Material for three-dimensional forming, three-dimensional object, and slice layer of three-dimensional object

A technology of three-dimensional objects and three-dimensional molding, which is applied in the direction of additive processing, etc., can solve the problems of mechanical properties of three-dimensional objects such as low tensile strength, and achieve the effects of improving the safety of preparation, improving the binding force, and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

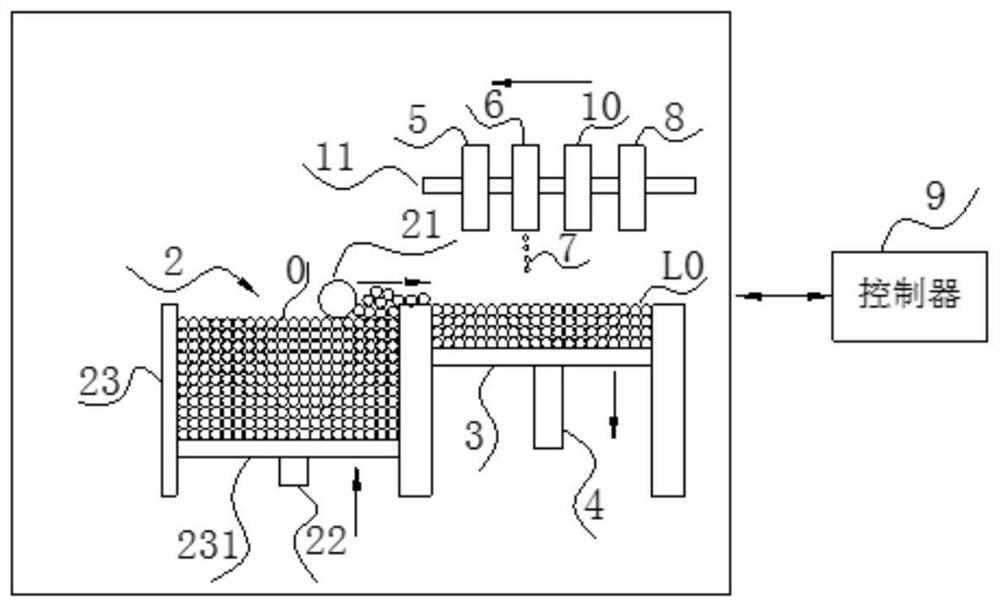

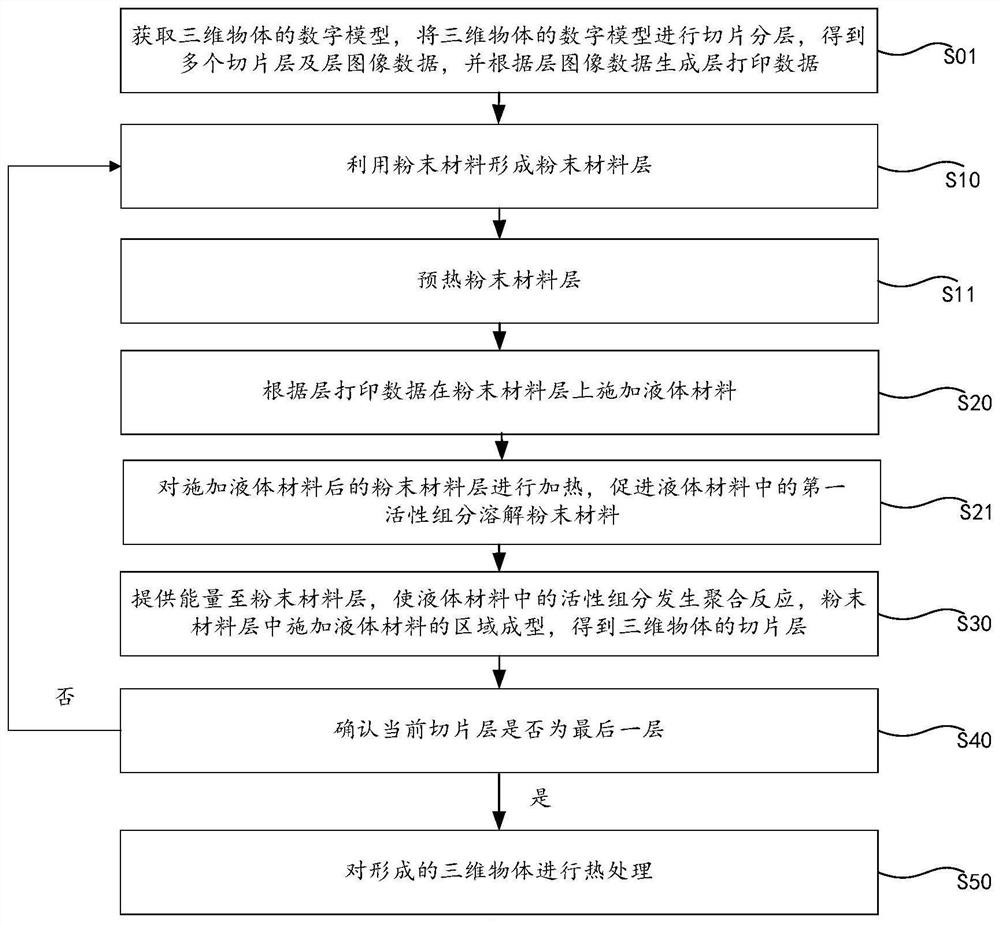

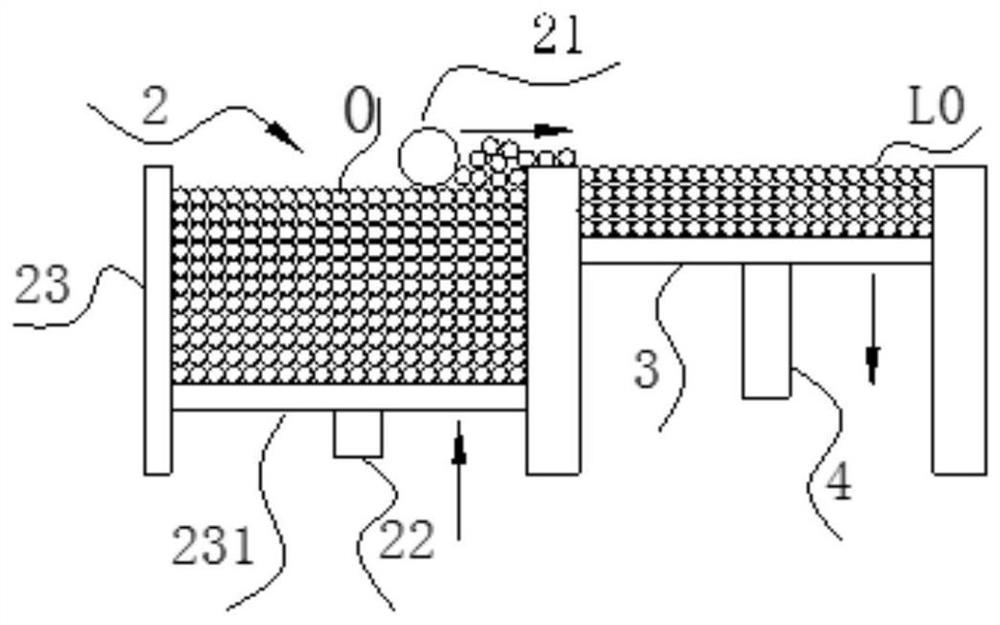

Method used

Image

Examples

Embodiment 1

[0119] Weigh 116.12g of hydroxyethyl acrylate, 0.25g of p-hydroxyanisole, 0.25g of antioxidant 168, and 100g of succinic anhydride in a reaction flask, start stirring, gradually raise the temperature to 120°C and keep it warm. After 2 hours of heat preservation, the measured acid value was lower than 260 mgKOH / g, and the temperature was lowered to discharge to obtain the carboxyl group-containing acrylate monomer D-11.

Embodiment 2

[0121] Weigh 88.11g of ethylene glycol monovinyl ether, 0.24g of p-hydroxyanisole, 0.24g of antioxidant 1010, and 148.11g of phthalic anhydride (phthalic anhydride) in a reaction bottle, start stirring, and gradually raise the temperature to 118°C And keep warm. After 2 hours of heat preservation, the measured acid value was lower than 237mgKOH / g, and the temperature was lowered to discharge to obtain carboxyl group-containing vinyl ether monomer D-21.

Embodiment 3

[0123] Weigh 102.13 ethylene glycol monoallyl ether, 0.30 g p-hydroxyanisole, 0.26 g antioxidant 1010, 0.7 g p-toluenesulfonic acid, and 154.17 g hexahydrophthalic anhydride in a reaction flask, start stirring, and gradually heat up to 118°C and keep warm. After 2 hours of heat preservation, the measured acid value was lower than 218 mgKOH / g, and the temperature was lowered to discharge to obtain carboxyl group-containing allyl ether monomer D-31.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com