Preparation method of highland barley beta-glucan

A technology for glucan and highland barley is applied in the field of preparation of highland barley β-glucan, which can solve the problems of β-glucan starch dissolution interference, complex process control parameters, low purity and low yield, etc., so as to reduce extraction interference. , the effect of improving yield and simple control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing highland barley β-glucan, characterized in that it specifically comprises the following steps:

[0039] (1) Add 50g of highland barley bran powder with a particle size of 75-100μm into 500g of water, stir evenly to obtain a highland barley bran powder slurry with a mass percentage concentration of 10%, and then control the temperature at 55°C for gelatinization for 15 minutes. Cool down to 25°C to obtain gelatinized liquid;

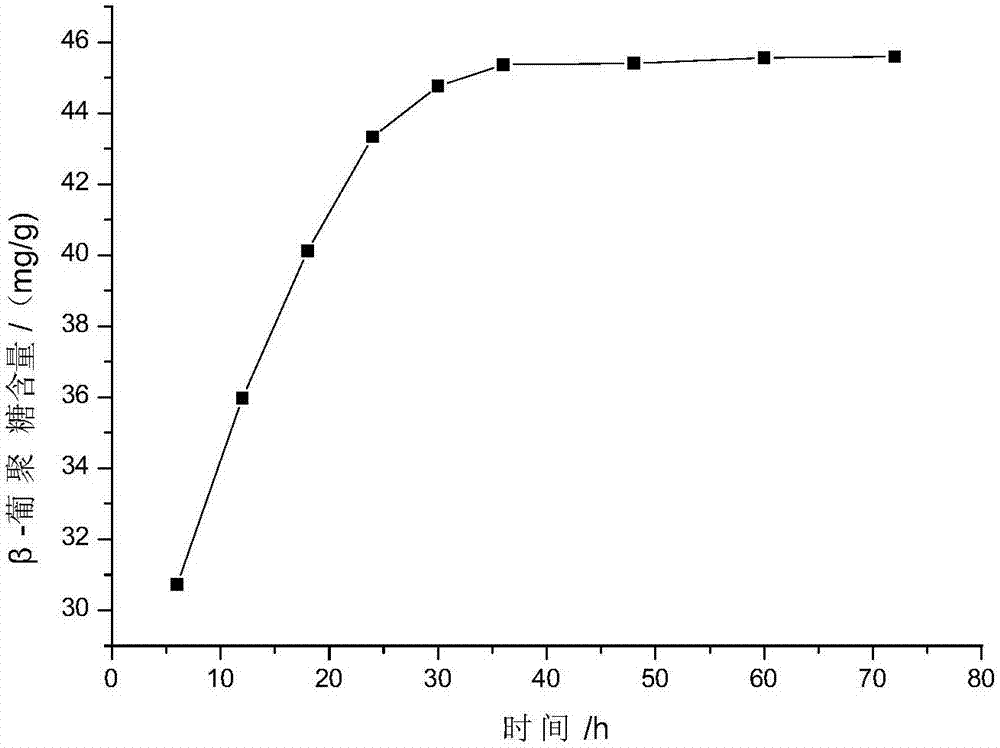

[0040] (2) Inoculate 0.025g of commercial brewer's active dry yeast into the gelatinized liquid obtained in step (1), then control the temperature at 25°C, stir at a speed of 180rpm, and ferment for 24 hours when there is no starch in the iodine solution test to obtain a fermented liquid ;

[0041] The amount of commercialized active dry yeast used in the above inoculation is 0.05% of the mass of highland barley bran powder used in step (1);

[0042] (3) Centrifuge the fermented liquid obtained in step (2) at a controlled s...

Embodiment 2

[0052] A method for preparing highland barley β-glucan, characterized in that it specifically comprises the following steps:

[0053] (1) Add 50g of highland barley bran powder with a particle size of 75-100μm into 330g of water, stir evenly to obtain a highland barley bran powder slurry with a mass percentage concentration of 15%, and then control the temperature at 60°C for gelatinization for 15 minutes. Cool down to 25°C to obtain gelatinized liquid;

[0054] (2) Inoculate 0.05g of commercial Saccharomyces cerevisiae active dry yeast into the gelatinized liquid obtained in step (1), then control the temperature at 30°C, stir at a speed of 180rpm, and ferment for 36 hours when there is no starch in the iodine solution test to obtain a fermented liquid ;

[0055] The amount of commercialized active dry yeast used in the above inoculation is 0.1% of the mass of highland barley bran powder used in step (1);

[0056] (3) Centrifuge the fermented liquid obtained in step (2) at ...

Embodiment 3

[0065] A method for preparing highland barley β-glucan, characterized in that it specifically comprises the following steps:

[0066] (1) Add 50g of highland barley bran powder with a particle size of 75-100μm into 330g of water, stir evenly to obtain a highland barley bran powder slurry with a mass percentage concentration of 15%, and then control the temperature at 60°C for gelatinization for 15 minutes. Cool down to 25°C to obtain gelatinized liquid;

[0067] (2) Inoculate 0.075g of commercial brewer's active dry yeast into the gelatinized liquid obtained in step (1), then control the temperature at 30°C, stir at a speed of 180rpm, and ferment for 48 hours when there is no starch in the iodine solution test to obtain a fermented liquid ;

[0068] The amount of commercialized active dry yeast used in the above inoculation is 0.15% of the quality of highland barley bran powder used in step (1);

[0069] (3) Centrifuge the fermented liquid obtained in step (2) at a controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com