Side chain functional polymer and preparation method thereof

A functionalized polymer technology, applied in the field of side chain functionalized polymers and its preparation, can solve problems such as complex synthesis steps, achieve fast polymerization rate, reduce reaction steps, and realize the effect of rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

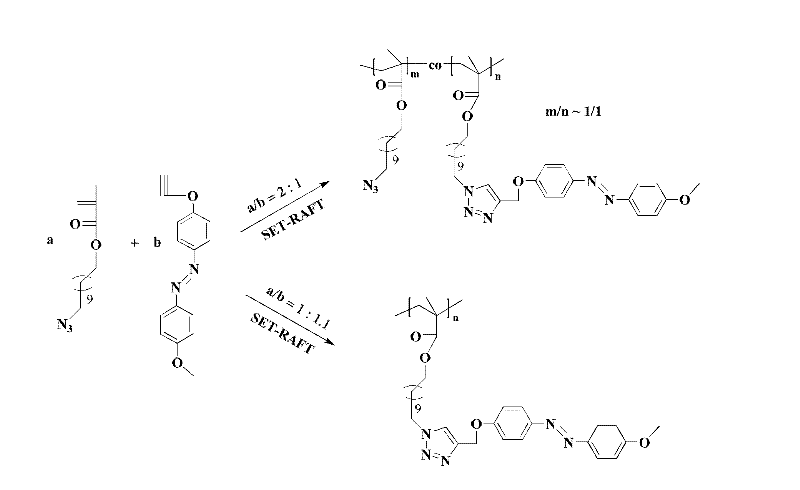

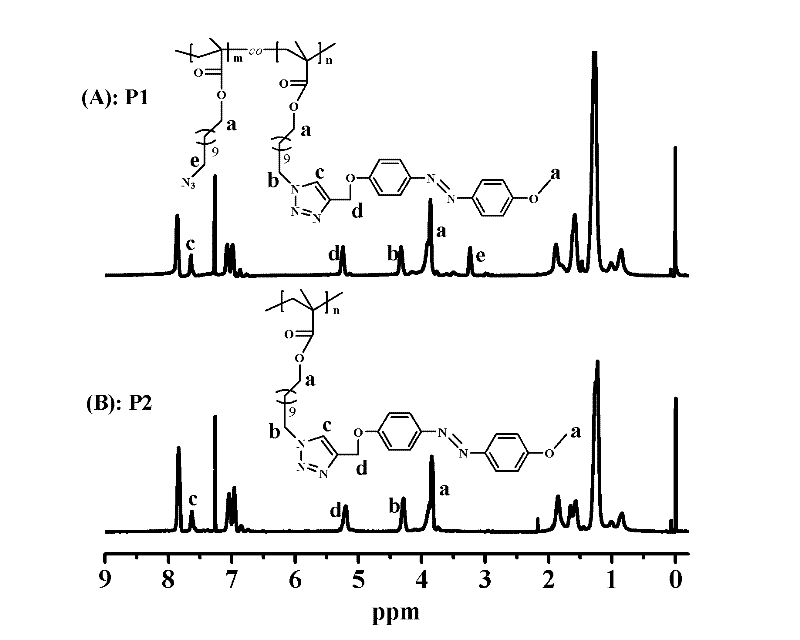

[0040] Example 1: One-step / one-pot method to prepare side chain functionalized polymers

[0041] (1) Preparation of monomers (reference: D.Damiron, M.Desorme, R-V.Ostaci, S.A.Akhrass, T.Hamaide, E.Drockenmuller, J.Polym.Sci.Part A: Polym.Chem.2009, 47, 3803): Add 12.55g of 11-bromoundecyl alcohol, 150mL of N,N-dimethylformamide and 9.75g of sodium azide aqueous solution in the reaction flask in sequence, stir at 80°C for 24 hours, then , add 150mL of dichloromethane to the reaction flask, the solution obtained is washed three times with 150mL of water, the organic layer is collected and dried overnight with anhydrous magnesium sulfate, then filtered, and rotary evaporated to obtain the colorless intermediate 11-azide undecyl alcohol. Take 8.50g of 11-undecanol azide, 4.85g of triethylamine and 100mL of anhydrous tetrahydrofuran in a reaction flask, and use an ice-salt bath to keep the temperature of the reaction solution at 0°C, and add 5.06g of methacryloyl chloride with A ...

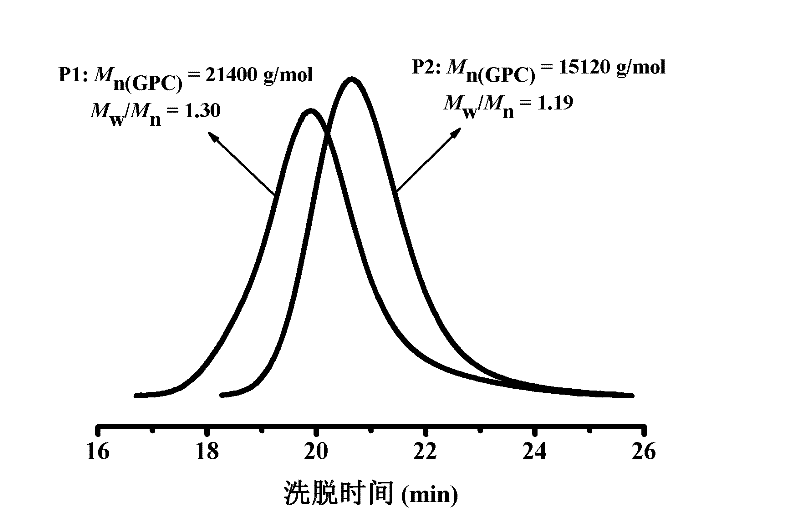

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com