspending to obtain the suspension. According to the invention, complex equipment is not needed, the preparation processis simple, and the problem of metal medium or organic solvent residues is avoided.

Owner:ZHEJIANG SUNDOC PHARMA SCI & TECH CO LTD

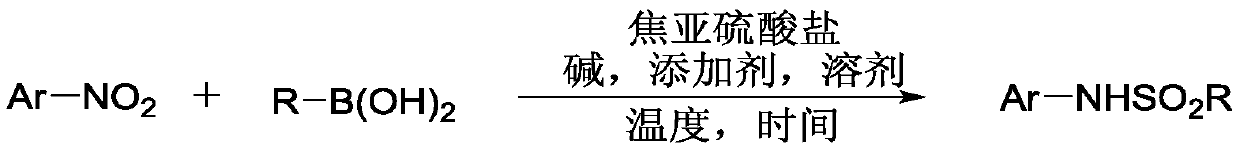

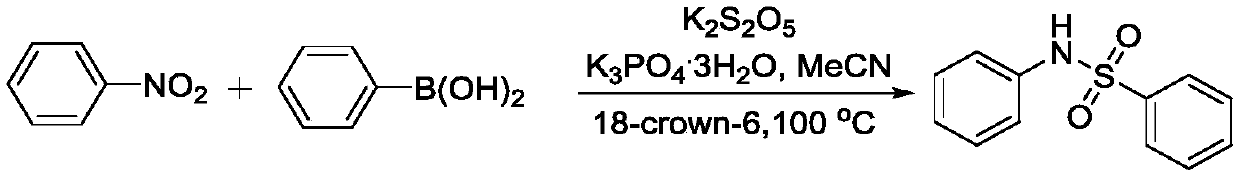

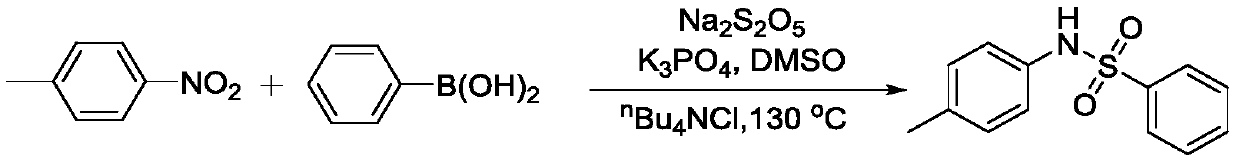

Method for coupling nitroaromatic compound and boric acid compound to synthesize sulfonamide compound

ActiveCN110372463AEasy to operateMild reaction conditionsSulfonyl/sulfinyl group formation/introductionSulfonic acid amide preparationOrganic solventOrganic synthesis

The invention belongs to the field of organic synthesis, and specifically discloses a method for coupling a nitroaromatic compound and a boric acid compound to synthesize a sulfonamide compound. The method for coupling the nitroaromatic compound and the boric acid compound to synthesize the sulfonamide compound comprises the steps that in an organic solvent, pyrosulfite is used as a source of SO2,and heating is carried out for a coupling reaction, and then after the post-treatment, the sulfonamide compound is obtained. The method for coupling the nitroaromatic compound and the boric acid compound to synthesize the sulfonamide compound is simple in operation, does not require nitrogen protection, and can be carried out under air. The nitroaromatic compound and the boric acid compound are abundant in source, relatively low in price, high in reaction yield, wide in applicability of a substrate and free in metal residual. The method for coupling the nitroaromatic compound and the boric acid compound to synthesize the sulfonamide compound can be used for synthesizing a series of sulfonamide compounds, and the synthesized compounds have wide application value in the fields of pesticidesand medicines.

Owner:ZHEJIANG UNIV

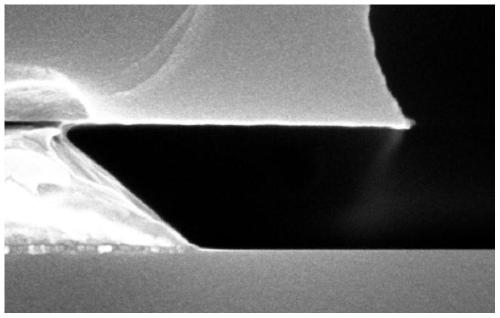

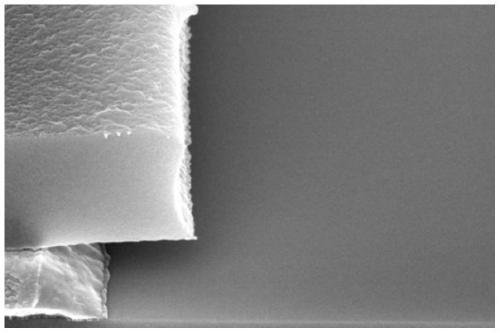

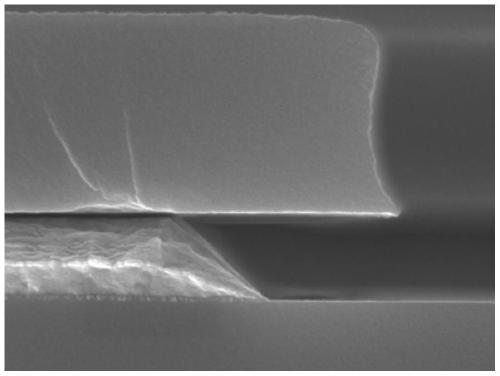

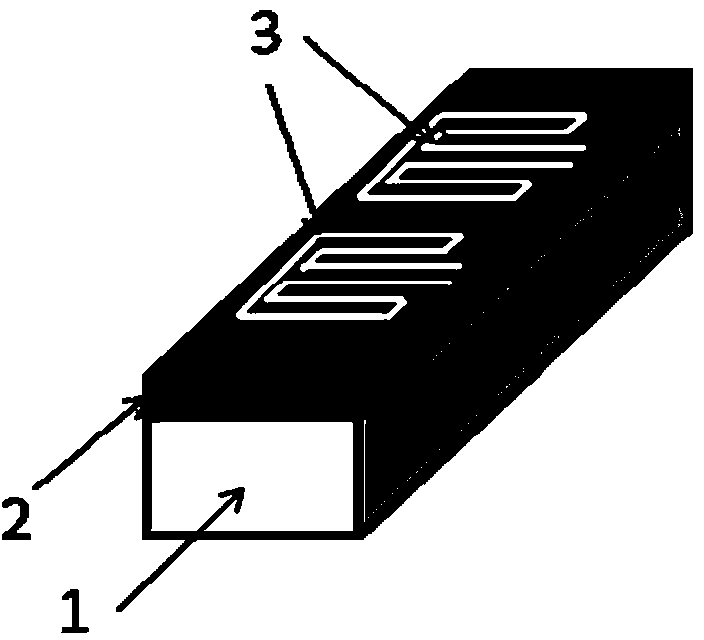

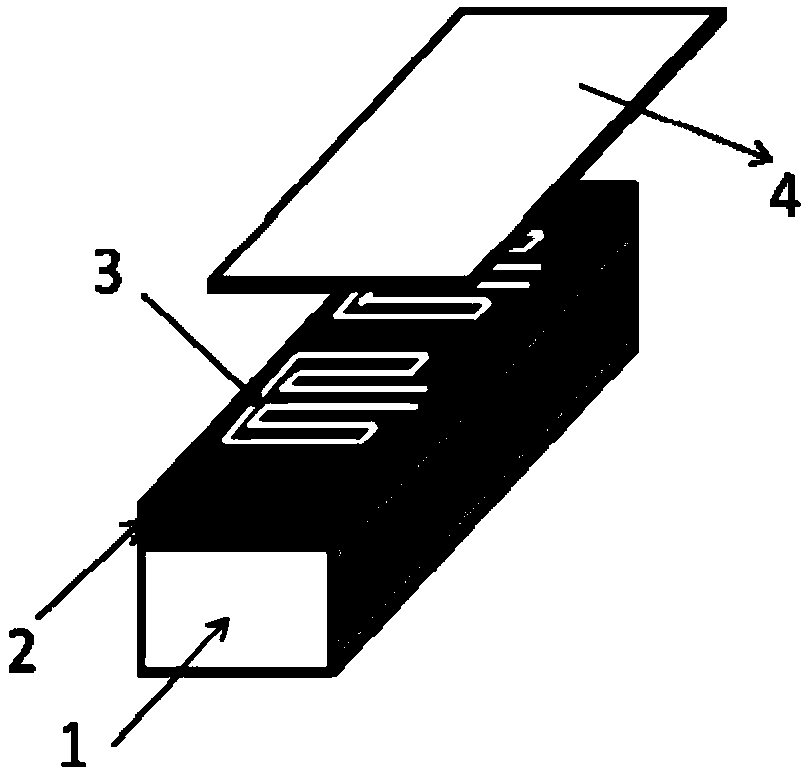

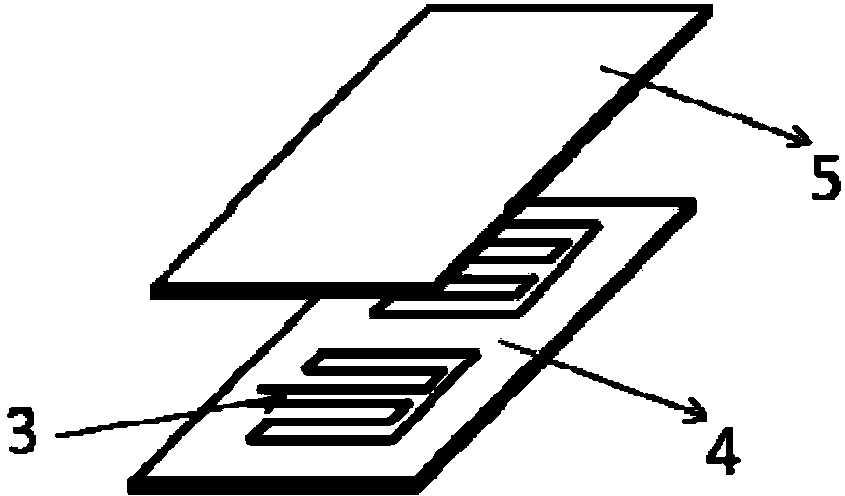

Metal electrode patch production method

ActiveCN104362227AReduce the binding forcePeel off smooth surfaceSemiconductor devicesOxide ceramicsMetal electrodes

The invention provides a high-conductivity metal electrode patch production method. The method includes: selecting a support substrate with at least the surface layer being nitride, and subjecting the support substrate to polishing treatment or surface hydrophilia treatment. The substrate comprises a silicon wafer or refractory ceramics; the silicon wafer comprises a monocrystalline silicon wafer or polycrystalline silicon wafer, and the refractory ceramics comprise oxide-free nitrogen ceramics and oxide ceramics. The suitable materials are selected, a method combining surface coating and surface treatment is utilized, binding force between the electrode and the substrate is lowered greatly, the electrode can be stripped directly with adhesive tape, the stripped surface is quite smooth, and no metal residual is left on the substrate. No organic solution process is related, electrode patches with shapes unlimited can be formed, and the shortcomings of complex procedures and low electric conductivity due to the fact that the electrode is produced on a device directly are overcome.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

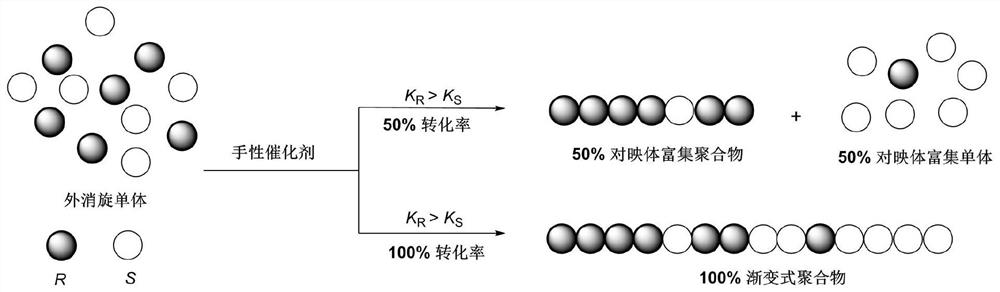

Synthetic method of gradient polyester

The invention discloses a synthetic method of gradient polyester. The invention belongs to the field of polymer synthetic materials. The invention aims to solve the technical problems of lack of research on chirality of a polymer chain and difficulty in synthesis and characterization in research on a chiral polymer in the prior art. The synthetic method of the gradient polyester comprises the following steps: under normal pressure and inert gas protection, in an organic solvent, racemic substituted lactone is used as a polymeric monomer, chiral phosphoric acid is used as a catalyst, and an alcohol compound is used as an initiator; and ring-opening resolution polymerization is realized by utilizing the difference of the reaction rates of two enantiomers in the polymeric monomer, so that the gradient polyester is obtained. According to the asymmetric resolution polymerization method for racemic substituted lactone, novel polyester with a gradient structure can be obtained, the types and application fields of polyester materials are expanded, and development of chiral polymer functional materials is promoted. The method is simple and convenient to operate, mild in condition and controllable in polymerization activity, and the generated polymer is free of metal residues.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

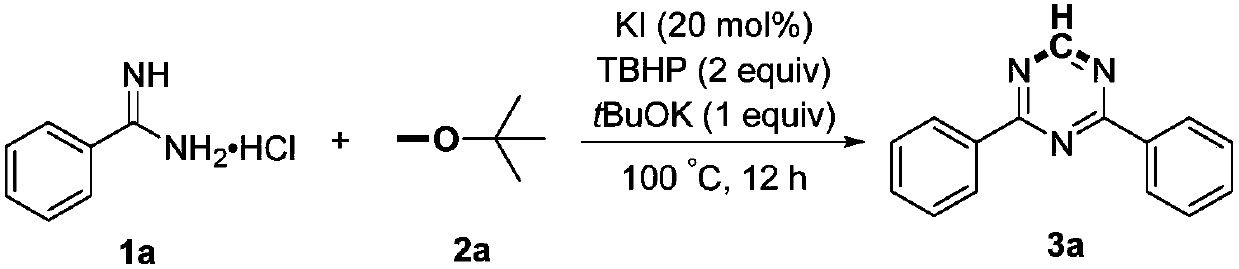

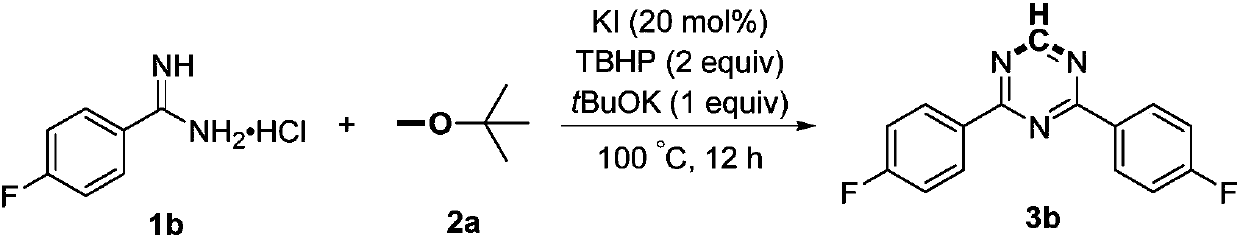

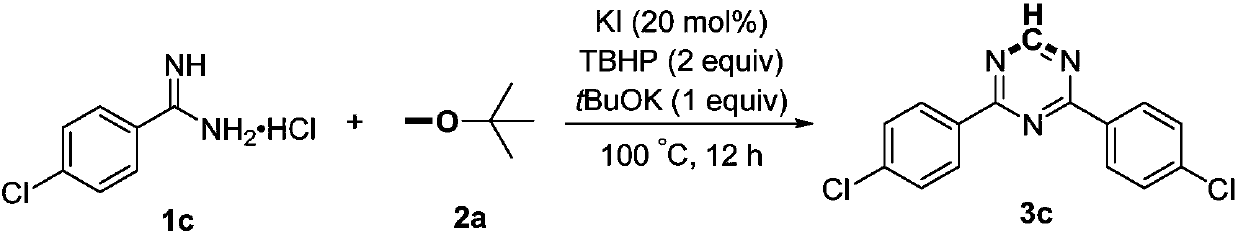

Preparation method of 2,4-di-substituted-1,3,5-triazine

ActiveCN107759530AWide variety of sourcesEasy to getOrganic chemistryPotassium iodinePotassium carbonate

The invention discloses a method for preparing 2,4-di-substituted-1,3,5-triazine. The method comprises the specific step: with substituted formamidine hydrochloride as a reaction substrate an iodine-containing compound as a catalyst, tert-butyl hydroperoxide as an oxidant, inorganic base as an acid binding agent and aliphatic ether as an organic solvent (also used as a carbon source), carrying outcarbon-hydrogen and carbon-oxygen bond deletion, nucleophilic addition, deaminizing condensation and oxidative aromatization reaction to obtain a 2,4-di-substituted-1,3,5-triazine compound, wherein achemical structural general formula of the substituted formamidine hydrochloride is shown in the description; the iodine-containing compound is selected from one of potassium iodide (KI), tetrabutylammonium iodide (TBAI), elemental iodine (I2) and N-iodosuccinimide (NIS); the inorganic base is selected from one of anhydrous potassium carbonate, anhydrous sodium carbonate, cesium carbonate, potassium hydroxide and potassium tert-butoxide; and the aliphatic ether is selected from one of methyl tert-butyl ether, ethyl ether and ethylene glycol dimethyl ether. The preparation method disclosed bythe invention has the characteristics of easily-obtained raw materials, low price and low toxicity of a catalyst, wide range of the substrate, simplicity and convenience in operation, greenness, environmental protection and the like.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

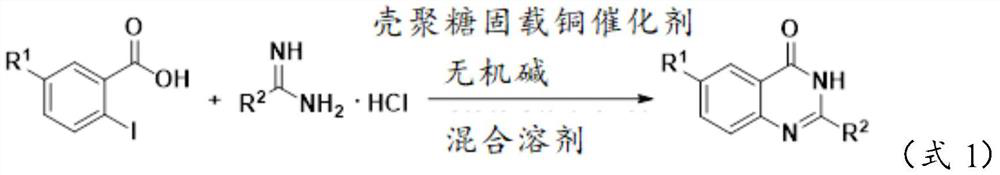

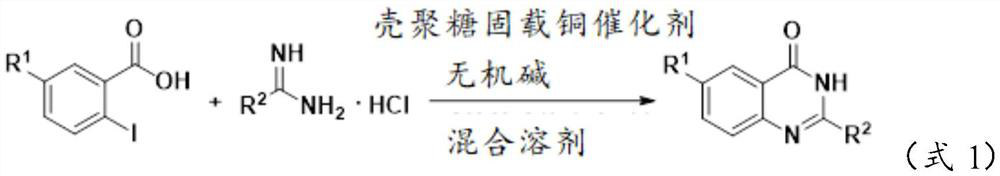

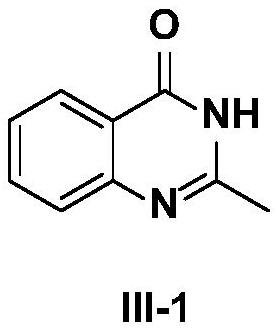

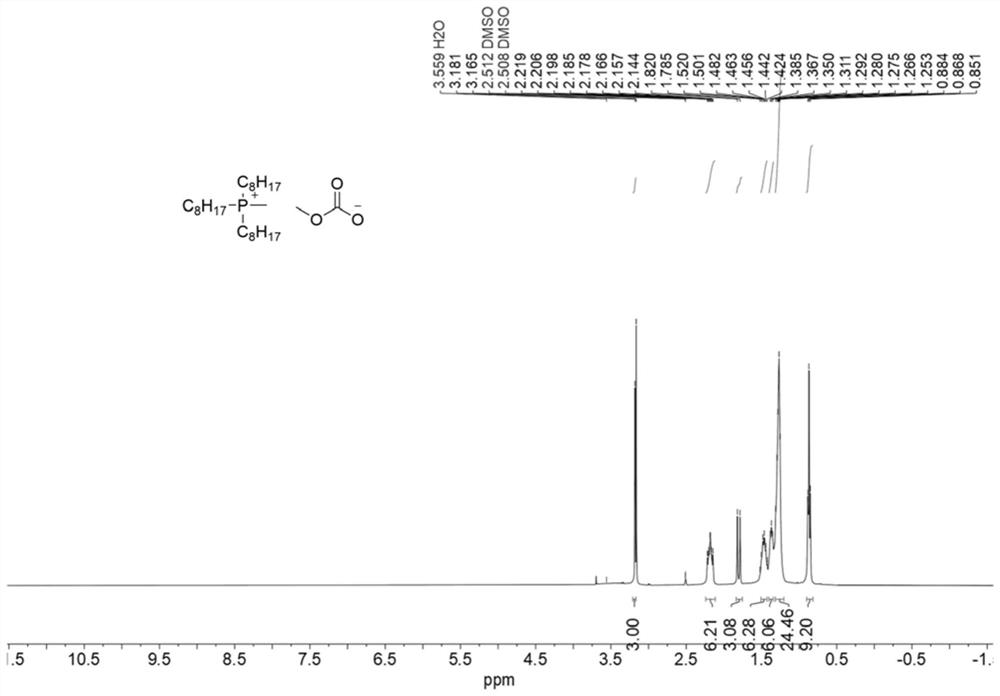

Method for preparing quinazolone and derivatives thereof by using chitosan-loaded copper catalyst

PendingCN112778218AEasy to removeNo metal residueOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEthyl acetateColumn chromatography

The invention discloses a method for preparing quinazolone and derivatives thereof by using a chitosan-loaded copper catalyst, which comprises the following steps of replacing residual gas in a reaction container with inert gas, adding a catalytic amount of copper ion-loaded chitosan catalyst, substituted 2-halogenated benzoic acid, substituted amidine hydrochloride, inorganic alkali and a mixed solvent into the reaction container, and heating for reaction, after the reaction time is 2-18 hours, extracting the product by using ethyl acetate, filtering and recovering the copper ion-loaded chitosan catalyst, concentrating the filtrate under reduced pressure, and purifying the product by column chromatography. The method has the advantages of low catalyst dosage, recoverability, easy separation after reaction, no metal residue, simple post-treatment, and suitableness for large-scale production.

Owner:HUBEI ENG UNIV

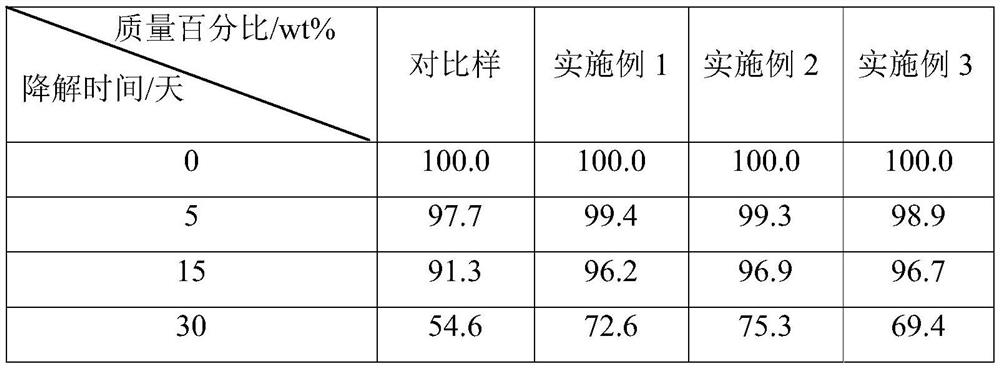

Method for degrading thermoplastic plastic polyethylene terephthalate

InactiveCN113214077ACommercially availableEasy to synthesizeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsThermoplasticPolymer science

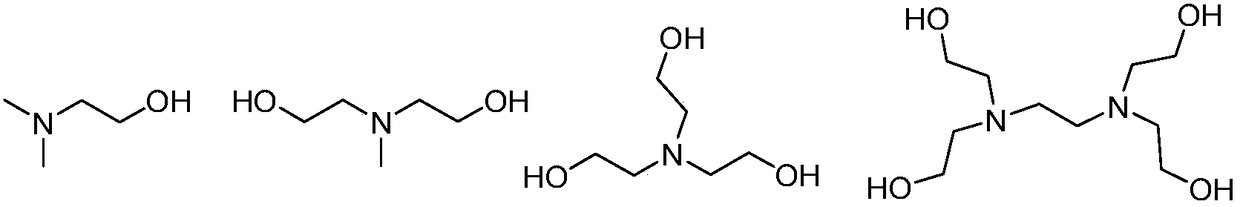

The invention discloses a method for degrading thermoplastic plastic polyethylene terephthalate, and belongs to the technical field of polyester degradation; a depolymerized monomer ethylene glycol terephthalate (BHET) is obtained by reacting a commercially available Wahaha beverage bottle as a PET raw material, dihydric alcohol as a solvent and a catalyst represented by a formula I provided by the invention. The raw materials of the catalyst used in the method are simple and easy to obtain, the catalyst can be synthesized through a one-step method, no metal residues exist in the whole reaction system, and even if the load of the catalyst is lower than 2%, a good catalytic effect (the degradation rate is larger than or equal to 90%) can be achieved. In addition, the solvent range of PET alcoholysis is expanded, and under the condition of the catalyst, ethylene glycol, propylene glycol, butanediol, hexanediol, butanediamine, hexamethylenediamine, monoethanolamine and diethanolamine serve as solvents, and the PET degradation rate of 90% or above is achieved.

Owner:NANJING UNIV OF TECH

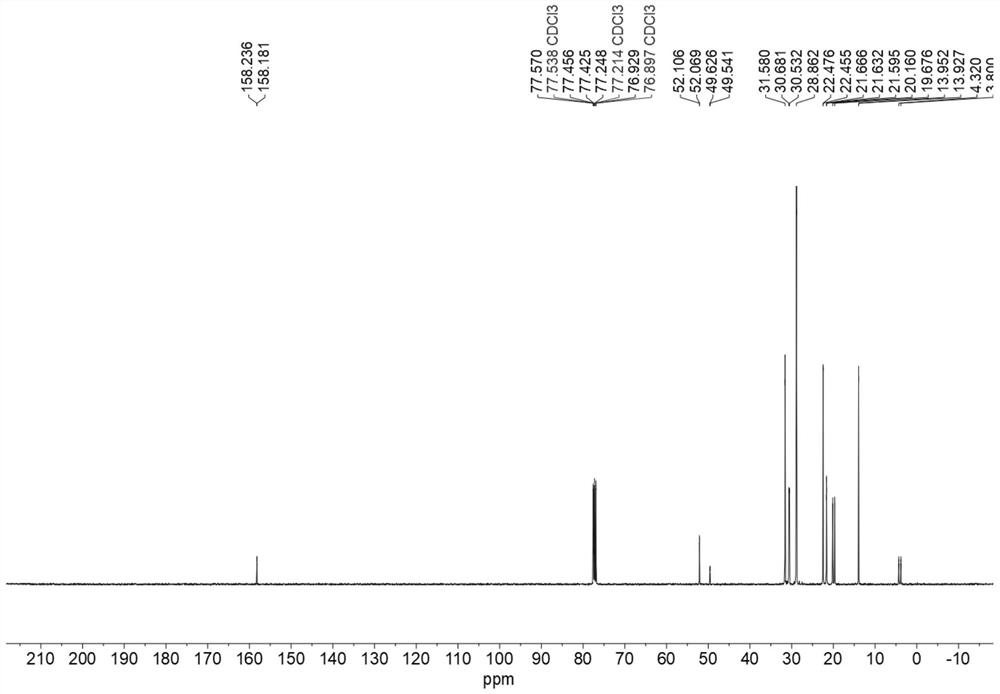

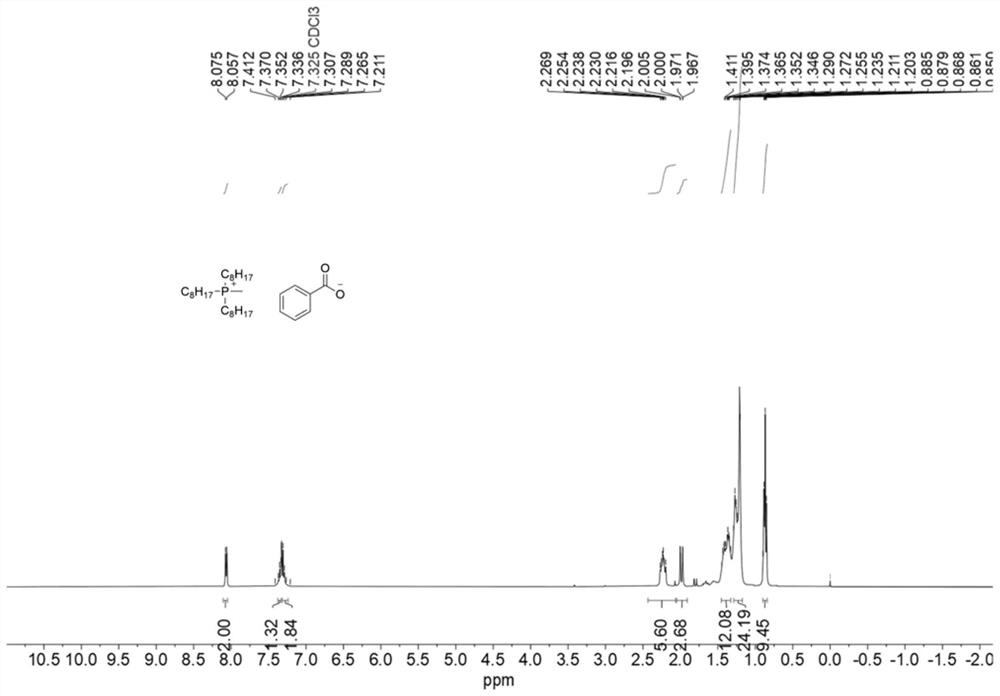

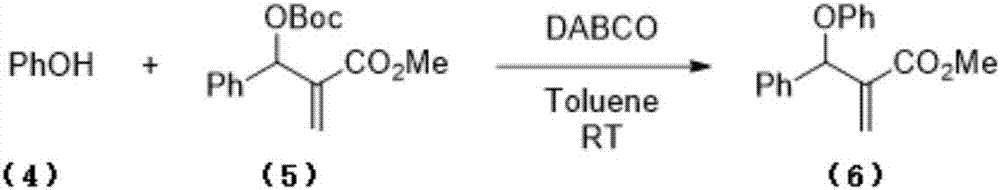

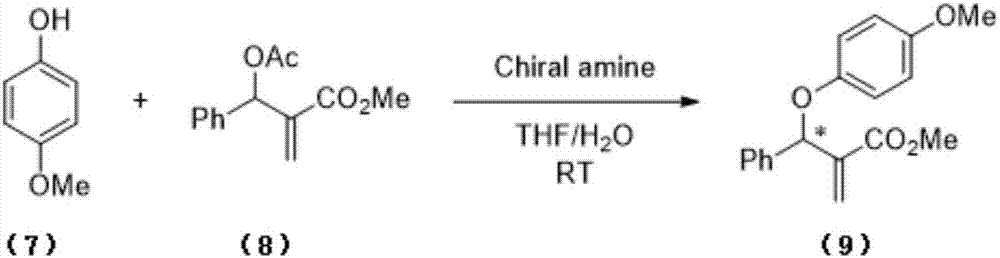

Chiral arylallyl ether compound and synthesis method therefor

InactiveCN107266317AHigh optical purityThe reaction is easy to operateOrganic compound preparationOrganic chemistry methodsArylLeaving group

The invention discloses a chiral arylallyl ether compound and a synthesis method therefor and belongs to the technical field of preparation of chemical pharmaceuticals and fine chemical industry. The compound is an important synthesis intermediate and has extensive bioactivity. According to the synthesis method, a series of arylallyl ether compounds with high optical purity are synthesized in a high-yield manner through subjecting cheap and readily-accessible aryl phenol compounds to a nucleophilic SN2' substitution reaction with an MBH reaction adduct with a leaving group in the presence of a chiral tertiary amine catalyst. The synthesis method provides a simple and practical technical route for the preparation of chiral arylallyl ether compounds and has extensive application in the technical field of preparation of chemical pharmaceuticals and fine chemical industry.

Owner:CHANGZHOU UNIV

Preparation method of hydrolysis-resistant hyperbranched polycaprolactone

The invention belongs to the technical field of biodegradable materials, and particularly relates to a preparation method of hydrolysis-resistant hyperbranched polycaprolactone. The preparation method comprises the steps of (1) mixing a hydroxyl-containing compound with a phosphazene catalyst, and then reacting with an epoxy compound to prepare hyperbranched polyether polyol; and (2) taking the hyperbranched polyether polyol as a macromolecular initiator, and continuously initiating a ring-opening polymerization reaction of caprolactone under the action of a phosphazene catalyst to prepare the hyperbranched polycaprolactone. The synthesis process is simple, the reaction activity is controllable, the prepared hyperbranched polycaprolactone has the advantages of no metal residue, excellent processability, controllable branching degree and hydrolysis resistance, and the application of the polycaprolactone material in the biomedical field is further widened.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Ring-opening polymerization method of cyclic monomer

ActiveCN111592644AMolecular weight controllableNarrow molecular weight distributionPolymer sciencePtru catalyst

The invention belongs to the field of organic synthesis, and particularly relates to a ring-opening polymerization method of a cyclic monomer, which adopts the specific scheme that ring-opening polymerization of the cyclic monomer is catalyzed by Lewis acid-base pairs in the presence of an initiator. Lewis acid-base pairs are used as a catalyst; on one hand, the range of the ring-opening polymerization catalyst is expanded; on the other hand, compared with a strong acid or strong alkali catalyst reported before, the catalyst has the characteristics of high catalytic efficiency and mildness, and the catalytic system activates the monomer and activates the initiator or chain end at the same time through a bifunctional activation mechanism, and has the characteristic of high efficiency compared with a reported monomer activation mechanism or chain end activation mechanism. By adopting the catalyst, the polyester product with the target molecular weight can be synthesized in a controlled manner as required, the molecular weight distribution index is relatively narrow, the product yield is high, the product conversion rate is high, and no monomer or metal residue exists.

Owner:NANJING UNIV OF TECH

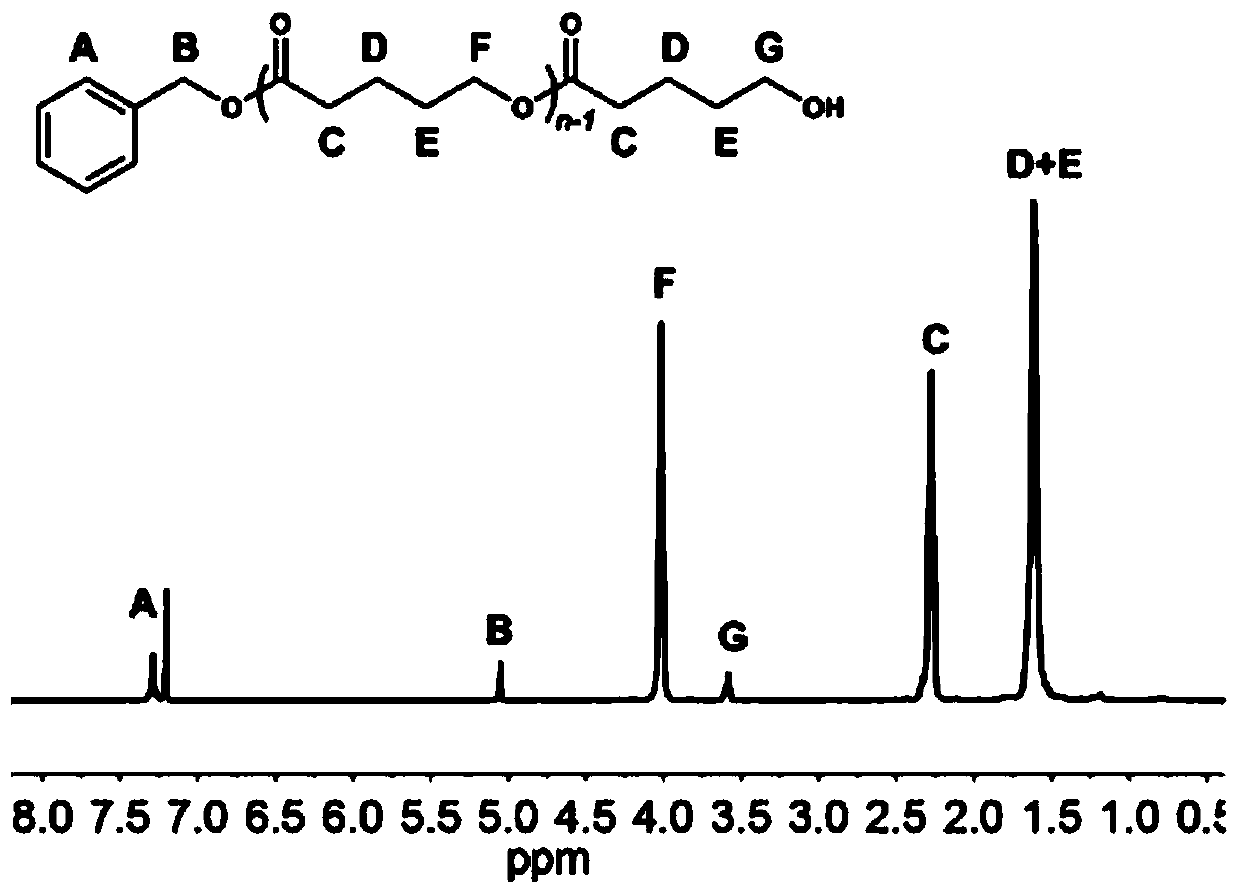

Method for producing poly(butylene succinate) with lipase as catalyst

The invention relates to a method for producing poly (butylene succinate) (PBS) with lipase as a catalyst. The steps comprises: step (1) 0.05 portion to 10 portions of enzyme, 10 portions to 20 portions of diethyl succinate, 5 portions to 10 portions of butanediol and 0.1 portion to 5.0 portions of water (by weight percentage) react at the temperature of 50 DEG C to 90 DEG C under normal pressurefor 2 hours to 5 hours, then react for 1 hour to 3 hours under the pressure of 4 mmHg to 40mmHg and then for 2 hours to 5 hours when the pressure is resumed to normal; and the process is repeated 3 times to 5 times; step (2) 30 portions to 100 portions of alkane or benzene ring solvent and 0.1 portion to 5.0 portions of water are added and reaction lasts 4 hours to 48 hours at the temperature of 50 DEG C to 90 DEG C when stirring is conducted; step (3) reduced pressure distillation is conducted for 2 hours to 5 hours and the solvent is recovered; and step (4) 15 portions to 20 portions of chloroform are added and dissolves, filtration is conducted and the filtrate is added with 60 portions to 80 portions of methanol and purified, thus obtaining the poly (butylene succinate) (PBS); and thefilter residue is enzyme and can be reused. The method is characterized by economy, low consumption, high output, no metal residue and environmental protection.

Owner:山东秋水化学科技有限公司

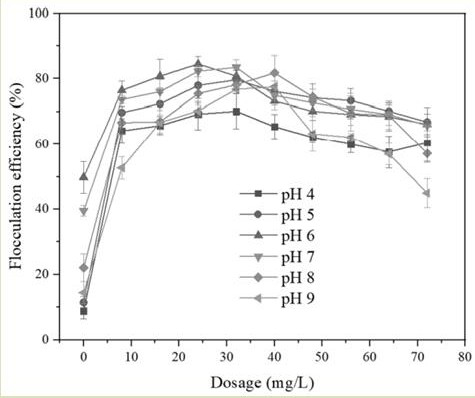

Environment-friendly flocculating agent and application thereof

ActiveCN114014428AReduce dosageAvoid introducingWater/sewage treatment by flocculation/precipitationLivestock breedingEnvironmental engineering

An environment-friendly flocculant and application thereof belong to the technical field of environment-friendly flocculants. At present, the most widely applied flocculants are mainly inorganic flocculants (such as polyaluminum chloride) and synthetic organic flocculants (such as polyacrylamide), the flocculants have certain toxicity and are difficult to degrade, secondary pollution can be caused when the flocculants are widely used, and waste residues cannot be treated. The invention provides an environment-friendly flocculating agent which is non-toxic, harmless, free of secondary pollution and good in performance and application of the environment-friendly flocculating agent. The main component of the environment-friendly flocculating agent is a dextran-citric acid anionic polymer. The preparation method comprises the following steps of: adjusting the pH value of a citric acid solution to 7-9 by using sodium hydroxide, well mixing and stirring the citric acid solution with a dextran solution, adding 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, and reacting for 12-36 hours, the molar ratio of edc to citric acid being (1-2): 1; and adding ethanol for precipitation, and washing and drying the precipitate to obtain the flocculant. Soybean meal waste liquid can be used for livestock breeding after being flocculated, the preparation is simple, and the efficiency is high.

Owner:SHANDONG JINYANG PHARMA

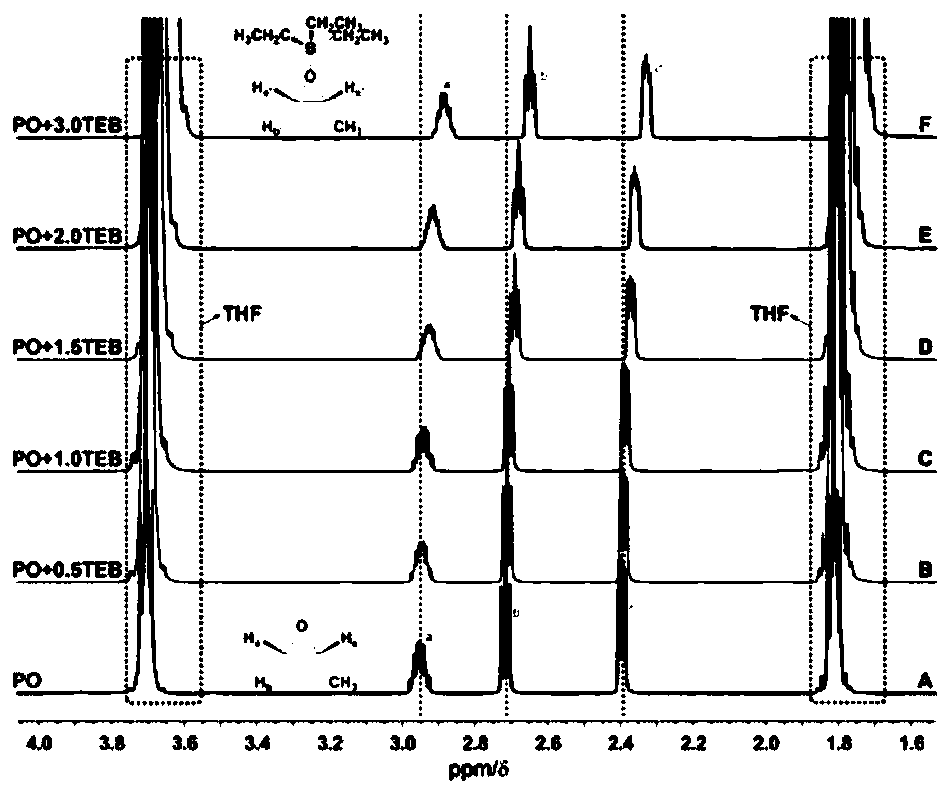

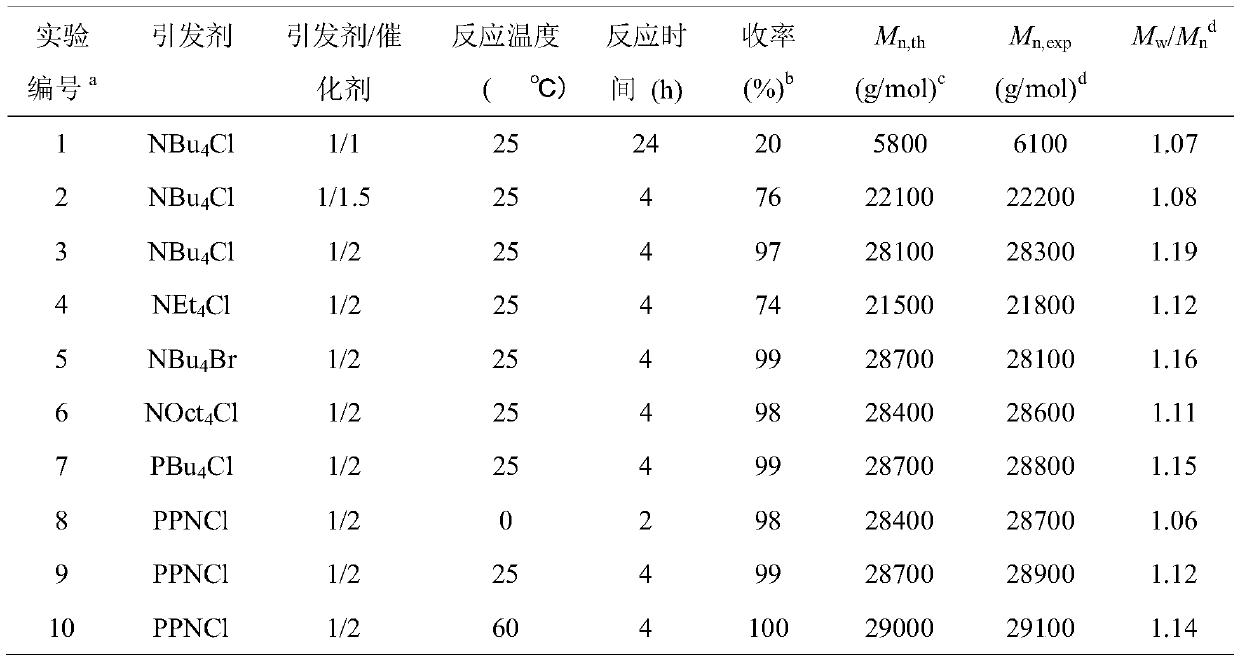

Catalyst system for preparing polyether materials for aviation

The invention provides a boron alkyl-halogenated onium salt system and an application thereof in living polymerization of epoxy monomers and belongs to the field of an epoxy resin. An epoxy monomer active anion controllable polymerization reaction system provided by the invention contains an initiator, a catalyst, a solvent and epoxy monomers, wherein the halogenated quaternary ammonium salt or halogenated quaternary phosphor salt is taken as the initiator and the boron alkyl is taken as the catalyst. The epoxy monomer polymerization system provided by the invention is capable of efficiently triggering the epoxy monomer controllable anionic polymerization reaction under the conditions of shorter period and room temperature. An epoxypropane / ethane polymer prepared according to the system provided by the invention can be applied to the additives of aviation chemical products.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com