Patents

Literature

37 results about "Dextran product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

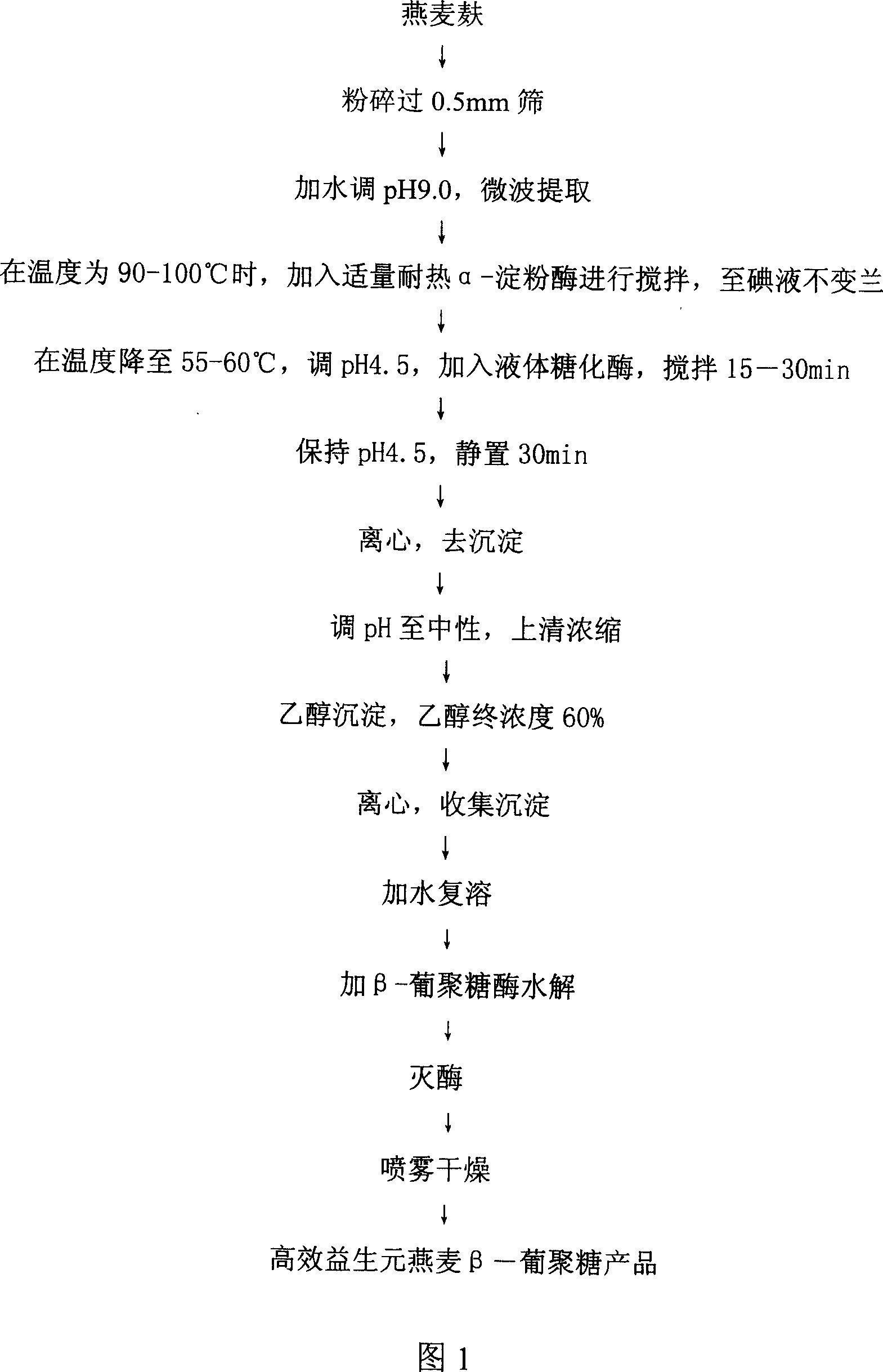

Process for preparing oat beta-glucans

InactiveCN1966531APromote growthInhibition of reproductionEnzymesFermentationGlucanaseEthanol precipitation

This inventnion relates to a preparation method for high-efficiency prebiotics oat beta-glucan, belonging to the quintessential processing technologies of oat. The said method includes using oat bran as raw materials, crushing, microwave-assisted-extracting, adding amylase and glucoamylase, isoelectric-point-precipitating, centrifugating and separating, concentrating the supernatant, precipitating with ethanol, centrifugating and collecting the precipitation, solving with water, hydrolyzing with beta-glucanase, and spray-drying process to obtain the high-efficiency prebiotics oat beta-glucan with significantly enhanced intestinal and fecal bifidobacteria and actobacillus value-added effect. The method is scientifically and rationally designed, and of great significance in achieving the comprehensive utilization of resources oat and increasing its added value.

Owner:JIANGNAN UNIV

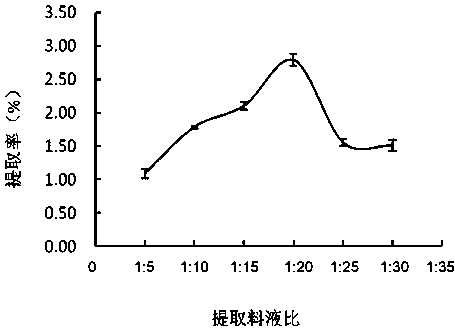

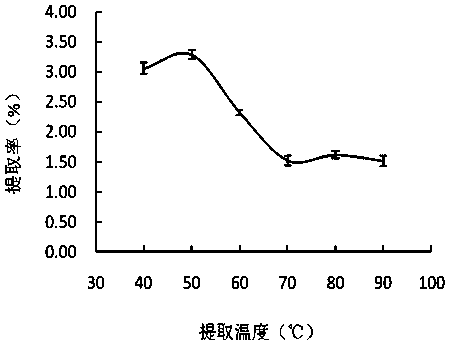

Method for extracting highland barley Beta-dextran and dietary fiber by combined-enzyme method

InactiveCN101555294AFully develop and utilizeIncrease economic value addedFood preparationFiberBARLEY BRAN

The invention discloses a method for extracting a Beta-dextran in highland barley bran and preparing a highland barley dietary fiber, belonging to the field of food processing. The method comprises the following steps of: extracting and centrifuging the highland barley bran taken as raw material at an alkaline condition by zymohydrolysis of secondary cellulose, thus obtaining a deposition A and a supernatant; depositing and centrifuging the supernatant under an acidic condition to remove albumen; adding a high-temperature resistant Alpha-amylase into the supernatant under a neutral condition for zymohydrolysis; centrifuging, depositing in water, depositing and re-dissolving the supernatant by water, centrifuging and taking the supernatant; repeatedly depositing the supernatant by a ammonium sulphate and obtaining the Beta-dextran product; adding a composite enzyme in the deposition A for zymohydrolysis; adding a hydrogen peroxide in the deposition A for decoloring; washing the deposition A repeatedly by water; obtaining a solid by centrifuging; and drying the solid at low temperature to obtain the highland barley dietary fiber. The method can sufficiently utilizes the highland barley bran, obtains two products of Beta-dextran and dietary fiber, effectively improves the economical additional value of the highland barley bran and has important realistic significance and wide application prospect for developing high-tech industries.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

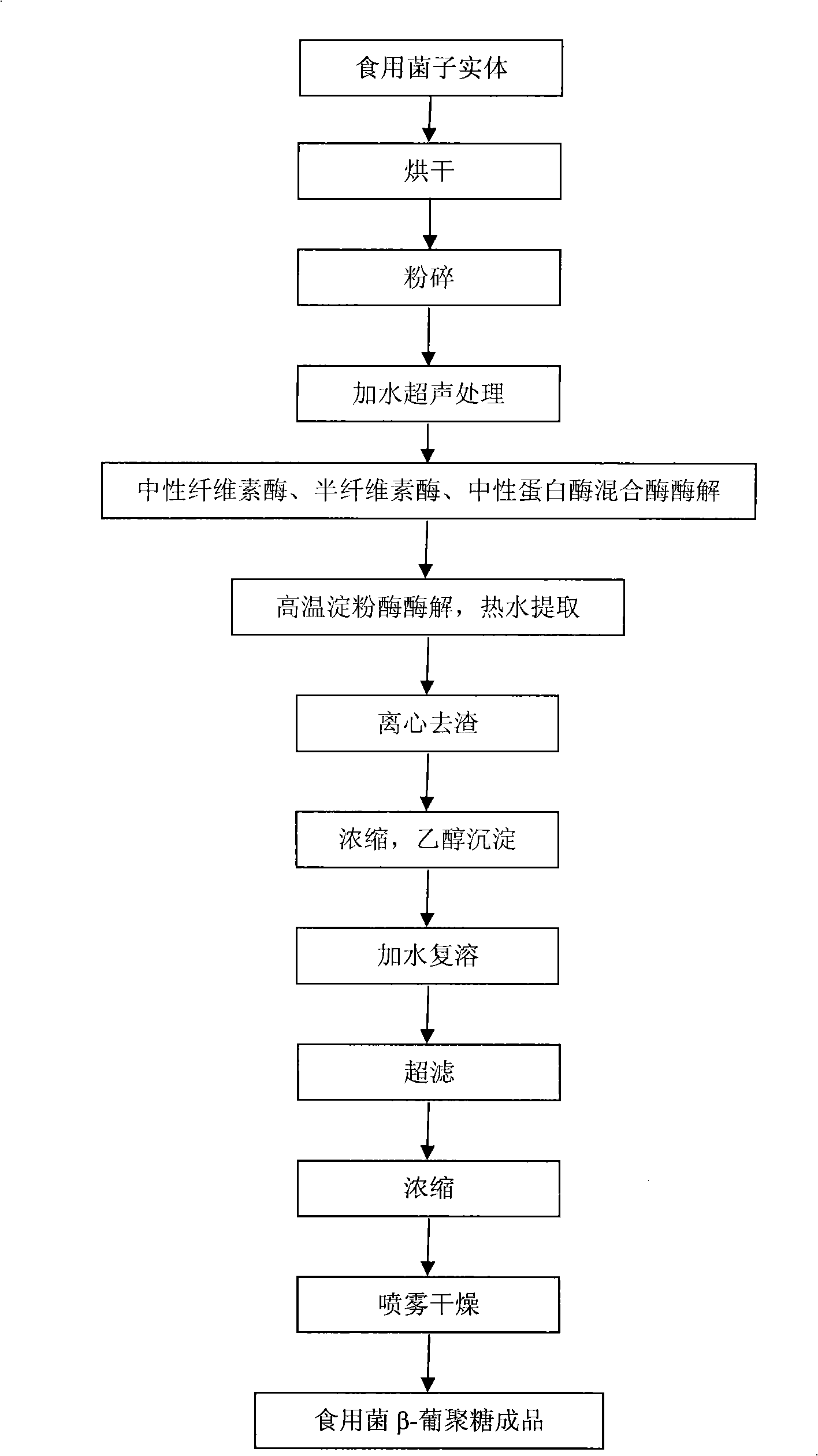

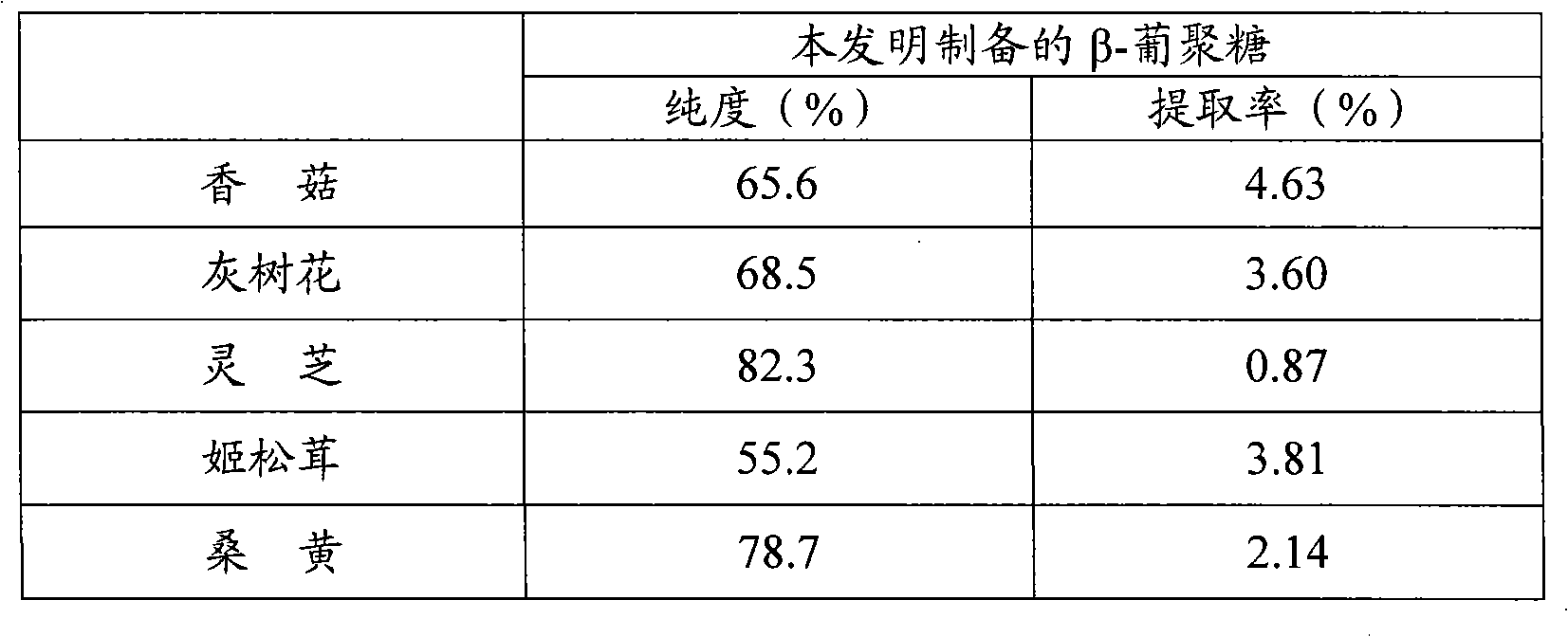

Preparation of edible fungus beta-dextran

The invention provides a preparation method of edible fungi Beta-glucan. In the method, ultrasonic pretreatment, neutral cellulose, hemi-cellulase, the cellulase enzyme digested by a neutral protease mixed enzyme, hemicellulose (like xylan, gelose and a plurality of heteroglycans) and proteins (and peptides) are mainly adopted; a high-temperature amylase is added for the enzyme digestion of the amyloid simultaneously when hot water is extracted; and a target is obtained through a sequent ethanol deposition and the edible fungi Beta-glucan with better activity is further obtained through the hyperfiltration of a film with an interception of 10,000. The preparation method has the advantages that: the product purity of the edible fungi Beta-glucan by adopting the method is high (55.2 to 82.3 percent); the preparation process does not have the residues of poisonous and harmful chemical reagents; the product is safe; the technical condition is moderate and is easy to be operated; and the preparation method is suitable for preparing all the edible fungi Beta-glucan and is suitable for commercial production.

Owner:ZHEJIANG UNIV OF TECH

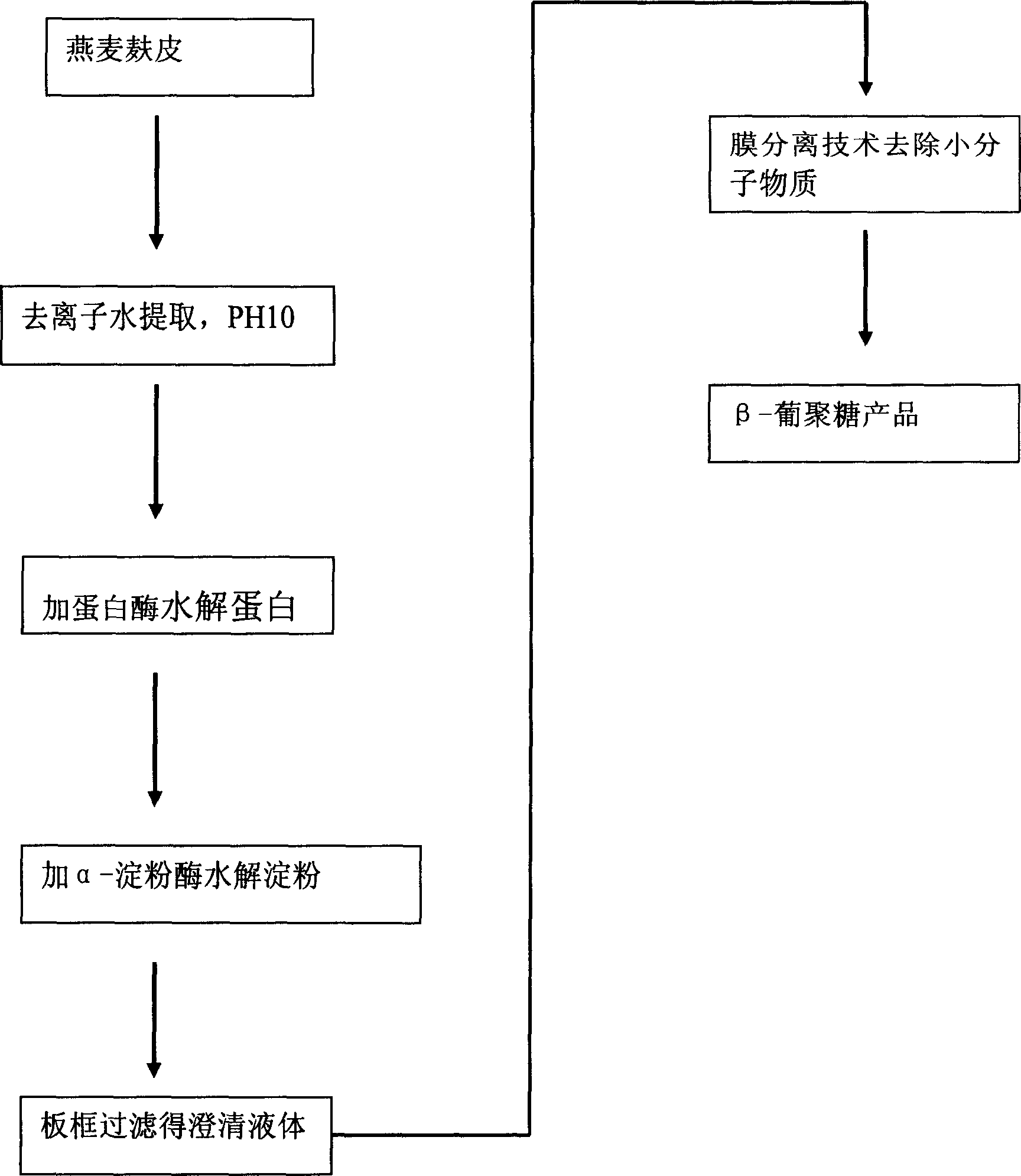

Method of extracting avenabeta glucosan

A process for extracting beta-glucosan from oats includes such steps as mixing oats bran with water, stirring at 50-60 deg.C, regulating pH=8-10, adding proteinase, hydrodyzing the protein in oats bran, adding alpha-amylase, treating at 80 deg.C, filtering to obtain clear liquid, ultrafiltering, and freeze-drying.

Owner:北京三友汇智生物技术有限公司

Method for extracting beta-D-glucan from cell walls of candida utilis

The invention provides a method for extracting beta-D-glucan from cell walls of candida utilis. The method includes steps of acquiring cells of the candida utilis; carrying out induction autolysis on the cells of the candida utilis; carrying out high-temperature digestion; ultrasonically breaking the walls; carrying out high-temperature extraction; carrying out degreasing; carrying out enzymatic hydrolysis to remove proteins, to be more specific, preparing suspension from degreased crude glucan by the aid of phosphoric acid buffer solution, carrying out enzymatic hydrolysis, carrying out reaction, then washing reaction products by the aid of water, centrifuging the reaction products, adding water into the reaction products, sufficiently uniformly mixing the reaction products and the water with one another to obtain mixtures, then heating the mixtures, deactivating enzymes, centrifuging the mixtures and freezing and drying the mixtures to obtain beta-D-glucan products. The method has the advantages that product degradation effects due to the traditional methods implemented by the aid of acid and alkali reagents can be prevented, and the method for extracting beta-glucan can be carried out under mild conditions; potato juice without the proteins is used as a culture medium for the candida utilis, accordingly, environmental pollution due to the discarded potato juice can be abated, and the method has important significance on environmental protection.

Owner:SHANGHAI INST OF TECH

Method for extracting water-soluble beta-glucan with high purity from grain bran

The invention discloses a method for extracting water-soluble beta-glucan with high purity from grain bran, comprising the following steps: taking grain bran as raw material, adding water and mixing evenly, carrying out high-pressure homogeneity, extraction, enzymolysis to obtain primary purifying solution, then adding yeast for fermentation, heating and precipitating protein and centrifuging to obtain two-stage purifying solution, spraying and drying to obtain the water-soluble beta-glucan product with high purity. The extraction method has the advantages of simple process, easy operation and low cost, and the prepared water-soluble beta-glucan has high purity and activity and fine and stable solubility, which is applicable to various drinks.

Owner:WENGYUAN GUANGYE QINGYI FOOD TECH +1

Preparation of high-purity immunological activity yeast beta-1,3-dextran with immunological activity

The invention discloses a method for preparing a high-purification yeast immunocompetence beta-1, 3-hyskon. In the preparation method, yeast raw material, after the pretreatment of autolysis, experiences enzymolysis and the precipitation thereof is collected after centrifugal filtration; after alkali treatment, the precipitation is neutralized by adding acid, washed, dehydrated, dried and crashed, and then the high-purification yeast immunocompetence beta-1, 3-hyskon product is obtained. The preparation method of the invention has the advantages of moderate condition, simple technique, easy operation and high yield, conforming to the policy of national cleaner production. Therefore, the invention is an environment-friendly and industrially feasible technical route. The product obtained by using the preparation method of the invention is characterized by high purification and high activity and is capable of obviously strengthening human body immunity, inhibiting the growth of a tumor and lowering cholesterin, thus can be applied in the industries of food, medicine and cosmetics.

Owner:GUANGDONG FOOD IND INST

Preparation method and use of low-molecular weight beta-glucan

The invention discloses a preparation method and a use of low-molecular weight beta-glucan and belongs to the technical field of food and beverage processing. The preparation method comprises the following steps of preparing an aqueous solution having a mass concentration of 1-5% from marketed food-grade cereal beta-glucan, carrying out treatment by endo-type beta-glucanase for 0.5-4h, controlling viscosity (2%, <100cp) and molecular weight (of 10-100KDa), carrying out decoloring by active carbon, collecting beta-glucan having the molecular weight of 10-100KDa by an ultrafilter membrane, and carrying out freeze drying to obtain a product. The low-molecular weight beta-glucan can be used in foods such as beer and beverages, improves daily intake of beta-glucan, improves human immunity and reduces cholesterol.

Owner:JIANGNAN UNIV

Enzyme treatment of glucans

InactiveUS20050255565A1Increase mobilityEnhanced ability to stimulate immune systemFungiSugar derivativesBiotechnologyGlucanase

β-(1-6)-Glucanase treatment of glucan from yeast cells, pure or feed grade, especially yeast from the family Saccharomyces and particularly Saccharomyces cerevisiae, provides a novel glucan product suitable for use in enhancing the stimulation of host animal immune systems. Solubilization of such yeast cell glucan is further disclosed to extend the usefulness of yeast cell glucan as an adjuvant.

Owner:BIOTEC PHARMACON

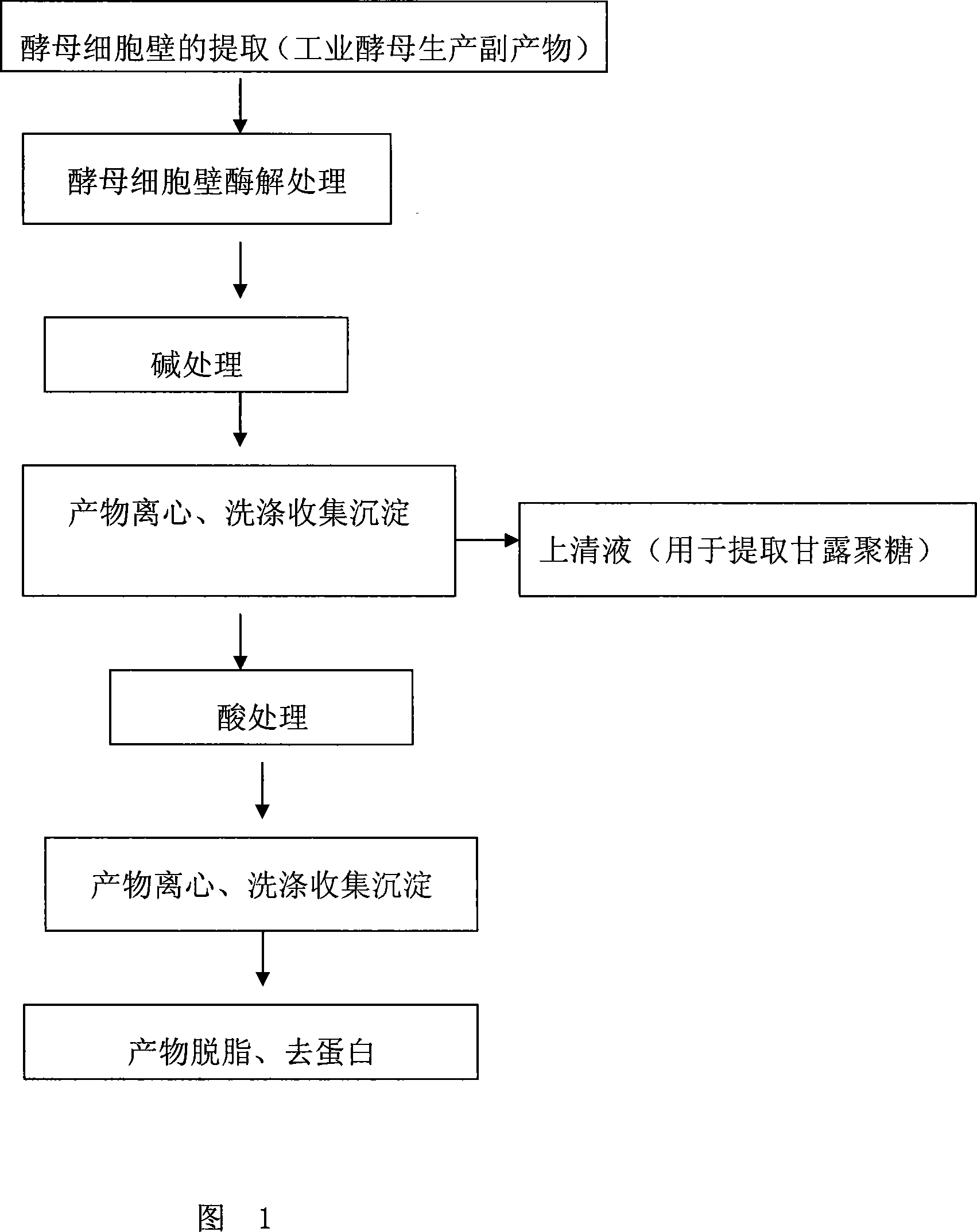

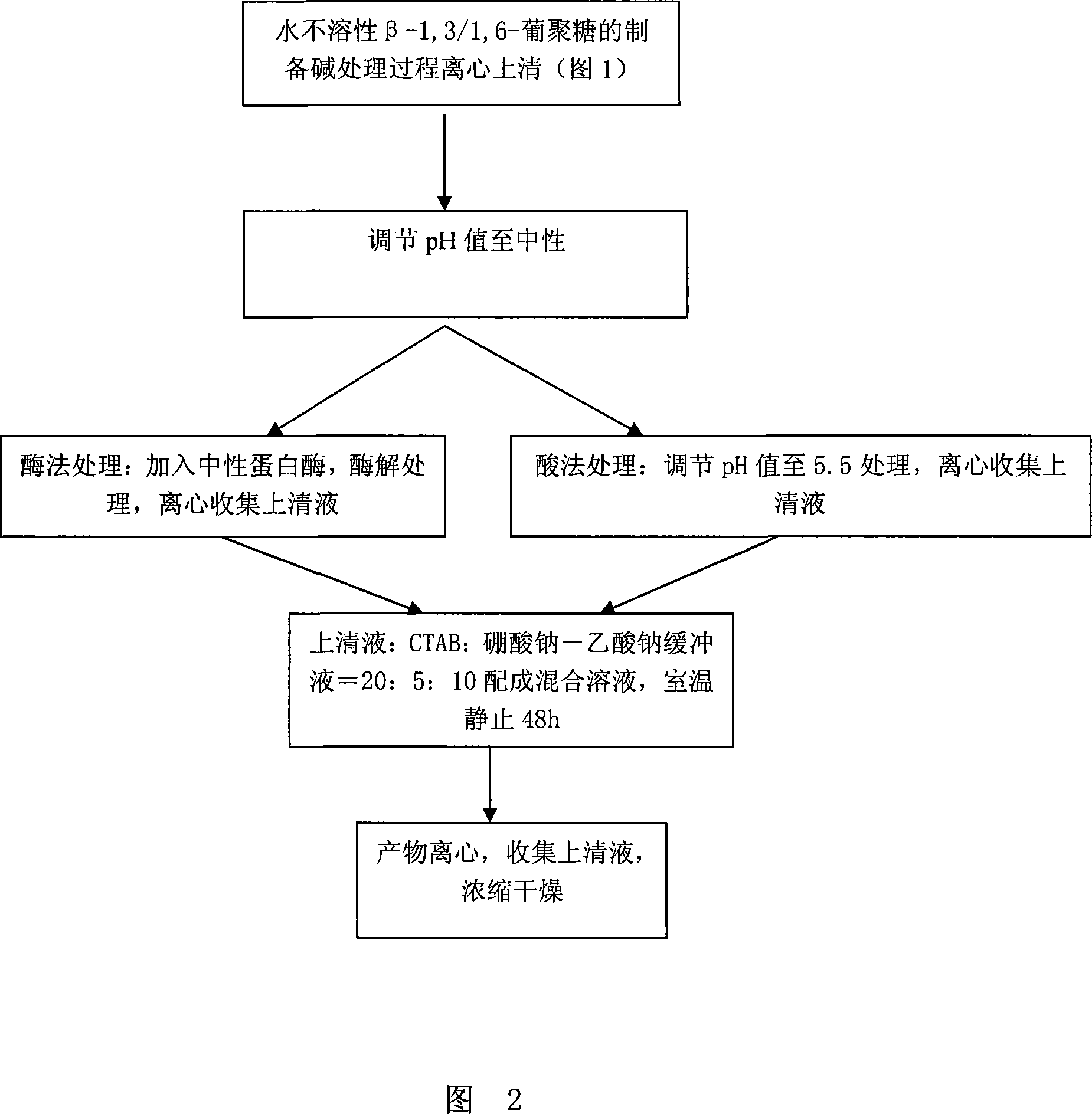

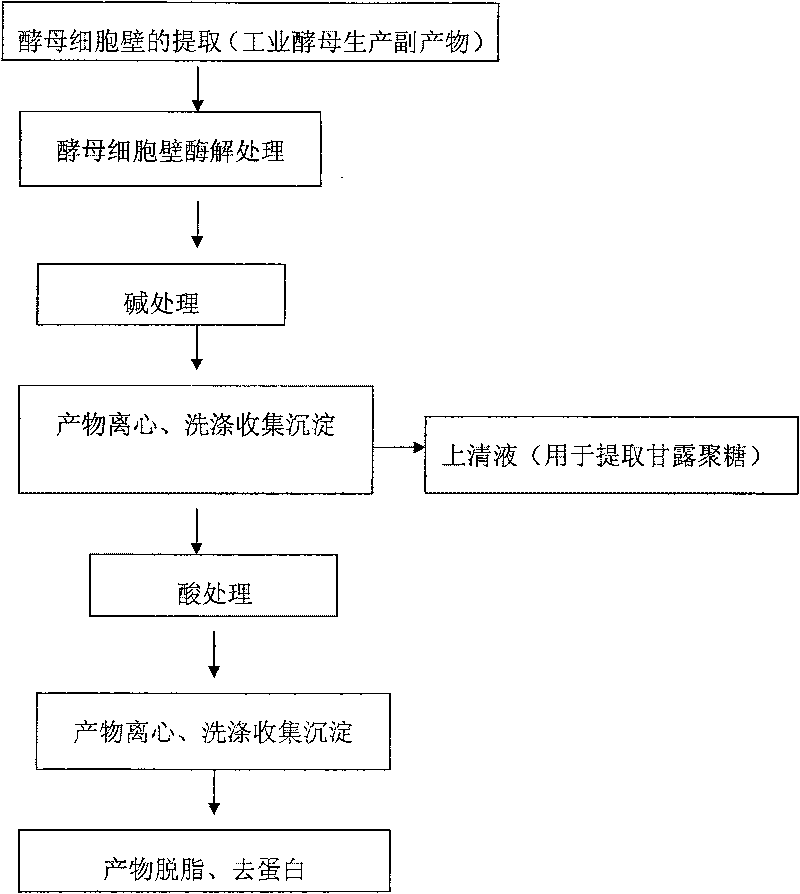

Method for preparing water-insoluble beta-1,3/1,6-dextran

The invention discloses a method for preparing water-insoluble beta-1, 3 / 1, 6-qlucan. The method has the steps as follow: 1)adding lysozyme into yeast cell wall suspending liquid for enzymolysis, centrifugation and collection at a temperature between 35 and 40 DEG C; 2) putting the product achieved from step 1) into NaOH solution and stirring for centrifugation and collection at a temperature between 35 and 4 DEG C; 3) depositing the product achieved from step 2) into acetic acid solution having concentration expressed in percentage by volume of 2-8 percent and stirring for centrifugation and collection; 4) stirring and washing the deposition after acid treatment and centrifugation of the step 3)by absolute ethyl alcohol and acetone and ether extract sequentially, and laying aside the treated ether extract for 12 to 24 hours, and drying in the centrifugation and collection way to achieve water-insoluble beta-1, 3 / 1, 6-qlucan. The invention is simple in control, and the beta-1,3-qlucan and the 1,6-qlucan prepared by the method have high purity and yield, and has the protein content and the fat content less than 1 percent.

Owner:CHINA AGRI UNIV

Method or Use of a Solubilized Glucan Product to Increase Immunostimulation in Animals

InactiveUS20080124349A1Increase mobilityEnhanced ability to stimulate immune systemOrganic active ingredientsBiocideBiotechnologyAdjuvant

β-(1-6)-Glucanase treatment of glucan from yeast cells, pure or feed grade especially yeast from the family Saccharomyces and particularly Saccharomyces cerevisiae, provides a novel glucan product suitable for use in enhancing the stimulation of host animal immune systems. Solubilization of such yeast cell glucan is further disclosed to extend the usefulness of yeast cell glucan as an adjuvant.

Owner:BIOTEC PHARMACON

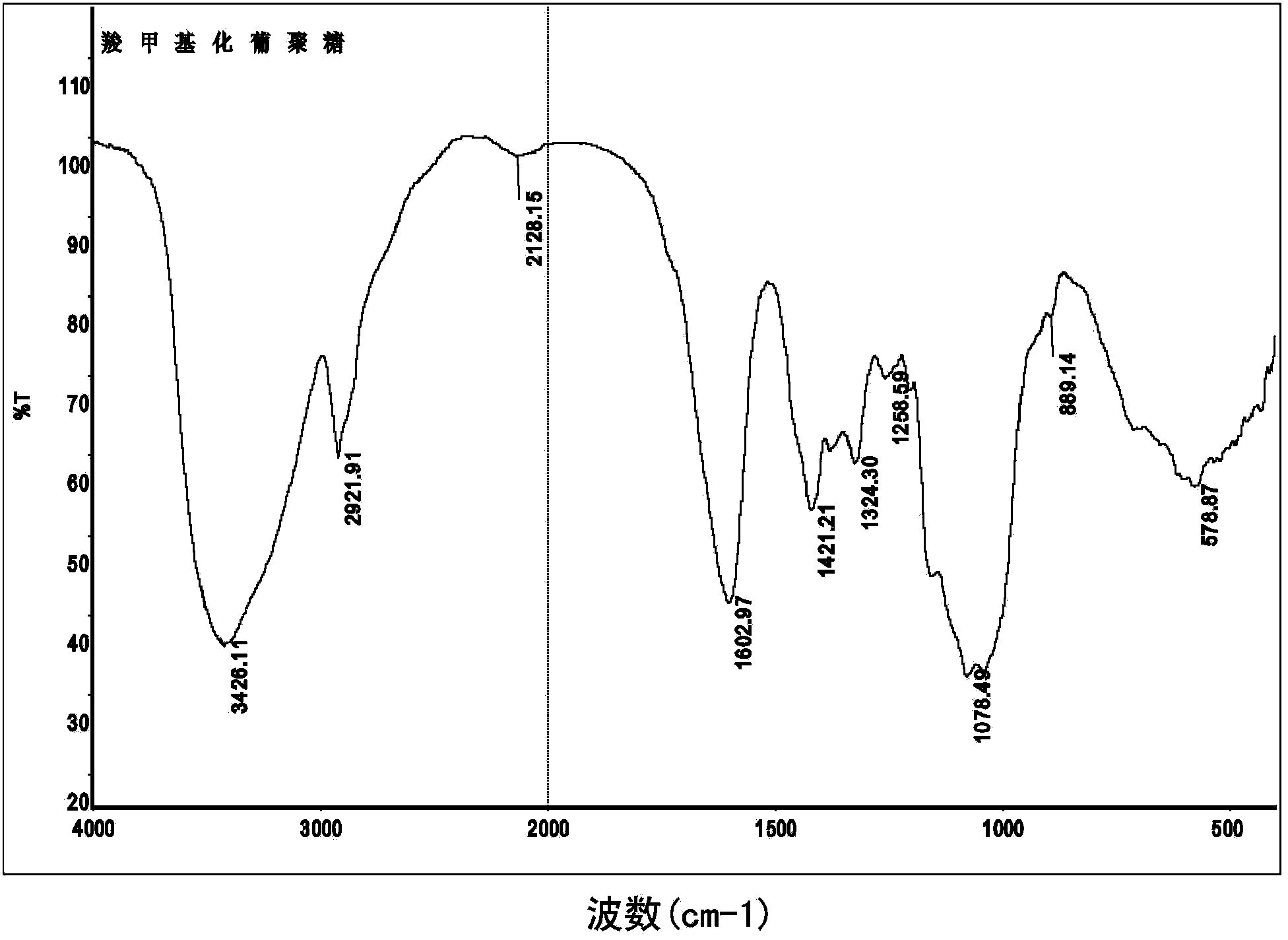

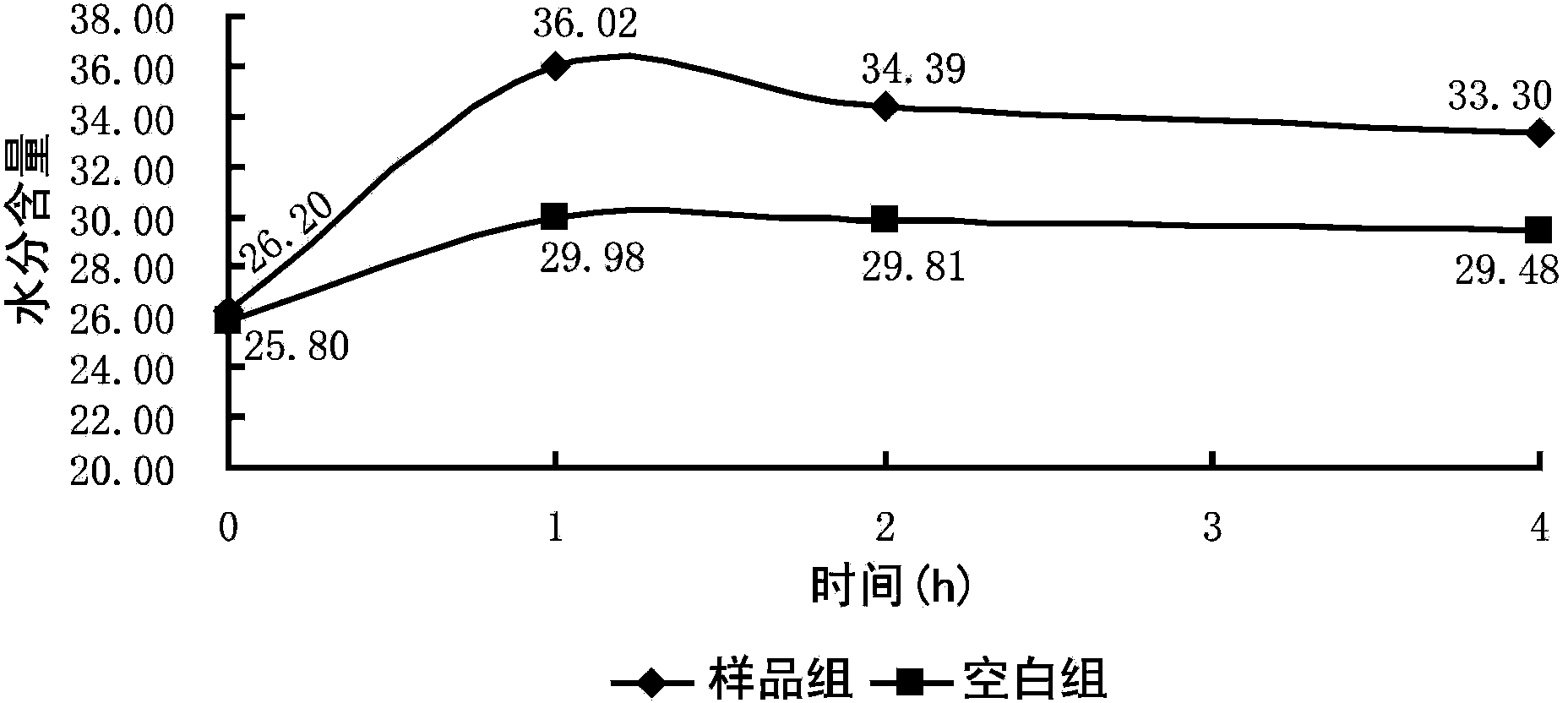

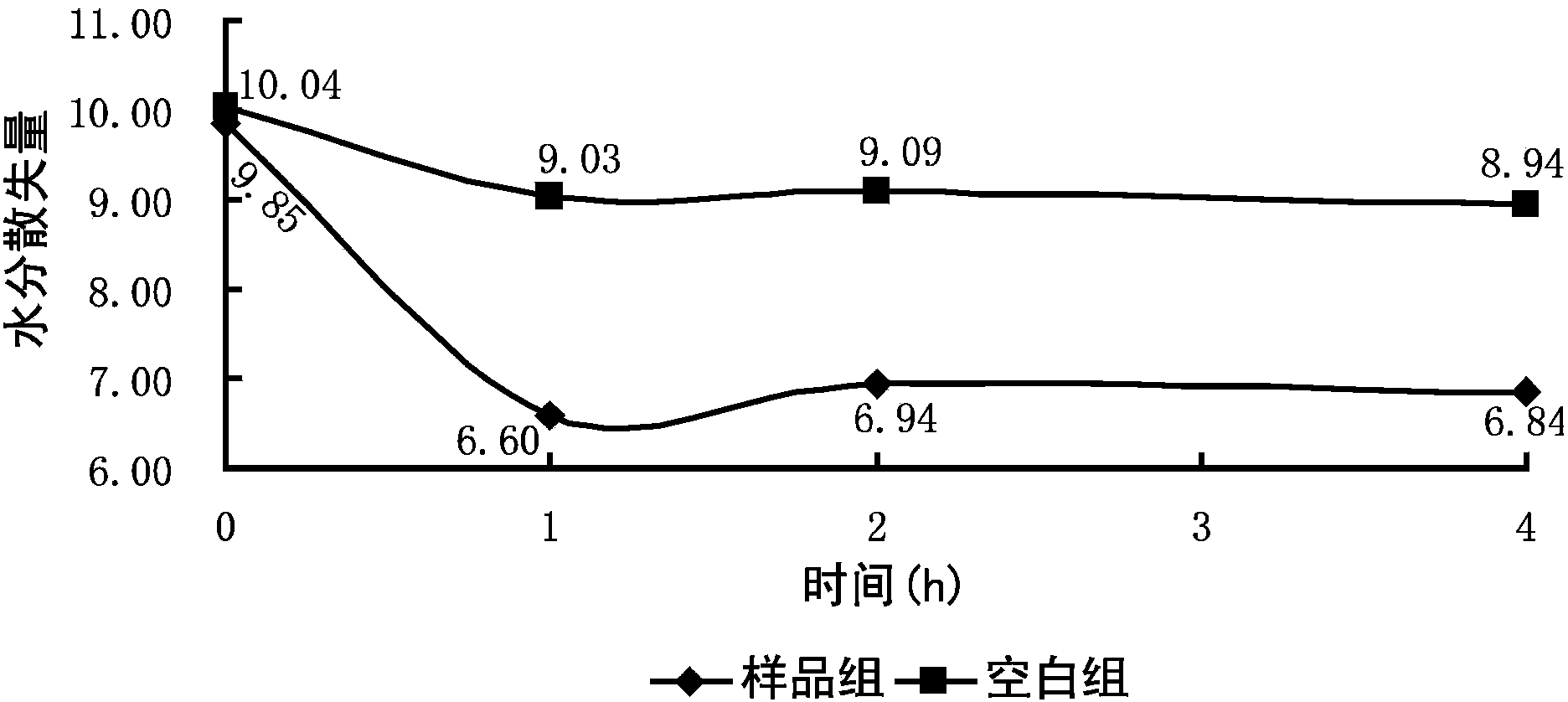

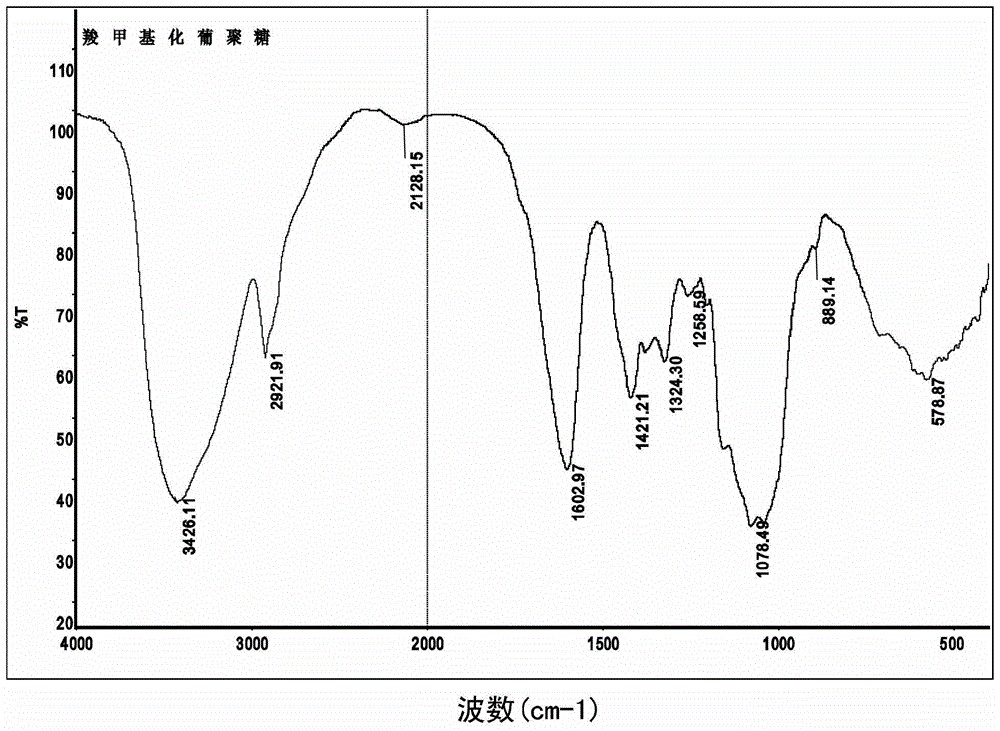

Method for preparing carboxymethyl yeast glucan product and product obtained by using same

ActiveCN103804511AAppropriate degree of substitutionModerate molecular weightCosmetic preparationsToilet preparationsMass ratioChloroacetic acids

The invention relates to a method for preparing a carboxymethyl yeast glucan product and a product obtained by using the same. The preparation method comprises the following steps: adding alkali to yeast glucan according to the ratio that per 1kg of yeast glucan contains 12.5-37.5mol of hydroxyl; simultaneously adding ethanol according to the mass ratio of the yeast glucan to the ethanol being 1:(0.5-2.5), and reacting at 0-30 DEG C; adding a chloroacetic acid to the obtained solution according to the mass ratio of the yeast glucan to the chloroacetic acid being 1:(0.3-1.0), simultaneously adding ethanol according to the mass ratio of the yeast glucan to the ethanol being 1:(0.5-1.5), reacting at 30-80 DEG C and cooling; and adding ethanol in the obtained solution to wash, simultaneously neutralizing by using a hydrochloric acid, washing and centrifugally separating to obtain sediment carboxymethyl yeast glucan. By adopting the carboxymethyl yeast glucan product obtained by the method, the substitution degree is 0.3-1.0, the molecular weight is 100-1,000KD, and the carboxymethyl yeast glucan product is completely dissolved into water, and has the effects of moisturizing, preventing aging and the like when being applied to the field of cosmetics.

Owner:ANGELYEAST CO LTD

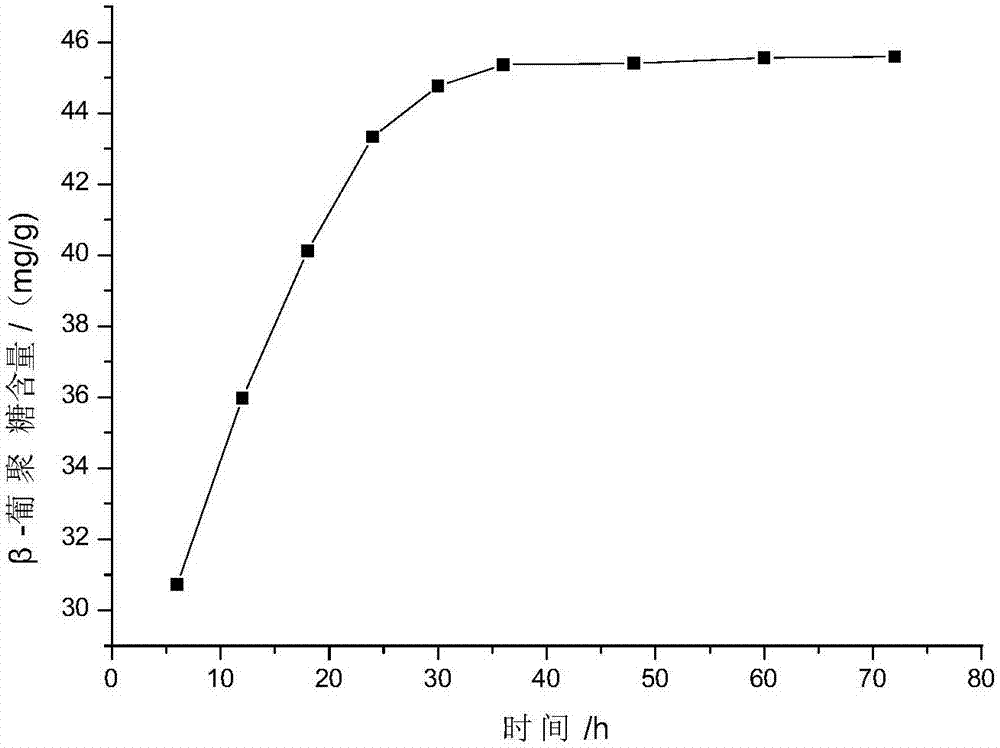

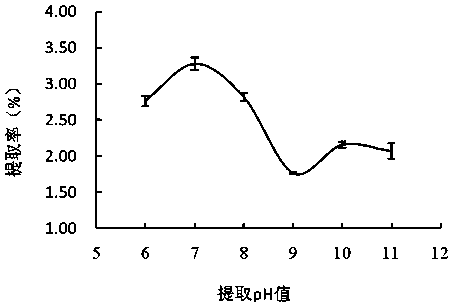

Preparation method of highland barley beta-glucan

The invention discloses a preparation method of highland barley beta-glucan. The preparation method comprises the following steps: taking highland barley bran as a raw material, inoculating commercial alcohol-fermentation active dry yeast after size mixing and gelatinizing, and fermenting by utilizing the yeast; carrying out centrifugation, concentration, alcohol precipitation, water dissolving, filtering and vacuum freeze drying, thus finally obtaining a highland barley beta-glucan product of which the yield is 4.32 to 4.92 percent, the purity is 85.25 to 91.61 percent and the obtaining rate is 82 to 95 percent. The preparation method disclosed by the invention has the advantages that the technology is simple, extracting conditions are mild, the requirements on operators and equipment are low, and the production cost is low.

Owner:润芳可(上海)生物科技有限公司

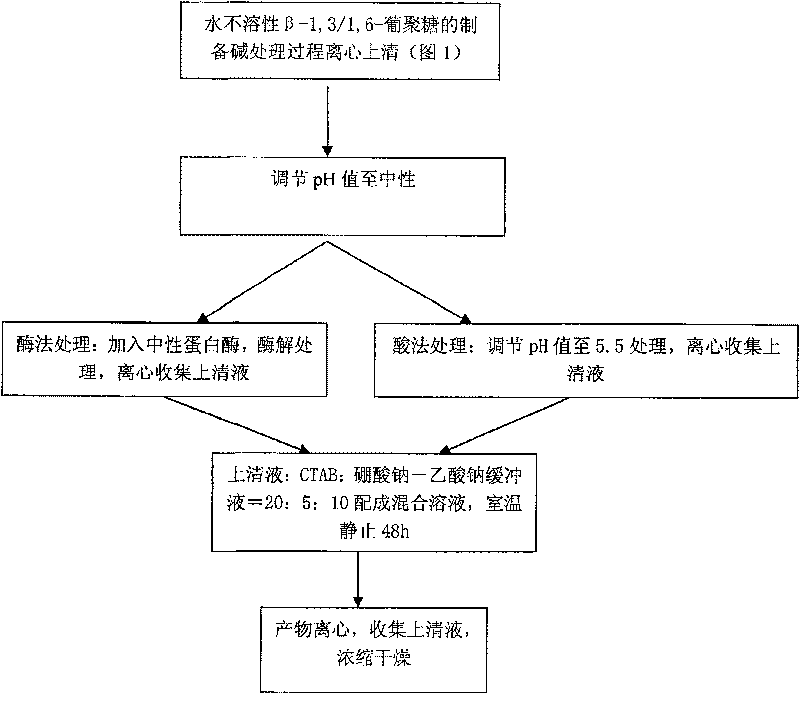

Soluble micromolecular beta-1,3-glucan for improving immunity of hepatitis patient

ActiveCN106243239AHigh purityClear ingredientsOrganic active ingredientsAntipyreticBiological bodyPhysical approach

The invention discloses soluble micromolecular beta-1,3-glucan for improving the immunity of a hepatitis patient. The purity of the obtained target product the soluble micromolecular beta-1,3-glucan is above 95% through treatment of a series of physical methods. The target product the soluble micromolecular beta-1,3-glucan is completely water soluble, the physiological activity, especially the biology immune activity, anti-inflammatory activity and the antitumor activity have a very significant effect, and especially the soluble micromolecular beta-1,3-glucan is used for auxiliary treatment of the hepatitis patient and can improve the immunity of the hepatitis patient.

Owner:SHANDONG UNIV QILU HOSPITAL

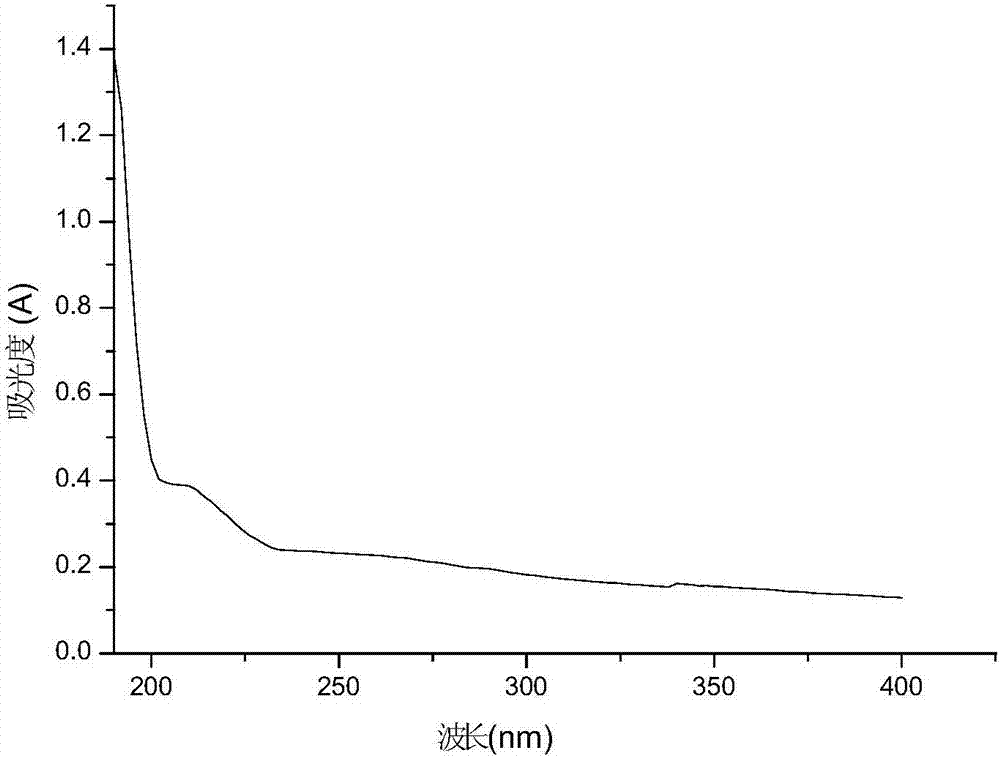

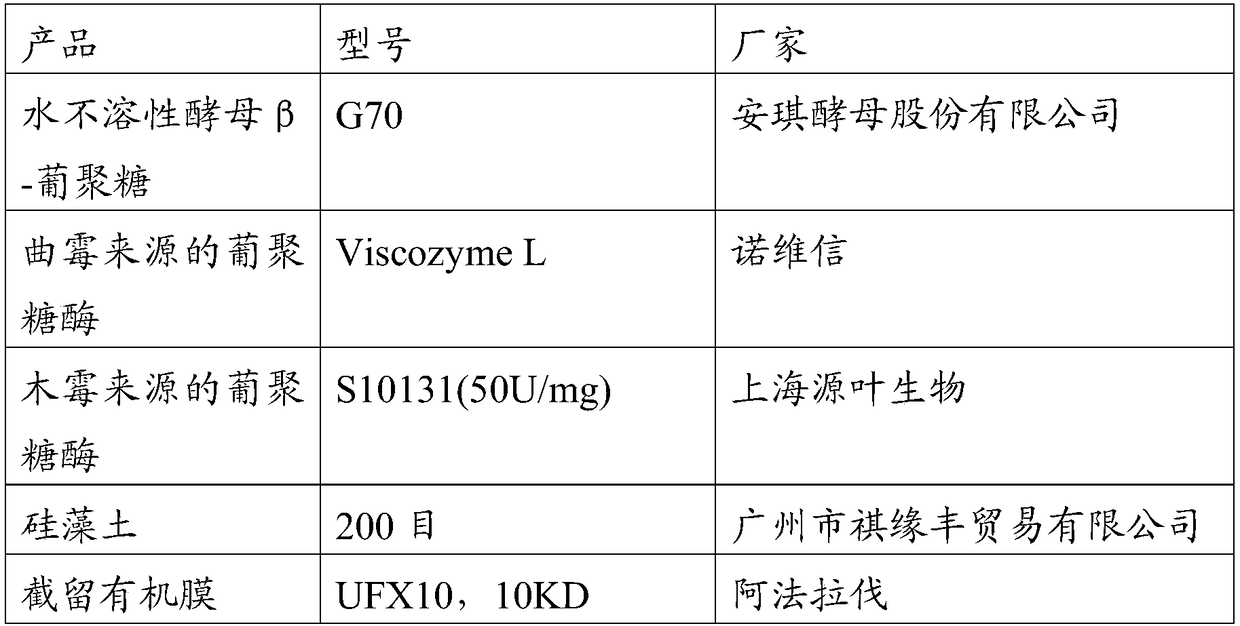

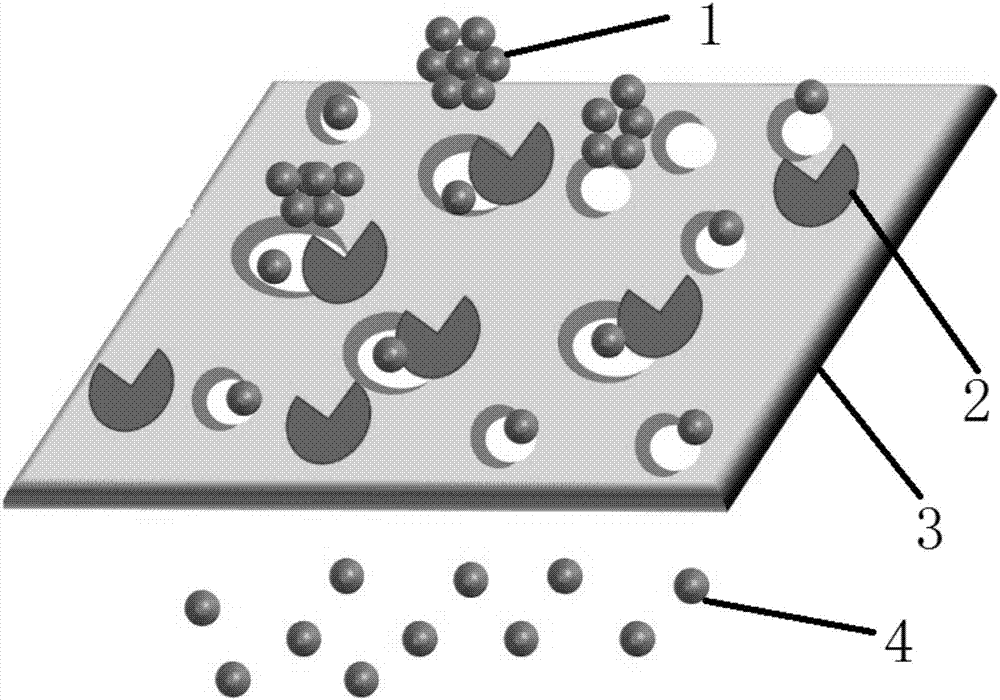

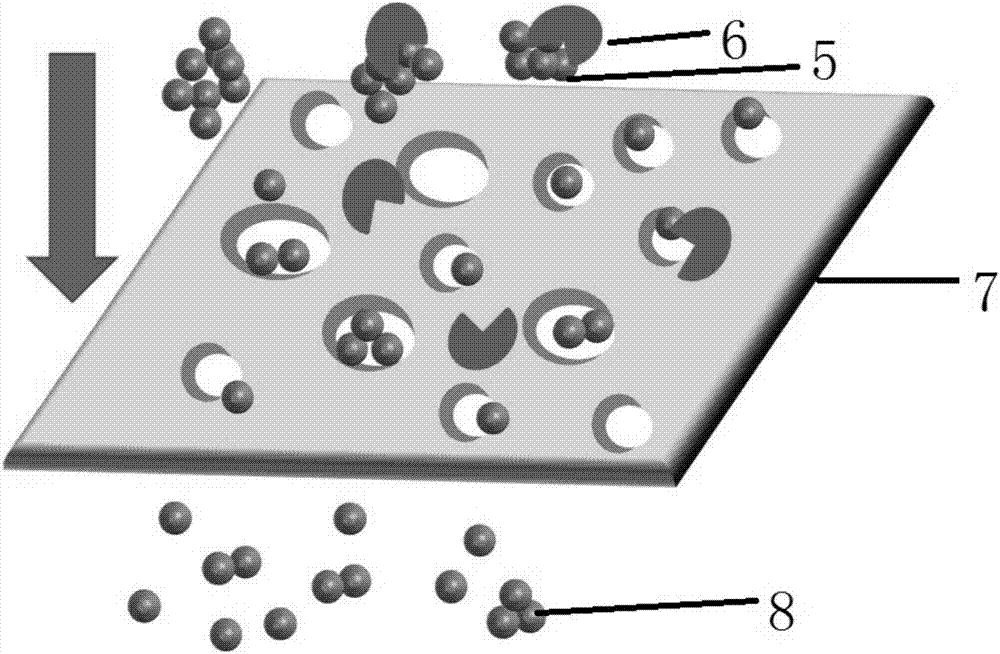

Water-soluble yeast beta-glucan as well as preparation method and application thereof

PendingCN108611385AMaintain molecular structureImprove solubilityOrganic active ingredientsAntinoxious agentsYeastGlucanase

The invention relates to the field of food processing, in particular to a water-soluble yeast beta-glucan as well as a preparation method and application thereof. The method comprises the following steps: enzymatic treatment: adding glucanase to a raw material containing water-insoluble yeast beta-glucan for treatment, and then separating and collecting supernatant; (2) filtering treatment: filtering the supernatant; (3) membrane separation: conducting membrane separation on the supernatant, and collecting trapped fluid to obtain the water-soluble yeast beta-glucan, wherein the glucanase is derived from aspergilli. A water-soluble yeast beta-glucan product obtained by the method provided by the invention is colorless, odorless, completely water-soluble, and maintains an original molecularstructure of a yeast glucan.

Owner:ANGEL NUTRITECH CO LTD

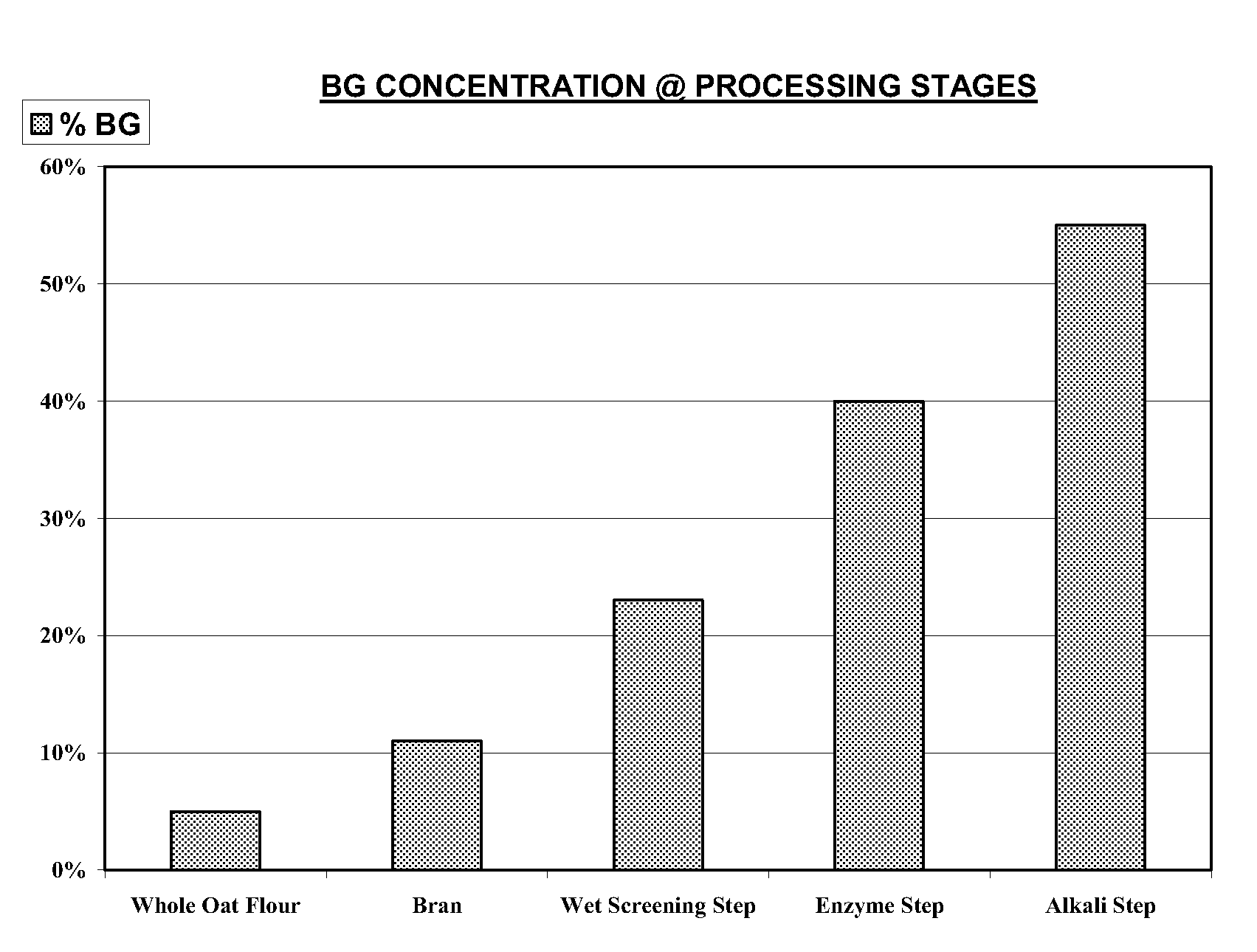

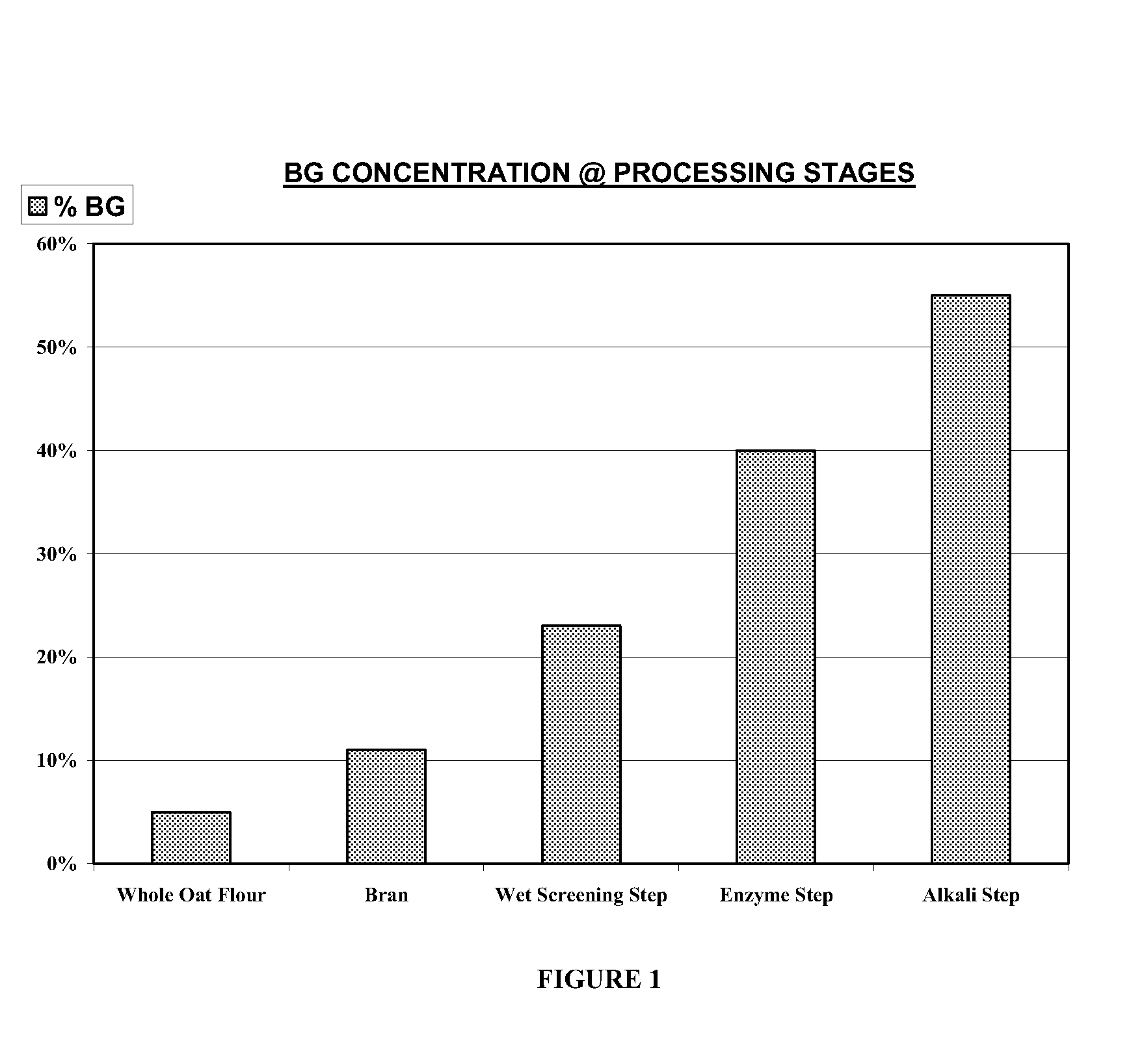

High Viscosity Beta Glucan Products And Methods of Preparation

The invention describes improved methods of preparing high concentration and high viscosity beta-glucan concentrates. More specifically, the invention describes methods wherein beta-glucan is concentrated from bran, whole grain and endosperm flours through various slurrying steps in a high concentration alcohol media utilizing various combinations of enzyme and alkali treatment steps.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Method for fermentation production of micro molecular weight dextran

InactiveCN103993052ASimple production processImprove average conversionMicroorganism based processesFermentationFractional PrecipitationAcid hydrolysis

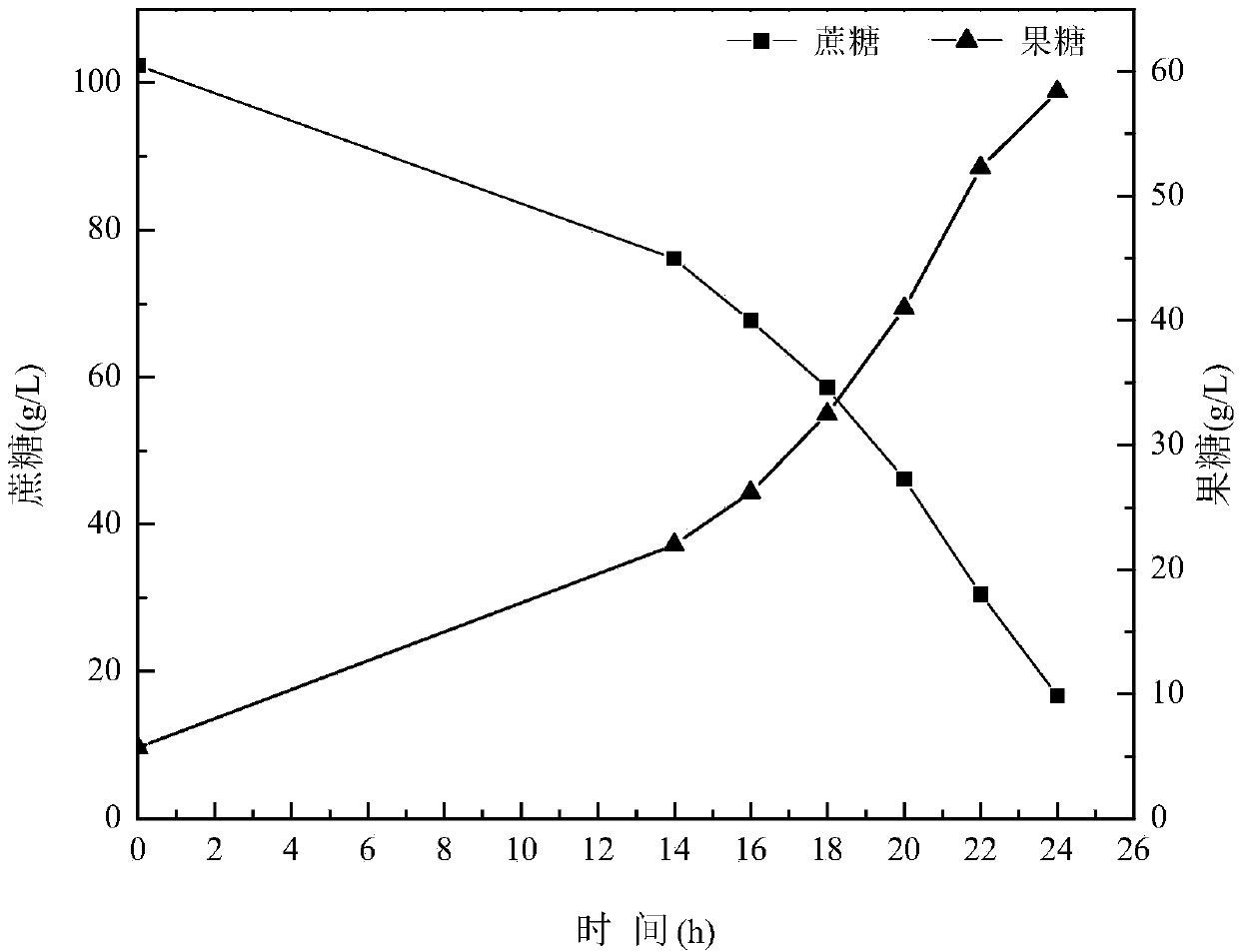

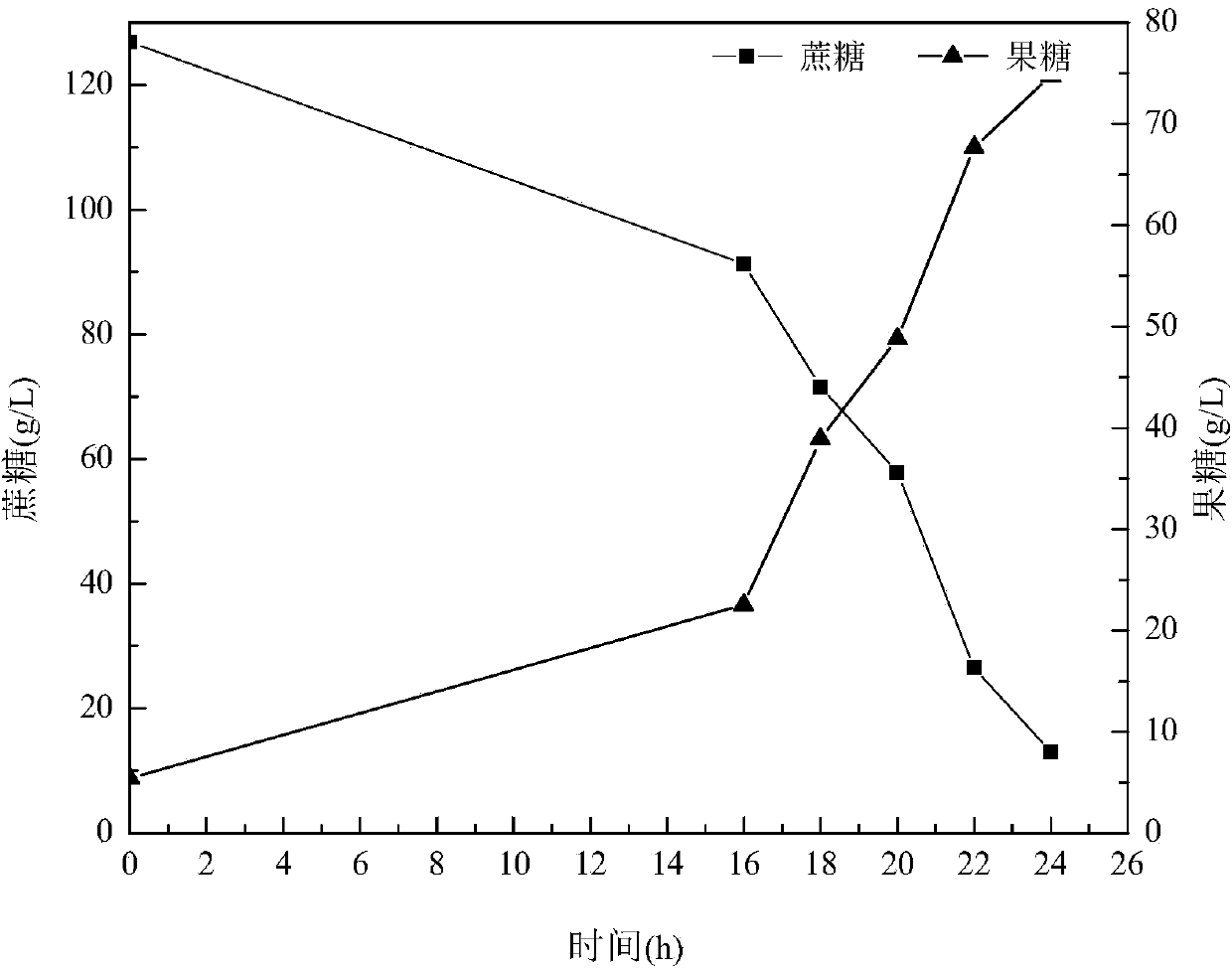

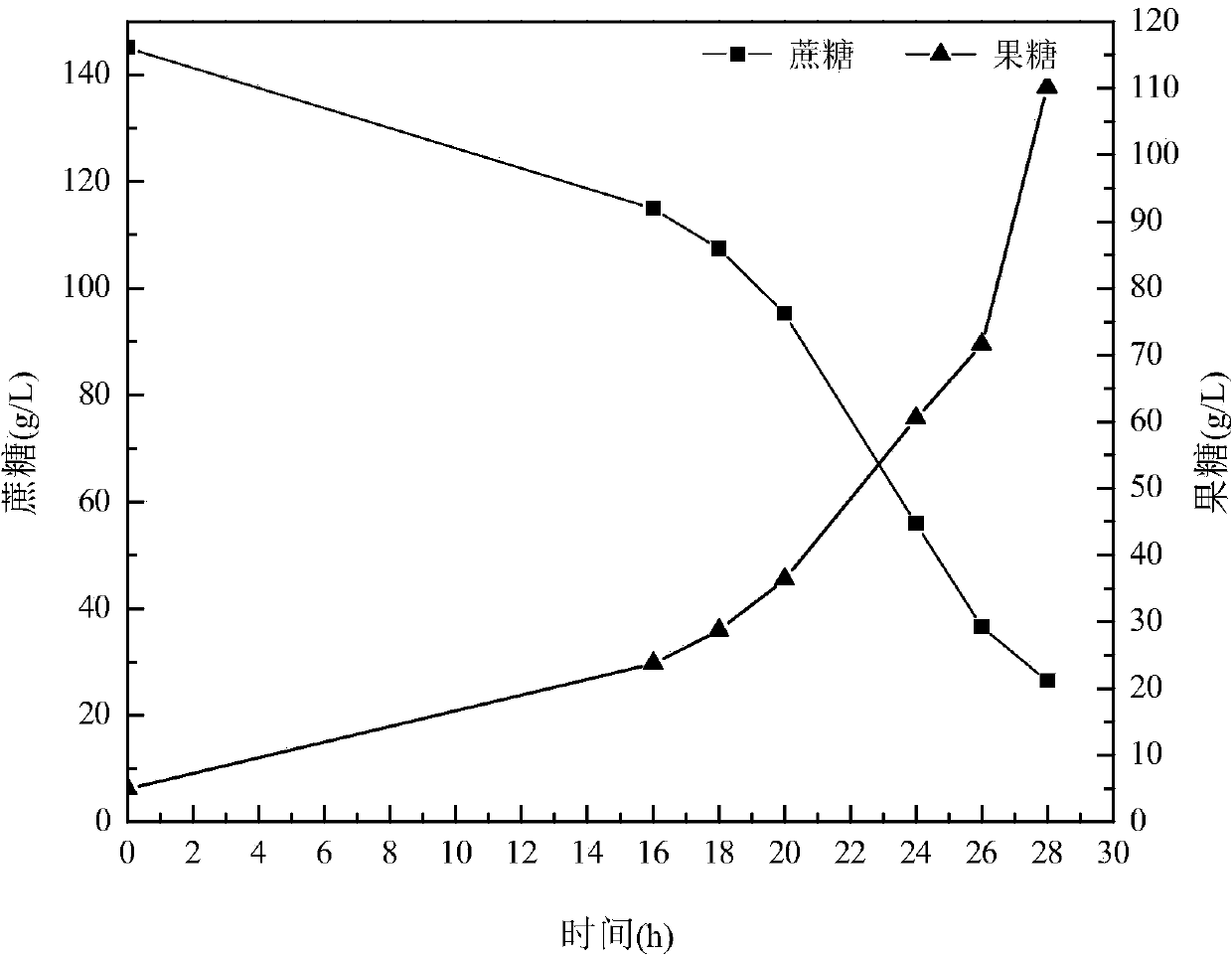

The present invention discloses a method for fermentation production of micro molecular weight dextran. According to the method, dextran hydrolase is added to a fermentation system at a bacterial growth logarithmic phase while a sucrose solution is subjected to fed batch so as to effectively improve the conversion efficiency of the sucrose, wherein conversion of 390 g of the sucrose in 24 h in the traditional process is increased to conversion of 750 g of the sucrose in 36 h; and after completing the fed batch, dextran hydrolase is added to the fermentation tank, and the molecular weight (less than 20000 Da) of the micro molecule dextran product can be controlled according to requirements, such that the production of the micro molecular weight dextran through the one-step method can be achieved, acid hydrolysis and alcohol fractional precipitation are not required, and the production process is simplified. According to the present invention, the sucrose conversion efficiency is significantly increased, the effective control effect on the molecular weight of the micro molecule dextran is significant, and the method of the present invention is the effective method for fermentation production of micro molecular weight dextran.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

Method for extracting beta-glucan in oat and oatmeal processing byproducts

The invention relates to the technical field of plant effective component refining and processing, in particular to a method for extracting beta-glucan in oat and oatmeal processing byproducts. The method for extracting the beta-glucan in the oat and oatmeal processing byproducts includes pretreating raw materials; extracting the beta-glucan and removing starch; removing proteins; carrying out concentration and ethanol precipitation; removing heteropolysaccharides; removing ammonium sulfate by means of ethanol precipitation; carrying out freeze drying to obtain extract. The method has the advantages that the oat and oatmeal processing byproducts are smashed, degreased and decolorized, enzymatic starch removal and beta-glucan extraction are simultaneously carried out, accordingly, the problem of difficulty in extracting oat beta-glucan coated in starch granules can be effectively solved, technologies can be simplified, and the cost can be reduced; isoelectric-point protein removal and enzymatic protein removal are combined with each other, and accordingly the protein contents of products can be reduced and reach 4.76%; the final ethanol concentration of ethanol precipitation systemsis 50%, polysaccharides with the molecular weights lighter than 5000 Da can be flocculated under the effective control of the ethanol concentration, and accordingly the purity of the oat beta-glucanproducts can be improved.

Owner:金维他(福建)食品有限公司

Alcohol-soluble beta-glucan extract, preparing method and application thereof and health-care wine

ActiveCN109134695AGood alcohol solubilitySimple processAlcoholic beverage preparationAlcoholBeta-glucan

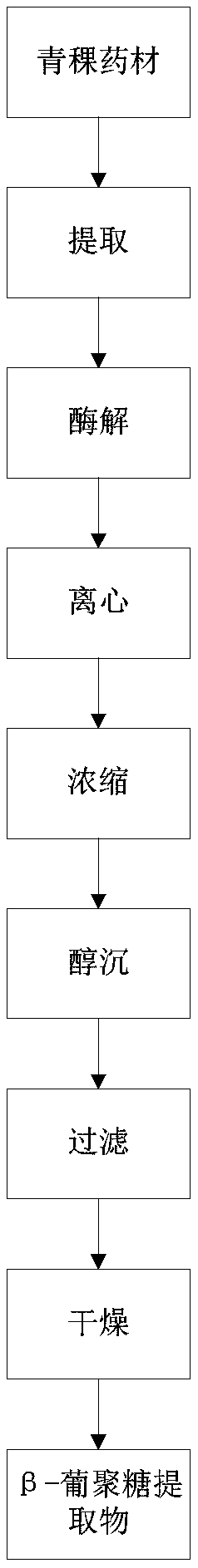

The invention discloses an alcohol-soluble beta-glucan extract, a preparing method and application thereof and health-care wine, and relates to the technical field of extraction of plant components. The preparing method of the alcohol-soluble beta-glucan extract comprises the steps of taking a medicinal material of hordeum vulgar L.var.nudumHook.f, adding an acid solution, and conducting acid extraction; adding alpha-amylase and glucoamylase into an acid extraction solution for enzymolysis, and then conducting enzyme denaturing to obtain an enzymolysis extraction solution; centrifuging and concentrating the enzymolysis extraction solution to obtain a concentrated solution; adding an ethanol solution into the concentrated solution for alcohol precipitation to obtain an alcohol precipitationsolution; filtering and drying the alcohol precipitation solution. The technology is simple, the operation is convenient, the production period is short, the efficiency is high, and the alcohol-soluble beta-glucan extract is suitable for industrial mass production; the alcohol solublility of the prepared alcohol-soluble beta-glucan extract is good, the alcohol-soluble beta-glucan extract can be dissolved into ethanol of different concentrations and is suitable for producing hordeum vulgar L.var.nudumHook.f beta-glucan products; the alcohol-soluble beta-glucan extract is applied to preparing the health-care wine; the health-care wind contains a large amount of hordeum vulgar L.var.nudumHook.f beta-glucan.

Owner:劲牌持正堂药业有限公司

Efficient scleroglucan extraction and purification method and application thereof

The invention discloses an efficient scleroglucan extraction and purificatiodn method and an application thereof. The method includes: 1), performing microwave enhanced dissolution after dilute alkali dissolution by a mycelium contained scleroglucan crude product or a high-concentration scleroglucan fermentation liquid raw material; 2), performing separation on the scleroglucan solution obtained form the step 1) to remove the insoluble mycelium with frame filter or centrifugal separation and merging a scrubbing solution into the scleroglucan solution by adopting the mycelium obtained from the scrubbing solution; 3), neutralizing the scleroglucan solution after bacterial removal; 4), treating the scleroglucan solution through an ultrafiltration membrane prior to desalting and concentrating, and washing the scleroglucan concentrated solution is washed through water and prior to desalting; 5), precipitating and washing the scleroglucan with ethyl alcohol to obtain the product after drying. Through treatment of a series of physical methods, the stable and efficient scleroglucan preparation process is established, chemical reaction is not needed, impurity components in the finished product are reduced, and the purity of the targeted scleroglucan product is up to 90%.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Refining and extracting method of dextran by membrane separation

ActiveCN102988989AHigh purityImprove product qualitySemi-permeable membranesBlood disorderFiltration membraneSeparation technology

Owner:JIANGSU JIUWU HITECH

Method for preparing water-insoluble beta-1,3/1,6-dextran

The invention discloses a method for preparing water-insoluble beta-1, 3 / 1, 6-qlucan. The method has the steps as follow: 1)adding lysozyme into yeast cell wall suspending liquid for enzymolysis, centrifugation and collection at a temperature between 35 and 40 DEG C; 2) putting the product achieved from step 1) into NaOH solution and stirring for centrifugation and collection at a temperature between 35 and 4 DEG C; 3) depositing the product achieved from step 2) into acetic acid solution having concentration expressed in percentage by volume of 2-8 percent and stirring for centrifugation andcollection; 4) stirring and washing the deposition after acid treatment and centrifugation of the step 3)by absolute ethyl alcohol and acetone and ether extract sequentially, and laying aside the treated ether extract for 12 to 24 hours, and drying in the centrifugation and collection way to achieve water-insoluble beta-1, 3 / 1, 6-qlucan. The invention is simple in control, and the beta-1,3-qlucanand the 1,6-qlucan prepared by the method have high purity and yield, and has the protein content and the fat content less than 1 percent.

Owner:CHINA AGRI UNIV

Method for directionally preparing dextran

The invention discloses a method for directionally preparing dextran. In the method, a highland barley extract is adopted as a raw material, dextran products with different molecular weights can be directionally prepared by controlling a ratio of dextran sucrase to dextranase, and products such as dextran 10, dextran 20, dextran 40, dextran 70, dextran 100, dextran 1000 and the like can be prepared.

Owner:JING BRAND

Method for producing yeast dextran by sweet jowar juice

ActiveCN101230371AHigh medicinal valueIncrease incomeFungiMicroorganism based processesTotal nitrogenCell wall

The invention provides a method of making yeast glucan from the sweet sorghum juice; the sweet sorghum juice is fermented, and the yeast is separated, autolyzed and hydrolyzed by adding enzyme, separated again; the supernatant is condensed into yeast extract; the precipitate is prepared into 5 to 8 percent solution, the sodium hydroxide having 2 to 5 wt percent of the cell wall is added, the reaction is carried out for 2 to 4 hours under 85 to 95 DEG C while mingling, and the solution is cooled to 40 to 60 DEG C, separated many times, regulated to neutral pH by acid, and then washed by water many times, then condensed to the concentration of 5 to 8 percent; the pH is regulated to 3.5 to 5; the temperature is raised to 60 to 75 DEG C; the temperature is kept for 30 to 60 min and then the pH is regulated to neutral state; the solution is then cooled down, washed, separated many times, and dried; finally, the finished product is obtained. The glucan product made by the method of the invention is primrose yellow or yellow; after detecting, the glucan content is more than 80 percent; the total nitrogen is less than 5 percent; the water content is less than 5 percent; the dust content is less than 2 percent; and the pH value is between 6.5 and 7.5.

Owner:兰州科近生物技术有限责任公司

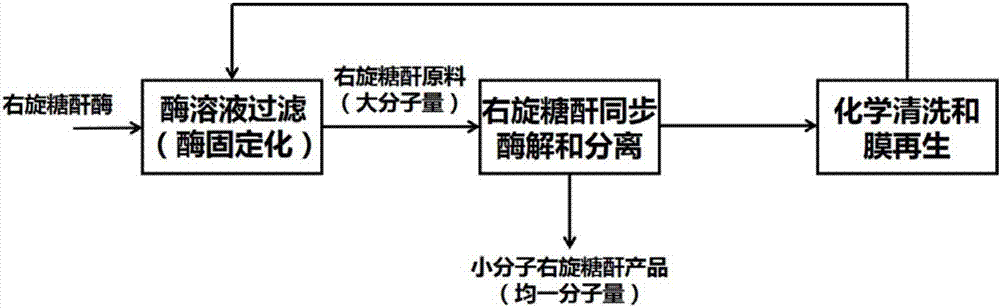

Method for producing small molecular dextran, product and application thereof

InactiveCN107988284AAchieve fixationRealize the control of membrane pore size distributionOrganic active ingredientsOn/in organic carrierUltrafiltrationEnzyme membrane

The invention relates to a method for producing small molecular dextran, a product and application thereof. The method comprises the following step: performing synchronous enzymolysis and separation on a dextran raw material in an integrated enzyme membrane reactor to obtain a small molecular dextran product, wherein the integrated enzyme membrane reactor comprises an ultrafiltration membrane system which adsorbs dextranase. The enzyme is immobilized on the ultrafiltration membrane system. The enzyme is firstly fixed to the ultrafiltration membrane system in advance, and the enzyme not only serves as a reaction catalyst, but also plays a role in regulating the pore size distribution of a membrane, so that the stability and the repeated practicality of the enzyme are improved and the production cost is reduced; in addition, the pore size distribution of the ultrafiltration membrane is reduced through enzyme immobilization, so that the molecular weight of the obtained small molecular dextran product is more uniform; the enzyme immobilization and the membrane pore size distribution regulation and control can be achieved through simple ultrafiltration enrichment. The method has the advantages of simple and safe operation, no use of a chemical additive and easy continuous and automatic production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A Soluble Small Molecule β-1,3-Glucan Used to Improve the Immunity of Hepatitis Patients

ActiveCN106243239BHigh purityClear ingredientsOrganic active ingredientsAntipyreticBiological bodyHepatitis

The invention discloses soluble micromolecular beta-1,3-glucan for improving the immunity of a hepatitis patient. The purity of the obtained target product the soluble micromolecular beta-1,3-glucan is above 95% through treatment of a series of physical methods. The target product the soluble micromolecular beta-1,3-glucan is completely water soluble, the physiological activity, especially the biology immune activity, anti-inflammatory activity and the antitumor activity have a very significant effect, and especially the soluble micromolecular beta-1,3-glucan is used for auxiliary treatment of the hepatitis patient and can improve the immunity of the hepatitis patient.

Owner:SHANDONG UNIV QILU HOSPITAL

Method for preparing plant starch glucan by weak electrolysis method

ActiveCN110387555AConducive to in-depth researchImprove product valueElectrolysis componentsElectrolytic organic productionInorganic saltsAlcohol

The invention discloses a method for preparing plant starch glucan by a weak electrolysis method. The problems that an existing glucan production technology is immature, difficult in classification, high in energy consumption and the like are solved. The method for preparing plant starch glucan comprises the steps that plant starch is used to prepare a plant starch solution and the plant starch solution is added to an electrolytic cell for electrolysis, wherein a direct current electrolysis method is used, the voltage is 15-45V, the initial temperature of electrolysis is 25 DEG C, the electrolysis time is 1-6h, and the concentration of an inorganic salt electrolyte is 1-5%(wt); and after the electrolysis, the pH value of the solution is adjusted to 6-7, precipitation is further performed,and the precipitate is collected and is subjected to alcohol washing and drying to obtain the plant starch glucan. The method for preparing plant starch glucan is simple in process, easy in classification, low in consumption, high in output, high in yield, low in raw material cost and low in production cost, and can obtain glucan products with different molecular weight.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Preparation method of carboxymethyl yeast glucan product and product prepared by the method

ActiveCN103804511BAppropriate degree of substitutionModerate molecular weightCosmetic preparationsToilet preparationsChloroacetic acidsEthyl Chloride

Owner:ANGELYEAST CO LTD

Method for extracting highland barley Beta-dextran and dietary fiber by combined-enzyme method

InactiveCN101555294BFully develop and utilizeIncrease economic value addedFood preparationBARLEY BRANFiber

The invention discloses a method for extracting a Beta-dextran in highland barley bran and preparing a highland barley dietary fiber, belonging to the field of food processing. The method comprises the following steps of: extracting and centrifuging the highland barley bran taken as raw material at an alkaline condition by zymohydrolysis of secondary cellulose, thus obtaining a deposition A and asupernatant; depositing and centrifuging the supernatant under an acidic condition to remove albumen; adding a high-temperature resistant Alpha-amylase into the supernatant under a neutral condition for zymohydrolysis; centrifuging, depositing in water, depositing and re-dissolving the supernatant by water, centrifuging and taking the supernatant; repeatedly depositing the supernatant by a ammonium sulphate and obtaining the Beta-dextran product; adding a composite enzyme in the deposition A for zymohydrolysis; adding a hydrogen peroxide in the deposition A for decoloring; washing the deposition A repeatedly by water; obtaining a solid by centrifuging; and drying the solid at low temperature to obtain the highland barley dietary fiber. The method can sufficiently utilizes the highland barley bran, obtains two products of Beta-dextran and dietary fiber, effectively improves the economical additional value of the highland barley bran and has important realistic significance and wide application prospect for developing high-tech industries.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method or use of a solubilized glucan product to increase immunostimulation in animals

InactiveUS7883875B2Increase mobilityEnhanced ability to stimulate immune systemSugar derivativesConfectionerySide chainGlucose polymers

A method of increasing immunostimulation in animals by administering to the animal a glucan product comprising a branched β-(1,3) glucan with β-(1,3)-linked side chains being attached by a β-(1,6)-linkage and being essentially free of side chains containing more than four β-(1,6)-bound glucose units.

Owner:BIOTEC PHARMACON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com