Composition capable of forming composite bone cement and bone cement formed by same

A composition and bone cement technology, which can be used in drug delivery, tissue regeneration, prostheses, etc., and can solve problems such as injury, surrounding tissue spinal cord, and lower maximum curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] This embodiment provides a composition capable of forming a composite bone cement and the bone cement formed therefrom, specifically, it can be embodied in the following method for preparing a composite bone cement or its slurry, and the method includes the following steps:

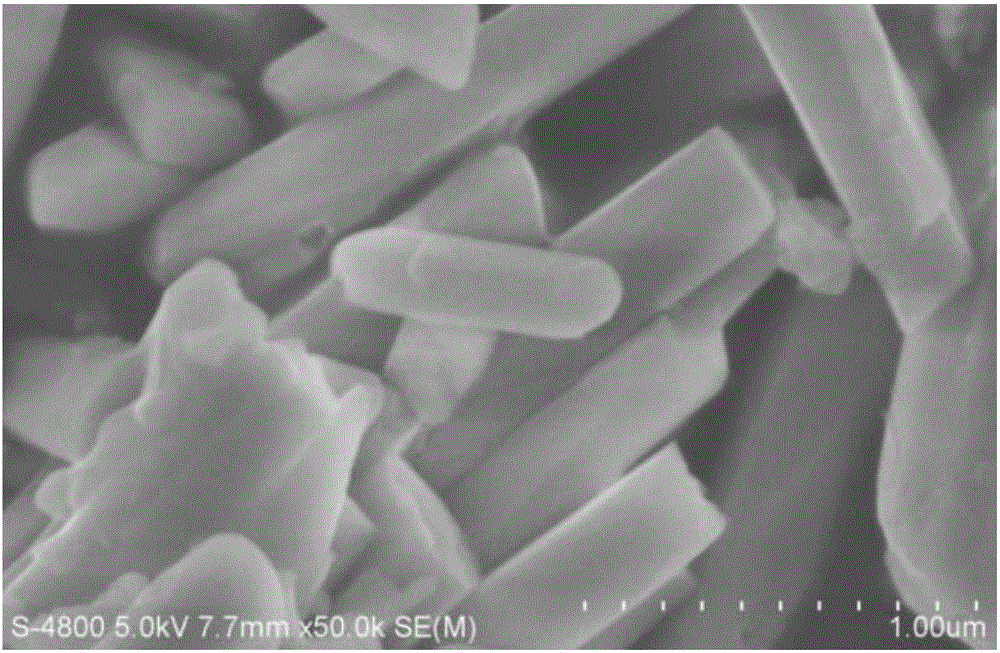

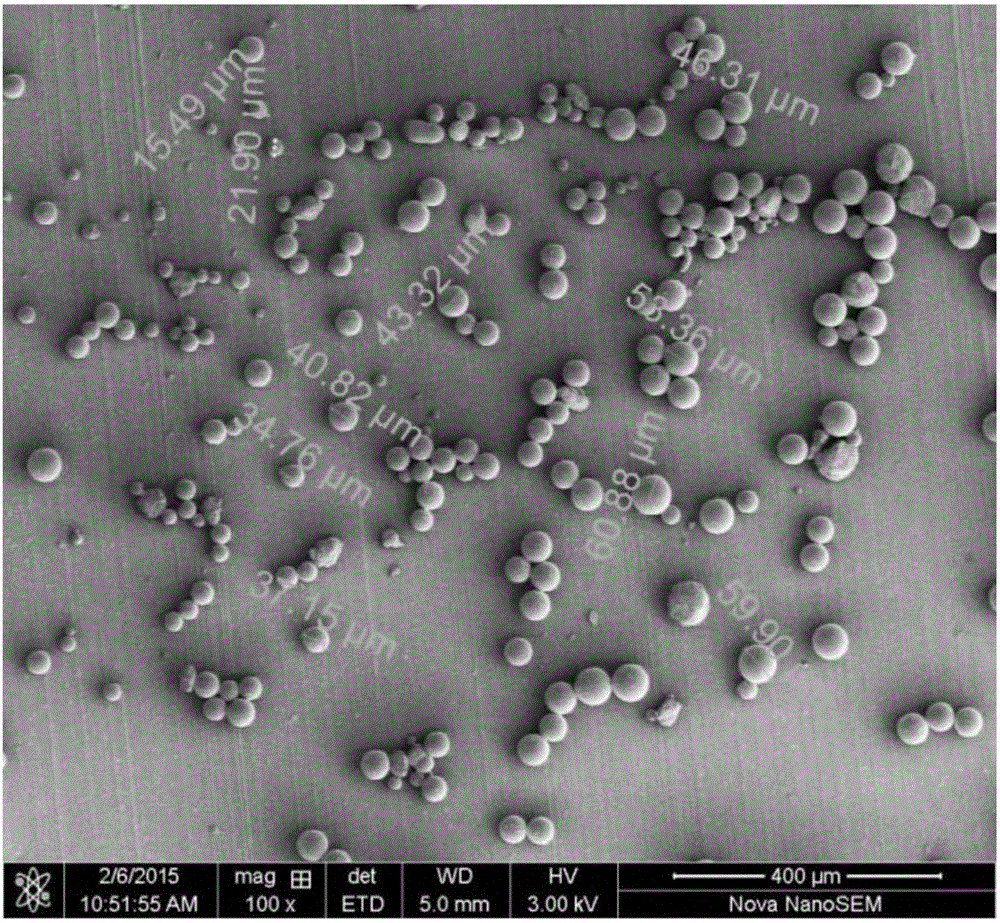

[0102] Select the polymethyl methacrylate (PMMA) powder with a particle size of 40-60 μm prepared by the aforementioned method, and see the microscopic morphology and particle size of the PMMA powder. figure 2 . Select natural tuna fish bone powder / hyaluronic acid microspheres prepared by the aforementioned method, wherein the mass percentage of tuna fish bone powder is 60%, the particle size is about 150 μm, and its microscopic appearance is shown in image 3 shown. The above-mentioned natural tuna fish bone powder / hyaluronic acid microspheres and PMMA powder, polymerization initiator dibenzoyl peroxide (BPO) are mixed according to the mass ratio of 30%: 68%: 2%, and obtained after disinfection ...

Embodiment 2

[0120] This embodiment provides a composition that can be formed and a bone cement formed therefrom. Specifically, it can be embodied in the following method for preparing a composite bone cement or its slurry. The method includes the following steps:

[0121] (1) Preparation of solid phase powder:

[0122] Select the polymethyl methacrylate (PMMA) powder with a particle size of 60-80 μm and the tuna fish bone powder / hyaluronic acid microspheres with a particle size of 40-80 μm prepared by the aforementioned method. Mix PMMA, tuna fish bone meal / hyaluronic acid microspheres and polymerization initiator dibenzoyl peroxide (BPO) according to the mass ratio of 60%:39%:1%, and obtain the solid phase of composite bone cement after disinfection powder;

[0123] (2) Preparation of solidified liquid:

[0124] Mix N,N-dimethyl-p-toluidine (DMPT) and liquid methyl methacrylate (MMA) uniformly according to the mass percentage of 1.5%:98.5% to prepare a solidified solution of composite ...

Embodiment 3

[0131] This embodiment provides a composition capable of forming a composite bone cement and the bone cement formed therefrom, specifically, it can be embodied in the following method for preparing a composite bone cement or its slurry, and the method includes the following steps:

[0132] (1) Preparation of solid phase powder:

[0133] Select polymethyl methacrylate (PMMA) powder with a particle size of 60-80 μm prepared by the aforementioned method, tuna fish bone powder / hyaluronic acid microspheres with a particle size of 100-200 μm and polymerization initiator diphenyl peroxide Formyl (BPO), mixed according to the mass ratio of 5%: 93.5%: 1.5%, is sterilized to obtain the solid-phase powder of composite bone cement;

[0134] (2) Preparation of solidified liquid:

[0135] Mix N,N-dimethyl-p-toluidine (DMPT) and methyl methacrylate (MMA) uniformly according to the mass percentage of 3%:97%, and prepare the solidifying solution of the composite bone cement;

[0136] (3) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com