Environment-friendly flocculating agent and application thereof

A flocculant, environmentally friendly technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problem of unreasonable treatment methods for solid residues, waste of nutrients, and difficult to clean and other problems, to achieve the effect of controllable product quality, reducing impurities, and saving the amount of flocculant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

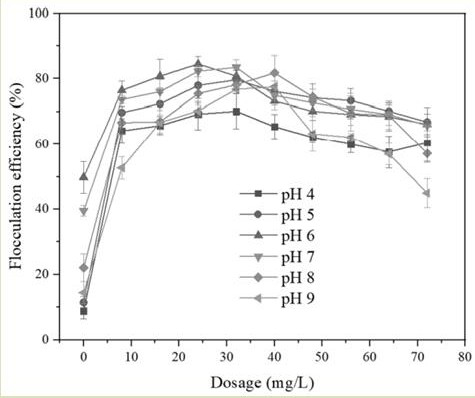

Image

Examples

Embodiment 1

[0034] A kind of dextran-citric acid anion type environment-friendly flocculant, the preparation method adopts the following steps:

[0035]1) Use acetic acid-calcium acetate buffer solution with pH=5.4 to prepare 0.58mol / L sucrose solution, add dextran sucrase enzyme solution to it, and the enzyme concentration is 5.0U / mL; carry out enzyme catalysis in a shaker at 25°C and 100rpm The reaction was carried out for 24 hours; the kinetic viscosity reached 9000CPS at the end of the reaction; the high-molecular-weight dextran product was precipitated with ethanol and washed twice, and then dried in a constant temperature blast oven at 40°C; the high-molecular-weight dextran product was dried and ground to obtain a high molecular weight Dextran solid powder;

[0036] 2) Prepare high molecular weight dextran solution and citric acid solution, adjust the pH value of citric acid solution to 7.5 with sodium hydroxide solution, mix and stir with dextran solution for 5 minutes, the concen...

Embodiment 2

[0038] A dextran-citric acid anion-type environmentally friendly flocculant, on the basis of Example 1, in step 2), the dextran concentration is set to 50g / L in the mixed solution, and the final molar ratio of citric acid to dextran anhydroglucose units is 1:1, other The conditions are the same as in Example 1.

Embodiment 3

[0040] A dextran-citric acid anion-type environmentally friendly flocculant, on the basis of Example 1, in step 2), the dextran concentration is set to 10g / L in the mixed solution, and the final molar ratio of citric acid to dextran anhydroglucose units is 0.1:1, and other The conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com