Branched-structure polyurethane-silicious polyacrylate hot melt adhesive and preparation method thereof

A technology of polyacrylate and branched structure, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of high melting temperature, low strength, poor weather resistance of hot melt adhesives, etc., and achieve wet Effects of low gas sensitivity, good storage stability, and low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

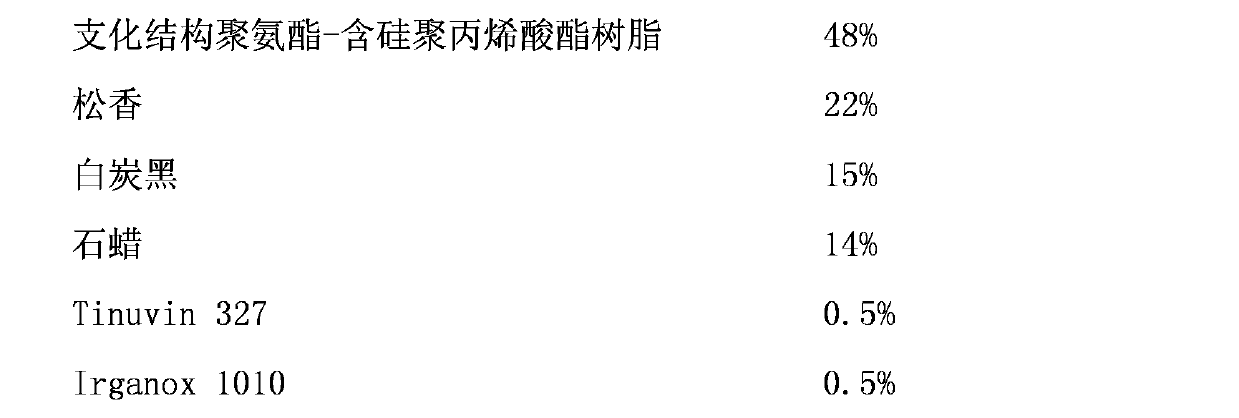

Embodiment 1

[0032] 1. Preparation of branched structure polyurethane-silicon-containing polyacrylate resin:

[0033] Add 17.2g of dimethylolbutyric acid and 120g of polycarbonate diol (Mn=3000) into a reactor equipped with a stirring and temperature control device, heat up to 50°C for melting and mixing, add 65g of dicyclohexylmethane diisocyanate, At the same time, 100g of n-butyl acrylate was added, and the temperature was controlled to 88°C for 95 minutes to obtain a polyurethane prepolymer with hydrophilic groups; 4g of trimethylolpropane and 5g of methyl ethyl ketone oxime were added, and the temperature was controlled to 85°C to continue the reaction for 150 minutes to obtain branched Chemical structure end-capped polyurethane prepolymer; add 11g triethylamine, add 500g deionized water to emulsify for 40min under high-speed stirring, then add 0.3g ammonium persulfate initiator, heat up to 80°C and react for 70min; dropwise add 10g vinyl three Ethoxysilane and 35g methyl methacrylate...

Embodiment 2

[0042] 1. Preparation of branched structure polyurethane-silicon-containing polyacrylate resin:

[0043] Add 18.2g of dimethylolbutyric acid and 130g of polytetrahydrofuran diol (Mn=2900) into a reaction kettle equipped with a stirring and temperature control device, heat up to 50°C for melting and mixing, add 70g of dicyclohexylmethane diisocyanate, and simultaneously Add 80g of n-butyl acrylate, control the temperature to 85°C and react for 120min to obtain a polyurethane prepolymer with hydrophilic groups; add 4.5g of trimethylolpropane and 5.6g of methyl ethyl ketone oxime, control the temperature to 85°C and continue to react for 120min to obtain Polyurethane prepolymer end-capped with branched structure; add 12g of triethylamine, add 500g of deionized water to emulsify for 50min under high-speed stirring, then add 0.4g of ammonium persulfate initiator, heat up to 82°C for 70min; add 10g of vinyl Triethoxysilane and 50 g of methyl acrylate continued to react for 150 min, ...

Embodiment 3

[0052] 1. Preparation of branched structure polyurethane-silicon-containing polyacrylate resin:

[0053]Add 18g of dimethylolpropionic acid and 130g of polytetrahydrofuran diol (Mn=2900) into a reaction kettle equipped with a stirring and temperature control device, heat up to 45°C for melting and mixing, add 90g of isophorone diisocyanate, and simultaneously add 95g of ethyl acrylate, temperature controlled to 88°C and reacted for 100min to obtain a polyurethane prepolymer with hydrophilic groups; add 7.5g of trimethylolpropane and 4.8g of methyl ethyl ketone oxime, temperature controlled to 75°C and continue to react for 170min to obtain branched Structure-terminated polyurethane prepolymer; add 11g of triethylamine, add 750g of deionized water to emulsify for 55min under high-speed stirring, then add 1.5g of ammonium persulfate initiator, raise the temperature to 77°C for 80min; add dropwise 12g of vinyl trimethoxy base silane and 50g methyl methacrylate, continue to react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com