Preparation method of polyester

A polyester and cyclic lactone technology, applied in the fields of organic catalysis and polymer materials, can solve the problems of catalyst recovery, high cost, and inability to simultaneously reflect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

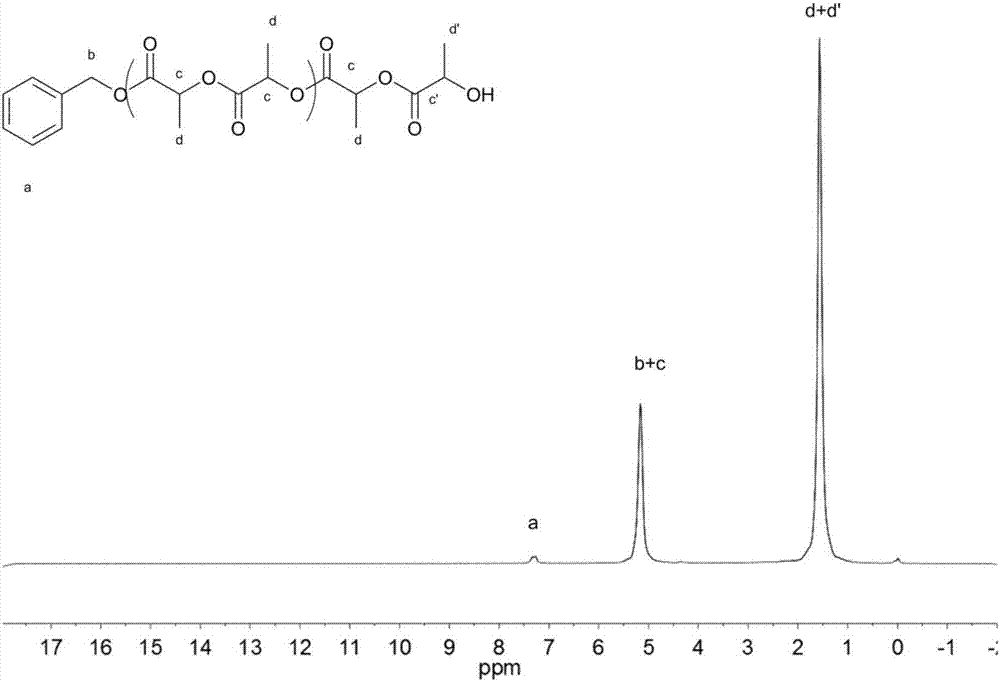

Embodiment 1

[0080] In a 10 mL polymerization tube, add butyrolactone (0.3856 g, 2.88 mmol), benzyl alcohol (10 μl, 0.096 mmol), and the compound shown in No. 13 (0.029 g, 0.096 mmol), and stir magnetically at 90 ° C for 2 h . After the reaction, the obtained crude product was dissolved in a minimum amount of dichloromethane, and then added into a cold methanol solution, and a polymer was precipitated. Centrifugation obtained 0.23 g of white solid, which was transferred to a vacuum drying oven for drying. polymer structure through 1 H NMR with 13 C NMR identification, the molecular weight and dispersion of the polymer were determined by GPC. After determination, the conversion rate of polymer is 90.6%, and the number average molecular weight M n 2600g mol -1 , M n / M w is 1.36. The compound shown in No. 13 of the present invention, in a 250ml reaction bottle, add the compound shown in No. 1 (12.27mmol, 1.5g), saccharin (12.27mmol, 1.5g), and stir overnight at 60°C in tetrahydrofura...

Embodiment 2

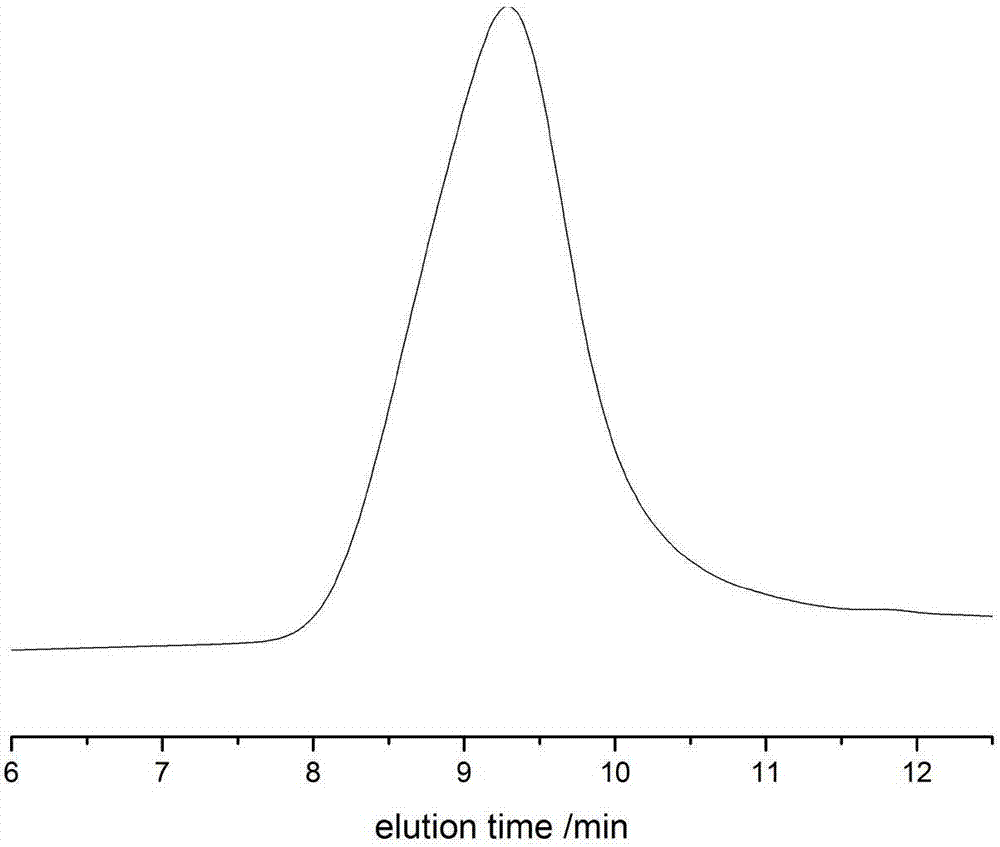

[0082] In a 10 mL polymerization tube, add valerolactone (0.288 g, 2.88 mmol), benzyl alcohol (10 microliters, 0.096 mmol), and the compound shown in No. 14 (0.0375 g, 0.096 mmol), and stir magnetically at 90 ° C for 1 h . After the reaction, the obtained crude product was dissolved in a minimum amount of dichloromethane, and then added into a cold methanol solution, and a polymer was precipitated. Centrifugation obtained 0.21 g of white solid, which was transferred to a vacuum drying oven for drying. polymer structure through 1 H NMR with 13 C NMR identification, the molecular weight and dispersion of the polymer were determined by GPC. After determination, the transformation rate of polymer is 92.8%, and the number average molecular weight M n 2900g mol -1 , M n / M w is 1.21. The compound shown in No. 14 of the present invention, in a 250ml reaction bottle, add the compound shown in No. 2 (12.27mmol, 1.5g), saccharin (12.27mmol, 1.5g), and stir overnight at 60°C in t...

Embodiment 3

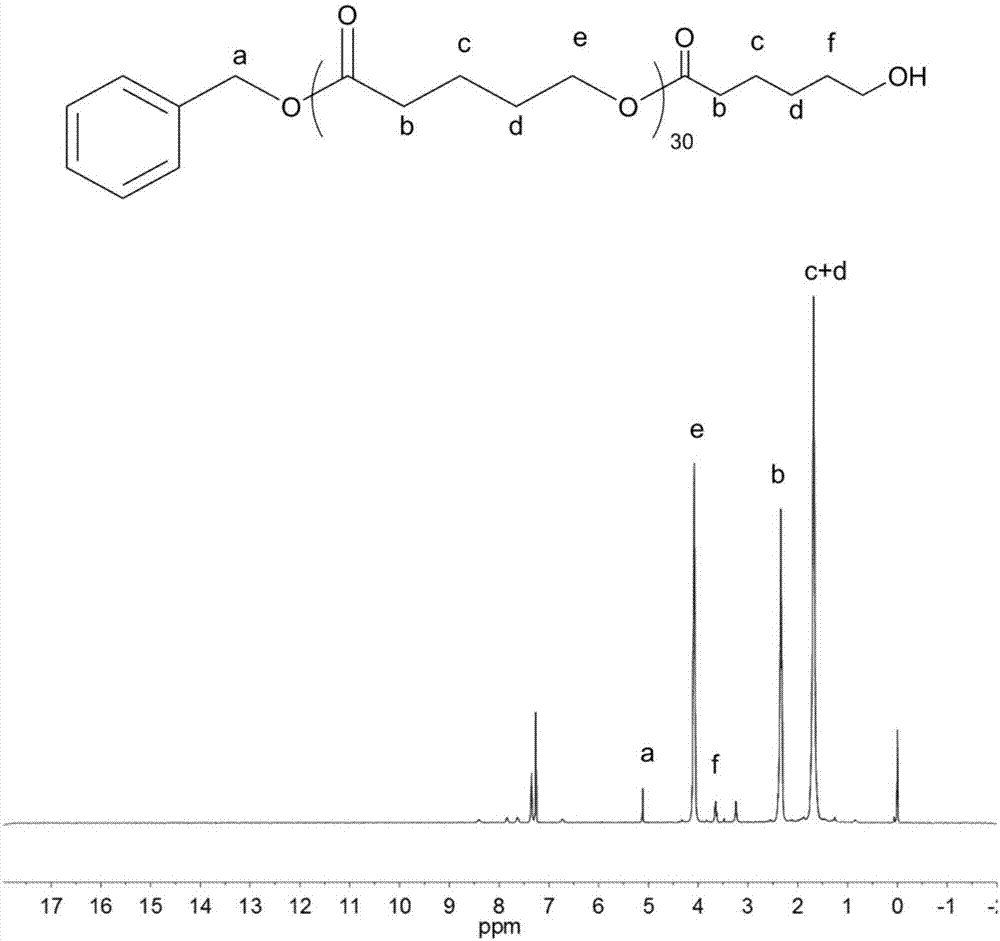

[0084]In a 10 mL polymerization tube, add caprolactone (0.328 g, 2.88 mmol), benzyl alcohol (10 microliters, 0.096 mmol), and the compound shown in No. 16 (0.038 g, 0.096 mmol), and stir magnetically at 100 ° C for 1 h . After the reaction, the obtained crude product was dissolved in a minimum amount of dichloromethane, and then added into a cold methanol solution, and a polymer was precipitated. Centrifugation obtained 0.23 g of white solid, which was transferred to a vacuum drying oven for drying. polymer structure through 1 H NMR with 13 C NMR identification, the molecular weight and dispersion of the polymer were determined by GPC. After determination, the transformation rate of polymer is 98.7%, and the number average molecular weight M n 3500g mol -1 ,M n / M w is 1.37. The compound shown in No. 16 of the present invention, in a 250ml reaction bottle, add the compound shown in No. 4 (12.27mmol, 1.5g), saccharin (12.27mmol, 1.5g), and stir overnight at 60°C in tetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com