Synthetic method of gradient polyester

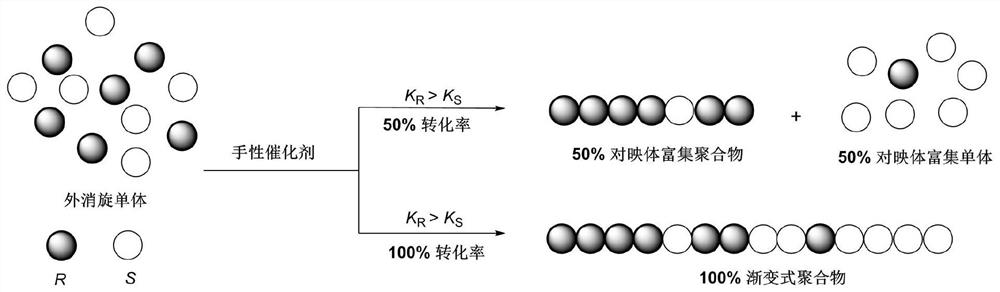

A synthesis method and gradient technology, applied in the field of gradient polyester synthesis, can solve problems such as difficult synthesis and difficult characterization, and achieve the effects of simple operation, mild conditions, and expansion of types and application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

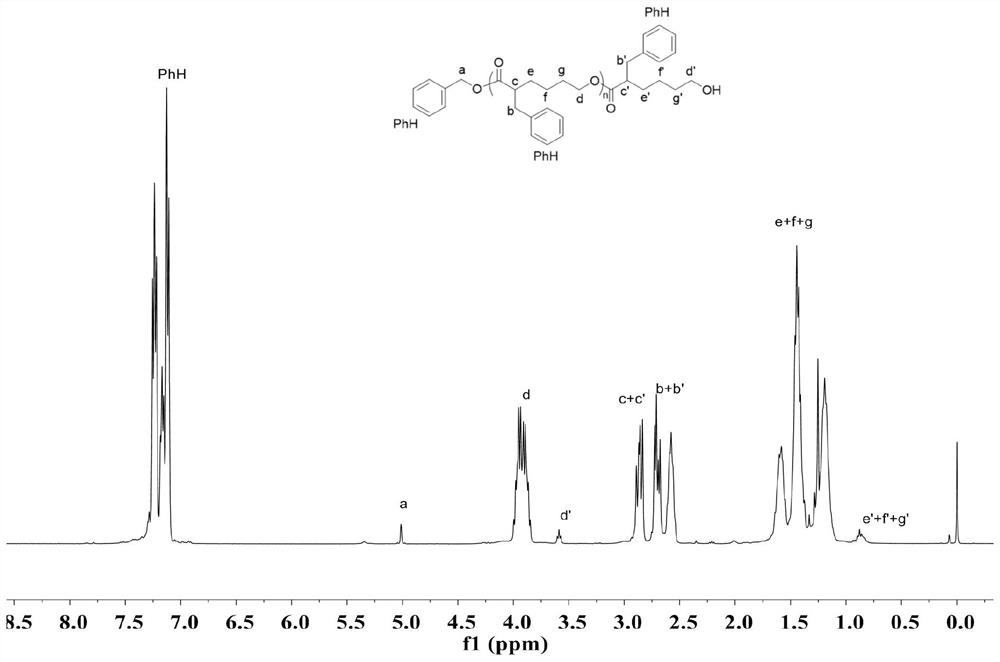

Examples

Embodiment 1

[0039] Embodiment 1: the synthetic method of a kind of gradient type polyester of the present embodiment is carried out as follows:

[0040]

[0041] Take a 5mL Schlenk tube, roast it and replace the argon, then add 1mL of toluene, ε-caprolactone (CL-1) monomer (250μmol, 50equiv.), CPA-1 catalyst (5μmol, 1equiv. ), then add 5 μL of benzyl alcohol in toluene solution, the concentration of benzyl alcohol in the toluene solution of benzyl alcohol is 1mol / L, move the reaction tube out of the glove box, and stir the reaction for 9h at 90°C to obtain the gradient polyε-hexyl Lactone.

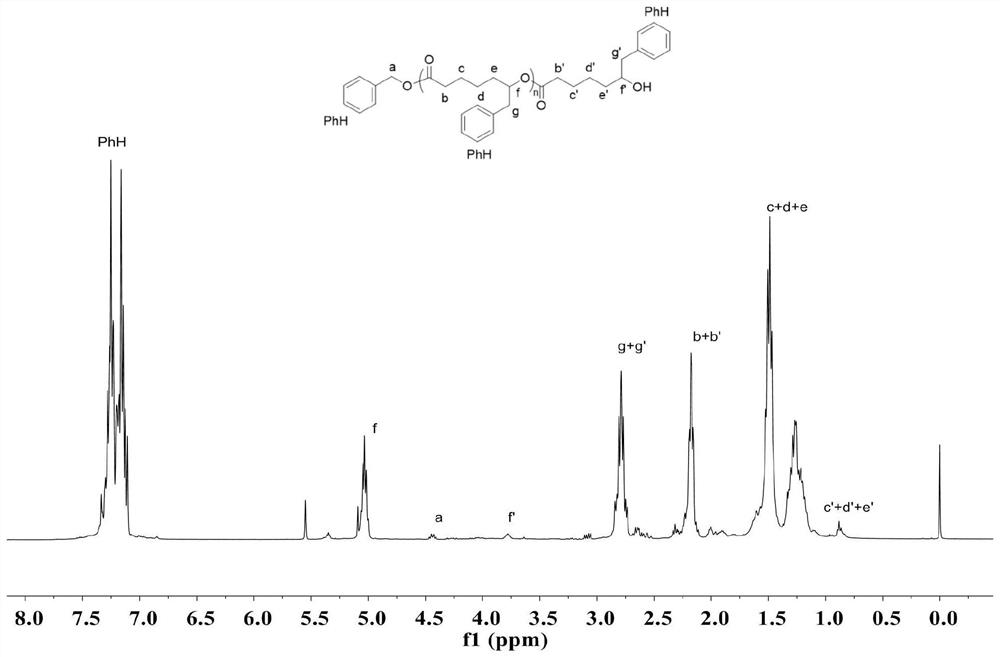

Embodiment 2

[0042] Embodiment 2: the difference between this embodiment and embodiment 1 is: the reaction time is 32h. Other steps and parameters are the same as in Example 1.

Embodiment 3

[0043] Embodiment 3: The difference between this embodiment and embodiment 1 is: the catalyst is CPA-2, and the reaction time is 16h. Other steps and parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com