Method for preparing attapulgite/nylon 6 nano-composite by negative ion ring-open method

A nano-composite material and anion ring-opening technology, which is applied in the field of heat-resistant nylon materials, can solve the problems of low relative molecular weight of polymers and long polymerization time, and achieve the effects of short reaction time, low polymerization temperature and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The method for preparing attapulgite / nylon 6 in-situ nanocomposite material by the anion ring-opening method involved in the present invention, the method is realized through the following process steps:

[0016] In the first step, weigh 200g of caprolactam and 0.6g of sodium hydroxide in the reactor and heat to 140°C, remove water in vacuum for 30min, and the vacuum degree is 10 -1 ~10 -3 Pa, after removing the water, remove the vacuum, add 1g of dry attapulgite, and ultrasonicate for 2 hours in a water bath at 80°C under sealed conditions, so that attapulgite forms a homogeneous solution in caprolactam.

[0017] In the second step, add 1.5g of activator 2,6-toluene diisocyanate, stir well, pour it into a mold preheated at 180°C, keep the temperature for 30min, and obtain attapulgite / nylon 6 in-situ nanocomposite after cooling Material.

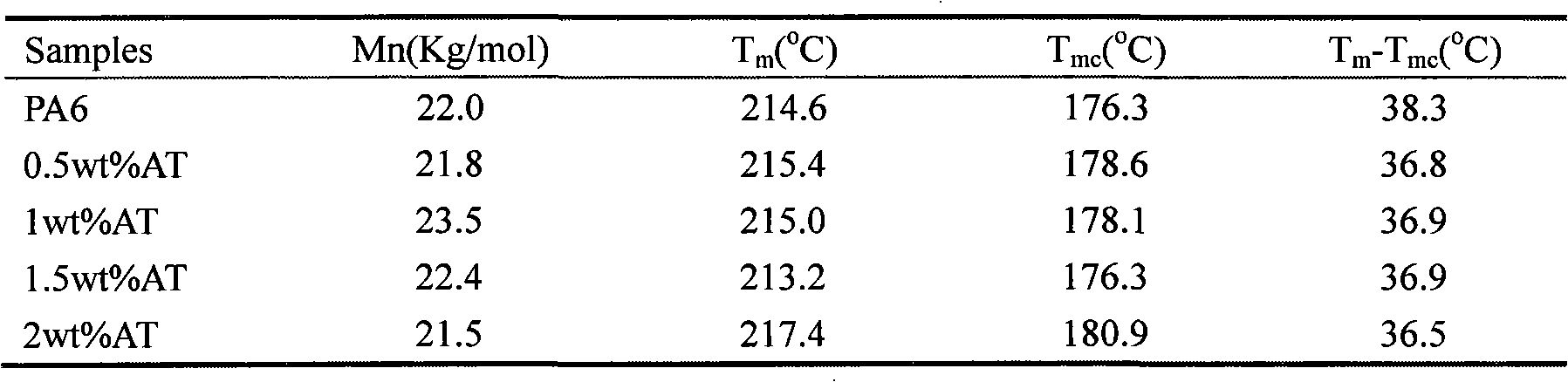

[0018] The thermal properties of the prepared in-situ nanocomposite material after SEM, DSC, and TGA analysis and characterization...

Embodiment 2

[0020] The method is basically the same as in Example 1, except that the content of attapulgite is changed to 2 g. The thermal properties of the prepared in-situ nanocomposite material after SEM, DSC, and TGA analysis and characterization are shown in Table 1.

Embodiment 3

[0022] The method is basically the same as in Example 1, except that the content of attapulgite is changed to 3g. The thermal properties of the prepared in-situ nanocomposite material after SEM, DSC, and TGA analysis and characterization are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com