Method for synthesizing pyrrolidone compound through continuous light-induced catalysis

An amine compound and compound technology, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problems of large metal residues and low reaction efficiency, and achieve no metal residues and light exposure. Uniform, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

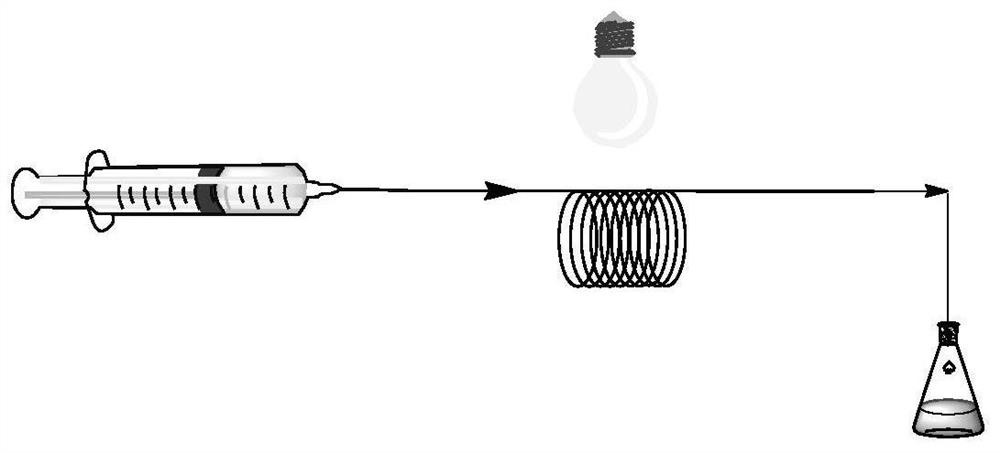

Method used

Image

Examples

Embodiment 1

[0043] At room temperature, 5,10-bis(4-(trifluoromethyl)phenyl)-5,10-dihydrophenazine (23.5mg, 50μmol, 5% equivalent), 2-bromo-2-methylpropane Ethyl acid (294.0μL, 2mmol, 2 equivalents), aniline (91.1μL, 1mmol, 1 equivalent) and styrene (116.8μL, 1mmol, 1 equivalent) were dissolved in the solvent DCE (4mL) and stirred with a stirring bar. Irradiate under simulated sunlight for 4h. Separate with petroleum ether and ethyl acetate 10:1 (volume ratio) eluent, and vacuum dry the obtained product for 4h. The conversion rate was 86%.

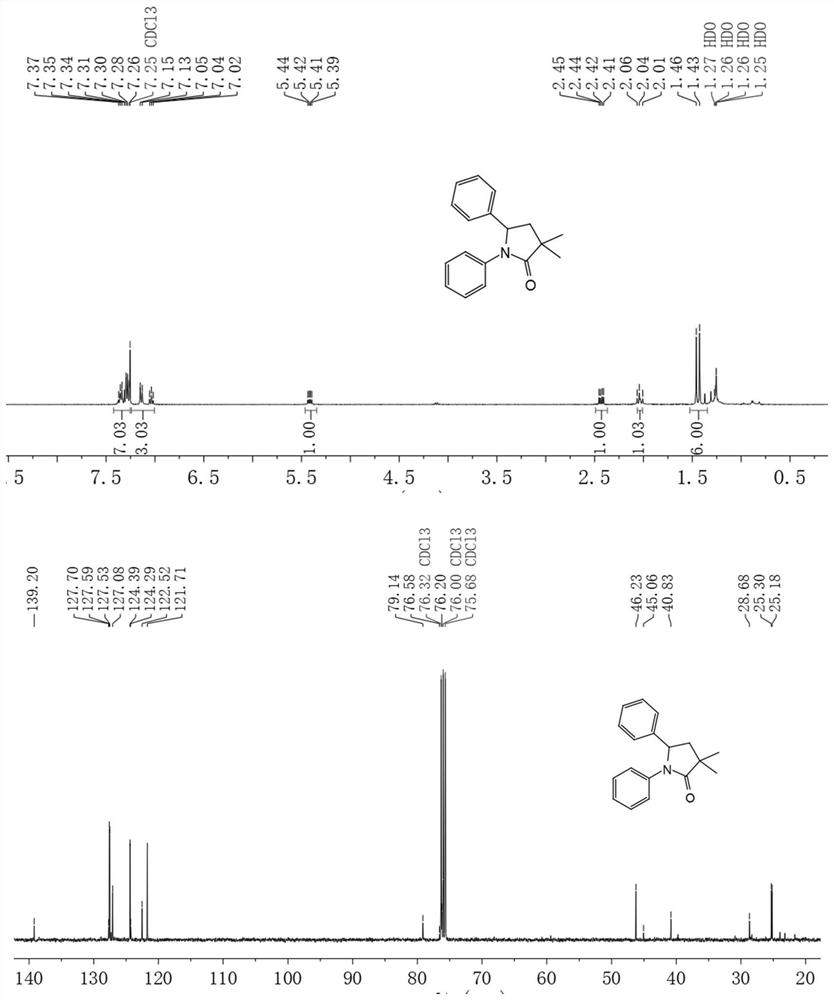

[0044] 1 H NMR(400MHz, Chloroform-d) δ7.42–7.25(m,7H), 7.24–7.01(m,3H), 5.42(dd,J=10.2,6.0Hz,1H),2.43(dd,J=12.7 ,6.0Hz,1H),2.04(s,1H),1.44(d,J=13.4Hz,6H). 13 CNMR (101MHz, Chloroform-d) δ139.20,127.70,127.59,127.53,127.32,127.08,124.39,124.29,122.52,121.71,121.67,121.43,79.14,45.06,40.83,39.74,25.30,25.18.HRMS calculated value C 18 H 19 NO[M+H + ]: 266.1539; Found: 266.1508.

Embodiment 2

[0046] At room temperature, 5,10-bis(4-(trifluoromethyl)phenyl)-5,10-dihydrophenazine (23.5mg, 50μmol, 5% equivalent), 2-bromo-2-methylpropane Ethyl acid (294.0μL, 2mmol, 2 equivalents), aniline (91.1μL, 1mmol, 1 equivalent) and styrene (116.8μL, 1mmol, 1 equivalent) were dissolved in the solvent DCE (4mL) to obtain a homogeneous solution. The above-mentioned homogeneous solution was pumped into the microchannel reactor, and the flow rate of the pump was controlled to be 0.1 mL / min. In the microchannel reactor under simulated sunlight, the retention time was 10min; the effluent liquid was collected with a sampling flask. Separate with petroleum ether and ethyl acetate 10:1 (volume ratio) eluent, and vacuum dry the obtained product for 4h. The conversion rate is 97%.

[0047] 1 H NMR(400MHz, Chloroform-d) δ7.42–7.25(m,7H), 7.24–7.01(m,3H), 5.42(dd,J=10.2,6.0Hz,1H),2.43(dd,J=12.7 ,6.0Hz,1H),2.04(s,1H),1.44(d,J=13.4Hz,6H). 13 CNMR (101MHz, Chloroform-d) δ139.20,127.70,127.59,127.5...

Embodiment 3

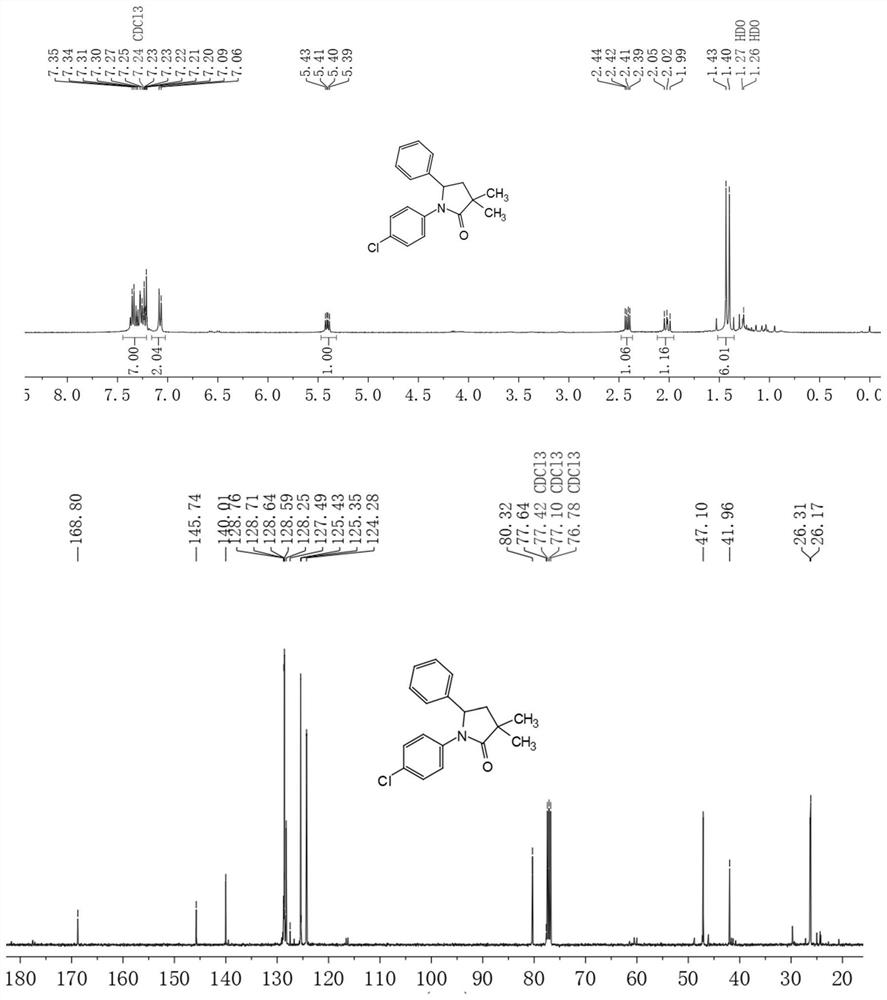

[0049] At room temperature, 5,10-bis(4-(trifluoromethyl)phenyl)-5,10-dihydrophenazine (23.5mg, 50μmol, 5% equivalent) was dissolved in the solvent DCE (2mL) to obtain The first homogeneous solution; ethyl 2-bromo-2-methylpropionate (294.0μL, 2mmol, 2 equivalents), aniline (91.1μL, 1mmol, 1 equivalent) and styrene (116.8μL, 1mmol, 1 equivalent) ) Was dissolved in the solvent DCE (2mL) to obtain a second homogeneous solution; then the above-mentioned first and second homogeneous solution was pumped into the microchannel reactor, and the pump flow rate was controlled to be 0.05mL / min. In the microchannel reactor, the retention time is 10 min; the effluent liquid is collected with a sampling flask. Separate with petroleum ether and ethyl acetate 10:1 (volume ratio) eluent, and vacuum dry the obtained product for 4h. The conversion rate is 96%. NMR figure 2 .

[0050] 1 H NMR(400MHz, Chloroform-d) δ7.42–7.25(m,7H), 7.24–7.01(m,3H), 5.42(dd,J=10.2,6.0Hz,1H),2.43(dd,J=12.7 ,6.0Hz,1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com