Akermanite/PMMA composite bone cement with osteogenesis inducing function and preparation method of akermanite/PMMA composite bone cement

A technology of magnesia feldspar and bone cement, which is applied in surgical adhesives, medical science, surgery, etc., to achieve the effect of improving biological activity and biocompatibility, wide application, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the described magnesia feldspar / PMMA composite bone cement with the function of inducing osteogenesis comprises the following steps:

[0029] (1) The feldspar powder was prepared by sol-gel method. Tetraethyl orthosilicate was mixed with deionized water and 2mol·L -1 Nitric acid mixed and hydrolyzed with stirring for half an hour. Then, calcium nitrate and magnesium nitrate were sequentially added into the mixed solution according to the metering ratio, and a clear solution was obtained after stirring for 5 hours, then sealed in an oven at 60°C for 24 hours and dried at 120°C for 48 hours to obtain a xerogel. Ball mill the xerogel and pass through a 120-mesh sieve, and finally calcinate at 1300°C for 3 hours, and cool naturally to obtain feldspar powder;

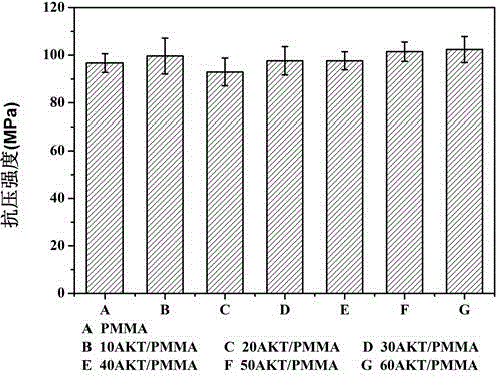

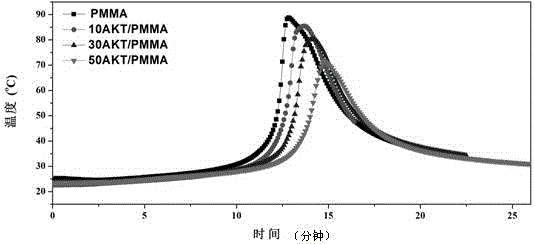

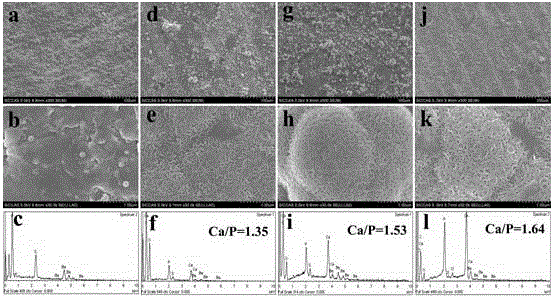

[0030] (2) sieve the feldspar powder obtained in step (1), uniformly mix the feldspar and PMMA powder of 5-60% by mass ratio, and then according to the ratio of bone cement monomer and PMMA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidification time | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com