Continuous production device for diazotization reaction

A production device and diazotization technology, applied in chemical methods for reacting liquids, organic chemistry, chemical instruments and methods, etc., can solve problems such as complex equipment layout, high local temperature, and prolonged reaction time, and achieve equipment The effect of simple layout, increased heat exchange area, and effective temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] In the present invention, unless stated to the contrary, the orientation words "upper, lower" used refer to the positional relationship described with reference to the drawings, and the orientation can change with the different orientations of components.

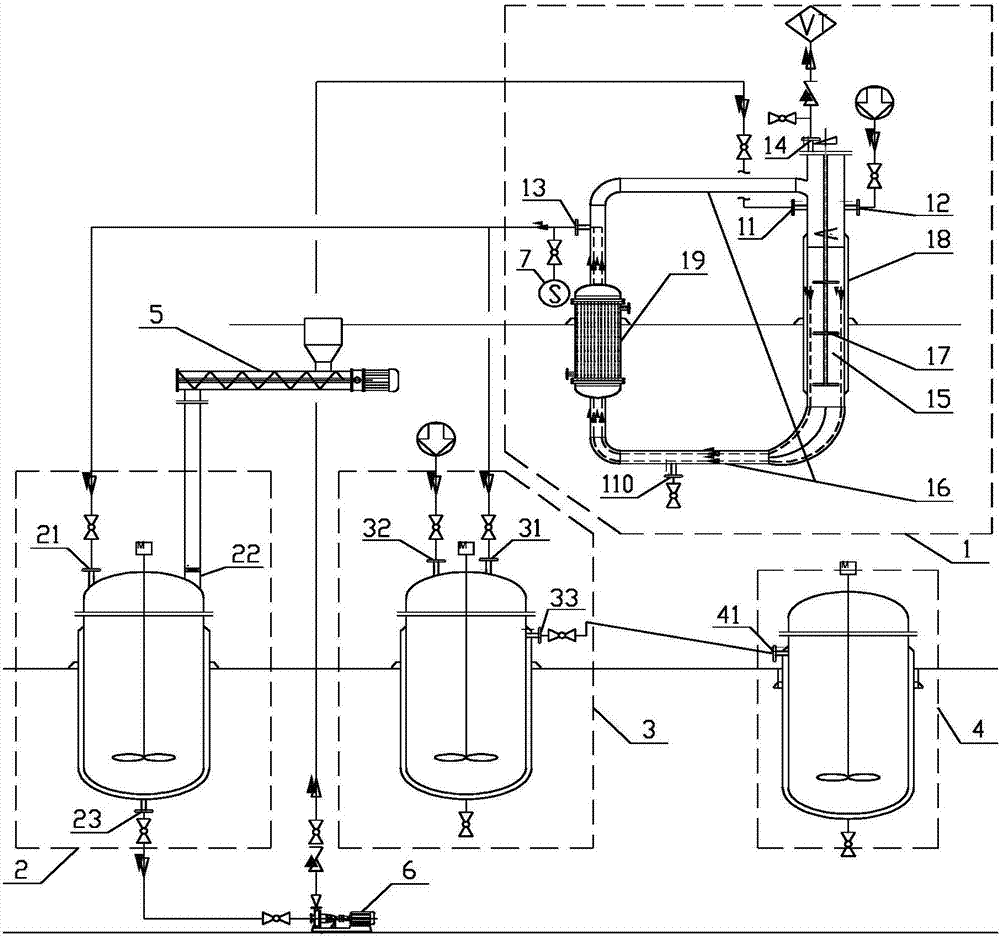

[0039] figure 1Shown is a schematic diagram of a continuous production apparatus for the diazotization reaction of an exemplary embodiment of the present invention.

[0040] Such as figure 1 Shown, the continuous production device of diazotization reaction comprises annular tubular reactor 1, and described annular tubular reactor 1 is provided with inlet A 11, inlet B 12, outlet C 13 and vent 14 ; The annular tubular reactor 1 includes a reaction pipeline part 15 and a communication pipeline part 16 connecting the upper part and the lower part of the reaction pipeline part 15; 17....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com