Aluminum product cleaning agent and preparation method thereof

A cleaning agent and technology for aluminum products, applied in the field of aluminum product cleaning agents and its preparation, can solve the problems of high corrosion of aluminum products, high product alkalinity, poor cleaning ability, etc., and achieve low dirt corrosion, strong cleaning power, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

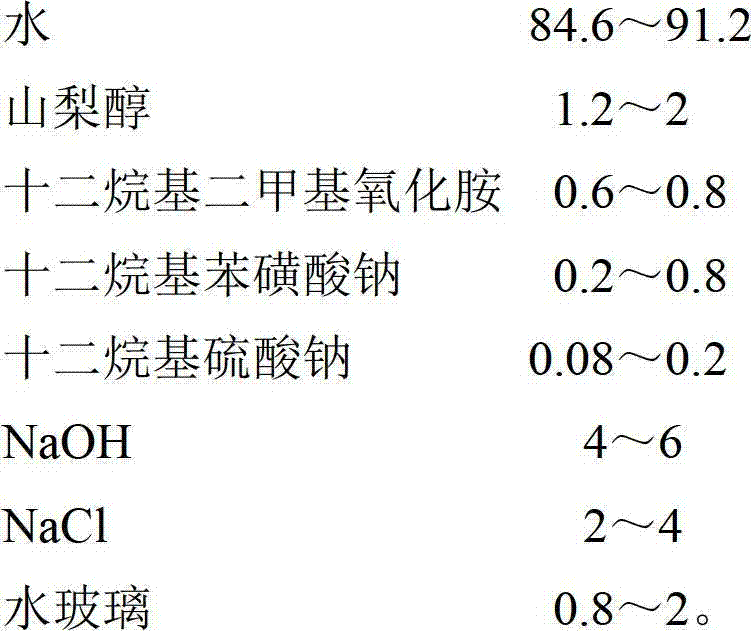

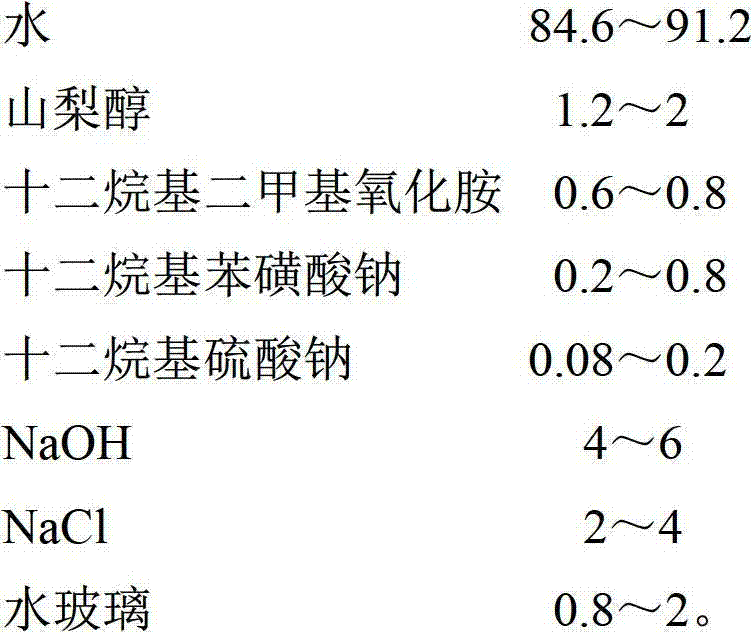

[0017] A cleaning agent for aluminum products, the composition of which is as follows:

[0018] 91.12Kg water, 1.2Kg sorbitol, 0.6Kg dodecyl dimethyl amine oxide, 0.2Kg sodium dodecylbenzenesulfonate, 0.08Kg sodium dodecyl sulfate, 4Kg NaOH, 2Kg NaCl, 0.8Kg water Glass.

[0019] Its preparation method of above-mentioned aluminum products cleaning agent, the steps are as follows:

[0020] (1) Put 11.46Kg water, 1.2Kg sorbitol, 0.6Kg dodecyldimethylamine oxide, 0.2Kg sodium dodecylbenzenesulfonate, and 0.08Kg sodium dodecylsulfate into the reaction kettle in turn, and stir until Completely dissolve to obtain mixture A, which is set aside for later use;

[0021] (2) Put 79.66Kg of water, 4KgNaOH, 2KgNaCl, and 0.8Kg of water glass into the reaction kettle in turn, stir until completely dissolved, and obtain mixture B;

[0022] (3) When the mixture B is cooled to room temperature, add the mixture A, stir well until it is uniform, and obtain the finished aluminum products cleanin...

Embodiment 2

[0024] A cleaning agent for aluminum products, the composition of which is as follows:

[0025] 846Kg water, 20Kg sorbitol, 8Kg dodecyl dimethyl amine oxide, 4Kg sodium dodecylbenzenesulfonate, 2Kg sodium dodecyl sulfate, 60KgNaOH, 40KgNaCl, 20Kg water glass.

[0026] Its preparation method of above-mentioned aluminum products cleaning agent, the steps are as follows:

[0027] (1) 106.4Kg water, 20Kg sorbitol, 8Kg dodecyl dimethyl amine oxide, 4Kg sodium dodecylbenzene sulfonate, 2Kg sodium dodecyl sulfate are dropped into the reaction kettle successively, stirred until completely dissolved, and obtained Mixture A, set aside for later use;

[0028] (2) Put 739.6Kg of water, 60Kg of NaOH, 40Kg of NaCl, and 20Kg of water glass into the reaction kettle in turn, and stir until completely dissolved to obtain mixture B;

[0029] (3) When the mixture B is cooled to room temperature, add the mixture A, stir well until it is uniform, and obtain the finished aluminum products cleaning...

Embodiment 3

[0031] A cleaning agent for aluminum products, the composition of which is as follows:

[0032] 455.6Kg water, 6Kg sorbitol, 3Kg dodecyl dimethyl amine oxide, 1Kg sodium dodecylbenzenesulfonate, 0.4Kg sodium dodecyl sulfate, 20Kg NaOH, 10Kg NaCl, 4Kg water glass.

[0033] Its preparation method of above-mentioned aluminum products cleaning agent, the steps are as follows:

[0034] (1) Put 57.28Kg of water, 6Kg of sorbitol, 3Kg of dodecyl dimethyl amine oxide, 1Kg of sodium dodecylbenzene sulfonate, and 0.4Kg of sodium dodecyl sulfate into the reaction kettle in turn, and stir until completely dissolved. Obtain mixture A, release for subsequent use;

[0035] (2) Put 398.32Kg of water, 20Kg of NaOH, 10Kg of NaCl, and 4Kg of water glass into the reaction kettle in turn, and stir until completely dissolved to obtain mixture B;

[0036] (3) When the mixture B is cooled to room temperature, add the mixture A, stir well until it is uniform, and obtain the finished aluminum products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com