Light fire brick and preparing method thereof

A refractory brick and lightweight technology, applied in the field of lightweight refractory bricks and their preparation, can solve the problems of low strength, high cost, affecting the economic benefits of tunnel kilns and oil shaft kilns, etc., and achieve high refractory temperature, low cost, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

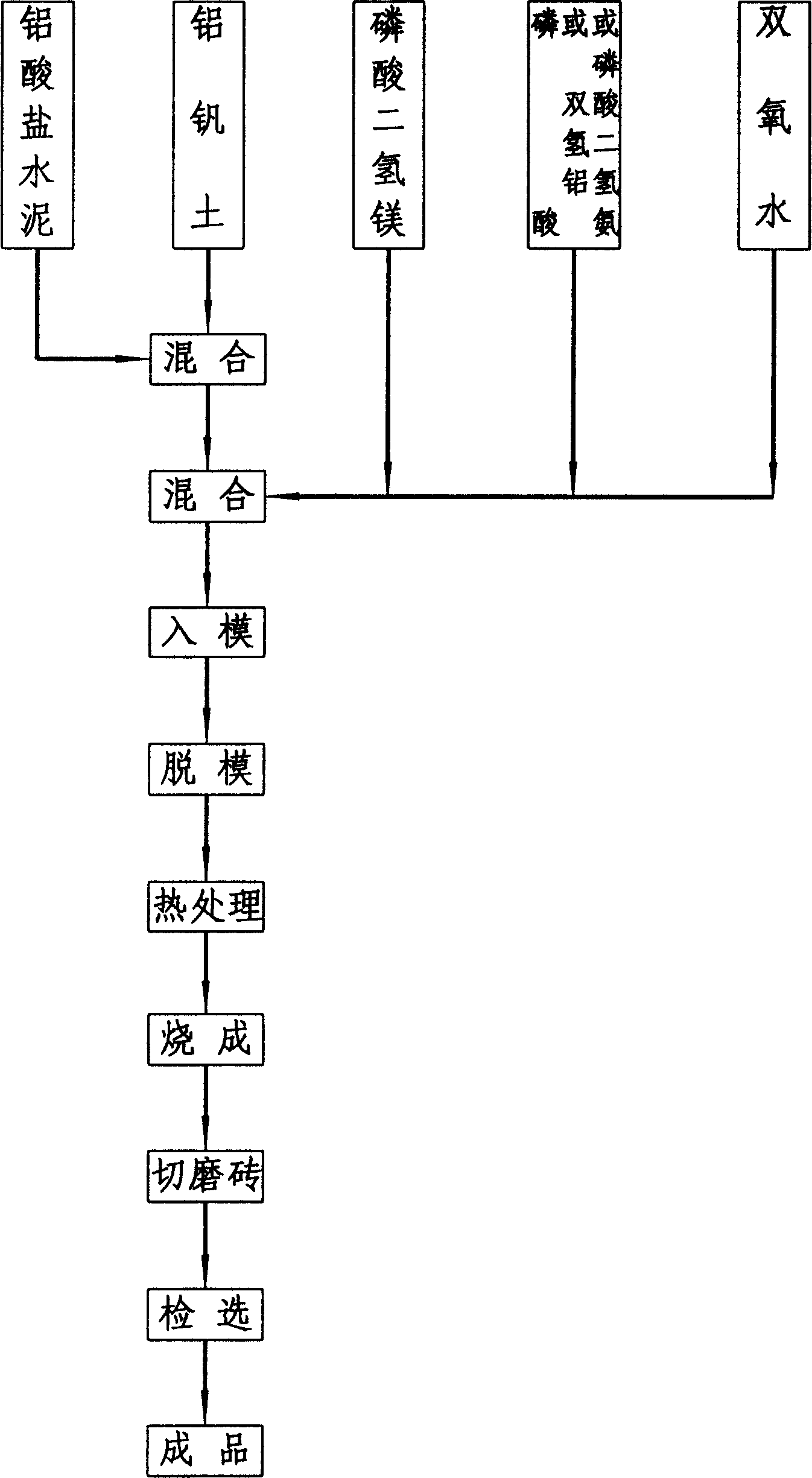

Image

Examples

Embodiment 1

[0021] First 100 grams of bauxite and 3.5 grams of bauxite cement are fully mixed to make mixture A;

[0022] Then 10ml concentration by weight is 35% magnesium dihydrogen phosphate solution and 10ml concentration by weight is 40% phosphoric acid and 2.5ml hydrogen peroxide fully mixed to make mixture B;

[0023] Pour mixture A and mixture B together and mix them well and then pour them into the mold. The mold is double-opened and lined with plastic paper to facilitate demoulding. After 24 hours of natural hardening, it will be demoulded and heat treated at 110-200°C. , and then fired at 1450-1750°C, and processed by a brick cutting machine and a brick grinding machine to get the finished product.

Embodiment 2

[0025] First 100 grams of bauxite and 4.5 grams of bauxite cement are fully mixed to make mixture A;

[0026] Then 15ml concentration by weight is that 30% magnesium dihydrogen phosphate solution and 15ml concentration by weight are 32% phosphoric acid and 2.5ml hydrogen peroxide fully mix and make mixture B;

[0027] Pour mixture A and mixture B together and mix them well and then pour them into the mold. The mold is double-opened and lined with plastic paper to facilitate demoulding. After 24 hours of natural hardening, it will be demoulded and heat treated at 110-200°C. , and then fired at 1450-1750°C, and processed by a brick cutting machine and a brick grinding machine to get the finished product.

Embodiment 3

[0029] First 100 grams of bauxite and 4 grams of bauxite cement are fully mixed to make mixture A;

[0030] Then 10ml concentration by weight is 35% magnesium dihydrogen phosphate solution and 10ml concentration is 40% aluminum oxide by weight and the hydrogen peroxide of 2.5ml fully mixes and makes mixture B;

[0031] Pour mixture A and mixture B together and mix them well and then pour them into the mold. The mold is double-opened and lined with plastic paper to facilitate demoulding. After 24 hours of natural hardening, it will be demoulded and heat treated at 110-200°C. , and then fired at 1450-1750°C, and processed by a brick cutting machine and a brick grinding machine to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com