Process for preparing oat beta-glucans

A technology of glucan and oat, which is applied in the field of preparation of high-efficiency biogenic oat β-glucan, can solve the problems of waste of resources, unclear, insufficient total output, etc., to promote growth, inhibit reproduction, and improve immunity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

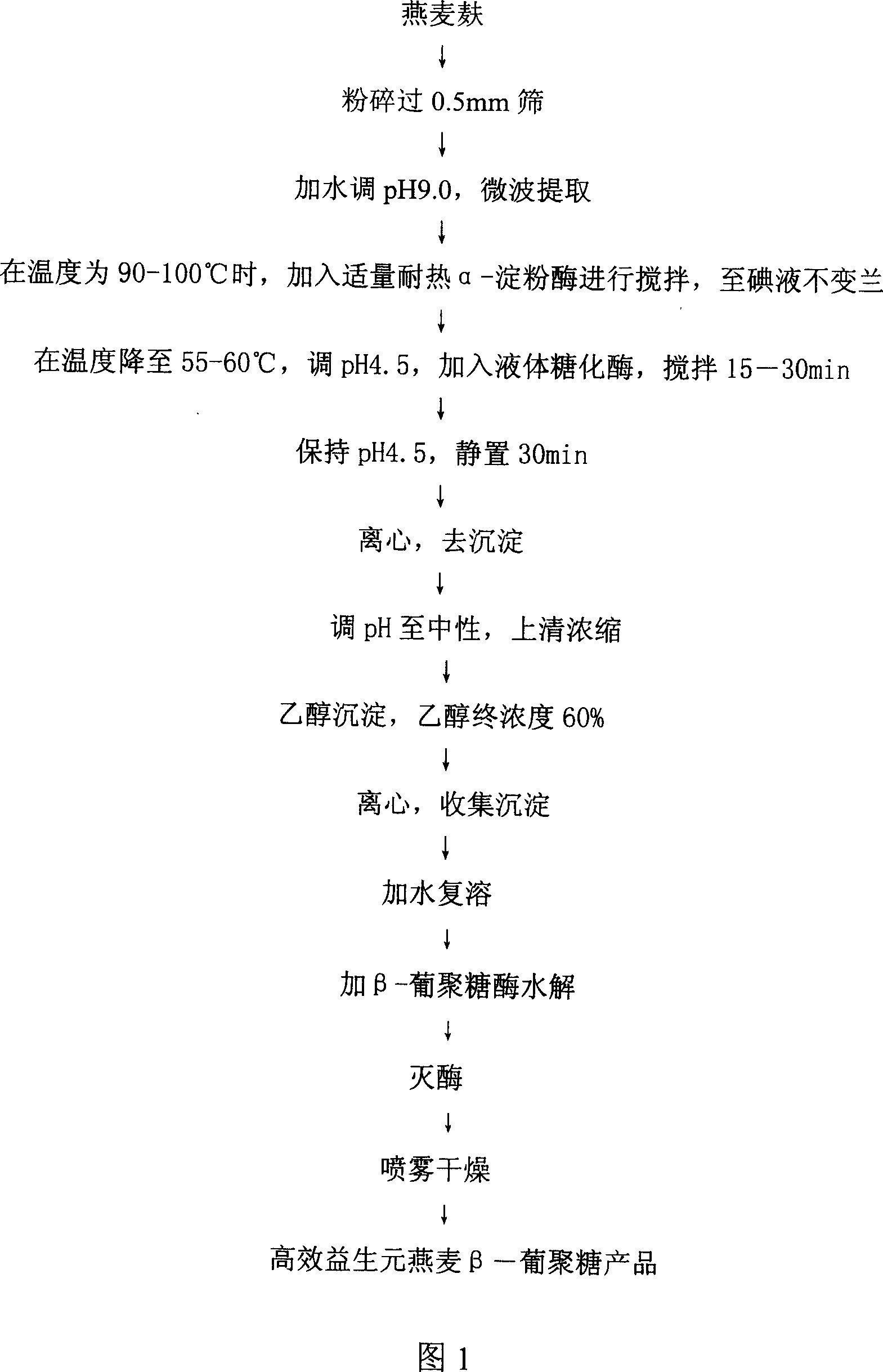

Image

Examples

Embodiment 1

[0038] Take 10kg of oat bran that has been crushed and passed through a 0.5mm sieve, add 120L of water, stir and mix, adjust the pH value to 9.0, treat it under the condition of microwave power 720W for 9min, heat up to 95°C, add heat-resistant α-amylase 0.18 After 1 L, stir for about 30 minutes until the iodine solution does not turn blue, lower the temperature of the extract to 55°C, adjust the pH of the extract to 4.5, add 0.12 L of liquid glucoamylase, continue to stir for 30 minutes, let stand for 30 minutes to precipitate, and heat up after the enzymolysis is complete. Incubate at 100°C for 10 minutes, cool to room temperature and centrifuge (3000r / min, 20min), collect the supernatant and adjust the pH to neutral, double-concentrate with a falling-film double-effect concentrator, add 55L of absolute ethanol to the suspension Centrifuge the solution (3000r / min, 30min) to recover the precipitate, add 8L of water to the precipitate and stir to dissolve, adjust the pH value t...

Embodiment 2

[0040] Take 15kg of oat bran that has been crushed and passed through a 0.5mm sieve, add 180L of water, stir and mix well, adjust the pH value to 9.0, treat it under the condition of microwave power 720W for 9min, raise the temperature to 90°C, and add 0.27L of heat-resistant α-amylase Stir for about 25 minutes until the iodine solution does not turn blue, lower the temperature of the extract to 60°C, adjust the pH of the extract to 4.5, add 0.18 L of liquid glucoamylase, continue to stir for 15 minutes, let stand for 30 minutes to settle, and heat to Incubate at 100°C for 10min, cool to room temperature and centrifuge (3000r / min, 20min), collect the supernatant and adjust the pH to neutral, concentrate twice with a falling film double-effect concentrator, add 90L of absolute ethanol to the suspension Carry out centrifugation (3000r / min, 30min) to recover the precipitate, add 12L of water to the precipitate and stir to dissolve, adjust the pH value to 6.5, add 12g of β-glucanas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com