Patents

Literature

123results about How to "Low polymerization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

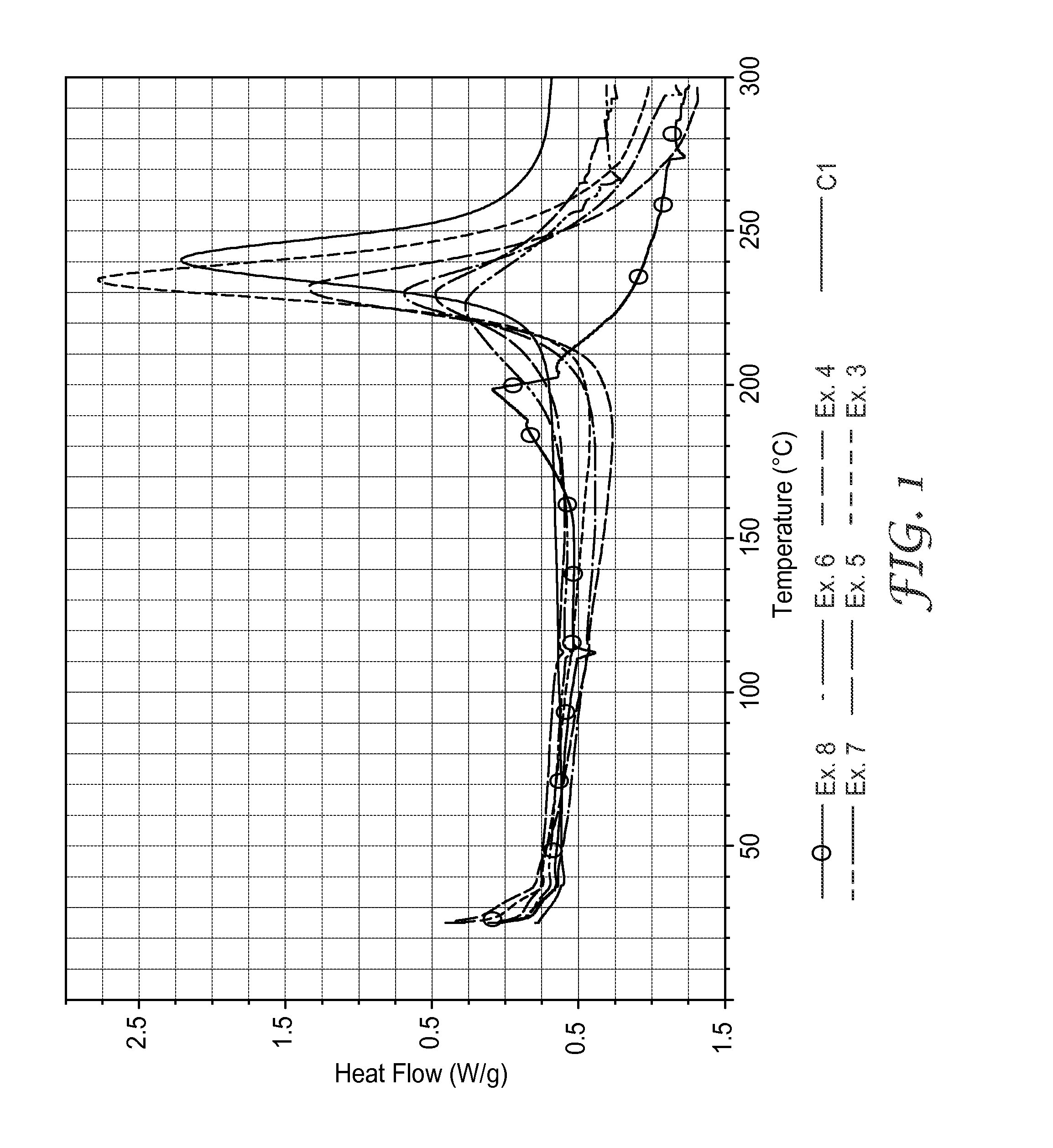

Ternary systems of benzoxazine, epoxy, and phenolic resins

Low viscosity ternary mixtures of benzoxazine, epoxy and phenolic resins have been developed. The blends render homogeneous and void free cured specimen with a wide range of properties. Melt viscosity values as low as 0.3 Pa.s at 100° C. can be achieved. The phenolic resin acts as a cure accelerator to the system, besides its typical function as a hardener of epoxy resin. Glass transition temperatures Tg as high as 170° C. can also be obtained.

Owner:EDISON POLYMER INNOVATION EPIC

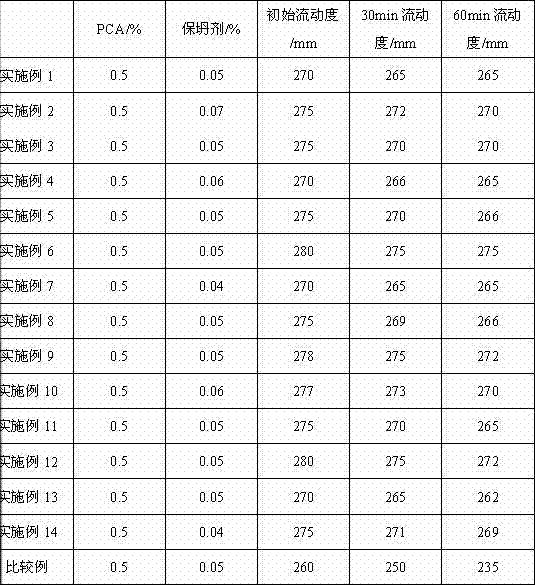

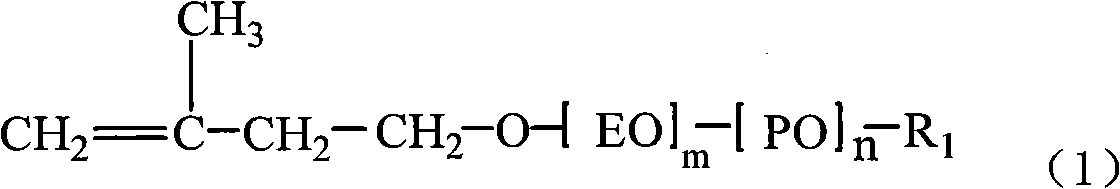

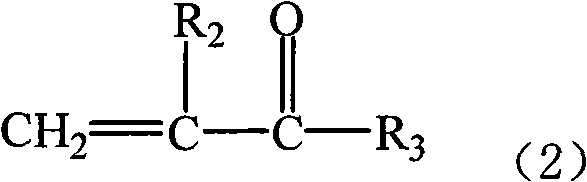

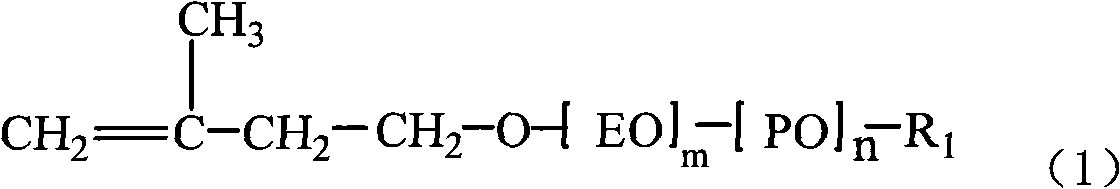

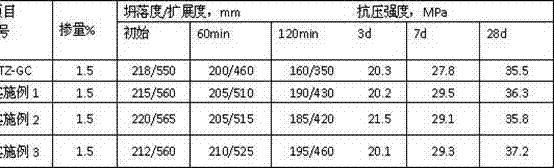

Slump loss resistant type gather carboxylate water-reducing agent and preparation method thereof

The invention provides a slump loss resistant type gather carboxylate water-reducing agent, which is a polymer of prenyl polyoxyethylene ether or prenyl polyoxyethylene propenyl ether or methyl allyl polyoxyethylene ether or methallyl polyoxyethylene propenyl ether (a macro-monomer A) and unsaturated carboxylic acid (a micro-monomer B) and an unsaturated carboxylic acid derivative (a micro-monomer C), belonging to the field of concrete admixtures. A synthetic method is as follows: the water-reducing agent is prepared by initiating the macro-monomer A, the micro-monomer B and the micro-monomer C through an oxidative-reductive initiating system by taking water as a solvent at lower temperature, and carrying out copolymerization under the action of a chain transfer agent. The water-reducing agent overcomes the disadvantages of being poor in slump loss resistance, long in setting time and the like of the water-reducing agent synthesized by allyl polyoxyethylene ether and has the advantages of being high in slump loss resistance, good for being suitable to different cements and low in influence on concrete setting time.

Owner:山西山大合盛新材料股份有限公司

Fluorine-contained surfactant and preparation method thereof

InactiveCN102172491AImprove surface activityHas a block structureTransportation and packagingMixingFluorine containingSURFACTANT BLEND

The invention discloses a fluorine-contained surfactant and a preparation method thereof. The fluorine-contained surfactant is characterized in that a fluorine-contained monomer and a non fluorine-contained monomer, such as acrylic ester are processed by an anion polymerization technology to obtain a segmented copolymer. Compared with the prior art, the fluorine-contained surfactant has a segmented structure, has the advantages of excellent surface activity, pure product, low polymerization temperature, high polymerization speed, wide application prospect and excellent efficacy in the field of leveling; and no active groups or catalysts are introduced in.

Owner:无锡市恒创嘉业纳米材料科技有限公司

Method for preparing semi aromatic copolymer nylon

ActiveCN103923313ALow polymerization temperatureLow polymerization pressurePolymer scienceOrganic chemistry

The invention relates to a method for preparing semi aromatic copolymer nylon, belonging to the technical field of preparation materials for high temperature resistant nylon with high strength and high stability. According to the method, nylon salt is firstly synthesized, then semi aromatic copolymer nylon prepolymer is mainly synthesized at lower temperature and lower pressure, the semi aromatic copolymer nylon prepolymer is prevented from yellowing due to oxidization at high temperature in discharging so as to affect the quality, due to the requirement of lower pressure, the requirement on preparation equipment is lowered, and the production cost is greatly lowered.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

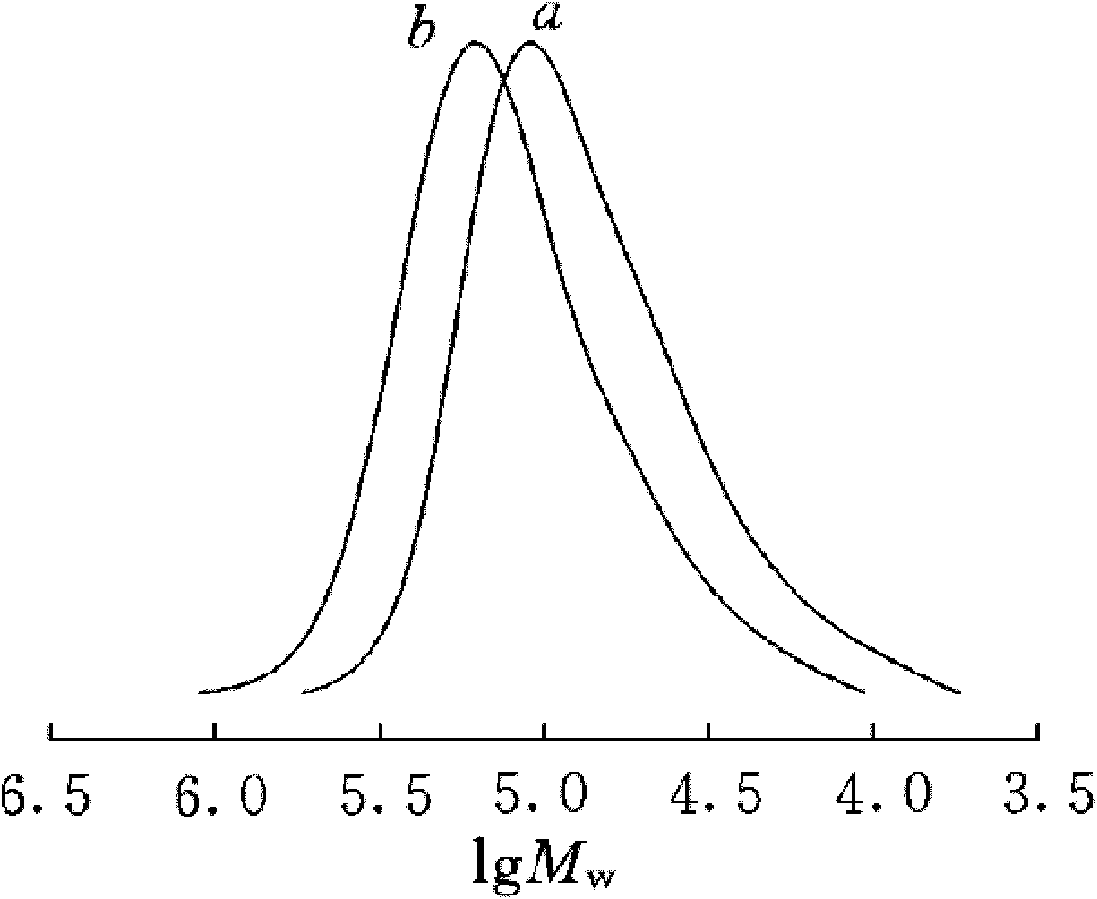

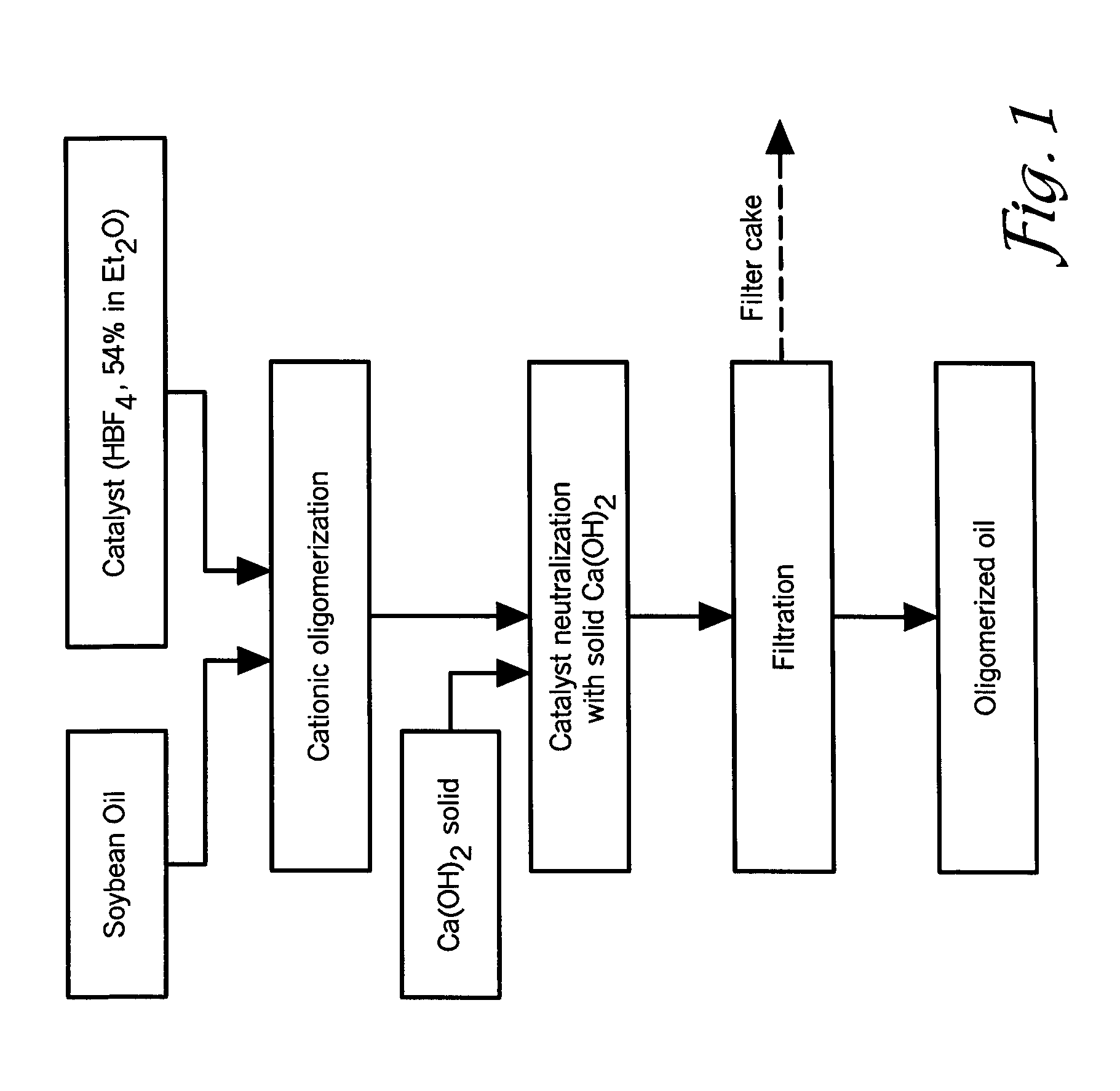

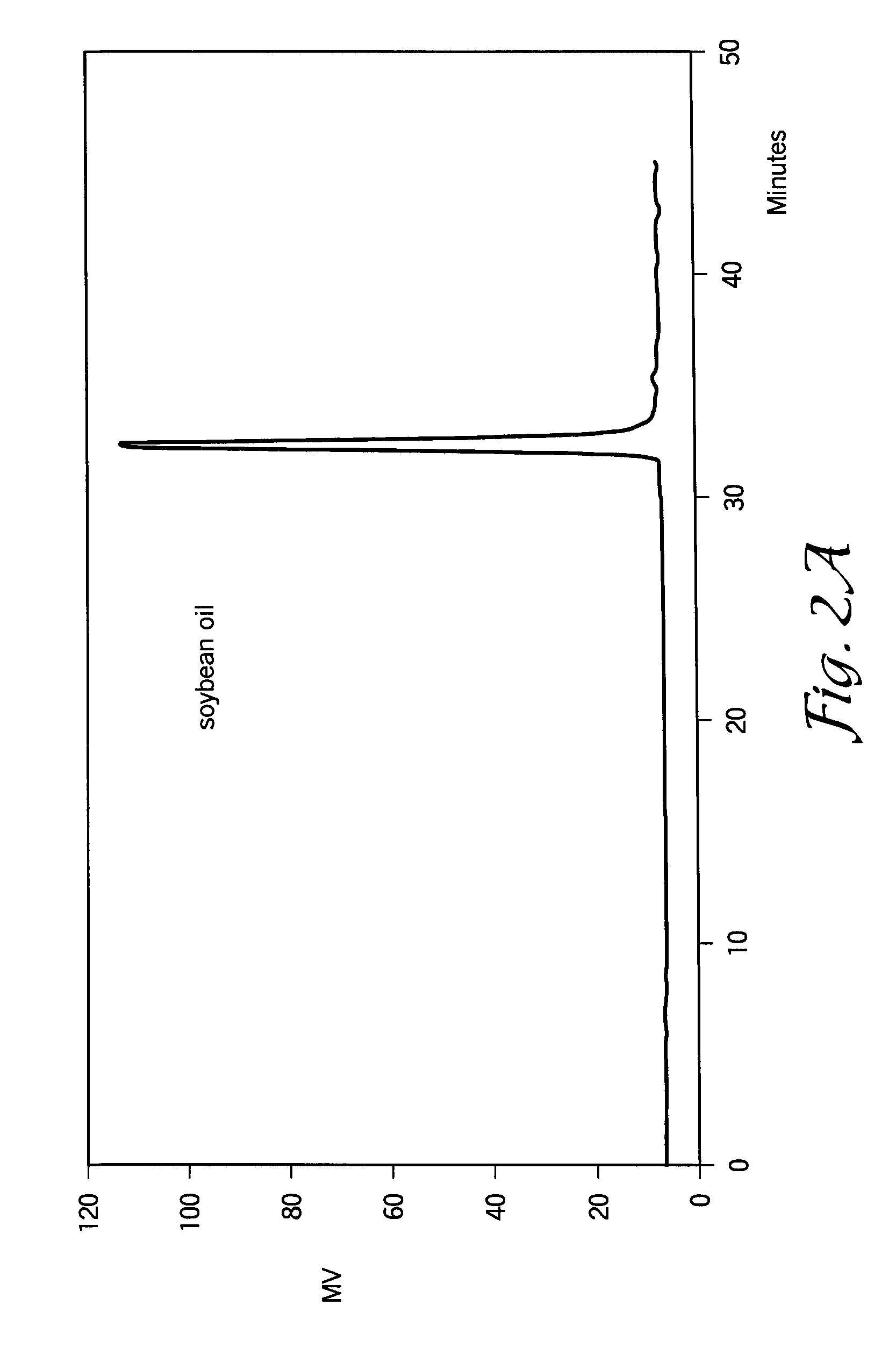

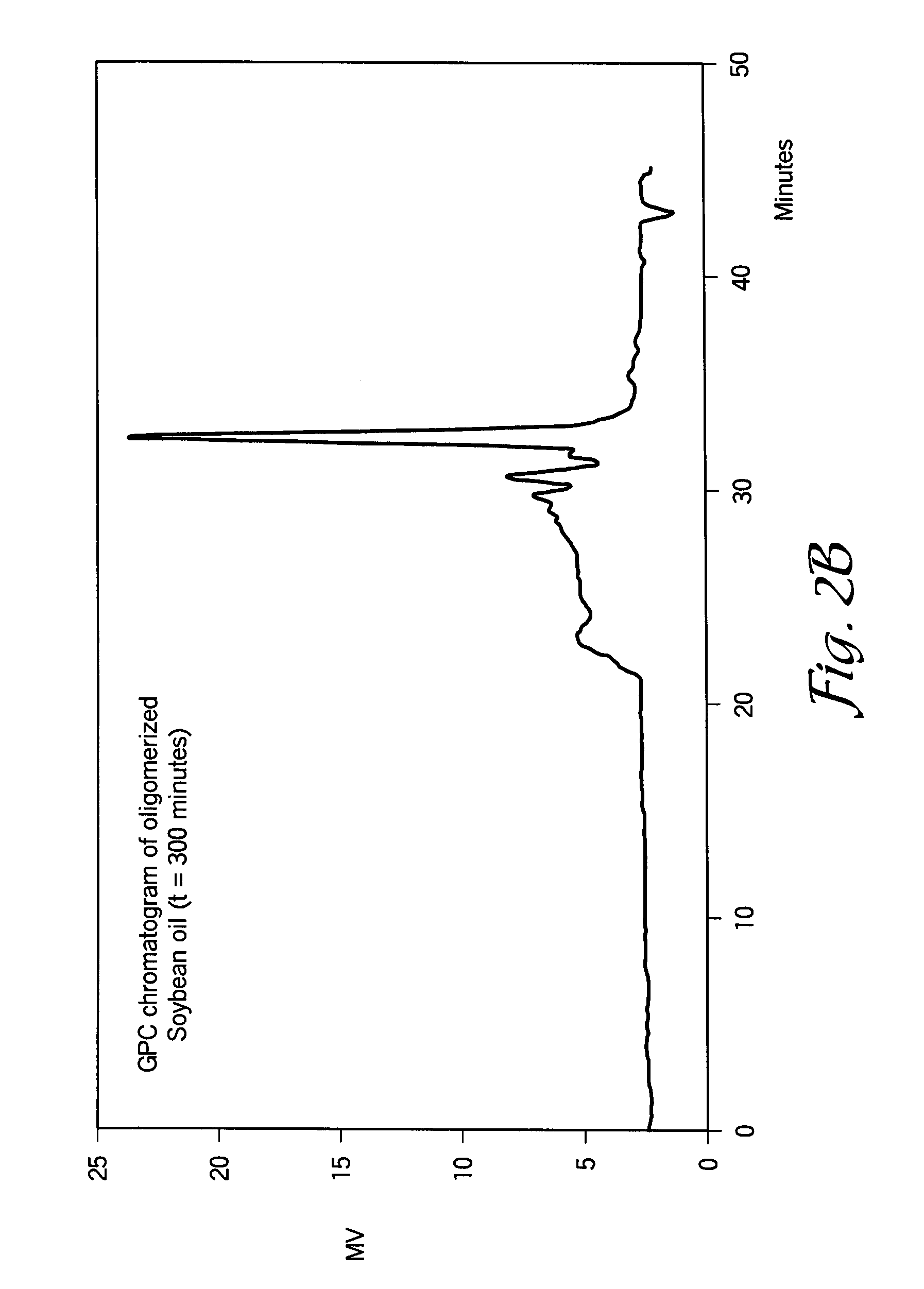

Cationic polymerization of biological oils

ActiveUS20080281071A1High of double bondReduce the numberFatty acid chemical modificationFatty acids production/refiningCationic polymerizationDouble bond

A method for the cationic polymerization of unsaturated biological oils (e.g., vegetable oils and animal oils) based on the cationic reaction of double bonds initiated by superacids is provided. The process occurs under very mild reaction conditions (about 70-110° C. and atmospheric pressure) and with short reaction times. The polymerized oils have a viscosity about 10 to 200 times higher than the initial oil and relatively high unsaturation (only about 10-30% lower than that of initial oils).

Owner:PITTSBURG STATE UNIVERSITY

Prenyl polyether polycarboxylate water reducing agent and synthesis method thereof

The invention provides a prenyl polyether polycarboxylate water reducing agent which is a polymer of prenyl polyoxyethylene ether or prenyl polyoxyethylene propylene ether (big monomer A) and unsaturated carboxylic acid and derivatives thereof (small monomer B), belonging to the field of concrete additives. A synthesis method of the water reducing agent comprises the following steps of: with water as a solvent, initiating the big monomer A and the small monomer B by adopting a redox initiation system under the lower temperature, and carrying out copolymerization under the action of a chain transfer agent to obtain the finished product. The water reducing agent overcomes the defects of low water reducing rate, poor slump loss resistance, long condensation time, and the like of a water reducing agent synthesized by allyl polyoxyethylene ether and has the advantages of high slump loss resistance, plenty water reducing and small influence on the condensation time of concrete.

Owner:SHANXI UNIV +1

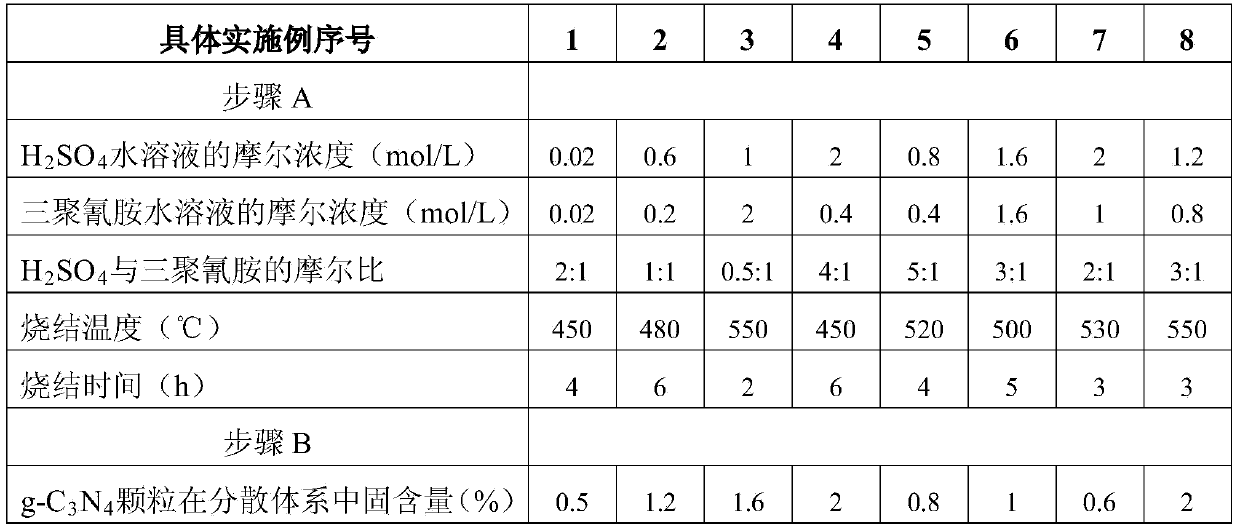

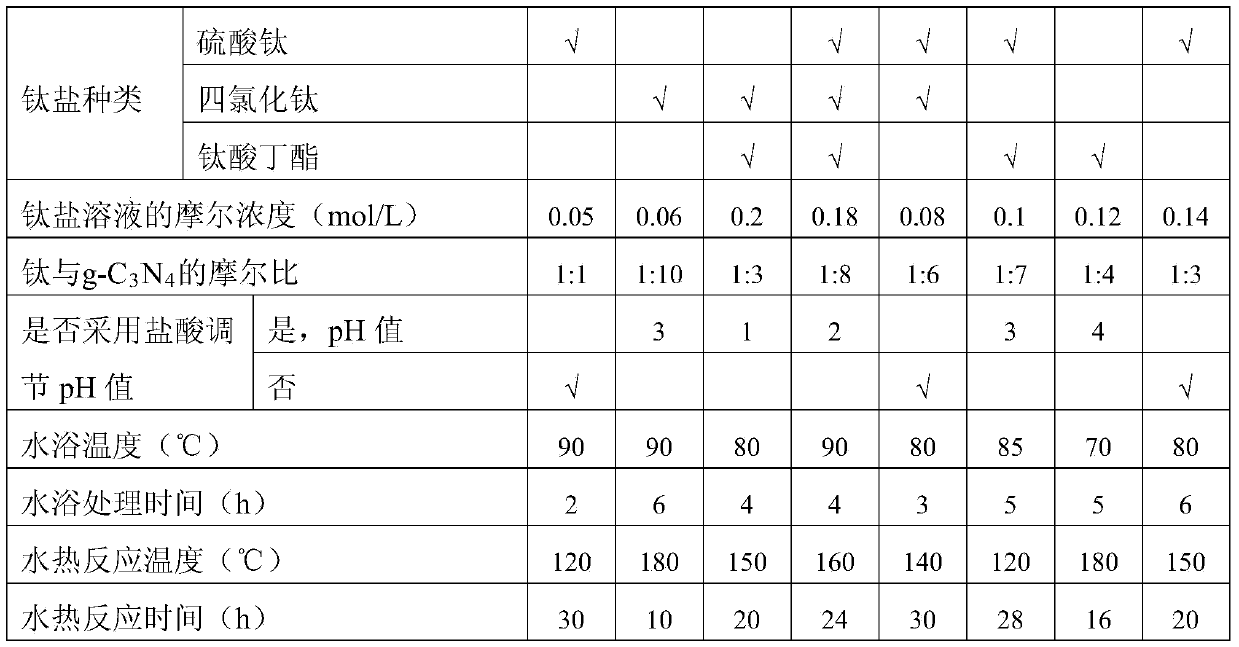

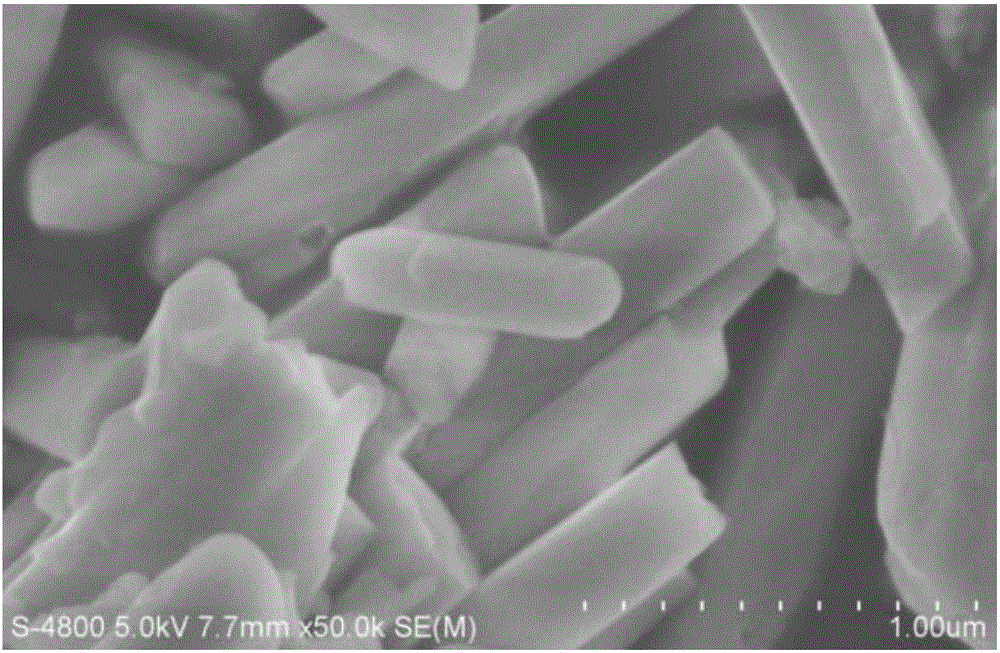

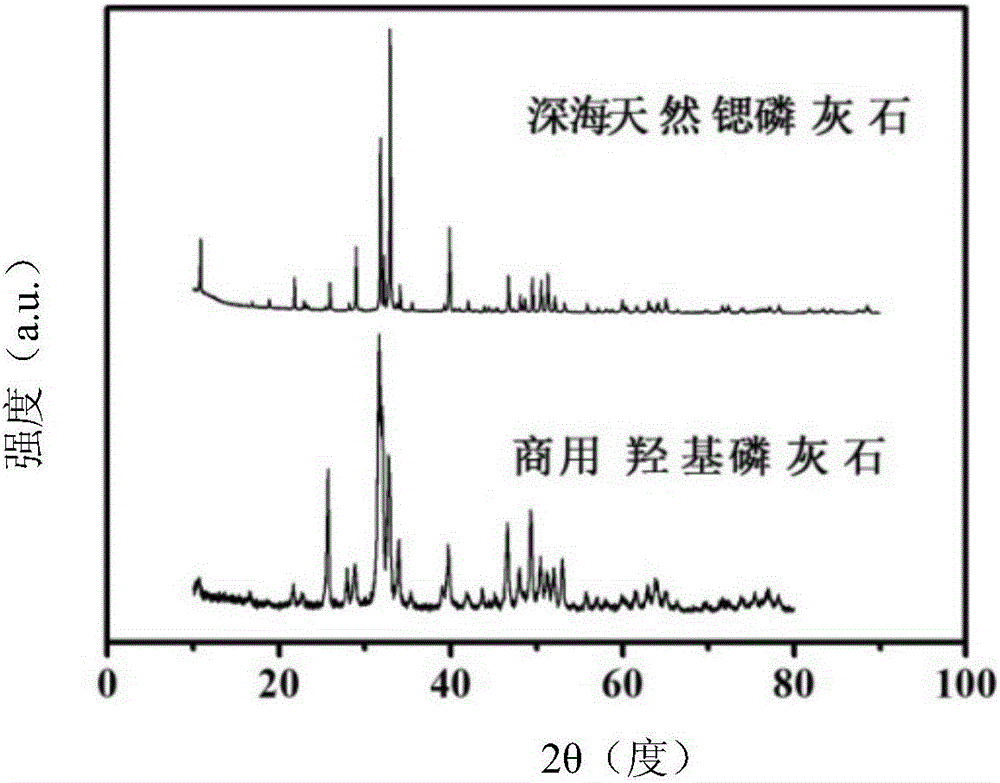

Preparation method of TiO2/porous g-C3N4 composite material

InactiveCN104209136ALow polymerization temperatureReduce aggregation energyPhysical/chemical process catalystsProtonationSemiconductor materials

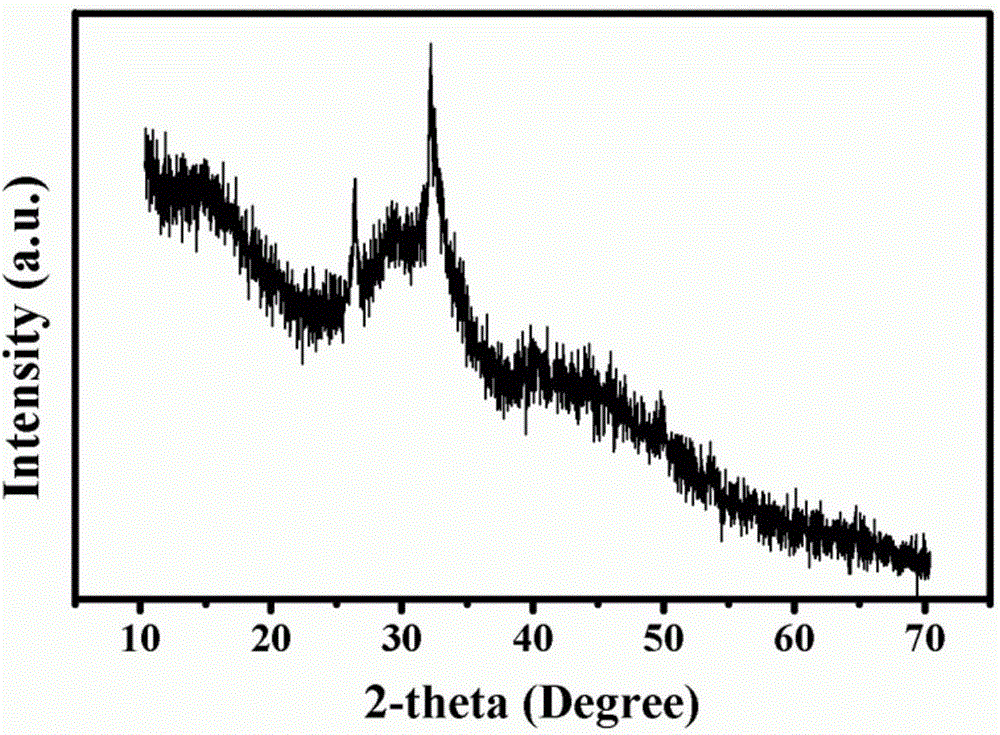

The invention relates to the field of semiconductor materials and aims at providing a preparation method of a TiO2 / porous g-C3N4 composite material. The preparation method of the TiO2 / porous g-C3N4 composite material comprises the following steps: dropwise adding H2SO4 aqueous solution into melamine aqueous solution to form a white suspension solution; stirring at the temperature of 80 DEG C for 2 hours to obtain sediment; filtering the sediment and respectively washing the sediment for three times by using distilled water and absolute ethyl alcohol, drying the washed sediment at the temperature of 60 DEG C for 24 hours to obtain melamine sulphate; adding the melamine sulphate into a corundum boat, subsequently sintering the melamine sulphate in a tubular furnace, cooling the melamine sulphate to room temperature and grinding an obtained yellow polymerization product into powder particles to obtain g-C3N4 particles. The preparation method of the TiO2 / porous g-C3N4 composite material has the beneficial effects that the g-C3N4 polymerization temperature is effectively reduced; by virtue of the protonation of the melamine, the polymerization energy of melamine is reduced; the melamine can polymerize at relatively low temperature to generate graphite-like g-C3N4.

Owner:ZHEJIANG UNIV

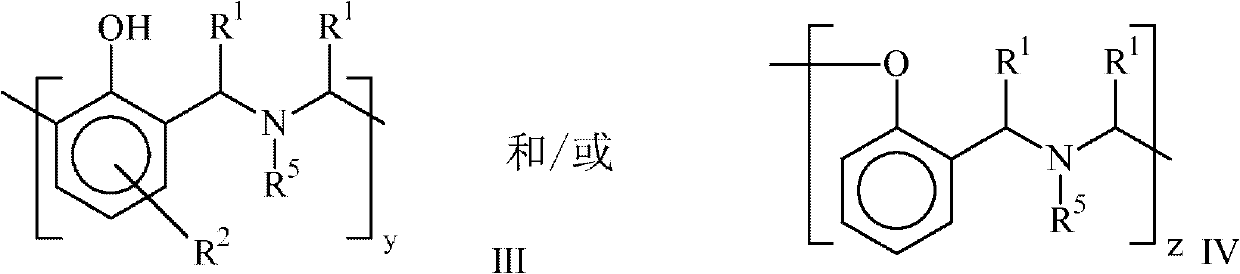

Activated arylamine-based polybenzoxazines

InactiveUS6160079AFacilitate ring openingLow polymerization temperatureSilicon organic compoundsGlass transitionElectron

Arylamines with electron donating groups such as alkyl and alkoxy groups in the meta position on the aromatic ring change the polymerization temperature of the benzoxazine prepared therefrom and offer an opportunity for an additional crosslinking site (the para position on the aromatic amine can couple to a Mannich base generated by the opening of the oxazine ring of the benzoxazine or a methylene bridge generated by a degradation reaction). Naphthenic amines with an alkyl or alkoxy substituent on the 5th through the 8th carbon atom on the naphthalene ring can function similarly. The polymers for benzoxazines prepared from at least 10% substituted aromatic or naphthenic amines are useful due to low polymerization temperatures and higher Tg (glass transition temperature).

Owner:EDISON POLYMER INNOVATION EPIC

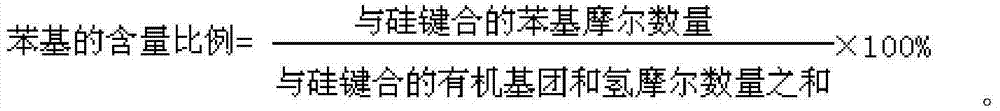

Preparation method of phenyl silicone oil

The invention relates to a preparation method of phenyl silicone oil. The method includes: mixing diphenyl cyclosiloxane with dimethyl cyclosiloxane according to certain proportion, adding an alkali catalyst to undergo copolymerization under certain temperature, then raising the temperature to 250-350DEG C, conducting cracking to obtain diphenyl-dimethyl cyclosiloxane, determining the proportions of a dimethyl chain link and a diphenyl chain link therein, mixing the diphenyl-dimethyl cyclosiloxane, an end-capping reagent, a catalyst or other cyclosiloxane and a promoter uniformly in proportion, carrying out polymerization under certain temperature, then deactivating the catalyst, conducting post-treatment, and removing low molecules, thus obtaining the target product phenyl silicone oil. The method provided by the invention can be used for preparing a variety of phenyl silicone oil, the obtained phenyl silicone oil has high quality and excellent transparency, and can be applied to optical packaging materials, personal care, lubricating oil and other fields.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL +1

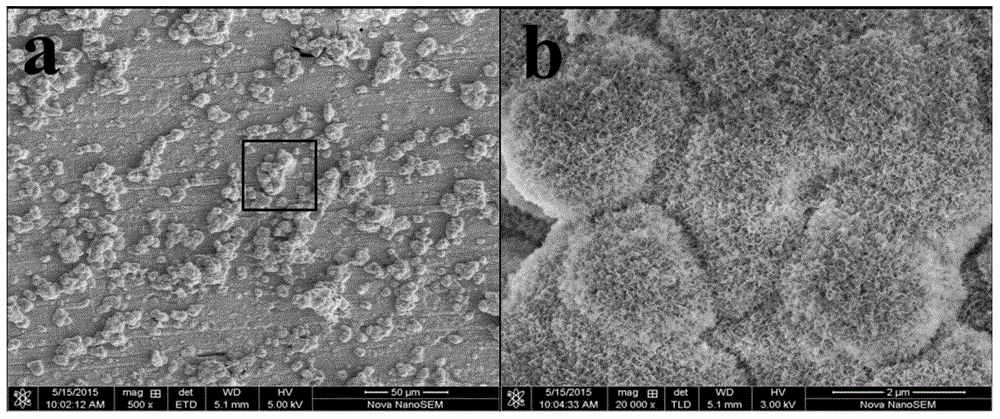

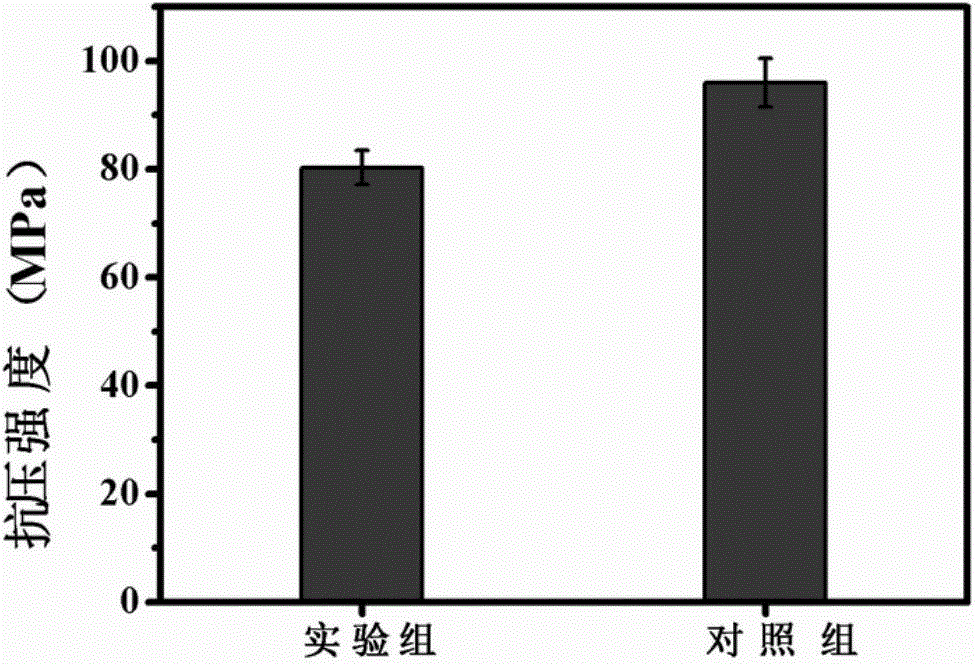

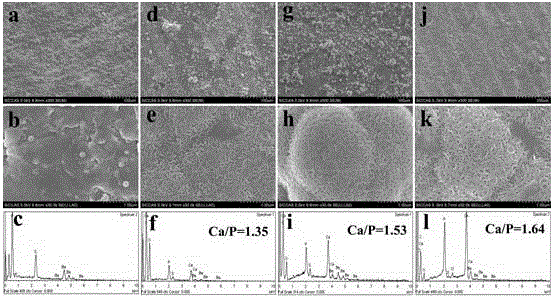

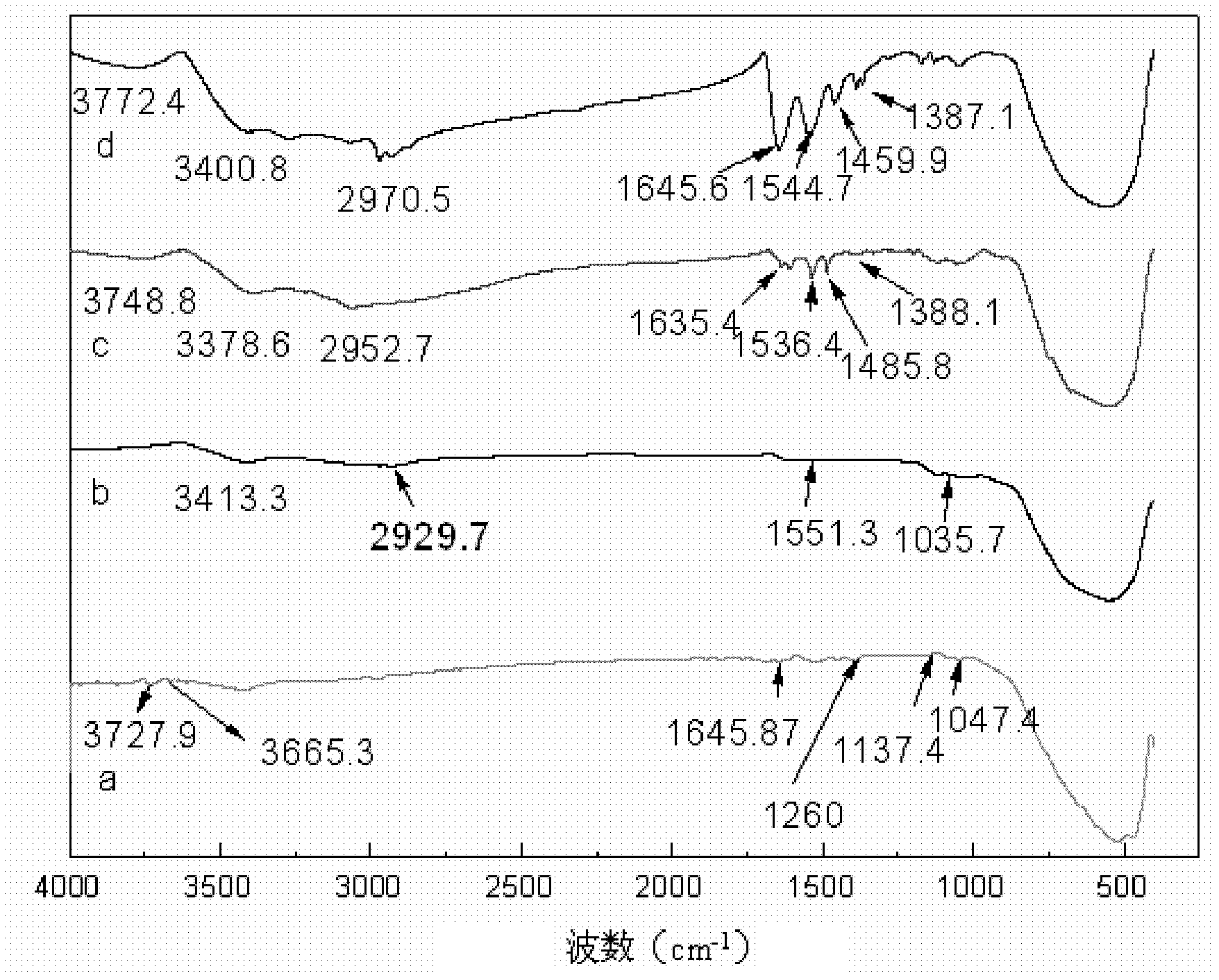

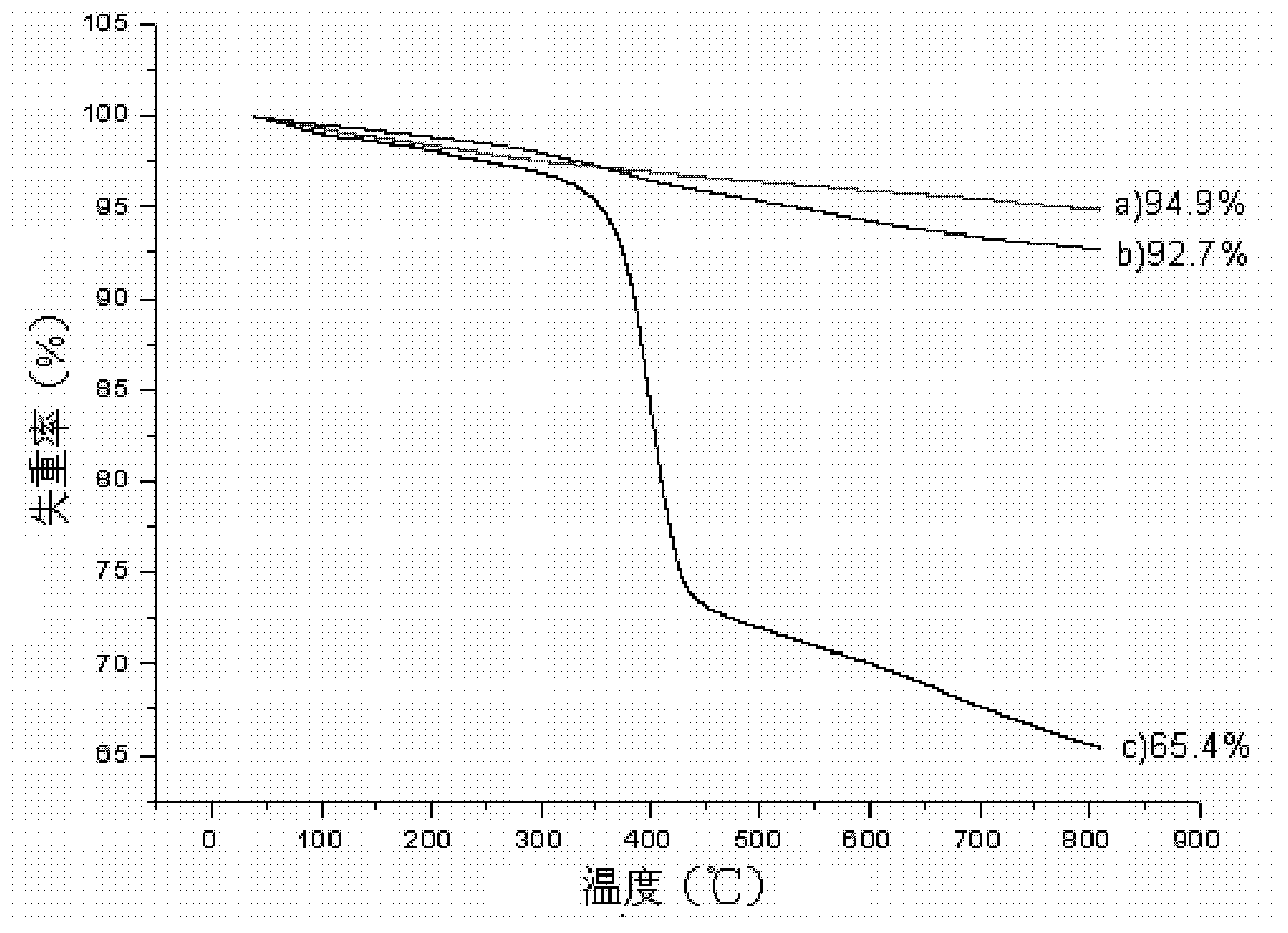

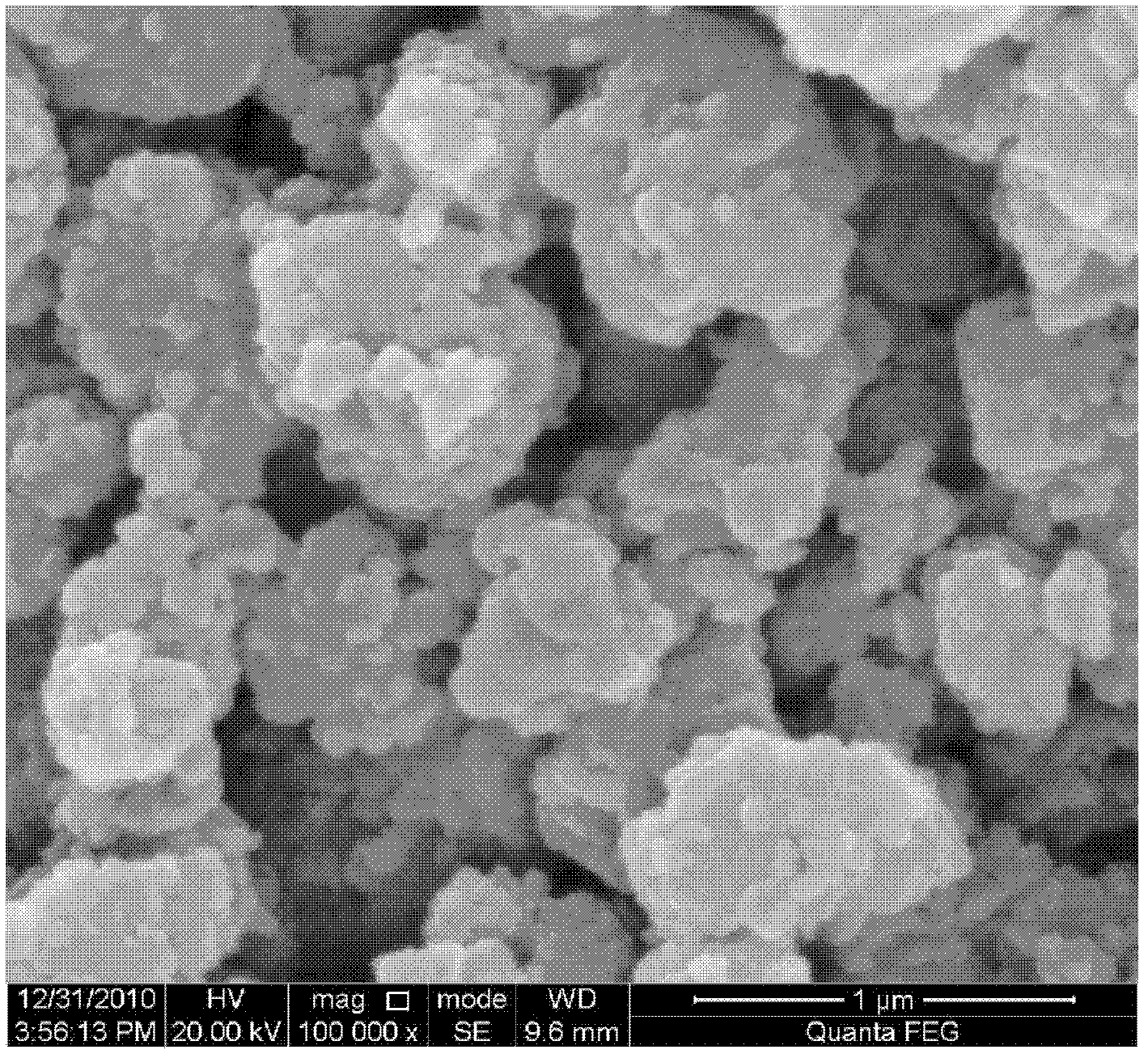

Compound bone cement precursor as well as preparation method and application of strontium borate bioglass/polymethyl methacrylate compound bone cement

ActiveCN104922731AGood injectabilityImprove biological activityProsthesisSolid phasesStrontium borate

The invention discloses a polymethyl methacrylate (PMMA) compound bone cement precursor which comprises solid phase powder and solidification liquid, wherein the solid phase powder comprises strontium borate bioglass, polymethyl methacrylate powder and a polymerization initiator, the solidification liquid comprises methyl methacrylate and a polymerization activator, and the mass of the solid phase powder is 50 to 80 percent of the mass sum of the solid phase powder and the solidification liquid. The invention also provides a preparation method of polymethyl methacrylate compound bone cement, the compound bone cement combines the performance of the strontium borate bioglass and pure PMMA bone cement, has excellent biological activity, biological degradability, biological compatibility as well as mechanical strength matched with bones, so as to achieve a good effect on prompting bone reconstruction; the invention also provides an application of the strontium borate bioglass / polymethyl methacrylate compound bone cement.

Owner:深圳市中科海世御生物科技有限公司

Single-component stable luminescent device embedding composition at room temperature

ActiveCN101220253AEasy to storeEasy to useOther chemical processesSemiconductor/solid-state device detailsTrifluoromethylHexafluorophosphate

The invention discloses a single-component encapsulating adhesive of a luminescent device with constant room temperature, and the components are: (1) epoxide resin and / or a monomer containing polymerizable double bond of C=C; (2) cation solicitation; (3) accessory ingredient: one or a combination of more than one of silicone adhesive accessory ingredient, foam killer, release agent, toner, antioxidant, and light scattering agent; the cation solicitation is: one of or a combination of more than one of triarylated matte onium based six fluorine antimonite, triarylated matte onium based six fluorine phosphate, phenyl octyloxy iodobenzene onium based six fluorine antimonite, quaternary ammonium group six fluorine antimonite, and quaternary ammonium group triflate. The encapsulating adhesive of the luminescent device is easy to be preserved; the use is convenient; double constituents of encapsulating adhesive are not needed to be blended when the encapsulation is conducted; the polymerization temperature is relatively low; the curing time is short, and the cured colloid is colorless and transparent with high transmittancy; the agglutinated property is constant; the adhesive is applicable to the encapsulating of the luminescent device, particularly for the encapsulating of a luminous diode.

Owner:杨钢

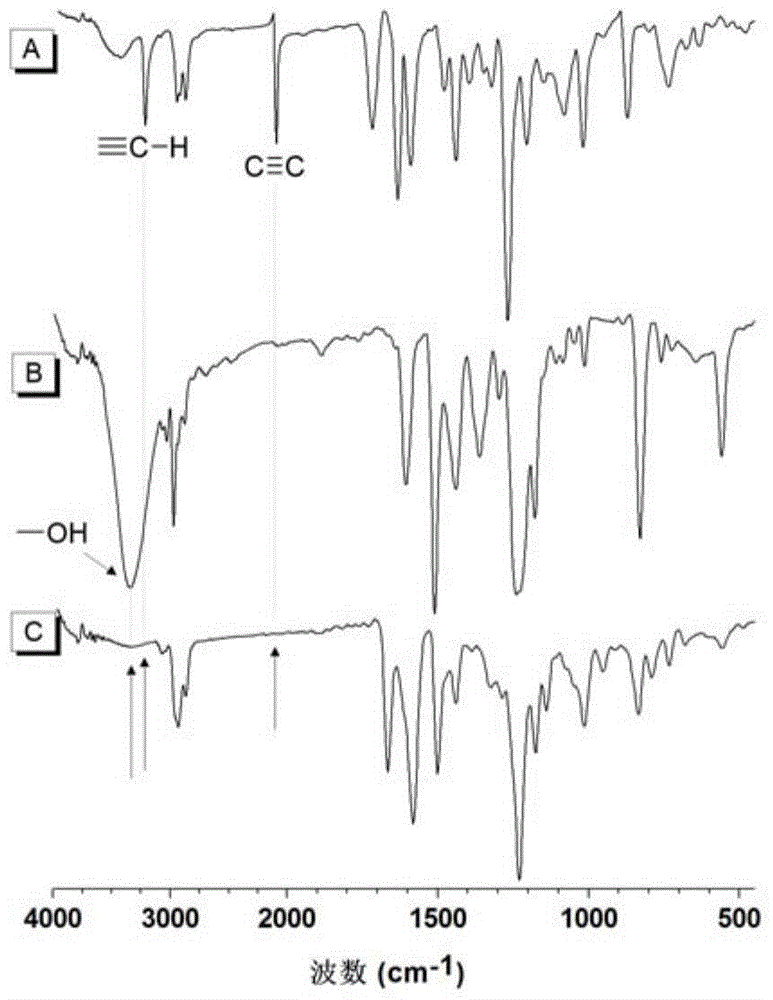

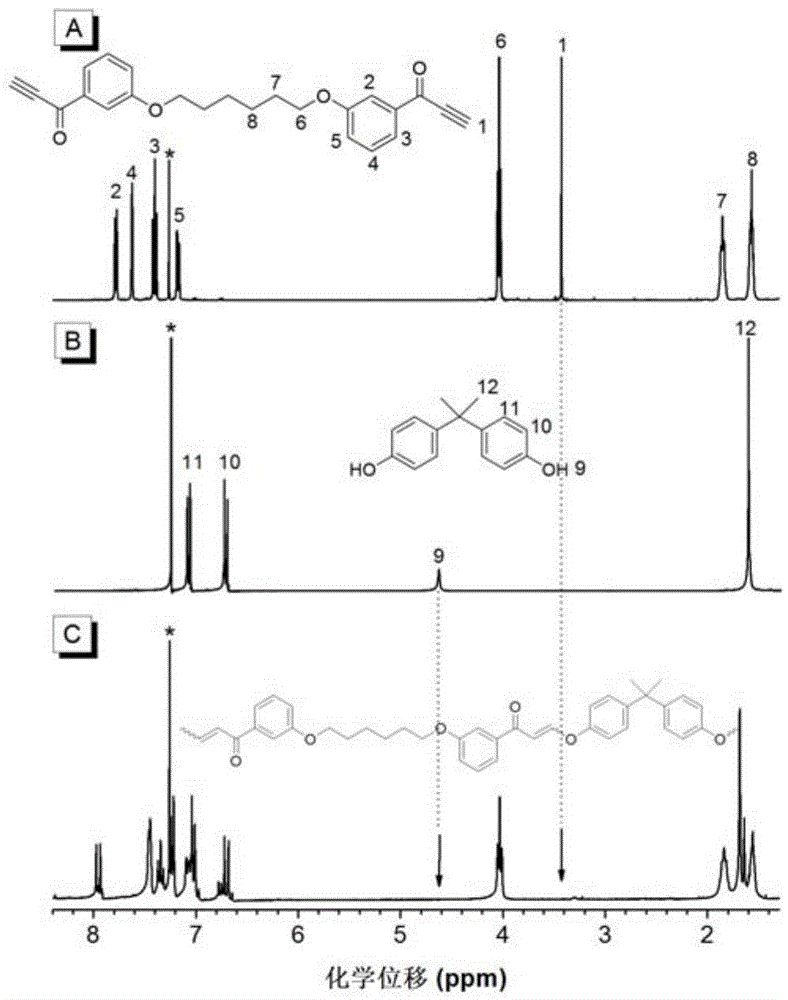

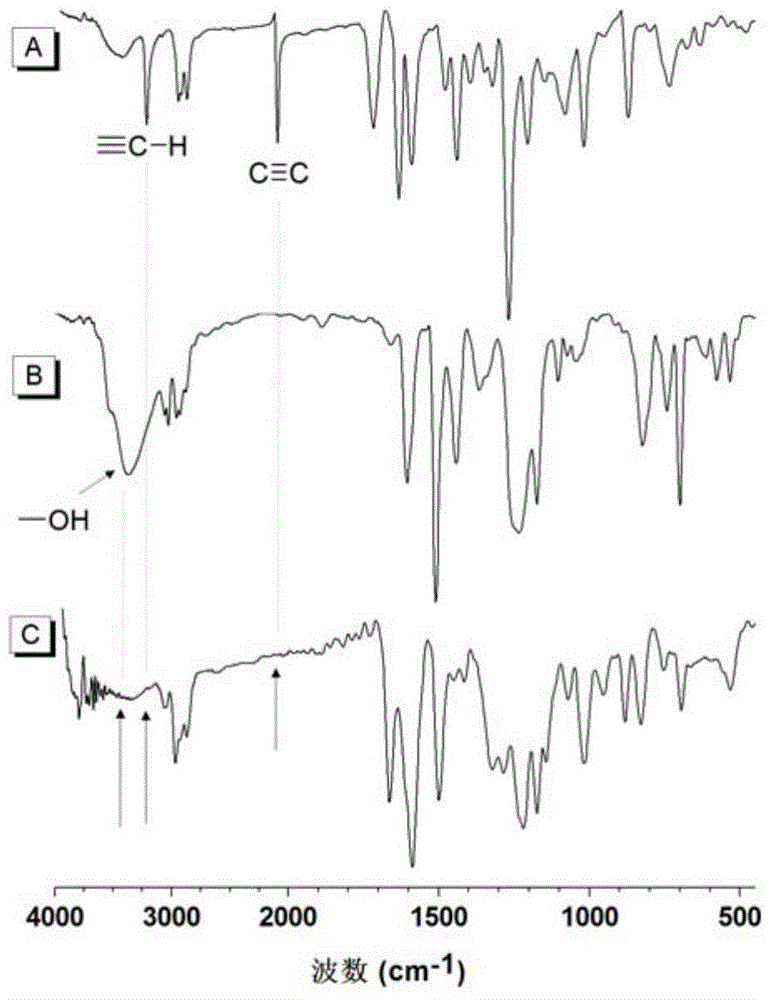

Polyene ether compounds and preparation method thereof

The invention discloses a preparation method of polyene ether compounds. The method includes: organic small-molecule 4-dimethylamino pyridine (DMAP) is used as the catalyst, binary alkynyl compounds and binary hydroxy compounds are mixed with organic solvent, and the polyene ether compounds are obtained by using the click polymerization reaction of alkynyl-hydroxy. The polyene ether compounds comprise an inner unit indicated by formula (I). The polymerization step is showed in the formula (V), wherein n is larger than 1, and R1 and R2 are selected from organic groups. The method has the advantages that water and oxygen do not need to be removed during reaction, polymerization temperature is low, polymerization efficiency is high, and no metal residues exist in products; the prepared polyene ether compounds are high in steric regularity, good in machinability, and high in heat stability, degradability and aggregation-induced emission performance.

Owner:ZHEJIANG UNIV

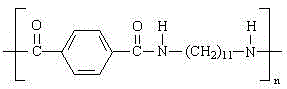

Semi-aromatic polyamide PA11T and preparation method thereof

ActiveCN104817693AHigh molecular weightHigh temperature high molecular weightPolymer scienceMaterial synthesis

The invention discloses a semi-aromatic polyamide PA11T and a synthetic method thereof and belongs to the technical field of high polymer material synthesis. The structure formula is shown in the description, wherein n is 10-200. The 1, 11-undecanedioic diamide and the terephthalic acid are taken as the raw materials and the synthetic process is finished in a drum type reaction kettle through a one-pot method. By adopting the method, the reaction devices and the synthetic steps are few, the reaction time is short, the polymerization temperature is low, and the method is pollution-free and suitable for the large-scale industrial production. The PA11T produced by the process is excellent in performance and has a good market prospect in the industries such as the electric products and the automobiles.

Owner:ZHENGZHOU UNIV +1

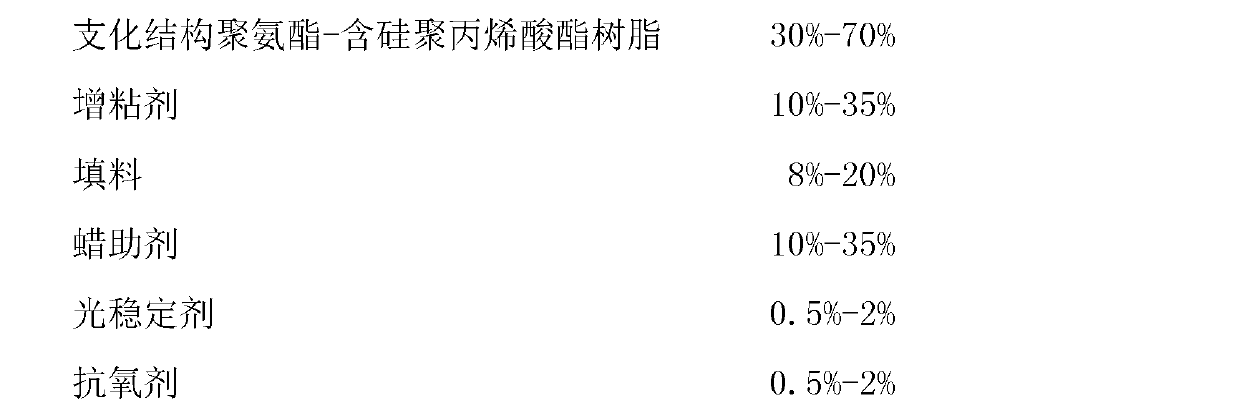

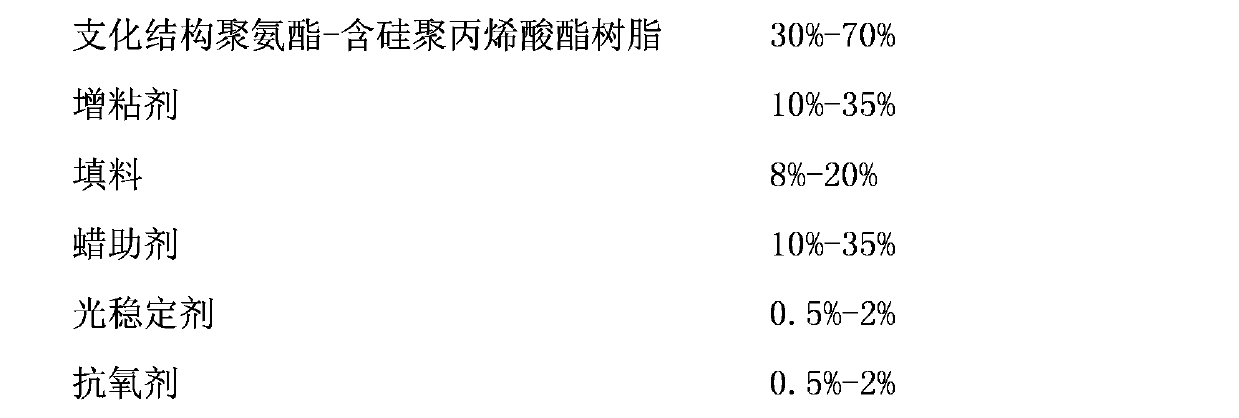

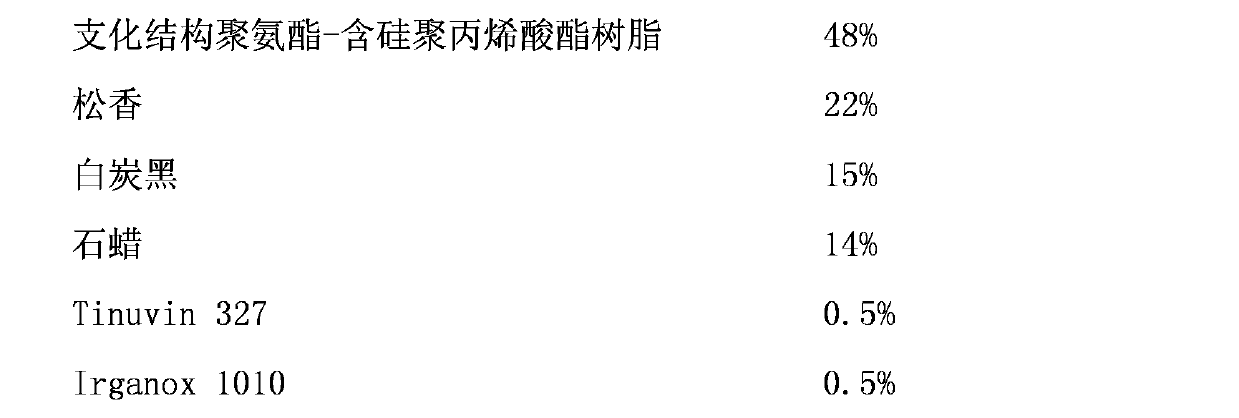

Branched-structure polyurethane-silicious polyacrylate hot melt adhesive and preparation method thereof

InactiveCN102911633ANo pollution in the processNon-flammablePolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a branched-structure polyurethane-silicious polyacrylate hot melt adhesive and a preparation method thereof. The branched-structure polyurethane-silicious polyacrylate hot melt adhesive mainly comprises the following components of branched-structure polyurethane-silicious polyacrylate resin, tackifier, fillers, wax additive, light stabilizer and antioxidant, wherein the branched-structure polyurethane-silicious polyacrylate resin is a polymer specially synthesized for the invention. The preparation method of the branched-structure polyurethane-silicious polyacrylate hot melt adhesive comprises the following steps of: heating and melting the antioxidant, the light stabilizer, the tackifier and the wax additive according to weight ratio of the hot melt adhesive, controlling temperature, adding the branched-structure polyurethane-silicious polyacrylate resin and the fillers in batches while stirring, discharging after melting and uniformly mixing adhesive solution, cooling, slicing and forming to obtain the prepared hot melt adhesive. According to the branched-structure polyurethane-silicious polyacrylate hot melt adhesive and the preparation method thereof, the problems of poor heat resistance and low strength of the traditional EVA (ethylene-co-vinyl acetate) hot melt adhesives, high energy consumption for preparation, high melt temperature and poor construction performance of polyester hot melt adhesives, and poor weather resistance, poor storage stability and higher cost of moisture-curing polyurethane hot melt adhesive are solved.

Owner:SICHUAN UNIV

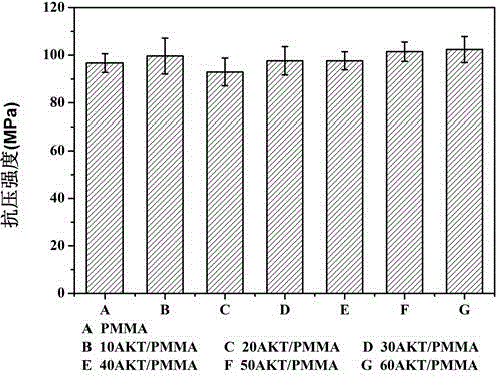

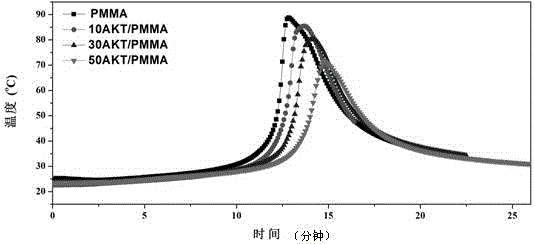

Akermanite/PMMA composite bone cement with osteogenesis inducing function and preparation method of akermanite/PMMA composite bone cement

ActiveCN104307035AImprove mechanical propertiesImprove biological activitySurgical adhesivesProsthesisBone cementMonomer

The invention discloses akermanite / PMMA composite bone cement with an osteogenesis inducing function and a preparation method of the akermanite / PMMA composite bone cement. The akermanite / PMMA composite bone cement comprises the following components: akermanite and PMMA bone cement, wherein the PMMA bone cement is prepared from a PMMA bone cement monomer and PMMA powder, and the mass ratio of the akermanite to PMMA powder is 5-60 percent.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Surface grafted poly (N-isopropyl acrylic amide) TiO2 nano particles and preparation method thereof

ActiveCN102320654AEvenly distributedThickness is easy to controlMaterial nanotechnologyTitanium dioxideSingle electronGrating

The invention discloses a preparation method of surface grafted poly (N-isopropyl acrylic amide) TiO2 nano particles, and belongs to the field of TiO2 poly (N-isopropyl acrylic amide) hybrid systems. The method comprises the following steps of: performing amino modification on the TiO2, grafting acyl bromide functional groups to the TiO2, and grafting the poly (N-isopropyl acrylic amide) (PNIPAM) to the surface of the TiO2 by a single electron transfer living radical polymerization (SET-LRP) method. The PNIPAM is grafted to the surface of the TiO2 by using the aqueous phase SET-LRP process, so that the polymer and the nano particles are distributed uniformly, the thickness of the polymer on the surface of the TiO2 is controllable, and the method has the characteristics of high grating rate, high grafting speed, low polymerization temperature, mild conditions and the like. The particles have wide application prospect in the fields of chemical mechanical polishing, water treatment, biomedical application and the like.

Owner:HARBIN INST OF TECH

Styrenated terpene resin as well as methods of making and using the same

ActiveUS7829630B2Facilitates minimizing and eliminatingLow polymerization temperatureNatural resin coatingsProtein adhesivesChemistryTerpene

The present invention relates to styrenated terpene resin, as well as methods of making an using the same.

Owner:KRATON CHEM LLC

Synthesis method of poly(butylene succinate)

The invention discloses a synthesis method of poly(butylene succinate), belonging to the technical field of high polymer material synthesis. The method comprises the following steps: (1) adding raw materials butanedioic anhydride and 1,4-butanediol and a catalyst into a polymerization plant, and reacting at 150-170 DEG C in an inert gas protective atmosphere for 1-3 hours; (2) carrying out prepolycondensation reaction at 170-200 DEG C under the pressure of 300-1500Pa for 1-5 hours; and (3) finally, heating to 200-230 DEG C, lowering the pressure to 10-100Pa, and polycondensing under such conditions for 1-5 hours to obtain the product poly(butylene succinate). The molecular weight of the product is 80-150 thousand. By adopting the composite catalytic system, the consumption of the butanediol is lower than the prior art, no antioxidant or chain extender is needed, the molecular weight of the product is high, and the reaction temperature is lowered. The butanedioic anhydride used as the reaction raw material has the advantages of high reaction activity, low dehydration and low requirements for corrosion resistance of equipment.

Owner:HENAN COAL CHEM IND GROUP INST +1

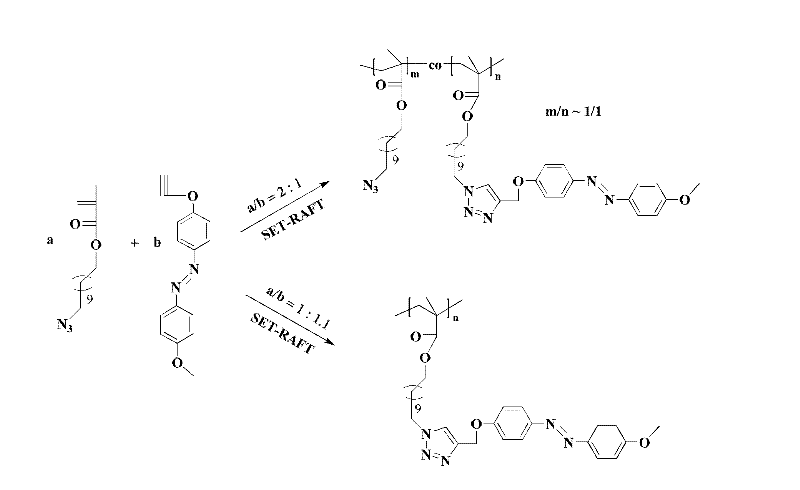

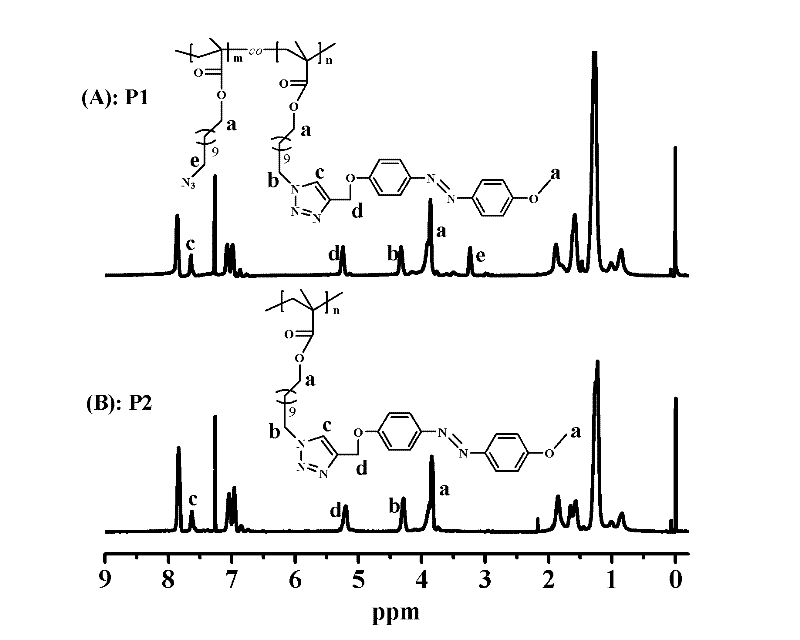

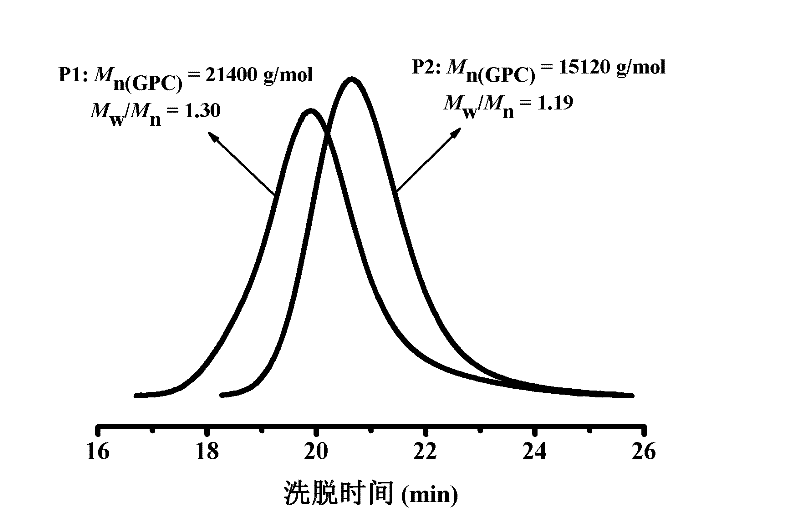

Side chain functional polymer and preparation method thereof

The invention discloses a side chain functional polymer and a preparation method thereof. A polymerization system consists of a monomer, an initiator, a chain transfer agent, a catalyst, a coordination agent and a coupling component, wherein the monomer is undecyl azidomethacrylic ester; the catalyst is copper; the coordination agent is N,N,N',N'',N''-pentamethyldiethylenetriamine; the coupling component is 4-methyoxyl-4'-propynyloxy azobenzene; single electron transfer (SET) is adopted for initiation to produce a free radical; polymerization reaction of the monomer is performed by a method for performing chain propagation in a reversible addition fragmentation chain transfer (RAFT) mode; meanwhile, click chemical reaction is performed; and monovalent copper is used for catalyzing an azide group and an alkynyl group in the coupling component to perform cycloaddition reaction so as to obtain the side chain functional polymer. Since the SET-RAFT method and the click chemical method are combined, the side chain functional polymer can be obtained by only one-step reaction; and thus, the reaction steps are reduced, the waste rate of the raw materials is reduced, rational utilization ofthe resources is realized, side reaction is basically avoided, and troublesome purification operation is avoided.

Owner:SUZHOU UNIV

Polybenzoxazine composition

InactiveCN102575006AOvercome significant drawbacks of aggregationImprove thermal stabilityChemical recyclingCoatingsSealantCoating

Owner:3M INNOVATIVE PROPERTIES CO

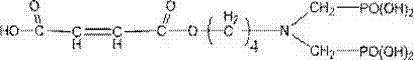

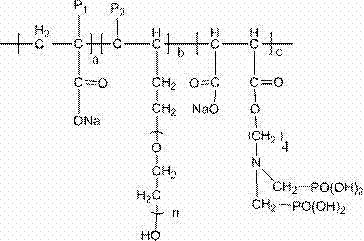

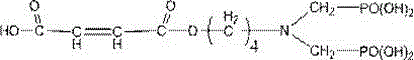

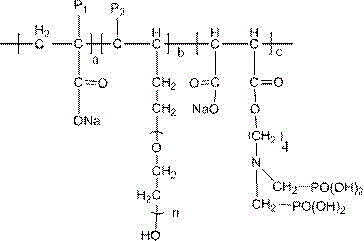

Polycarboxylate superplasticizer containing phosphine and preparation method thereof

The invention discloses a polycarboxylate superplasticizer containing phosphine and a preparation method thereof. The polycarboxylate superplasticizer is prepared from the following components by weight through redox free radical polymerization: 100 parts of isoprene polyoxyethylene ether, 8 to 30 parts of a component R, 7.5 to 14.5 parts of a component R1, 0.25 to 1 part of a component R2, 0.17 to 1 part of a chain transferring agent, 0.6 to 3.5 parts of an initiator and 106 to 180 parts of water. According to the invention, a phosphonate structure is introduced into the polycarboxylate superplasticizer, so slump retaining capability of the polycarboxylate superplasticizer is effectively improved, and a reliable and stable solution is provided to overcome the problem of long-acting slump loss resistance. The method adopts redox free radical polymerization technology and has the advantages of a low polymerization temperature, simple preparation technology, low requirements on equipment, easy realization of enlarged and controlled production, low cost, safety and environmental protection.

Owner:SICHUAN SEDAR CHEM

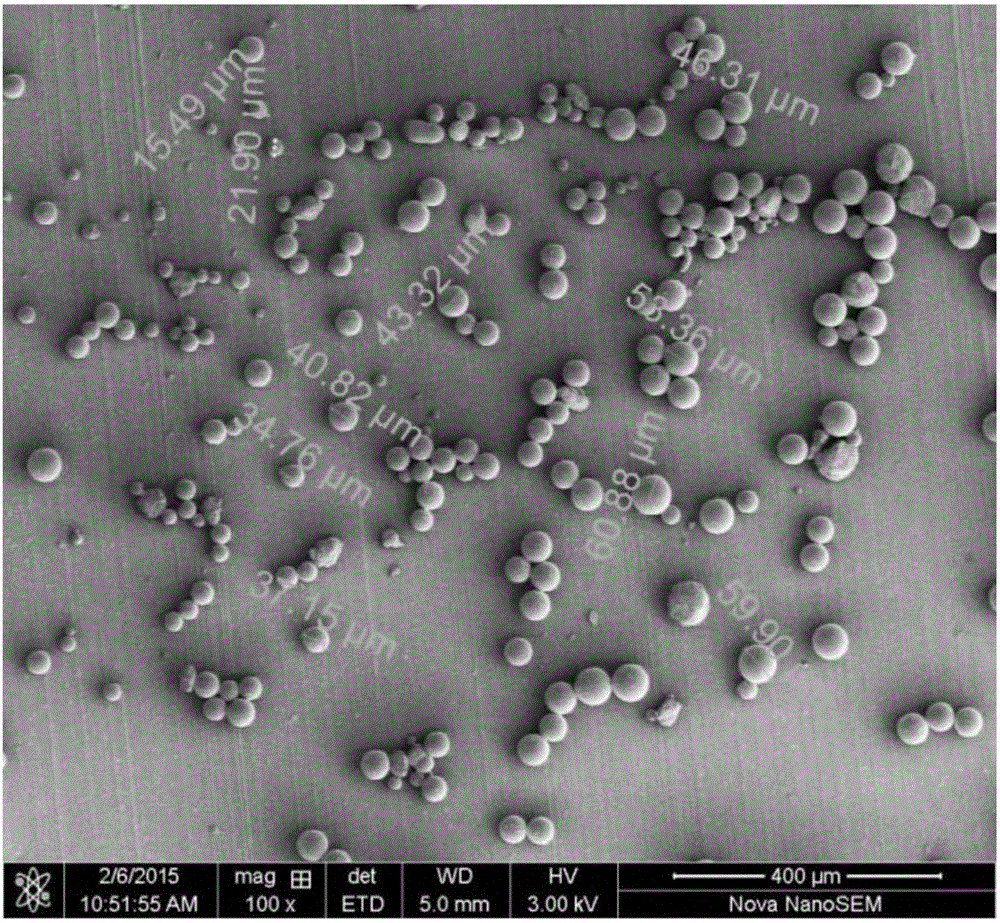

Composition capable of forming composite bone cement and bone cement formed by same

ActiveCN106139253AImprove utilizationReduce pollutionPharmaceutical delivery mechanismTissue regenerationMicrospherePolymethyl methacrylate

The invention provides a composition capable of forming composite bone cement and the bone cement formed by the same. The composition contains a composition forming polymethyl methacrylate bone cement and tuna fish bone meal / hyaluronic acid microspheres. The composition contains, by 100% total weight, the tuna fish bone meal / hyaluronic acid microspheres accounting for the mass fraction of 8%-60%. The microspheres are prepared from tuna fish bone meal and hyaluronic acid as raw materials, and by the 100% total weight of the tuna fish bone meal and hyaluronic acid, the mass fraction of the tuna fish bone meal accounts for 30%-70%, and the mass fraction of the hyaluronic acid accounts for 30%-70%. The tuna fish bone meal / hyaluronic acid microspheres promoting bone growth are added in the composition on the basis that the composition can form a PMMA bone cement composition, and the obtained bone cement has the advantages of excellent biological activity, biocompatibility, bone integration performance and the like.

Owner:SHENZHEN INST OF ADVANCED TECH +2

Polybenzoxazine composition

ActiveUS20150218429A1Improve thermal stabilityLow polymerization temperatureCoatingsAdhesivesSealantCoating

Owner:3M INNOVATIVE PROPERTIES CO

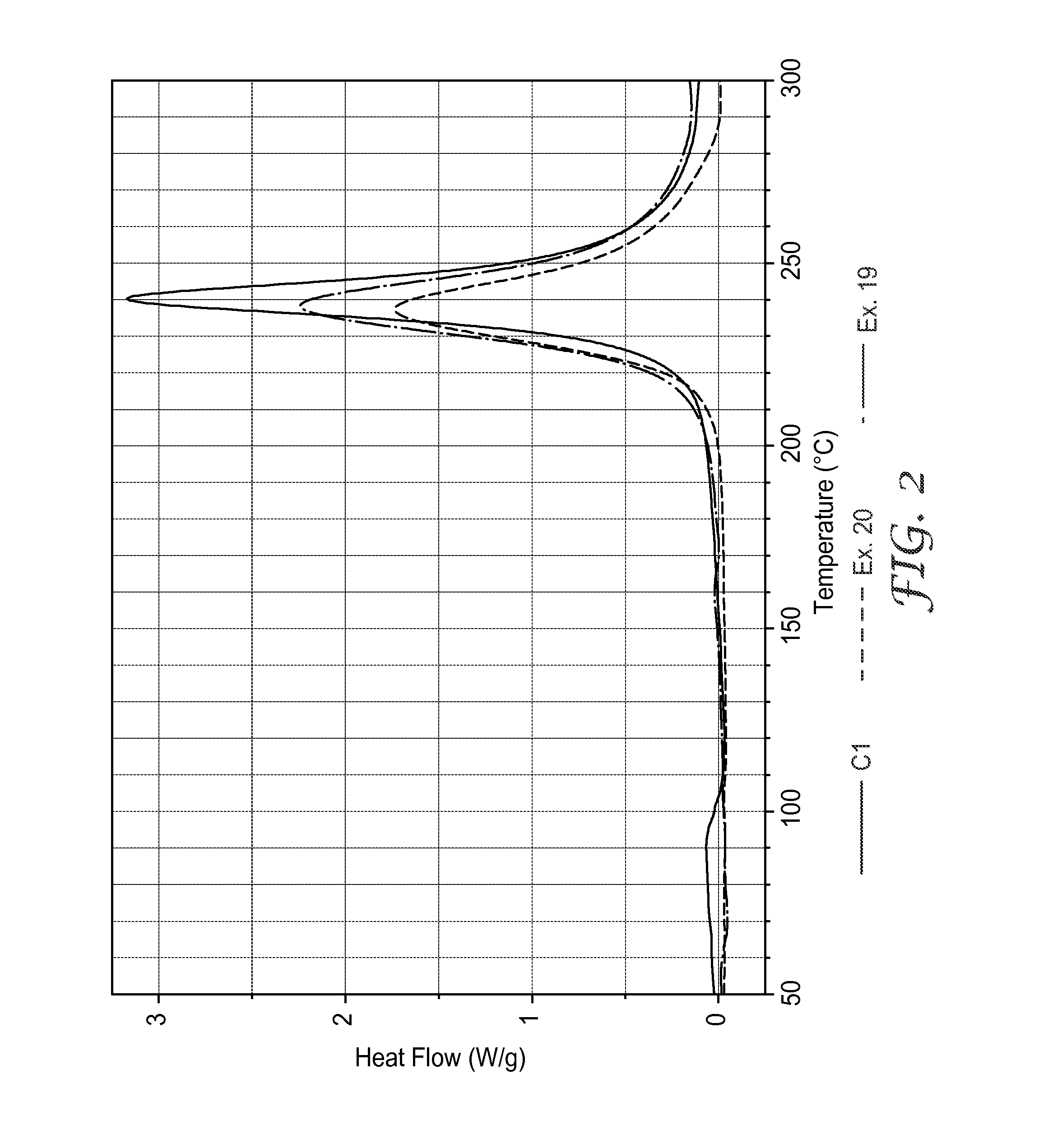

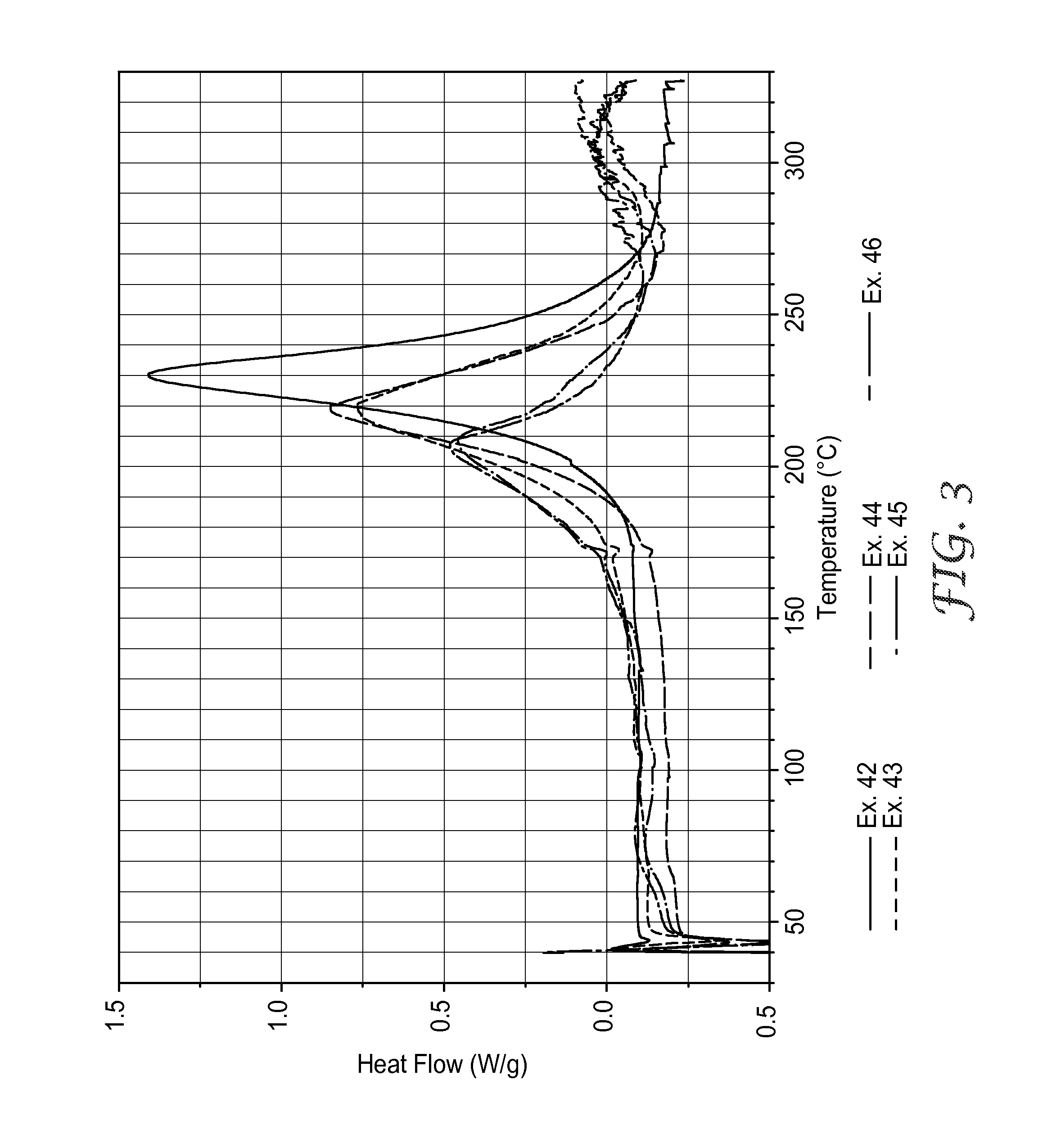

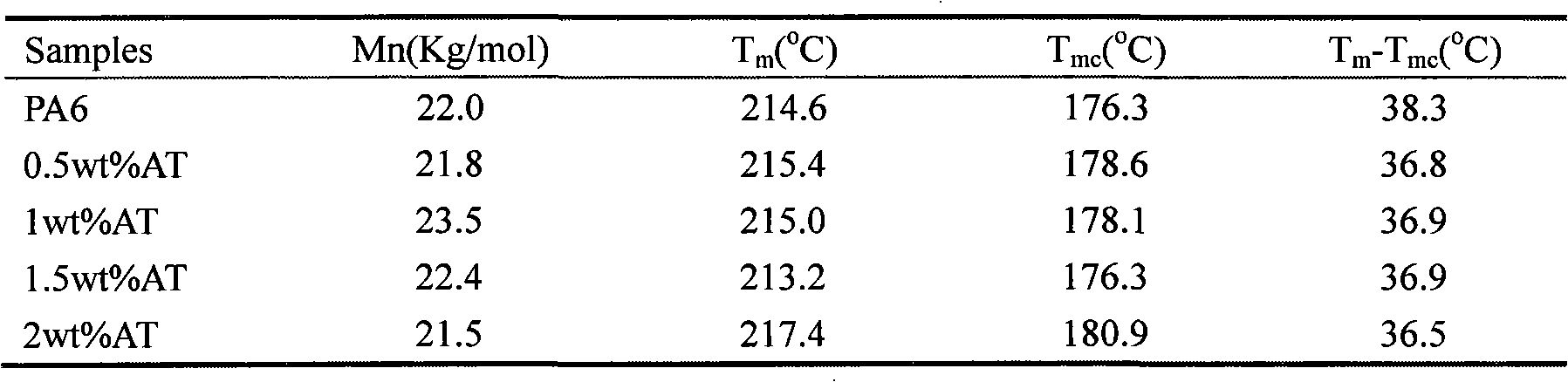

Method for preparing attapulgite/nylon 6 nano-composite by negative ion ring-open method

The invention relates to a method for preparing an attapulgite / nylon 6 nano-composite by a negative ion ring-open method, the composite comprises raw materials of caprolactam, attapulgite, an activating agent, a catalyst and the like, firstly, the caprolactam and the catalyst are heated to 140 DEG C for vacuum de-watering, then dry attapulgite is added thereto for 2h ultrasound processing in a water bath at a temperature of 80 DEG C under confinement until the attapulgite forms an even solution in a caprolactam melt, then the activating agent is added, the mixture is agitated fully and evenly and poured into a die preheated at a temperature of 180 DEG C, and the attapulgite / nylon 6 in situ nano-composite is obtained after cooling and demoulding. In the attapulgite / nylon 6 in situ nano-composite prepared by the method, the attapulgite can be dispersed in a nylon 6 matrix evenly by a nanoscale, and the melt temperature, crystallization temperature and the heat stability of the composite are all increased.

Owner:HEFEI GENIUS NEW MATERIALS

A kind of phosphine-containing polycarboxylate water reducer and its preparation method

Owner:SICHUAN SEDAR CHEM

Polybenzoxazine composition

ActiveCN104781308AOvercome significant drawbacks of aggregationImprove thermal stabilityCoatingsAdhesivesSealantChemistry

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparation of small-particle-size polybutadiene latex

ActiveCN106866885AModerate activation energyThe activation energy is moderate, making the polymerization reaction temperature moderatePolymer sciencePolybutadiene

The invention provides a method for rapid synthesis of a small-particle-size polybutadiene latex; in the premise of ensuring the comprehensive performance of ABS resin, the polymerization time of the small-particle-size polybutadiene latex is shortened to 4-7 hours, the polymerization time is greatly shortened, and the reaction can be rapidly and evenly performed, so that the polymerization time of a large-particle-size polybutadiene latex is shortened, the ABS resin production cycle is further shortened, and the production capacity of an ABS device is greatly improved; and at the same time, the method can reduce the polymerization temperature and decrease the polymerization pressure, and allows the polymerization to be performed in relatively stable conditions.

Owner:PETROCHINA CO LTD

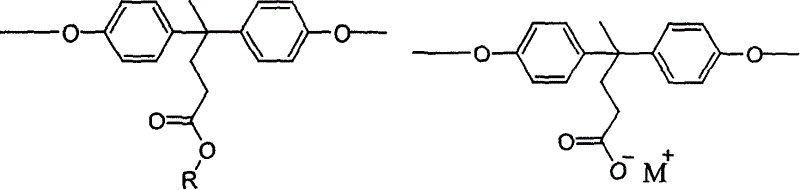

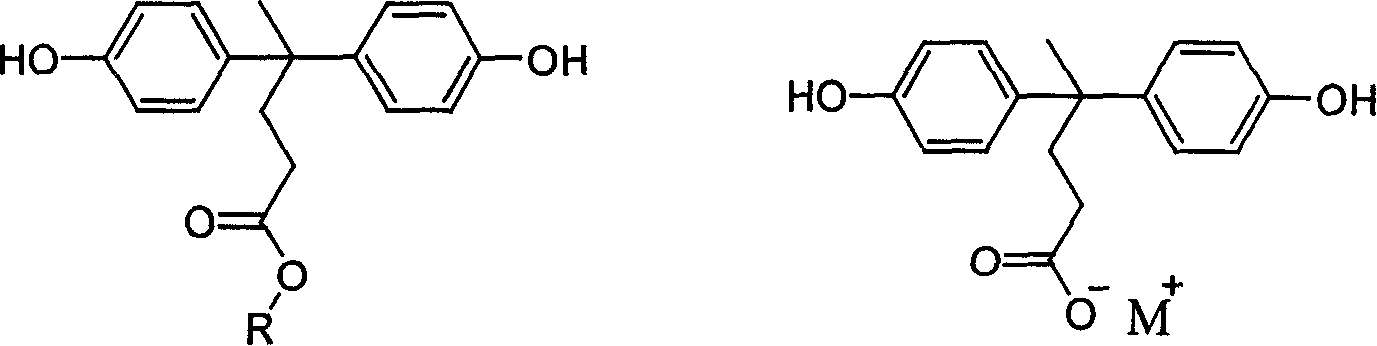

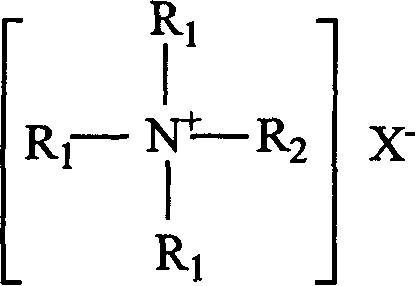

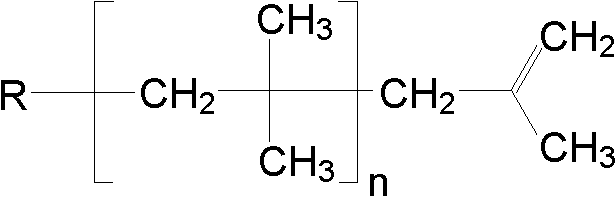

Copoaromatic ether and preparation thereof

A copolyester aryl and its production are disclosed. The copolyester aryl consists of bisphenol A structural unit, terephthalyl acyl structural unit, isophthalamic acyl structural unit, at least a diphenolic acid or diphenolic ester structural unit or diphenolic salt structural unit, or hung carboxy, carboxylic ester and carboxylic salt on side chain. The process is carried out by taking bisphenol monomer containing at least a diphenolic acid or its derivative and phthalchlorine monomer as raw material, taking quaternary ammonium salt as phase transfer catalyst, and interfacial polycondensation reacting under 10-50 Deg C. to obtain copolyester aryl. It achieves fast polymerization speed, short time, low temperature, more yield and molecular weight.

Owner:ZHEJIANG UNIV

Initiation system for preparation of high reaction activity polyisobutylene and application

ActiveCN102775534AHigh molecular weightThe polymerization process is stable and controllablePolymer scienceCationic polymerization

The invention relates to an initiation system for preparation of high reaction activity polyisobutylene and application. The initiation system consists of SnCl4, water and an organic compound containing oxygen, nitrogen and / or sulphur. The initiation system is added into an isobutene-containing polymerization raw material to induce cationic polymerization. The polymerization temperature is controlled at -60-30DEG C, and the polymerization reaction is stable and easy to control. Optimally, the terminal group alpha-double bond content can reach 98%. And according to needs, the initiation system can be used to prepare high reaction activity polyisobutylene with a number average molecular weight of 500-5000, a molecular weight distribution index up to 1.3 and an alpha-double bond content greater than 80%mol, a low molecular weight and narrow molecular weight distribution, and high reaction activity polyisobutylene with a number average molecular weight of 8000-15000, a molecular weight distribution index up to 1.6, an alpha-double bond content over 80%mol, a medium molecular weight and narrow molecular weight distribution.

Owner:BEIJING UNIV OF CHEM TECH

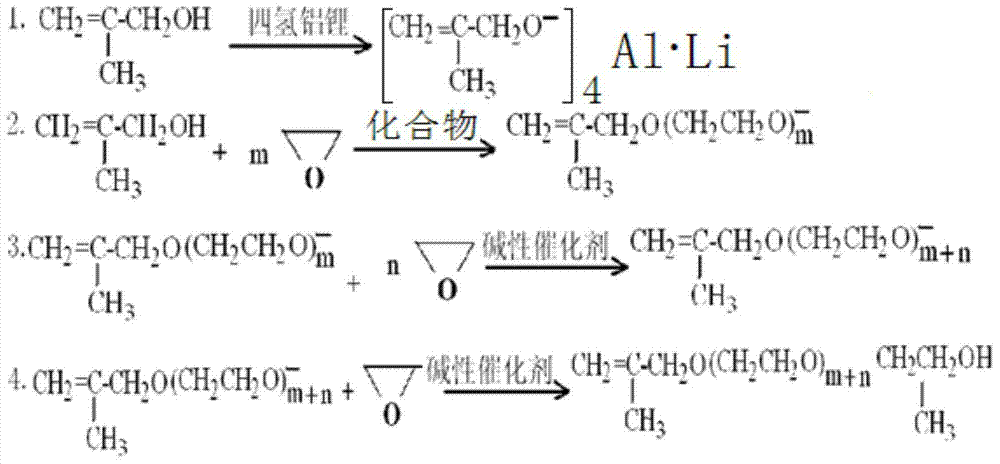

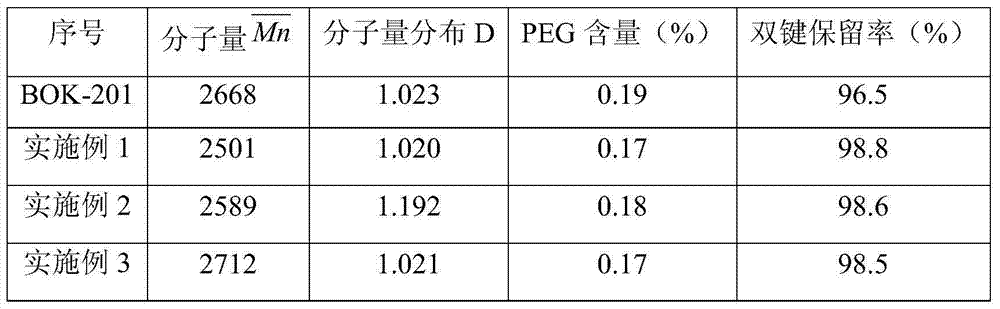

Preparation method of polycarboxylate water reducer macromonomer methallyl alcohol polyoxyethylene ether

The invention relates to a polycarboxylate water reducer and specifically relates to a preparation method of polycarboxylate water reducer macromonomer methallyl alcohol polyoxyethylene ether. The method comprises the following steps: performing condensation reaction with ethylene oxide by taking lithium aluminum tetrahydride as a catalyst and taking an intermediate product obtained by reaction of methallyl alcohol and lithium aluminum tetrahydride and methallyl alcohol as raw materials to obtain a methallyl alcohol oligomer, further enabling the methallyl alcohol oligomer to perform condensation reaction with the added ethylene oxide under the action of an alkaline catalyst, terminating with propylene oxide, and adding glacial acetic acid to neutralize to obtain methallyl alcohol polyoxyethylene ether. The preparation method provided by the invention has the advantages of simple process, safety, low reaction temperature, short reaction time and low production cost; and obtained methallyl alcohol polyoxyethylene ether has narrow distribution of relative molecular weight and high retention rate of double bonds.

Owner:山东卓星化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com