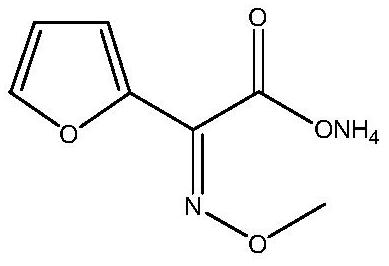

Synthetic method of furan ammonium salt

A technology of furan ammonium salt and synthesis method, which is applied in the direction of organic chemistry, can solve the problems of low yield, and achieve the effects of high yield, reduced production cost, and reduced ammonia nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

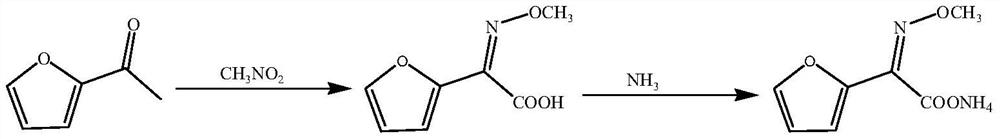

Method used

Image

Examples

Embodiment 1

[0024] Stir 180g of purified water and 18g of sulfuric acid evenly, add 1.1g of copper chloride, stir evenly, add 20g of acetylfuran, control the temperature at 52±2°C, slowly inject 23g of methyl nitrite, control the aeration time at 1 hour, and the aeration is completed After the reaction was incubated for 3 hours, after the reaction was completed, liquid caustic soda was added to adjust its pH value to 4, 1 g of activated carbon was added to the reaction solution, stirred for 30 minutes and filtered, after the filtration was completed, 200 mL of dichloromethane was added to extract twice, and the organic phase was combined. Slowly add a saturated ethanol solution of ammonia gas (a saturated ethanol solution of ammonia gas at -5°C) dropwise to the organic phase to adjust the pH to 8, keep stirring at 0°C for 30 min, and filter with suction to obtain a light yellow solid with a volume ratio of two Methyl chloride:ethanol=6:1 mixed solution 200mL soaks and washes the filter cak...

Embodiment 2

[0026] Stir 180g of purified water and 20g of sulfuric acid evenly, add 1.3g of ferric chloride, stir evenly, add 20g of acetylfuran, control the temperature at 55-60°C, slowly introduce 23g of methyl nitrite, control the aeration time at 2 hours, and the aeration is completed Rear insulation reaction 6 hours, add liquid caustic soda to adjust its pH value to 6 after the completion of the reaction, add 1g gac to the reaction solution, stir and filter for 30 minutes,

[0027] After filtration, add 200mL dichloromethane to extract twice, combine the organic phases, and slowly add a saturated ethanol solution of ammonia gas (-5°C ammonia ethanol saturated solution) to the organic phase to adjust the pH to 8. Lower heat preservation and stirring for 30min, suction filtration, to obtain a light yellow solid, with a volume ratio of dichloromethane: ethanol=6:1 mixed solution 200mL bubble wash filter cake, to obtain a white powdery solid, i.e. furan ammonium salt 22.1g, yield It is 6...

Embodiment 3

[0029] Stir 180g of purified water and 17g of sulfuric acid evenly, add 1.25g of copper chloride, stir evenly, add 20g of acetylfuran, control the temperature at 55-60°C, slowly introduce 23g of methyl nitrite, control the aeration time at 5 hours, and the aeration is completed After the reaction was incubated for 5 hours, after the reaction was completed, ammonia water was added to adjust its pH value to 5, and 1 g of activated carbon was added to the reaction solution, stirred for 30 minutes and filtered.

[0030] After filtration, add 200mL dichloromethane to extract twice, combine the organic phases, and slowly add a saturated ethanol solution of ammonia gas (-5°C ammonia ethanol saturated solution) to the organic phase to adjust the pH to 8. Lower heat preservation and stirring for 30min, suction filtration, to obtain a light yellow solid, with a volume ratio of dichloromethane: ethanol=6:1 mixed solution 200mL bubble wash filter cake, to obtain a white powdery solid, i.e....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com