Fluorine-contained surfactant and preparation method thereof

A technology of surfactant and carbon number, which is applied in chemical instruments and methods, photosensitive materials for optomechanical equipment, transportation and packaging, etc., can solve the difficulties of industrial production, the influence of polymer performance, and the complexity of the preparation process, etc. problems, to achieve the effect of excellent surface activity, fast polymerization speed and pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using diethyl ether as a solvent, 1'-ethoxyethoxy)propyl chloride and metal lithium undergo lithiation reaction in a high vacuum device to prepare (1'-ethoxyethoxy)propyllithium.

[0038] Polymerization adopts high vacuum (-3 Pa) and sealed anionic polymerization experiment technology. In the high vacuum polymerization device, 100 ~ 150mL THF is used as the polymerization solvent, 1.0mL 0.5mol / L 3 (1'-ethoxyethoxy) propyllithium is the initiator, and the initiator and C 3 f 7 CH 2 CH 2 CH 2 OCOCH=CH 2 (Molar ratio 1:1.2) After polymerization for 1 to 3 hours, quickly cool to -78°C with a liquid nitrogen / isopropanol bath, then slowly add 5.0 to 15.0 g of methyl styrene, and add 0.02 g of methyl styrene after polymerization for 0.5 to 1 hour. g CH 3 OH terminates the reaction. The reacted polymer is subjected to rotary evaporation at 60-70°C to remove the solvent, precipitation and purification with n-hexane, repeated three times, and finally dried in a vacuum oven...

Embodiment 2~4

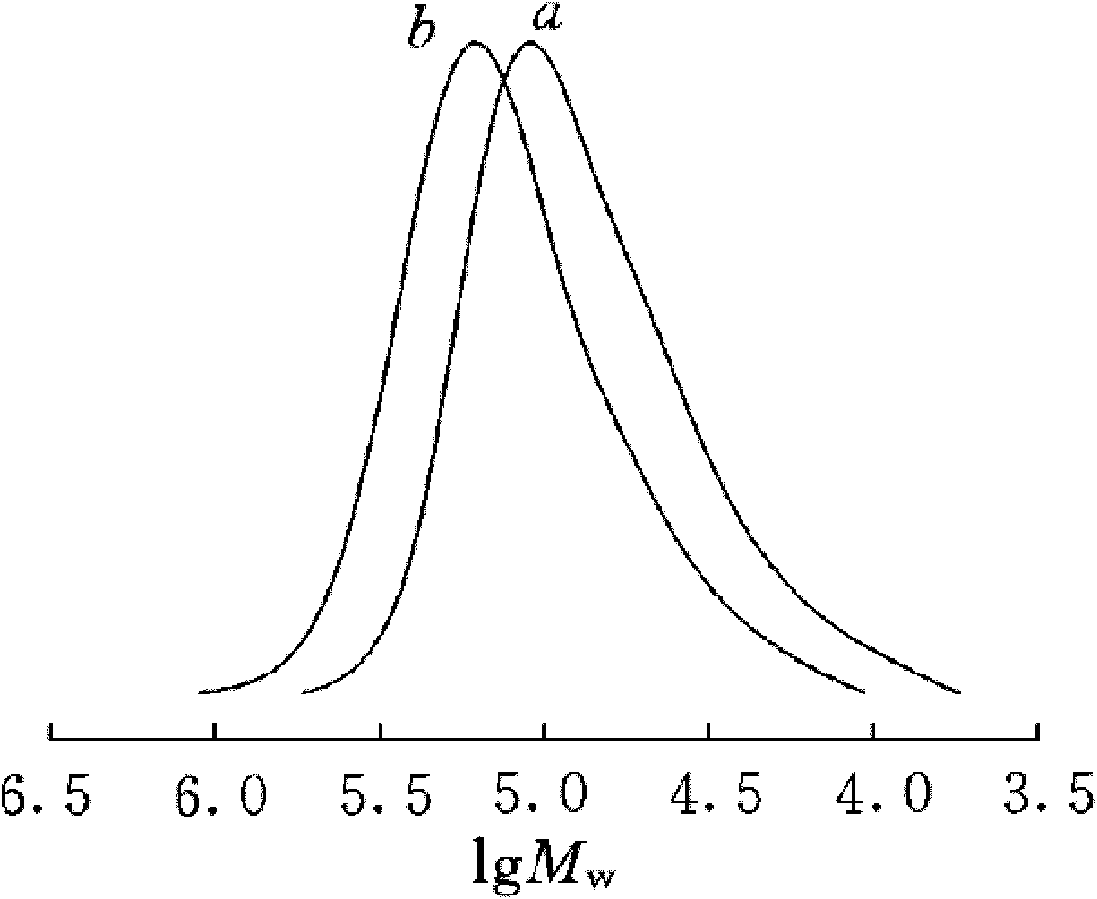

[0040] Except for changing the type of fluorine-containing monomer in Example 1, the initiator, solvent, second monomer, and polymerization temperature are the same as those described in Example 1. Wherein the fluorine-containing monomers used are respectively: (CF 3 ) 2 CF(CF 2 ) 2 C(CH 3 ) 2 OCOCH=CH 2 , (CF 3 ) 3 CCF 2 CH 2 C(CH 3 ) 2 OCOCH=CH 2 、CF 3 CF 2 CF 2 (CF 3 ) CFCH 2 CH 2 CH 2 CH 2 OCOCH=CH 2 . The number average molecular weight of the obtained polymer is 9000-10000.

Embodiment 5~8

[0042] Except for changing the type of fluorine-containing monomer and the second monomer in Example 1, the initiator, solvent, and polymerization temperature are the same as those described in Example 1. Wherein the second monomer used is 4-cyanophenyl acrylate, and the first monomers containing fluorine are respectively: The number average molecular weight of the obtained polymer is 1000-100000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com