Preparation of edible fungus beta-dextran

A technology of edible fungi and glucan, which is applied in the field of preparation of edible fungus β-glucan, which can solve the problems of large investment, time-consuming, laborious and money-consuming, and high operation requirements in production plants, and achieve product safety, mild technical conditions, The effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

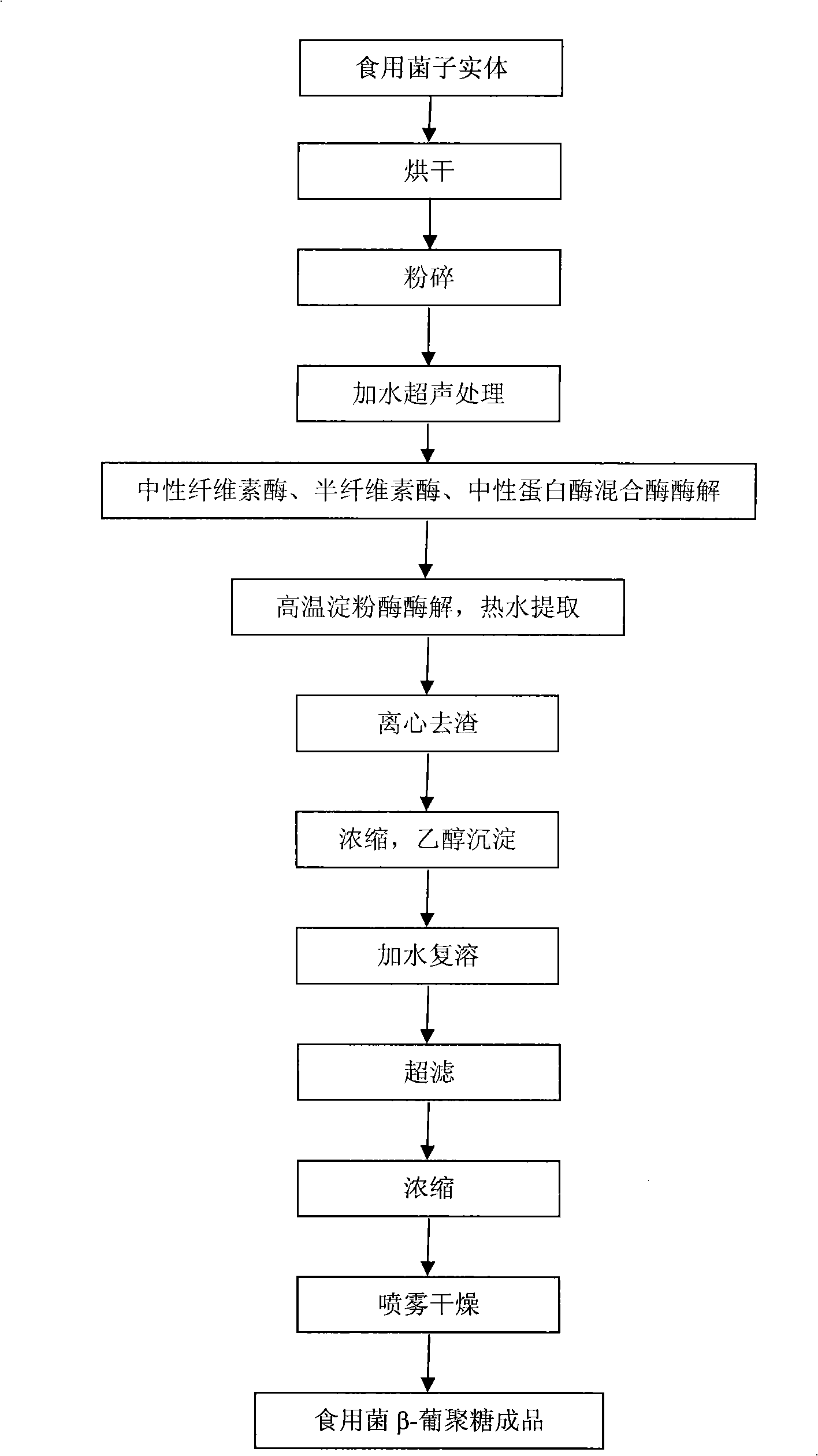

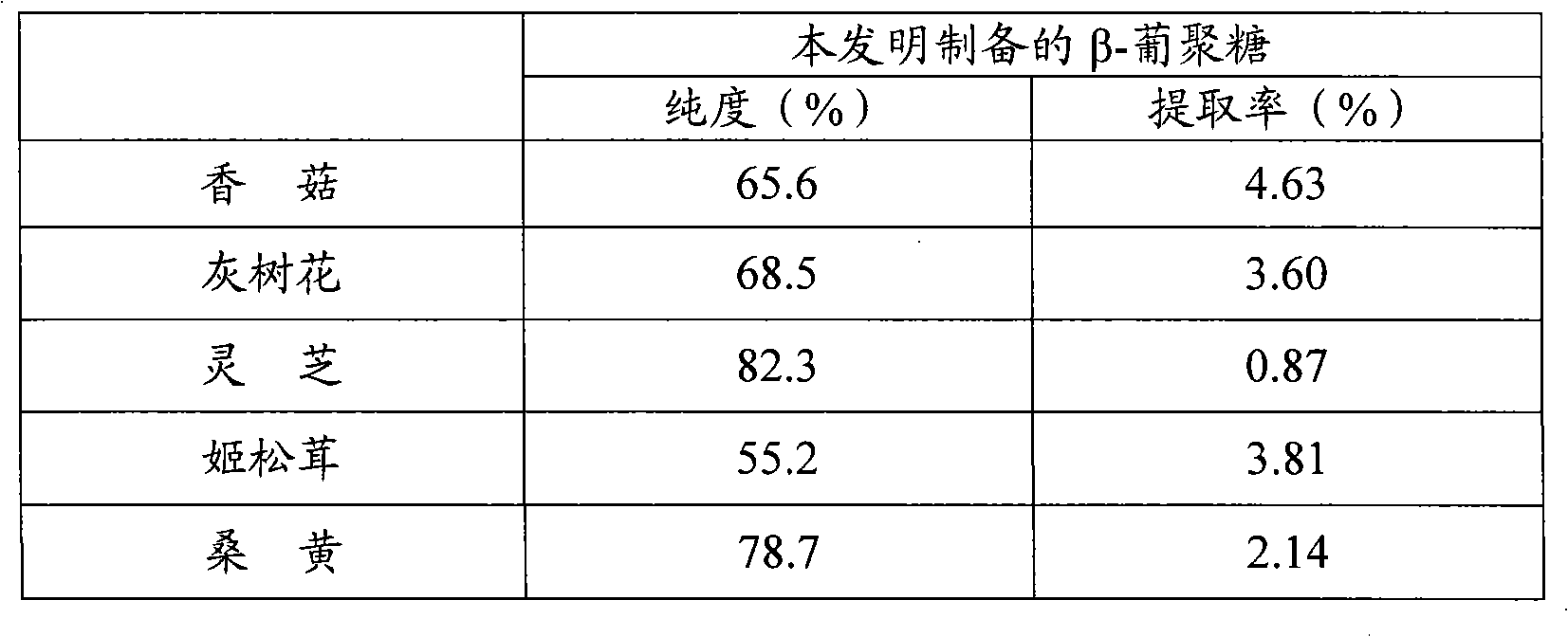

[0064] See the process flow figure 1 , mushroom fruiting body → 80 ℃ hot air drying for 2 hours → crushed to 80 mesh → take 1 kg of dry powder of mushroom fruiting body, add 10 kg of water → 45KHz, power 550W, ultrasonic treatment at room temperature for 20 minutes → add 20 kg of water, and add 6.2 g of CaCl 2 →Add liquid neutral cellulase 40mL (enzyme activity 20000IU / mL, Ningxia Hersbit Biotechnology Co., Ltd.), liquid hemicellulase 33.3mL (enzyme activity 30000IU / mL, Ningxia Hersbit Biotechnology Co., Ltd.) and Liquid neutral protease 66.7mL (enzyme activity 30000IU / mL, Ningxia Heshibi Biotechnology Co., Ltd.), natural pH (that is, no pH adjustment, generally 6.5-7.0), keep warm at 45°C, stir and mix for 1.5h → add Liquid high-temperature amylase 25mL (enzyme activity 20000IU / mL, Ningxia Heshibi Biotechnology Co., Ltd.), 95 ℃ hot water stirring extraction for 2h→cool to room temperature→5000r / min, centrifuge for 10min to remove residue→supernatant (about 30L) → Concentrat...

Embodiment 2

[0066] See the process flow figure 1 , Grifola frondosa fruiting body → 80 ℃ hot air drying for 2 hours → crushed to 100 mesh → take 1kg of dry powder of Grifola frondosa fruiting body, add 10kg of water → 45KHz, power 660W, ultrasonic treatment at room temperature for 20min → add 15kg of water, and add 5.2 g CaCl 2 →Add liquid neutral cellulase 30mL (enzyme activity 20000IU / mL), liquid hemicellulase 30mL (enzyme activity 30000IU / mL) and liquid neutral protease 60mL (enzyme activity 30000IU / mL), natural pH (i.e. not adjusted pH, generally 6.5-7.0), keep warm at 45°C, stir and mix for 1.5h enzymatic hydrolysis → add liquid high-temperature amylase 15mL (enzyme activity 20000IU / mL), stir and extract with hot water at 95°C for 1.5h → cool to room temperature → 5000r / min , 10min centrifugation to remove slag→supernatant (about 25L)→concentrate under reduced pressure to 6L→add 14L of edible ethanol→precipitate, add water 10 times the weight of water to redissolve→10,000 molecular ...

Embodiment 3

[0068] See the process flow figure 1 , Ganoderma lucidum fruiting body → 80 ℃ hot air drying for 2 hours → crush to 100 mesh → take 1 kg of dry Ganoderma lucidum fruiting body powder, add 6 kg of water → 45KHz, power 560W, ultrasonic treatment at room temperature for 30 minutes → add 13 kg of water, and add 6 g of CaCl 2 →Add liquid neutral cellulase 40mL (enzyme activity 20000IU / mL), liquid hemicellulase 33.3mL (enzyme activity 30000IU / mL) and liquid neutral protease 40mL (enzyme activity 30000IU / mL), natural pH (that is, not Adjust the pH, generally at 6.5-7.0), keep warm at 50°C, stir and mix for enzymatic hydrolysis for 1.0h → add liquid high-temperature amylase 10mL (enzyme activity 20000IU / mL), stir and extract with hot water at 95°C for 1.5h → cool to room temperature → 5000r / mL min, 10min centrifugation to remove residue→supernatant (about 18L)→concentrate under reduced pressure to 6L→add 9L of edible ethanol→precipitate, add 15 times the weight of water to redissolve→...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com