Slump loss resistant type gather carboxylate water-reducing agent and preparation method thereof

A technology of polycarboxylate and water reducing agent, applied in the field of concrete admixtures, can solve the problems of unstable raw materials of macromolecular monomers, complicated intermediate separation and purification process, great influence of cement hydration, etc., and achieves superior performance and easy promotion. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

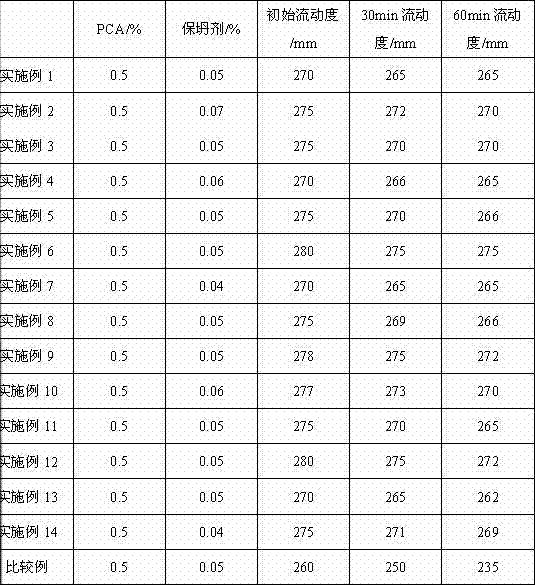

Examples

Embodiment 1

[0041] Add 150g of IB-500 and 100.0g of deionized water into a 1000ml four-neck flask equipped with mechanical stirring, temperature controller, and dripping device, and heat up while stirring and dissolving. When the temperature rises to 50°C, add 1.1g of 30% Hydrogen peroxide, when the temperature reaches 60 ℃, start to drop the mixed aqueous solution of acrylic acid and acrylamide (43.2g of acrylic acid, 63.9g of acrylamide dissolved in 26.8g of deionized water), the mixed solution of vitamin C and thioglycolic acid (0.5g Vitamin C, 0.3g thioglycolic acid dissolved in 39.2g deionized water), the adding time of the mixed solution of acrylic acid and acrylamide is controlled at 2.5 hours, the dropping time of vitamin C solution is controlled at 3h, and the reaction temperature is controlled at 60±2°C . After the dropwise addition, continue to keep warm for 0.5 hours, then cool to below 40°C, add sodium hydroxide aqueous solution (24.0g sodium hydroxide dissolved in 231.1g dei...

Embodiment 2

[0043]Add 160g of IB-1000 and 106.7g of deionized water into a 1000ml four-neck flask equipped with mechanical stirring, temperature controller and dripping device, and heat up while stirring and dissolving. When the temperature rises to 50°C, add 1.0g of over Ammonium sulfate, when the temperature reaches 60 ° C, start to drop the mixed aqueous solution of acrylic acid and hydroxyethyl acrylate (34.6g of acrylic acid, 55.7g of hydroxyethyl acrylate dissolved in 22.6g of deionized water, the mixed solution of sodium sulfite and mercaptopropionic acid (0.4g of sodium sulfite, 0.4g of mercaptopropionic acid dissolved in 39.2g of deionized water), the dropping time of the mixed solution of acrylic acid and hydroxyethyl acrylate is controlled at 2.5 hours, the dropping time of sodium sulfite solution is controlled at 3h, and the reaction temperature is controlled at 60±2°C. After the dropwise addition, continue to keep warm for 0.5 hours, then cool to below 40°C, add sodium hydroxi...

Embodiment 3

[0045] Add 155g of IB-1500 and 103.3g of deionized water into a 1000ml four-neck flask equipped with mechanical stirring, temperature controller, and dripping device, and heat up while stirring and dissolving. When the temperature rises to 50°C, add 1.2g of over Potassium sulfate, when the temperature reaches 60°C, start to drop the mixed aqueous solution of acrylic acid and hydroxypropyl acrylate (22.3g of acrylic acid, 26.9g of hydroxypropyl acrylate dissolved in 12.3g of deionized water), vitamin C and thioglycolic acid solution (0.8g vitamin C, 0.5g mercaptoacetic acid dissolved in 63.7g deionized water), the dropping time of the mixed solution of acrylic acid and hydroxypropyl acrylate was controlled at 2.5 hours, the dropping time of the vitamin C solution was controlled at 3h, and the reaction temperature Controlled at 60±2°C. After the dropwise addition, continue to keep warm for 0.5 hours, then cool to below 40°C, add sodium hydroxide aqueous solution (12.4g sodium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com