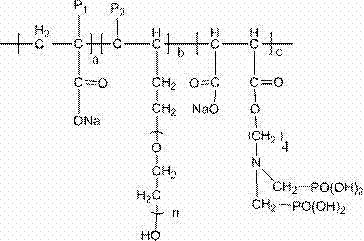

Polycarboxylate superplasticizer containing phosphine and preparation method thereof

A technology of phosphine polycarboxylate and water reducer, which is applied in the field of phosphine polycarboxylate water reducer and its preparation, can solve the problems of inability to meet the requirements of concrete construction and sustainable development, high energy consumption of the production process, environmental pollution, collapse Large changes in slump and other problems, to achieve the effects of easy scale-up and control of production, maintaining water solubility and steric hindrance, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

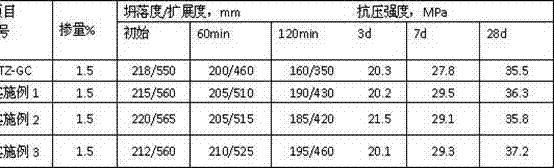

Examples

Embodiment 1

[0031] According to the following ingredients and weight ratio:

[0032] Isoprene polyoxyethylene ether (molecular weight 1600) 100g;

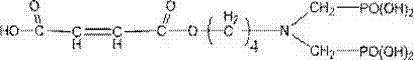

[0033] Component R (N,N Dimethylene Phosphonic Acid Aminobutyl Maleate) 16g;

[0034] Component R 1 (acrylic acid) 14.5g;

[0035] Component R 2 (Ascorbic acid) 0.35g;

[0036] Chain transfer agent (mercaptopropionic acid) 0.4g;

[0037] Initiator (27.5% hydrogen peroxide) 2.5g;

[0038] 145g of water;

[0039] Preparation:

[0040] S1, weigh raw materials according to the above formula;

[0041] S2. Put the weighed isoprene polyoxyethylene ether and component R into the reaction kettle, add 68g of water, start stirring, slowly raise the temperature to 35-45°C, and prepare a uniform concentrated solution;

[0042] S3, prepare dropwise component A, the R 1 Add 17g of water, stir evenly, and prepare a solution;

[0043] S4, prepare and add component B dropwise, and the R 2 Mix with the chain transfer agent and the remaining 60g of ...

Embodiment 2

[0046] According to the following ingredients and weight ratio:

[0047] Isoprene polyoxyethylene ether (molecular weight 3200) 100g;

[0048] Component R (N,N dimethylene phosphonic acid aminobutyl maleate) 9.5g;

[0049] Component R 1 (1:1 mixture of methacrylic acid and acrylic acid) 10g;

[0050] Component R 2 (sodium bisulfite) 0.55g;

[0051] Chain transfer agent (mixture of mercaptoacetic acid and mercaptopropionic acid) 0.3g;

[0052] Initiator (potassium persulfate) 2g;

[0053] 120g of water;

[0054] Preparation:

[0055] S1, weigh raw materials according to the above formula;

[0056] S2. Put the weighed isoprene polyoxyethylene ether and component R into the reaction kettle, add 55g of water, start stirring, slowly raise the temperature to 35-45°C, and prepare a uniform concentrated solution;

[0057] S3, prepare dropwise component A, the R 1 Add 15g of water, stir evenly, and prepare a solution;

[0058] S4, prepare and add component B dropwise, and the ...

Embodiment 3

[0061] According to the following ingredients and weight ratio:

[0062] Isoprene polyoxyethylene ether (molecular weight 2400) 100g;

[0063] Component R (N,N Dimethylene Phosphonic Acid Aminobutyl Maleate) 21g;

[0064] Component R 1 (acrylic) 9.5g;

[0065] Component R 2 (hanging white block) 0.8g;

[0066] Chain transfer agent (dodecyl mercaptan) 0.6g;

[0067] Initiator (ammonium persulfate) 1.5g;

[0068] 160g of water;

[0069] Preparation:

[0070] S1, weigh raw materials according to the above formula;

[0071] S2. Put the weighed isoprene polyoxyethylene ether and component R into the reaction kettle, add 75g of water, start stirring, slowly raise the temperature to 35-45°C, and prepare a uniform concentrated solution;

[0072] S3, prepare dropwise component A, the R 1 Add 25g of water, stir evenly, and prepare a solution;

[0073] S4, prepare and add component B dropwise, and the R 2 Mix with the chain transfer agent and the remaining 60g of water, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com