Patents

Literature

49 results about "Styrene-acrylonitrile resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Styrene acrylonitrile resin is a copolymer plastic consisting of styrene and acrylonitrile. It is also known as SAN. It is widely used in place of polystyrene owing to its greater thermal resistance. The chains of the polymer show alternating repeat units of styrene and acrylonitrile, and it is a copolymer.

Low-gloss polycarbonate styreneresin composite and preparation method thereof

InactiveCN101787192AReasonable preparation processSolve technical problems with severe performance degradationStyrene-acrylonitrile resinAcrylonitrile-butadiene-styrene resin

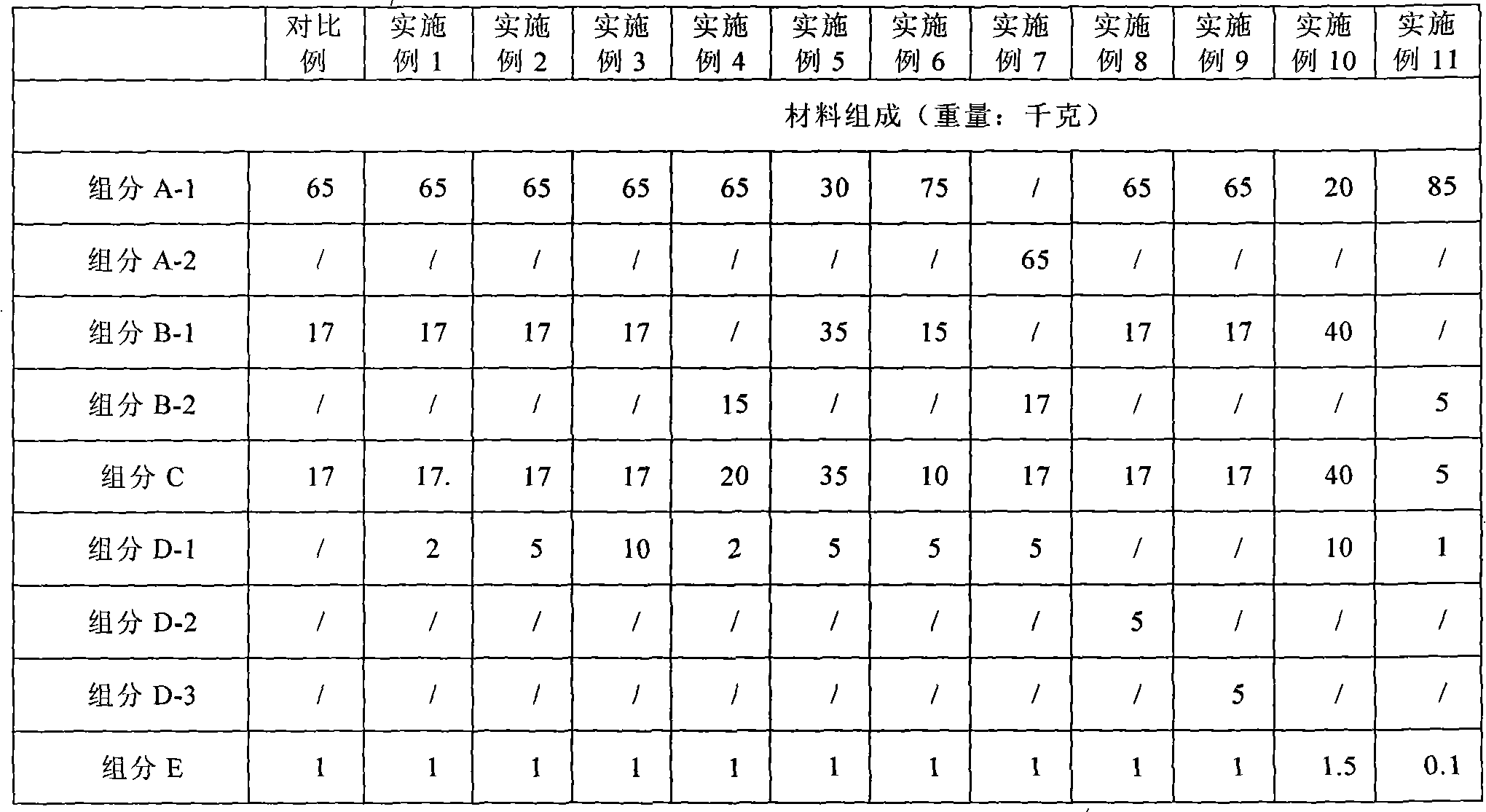

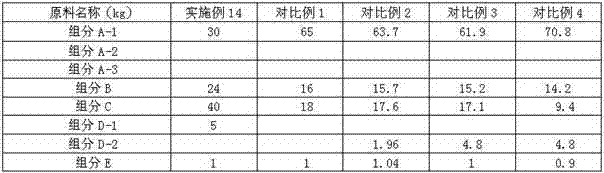

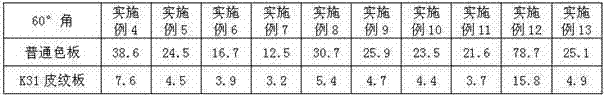

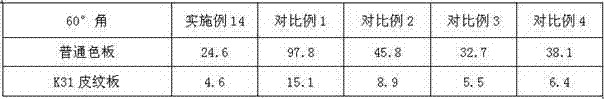

The invention relates to a low-gloss polycarbonate styreneresin composite and a preparation method thereof. The composite comprises the following components (by weight percent): 20-85wt% of polycarbonate resin, 5-50wt% of styrene flexibilizer, 5-40wt% of styrene-acrylonitrile resin,1-10wt% of specific matting agent, and 0.1-1.5wt% of processing agent; the materials are premixed for 3-10 minutes in a high speed mixer, then premix compound is subject to melt extrusion at 230-300 DEG C by a double screw extruding machine, and cooling and pelletizing are carried out, thus obtaining the low-gloss polycarbonate (PC) / styreneresin composite. Compared with the prior art, the invention has the advantages that preparation technology is reasonable and the technical problem of degradation of performance of products as matting efficiency of polycarbonate (PC) / styreneresin composite is low is solved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Reactive extrusion matte agent, low gloss PC/ABS alloy and its preparation method

ActiveCN102382348AExcellent MatteImprove mechanical propertiesStyrene-acrylonitrile resinPolycarbonate

The invention relates to a reactive extrusion matte agent, a low gloss PC / ABS alloy by using the reactive extrusion matte agent and a preparation method thereof. The low gloss PC / ABS alloy comprises the following components of: by weight, 20-80% of a polycarbonate resin, 5-50% of an ABS resin, 5-40% of a styrene-acrylonitrile resin, 1-10% of the reactive extrusion matte agent and 0.1-1.5% of a processing aid. The preparation method provided by the invention comprises the following steps of: premixing the above materials in a high-speed mixer for 3-10 minutes, allowing the premix to enter intoa double screw extruder for melting extrusion at the temperature of 230-300 DEG C, cooling, followed by granulation to obtain the low gloss PC / ABS alloy. In comparison with the prior art, the preparation method provided by the invention has advantages of reasonable technology, low cost, high efficiency of reducing gloss and stable product performance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

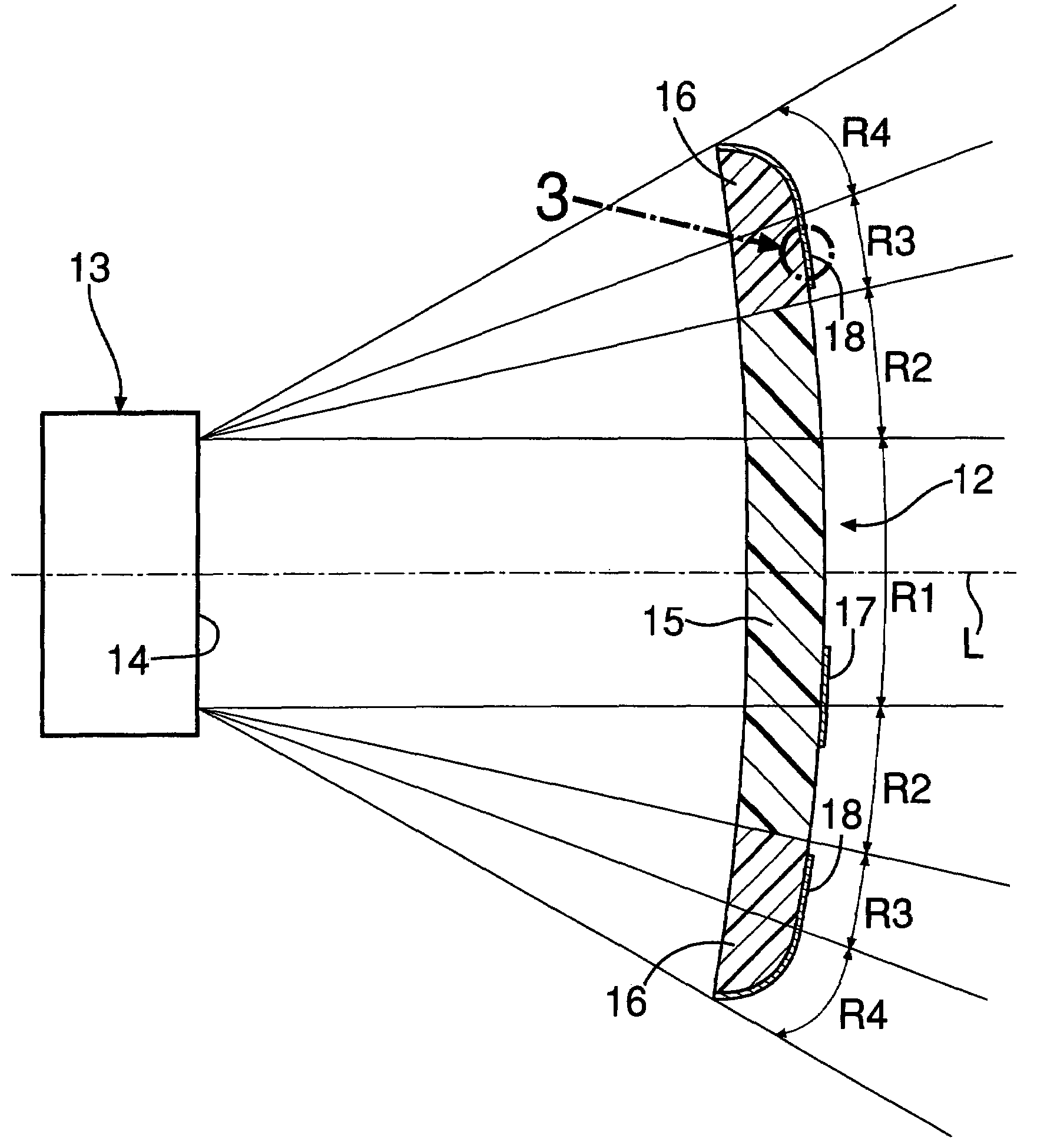

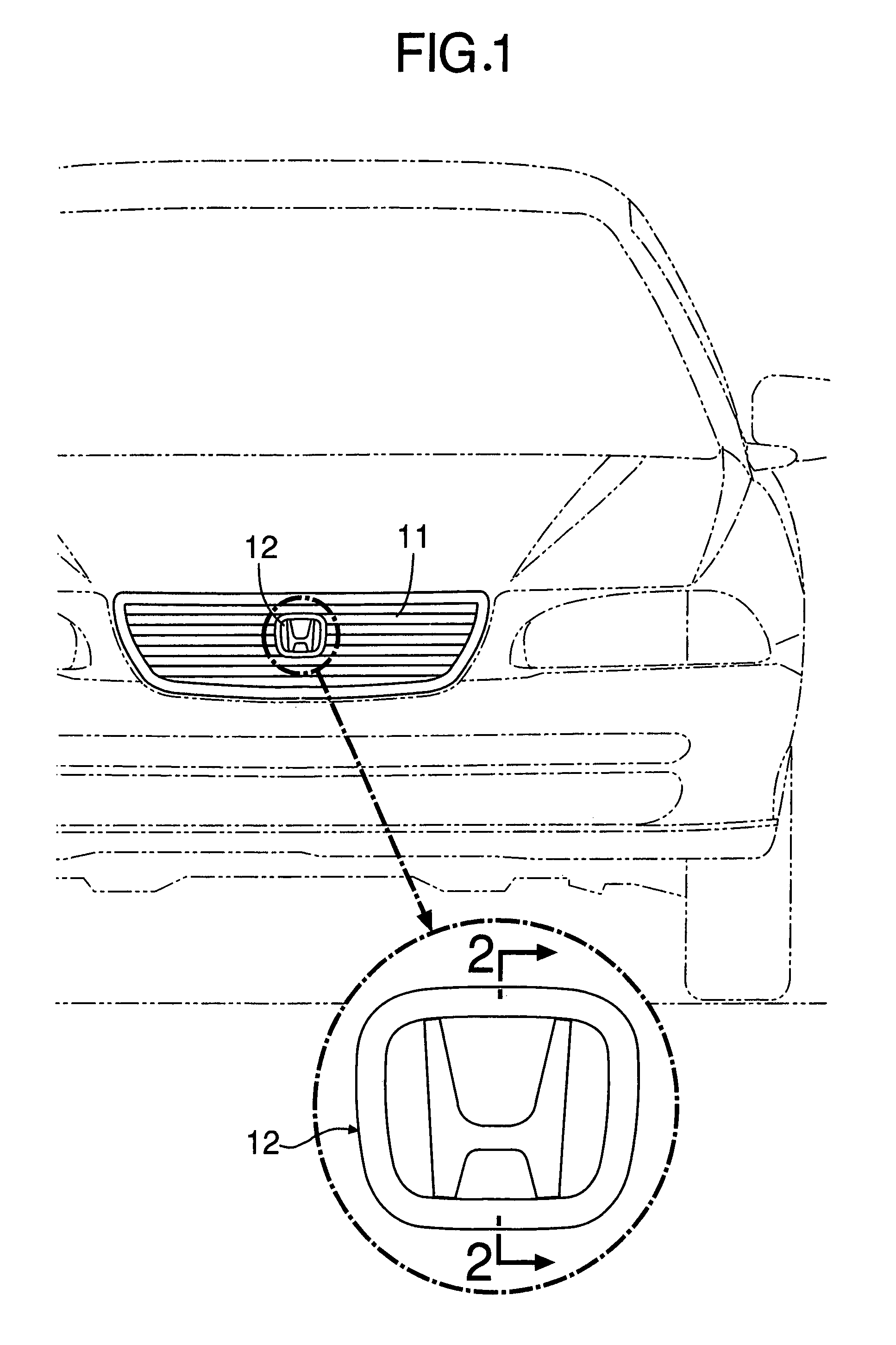

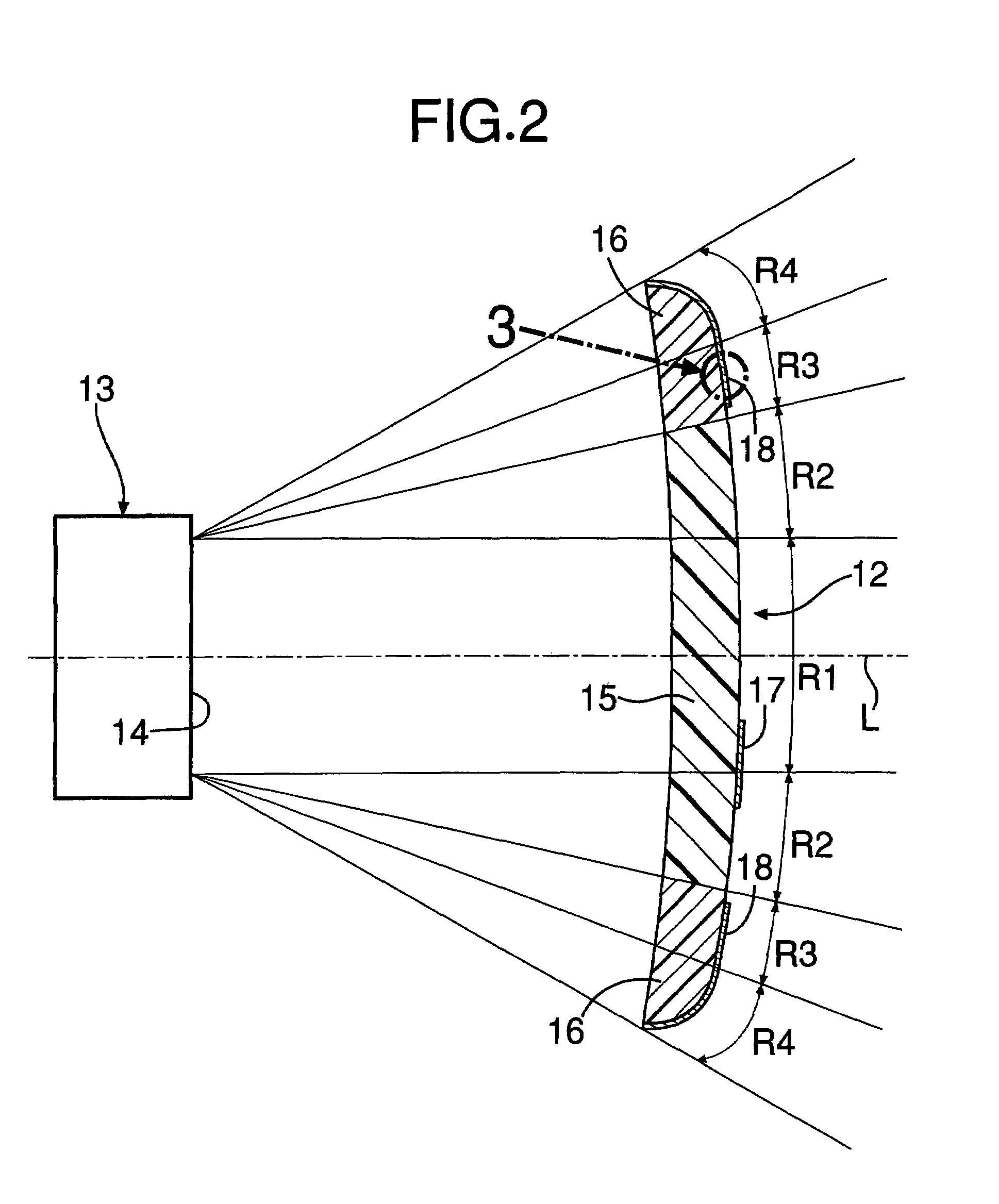

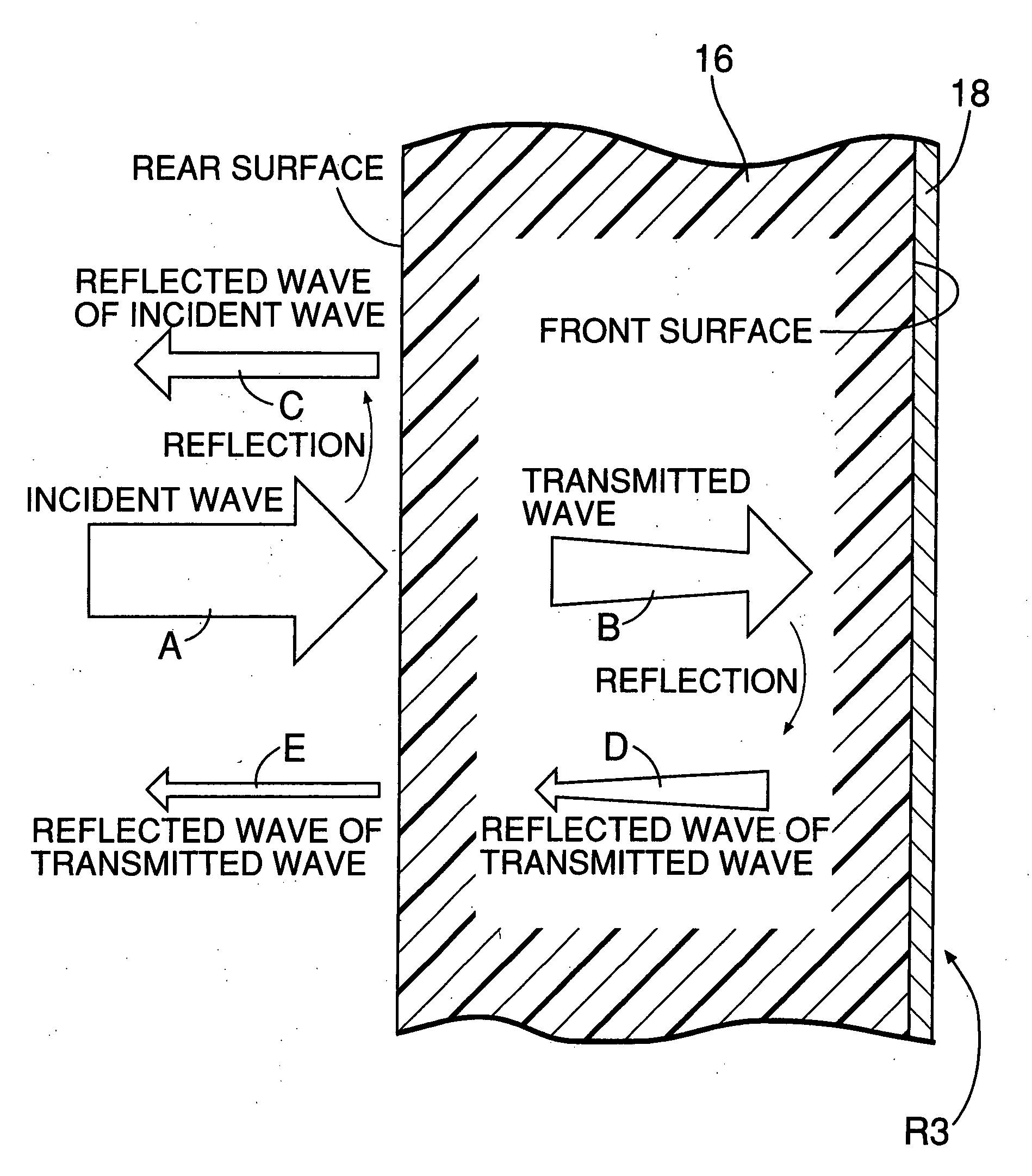

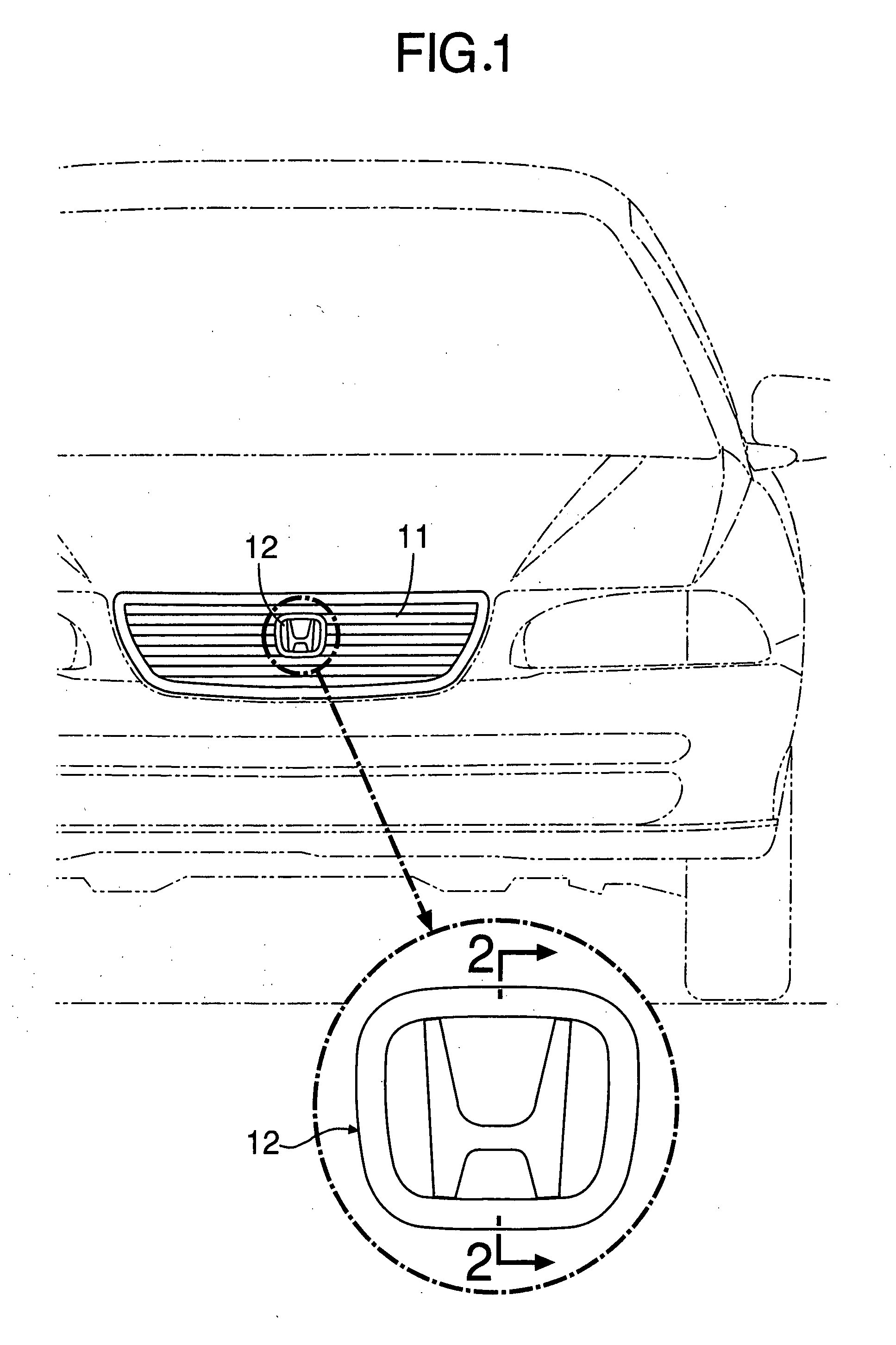

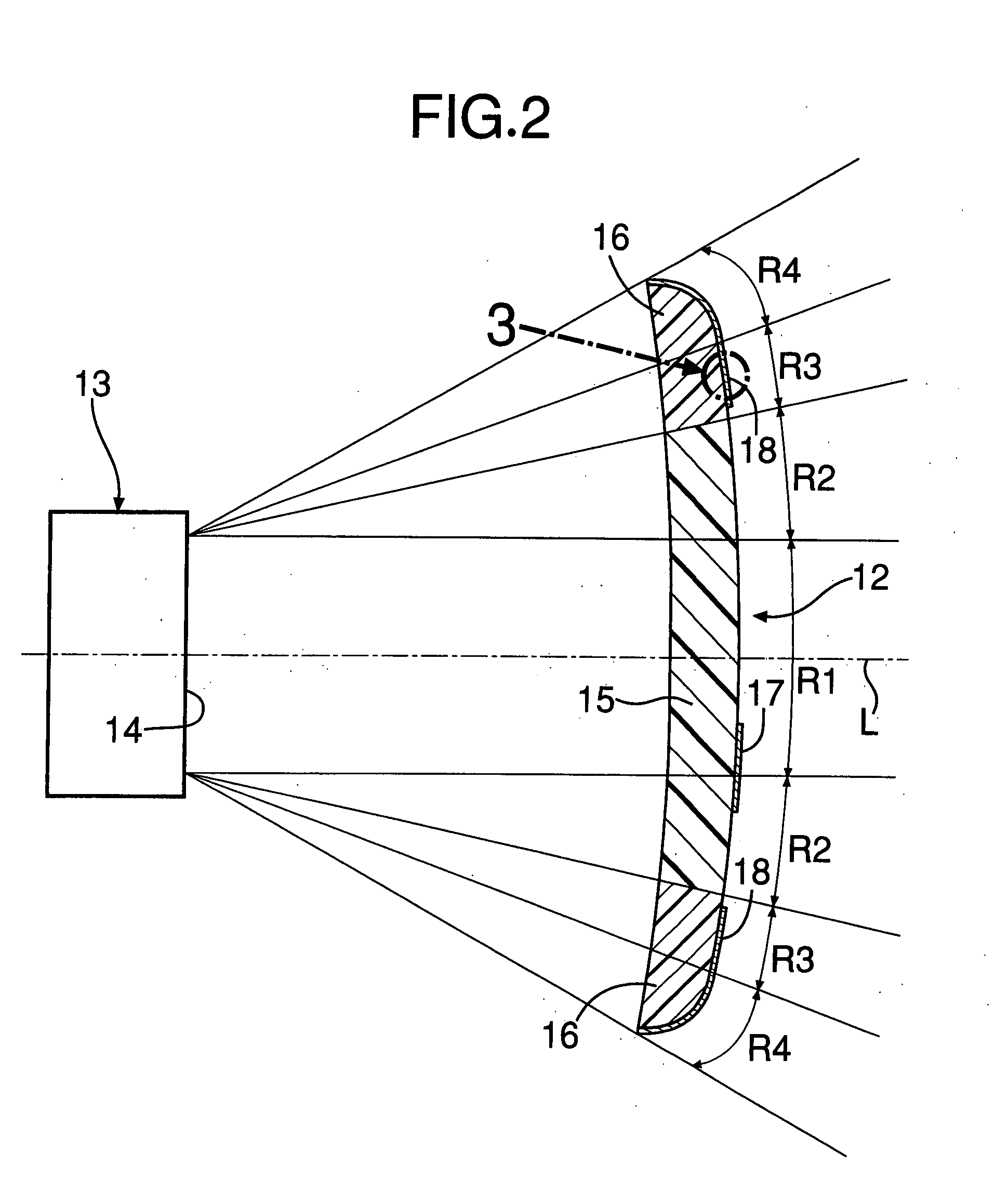

Exterior component disposed on front surface of radar device of vehicle

InactiveUS7508353B2Increase freedomLow costAntenna adaptation in movable bodiesRadiating element housingsAttenuation coefficientStyrene-acrylonitrile resin

An exterior vehicle component includes a proximity member disposed along an outer perimeter of an electromagnetic wave transmission member provided at a center of the component which is disposed in front of a radar device. The proximity member includes a chromium-plated portion formed on its front surface which reflects an electromagnetic wave. The proximity member is formed of an acrylate-styrene-acrylonitrile resin or a modified polyphenylene oxide resin having an attenuation coefficient for electromagnetic wave transmission, which is equal to or greater than a predetermined value.

Owner:HONDA MOTOR CO LTD

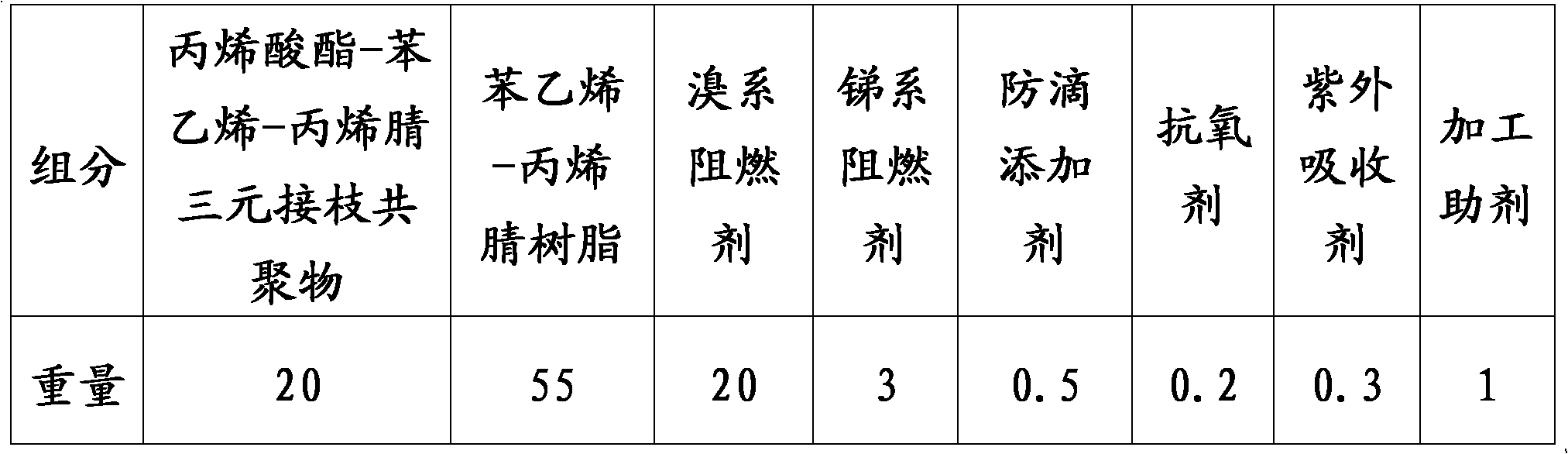

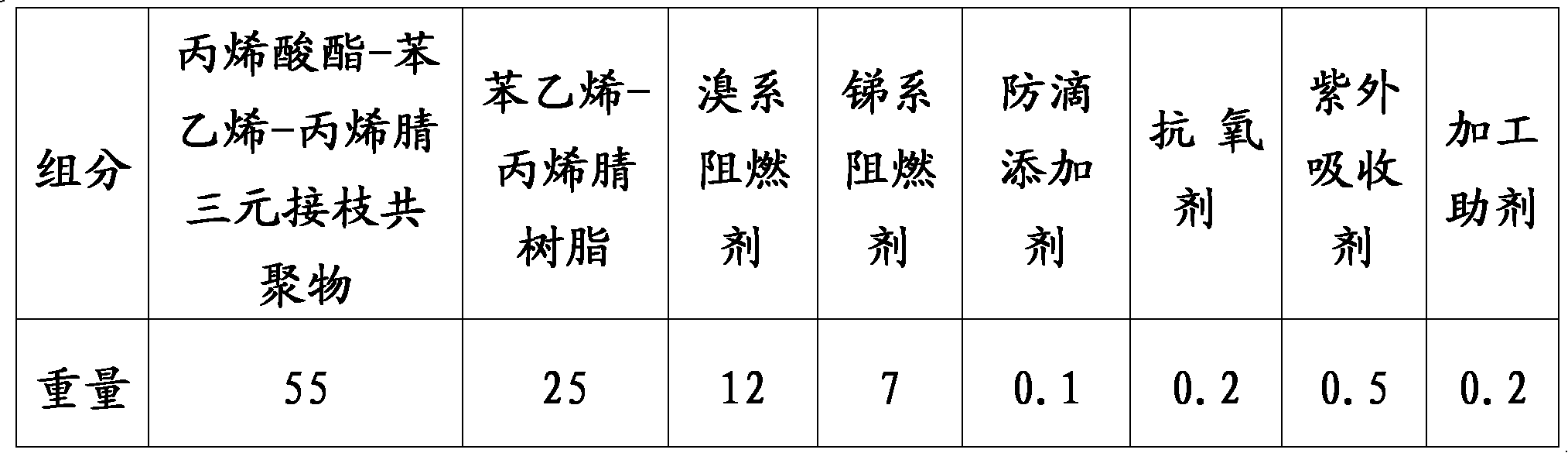

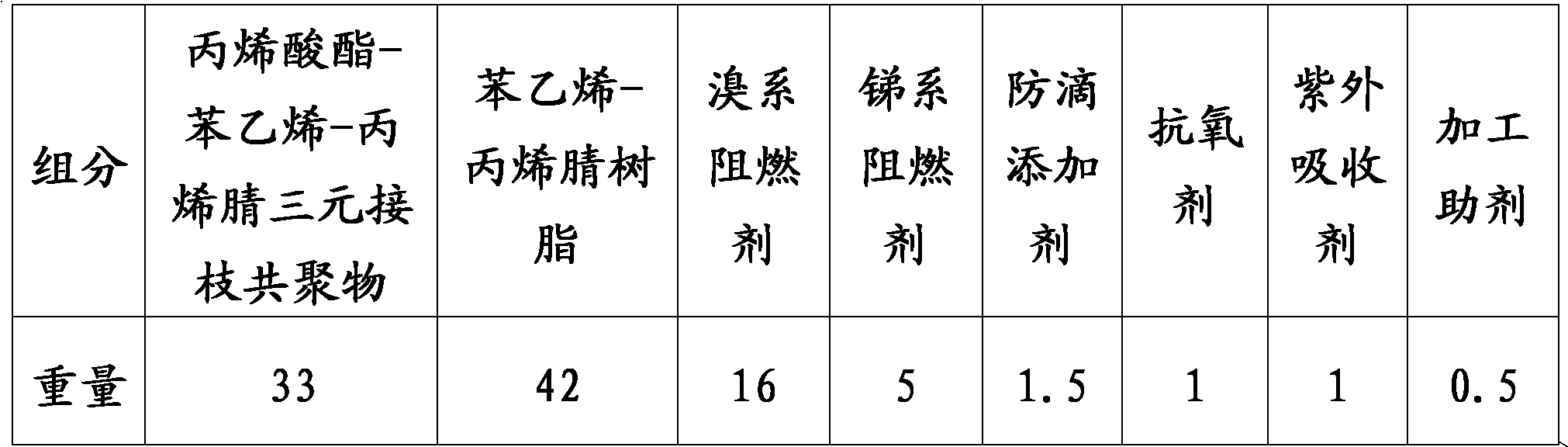

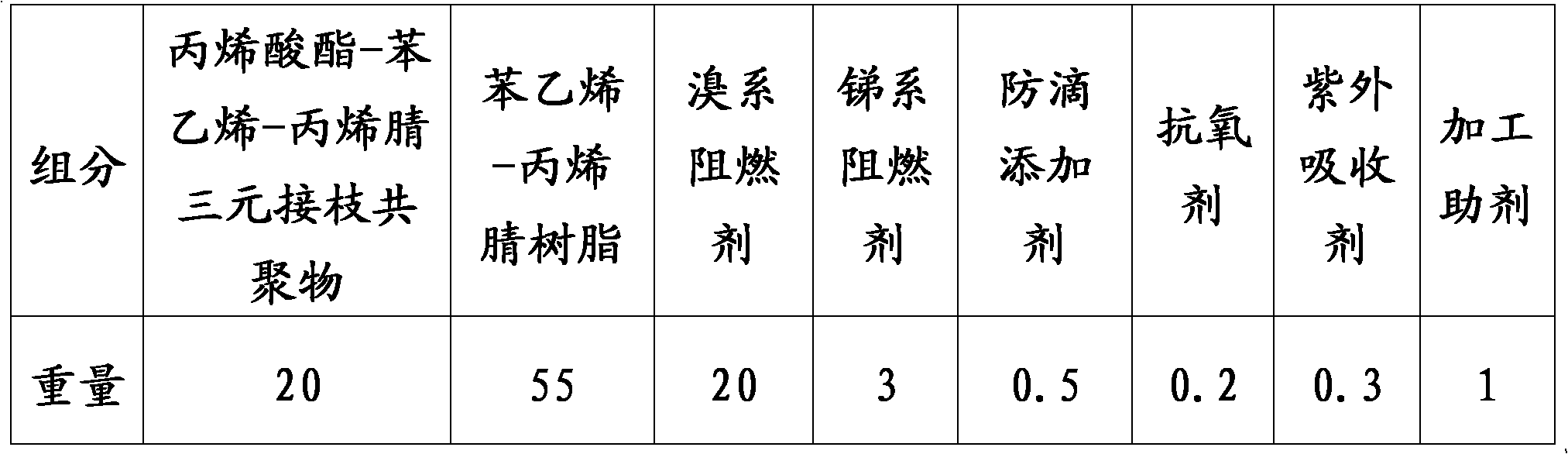

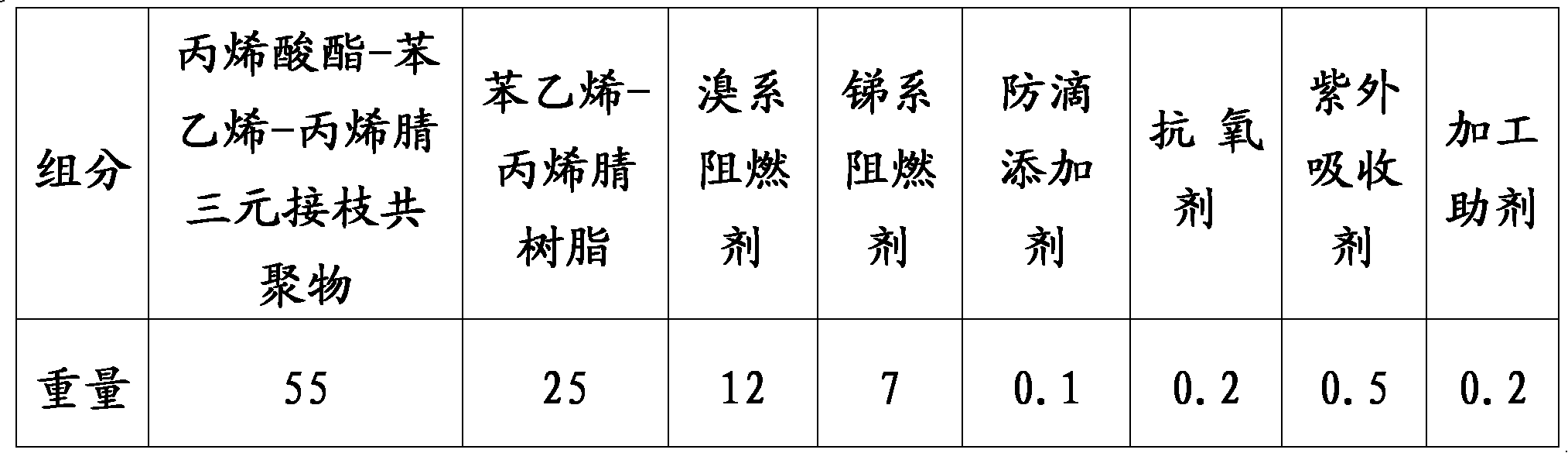

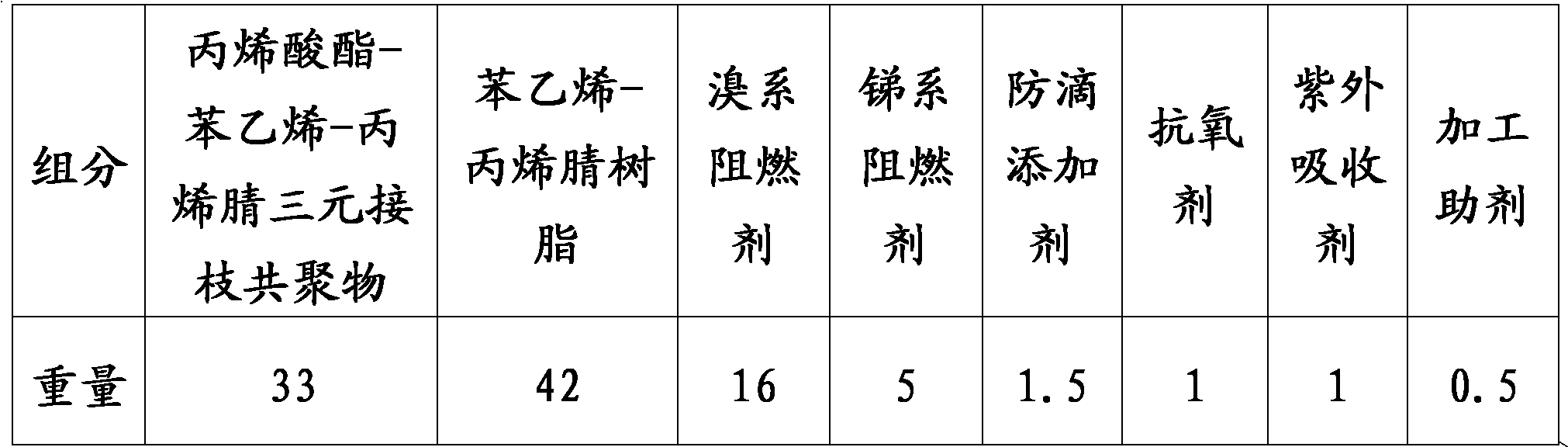

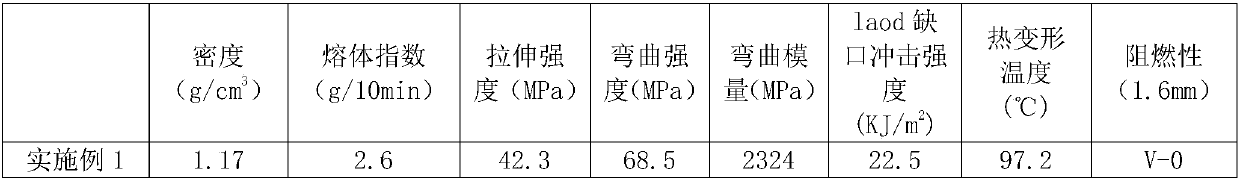

Flame-retarded ASA (Acrylic ester-Styrene-Acrylonitrile) modified resin and preparation method thereof

The invention relates to flame-retarded resin, in particular to flame-retarded ASA (Acrylic ester-Styrene-Acrylonitrile) modified resin and a preparation method thereof. The flame-retarded ASA modified material in the prior art has the defects of low flame-retarded level, flammability and unsafe use in outdoor equipment, electric appliances, and the like. The flame-retarded ASA modified material comprises the following substances in weight ratio: 20-55 parts of acrylic ester-styrene-acrylonitrile-ternary graft copolymer, 25-55 parts of styrene-acrylonitrile resin, 12-20 parts of bromine flame retardant agents, 3-7 parts of stibium flame retardant agents, 0.1-1.5 parts of drip-proof additive, 0.2-1% of antioxidant, 0.3-1% of ultraviolet absorbent and 0.2-1% of processing agent. The preparation method comprises the following steps of: accurately weighing each component and placing into a high speed mixer for uniform mixing; introducing into a twin screw extruder with a long diameter; mixing and milling; extruding; pulling into strips; cooling; and cutting into granules and packaging. The invention has the advantages of satisfying the flame retarded property and having more balanceable thermal stability, processing liquidity and impact strength; and the preparation method is simple and easy for operation.

Owner:SHANGHAI KINGFA SCI & TECH +1

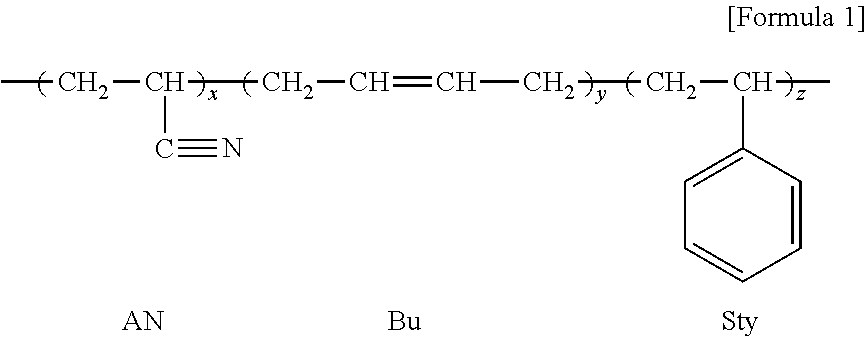

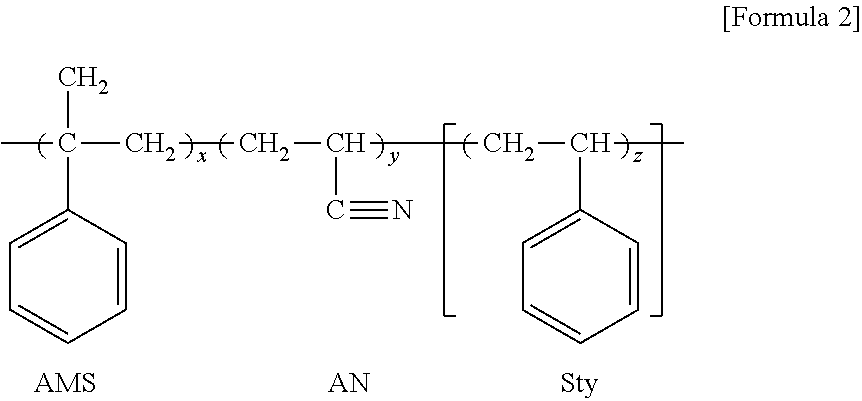

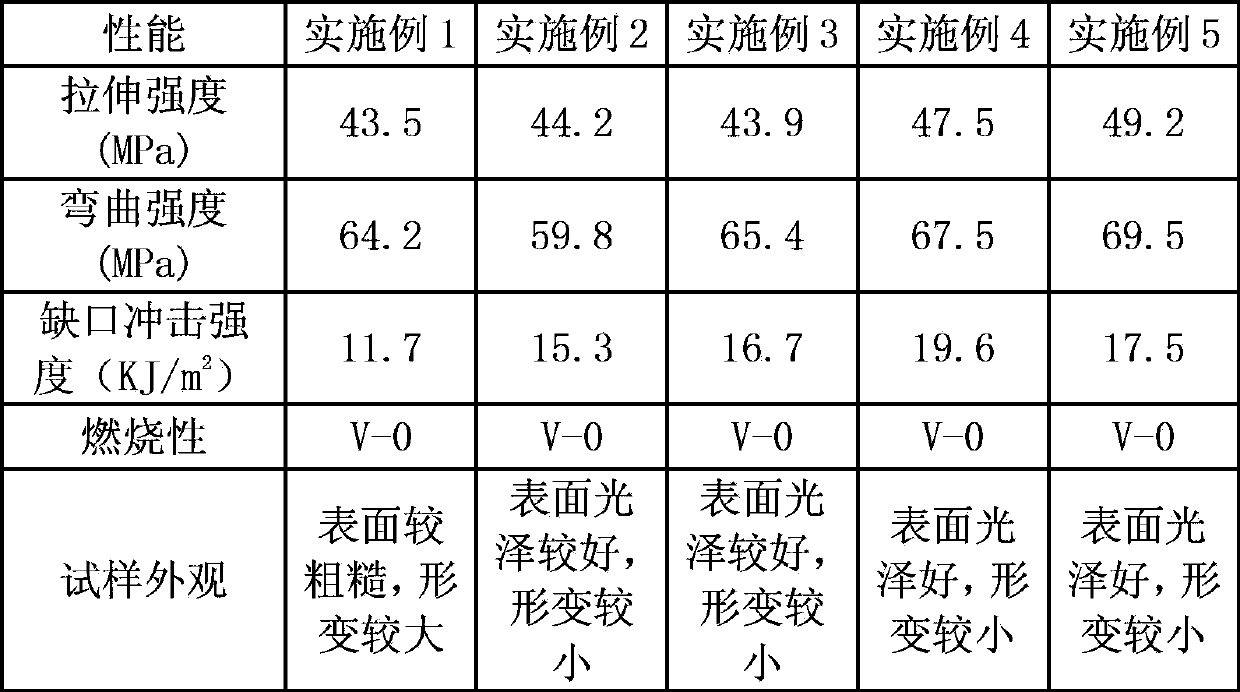

Thermoplastic resin composition and molded article employing same

The present invention relates to a styrene-based thermoplastic resin composition with improved flowability and, more specifically, a thermoplastic resin composition, which retains heat resistance and improved flowability by introducing a low-molecular weight styrene-acrylonitrile (SAN) resin into an acrylonitrile-butadiene-styrene (ABS) resin, which has enhanced heat resistance through the addition of a heat-resistant resin, and to a molded article into which the composition is molded. According to the resin composition, there can be obtained: a thermal resin composition, which has an improvement in the flowability of the heat-resistant ABS resin and retains non-deteriorating or favorable heat resistance and impact resistance; and a molded article.

Owner:LG CHEM LTD

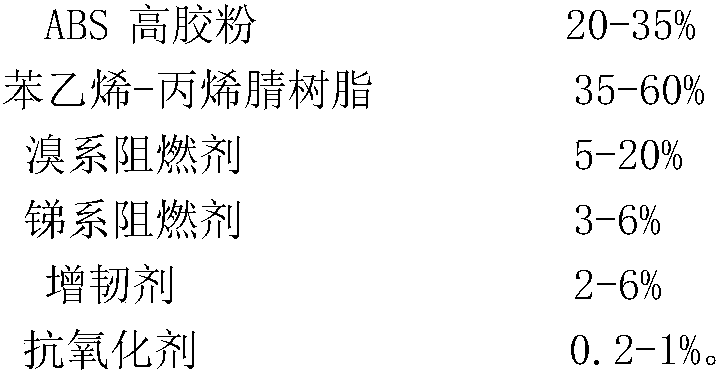

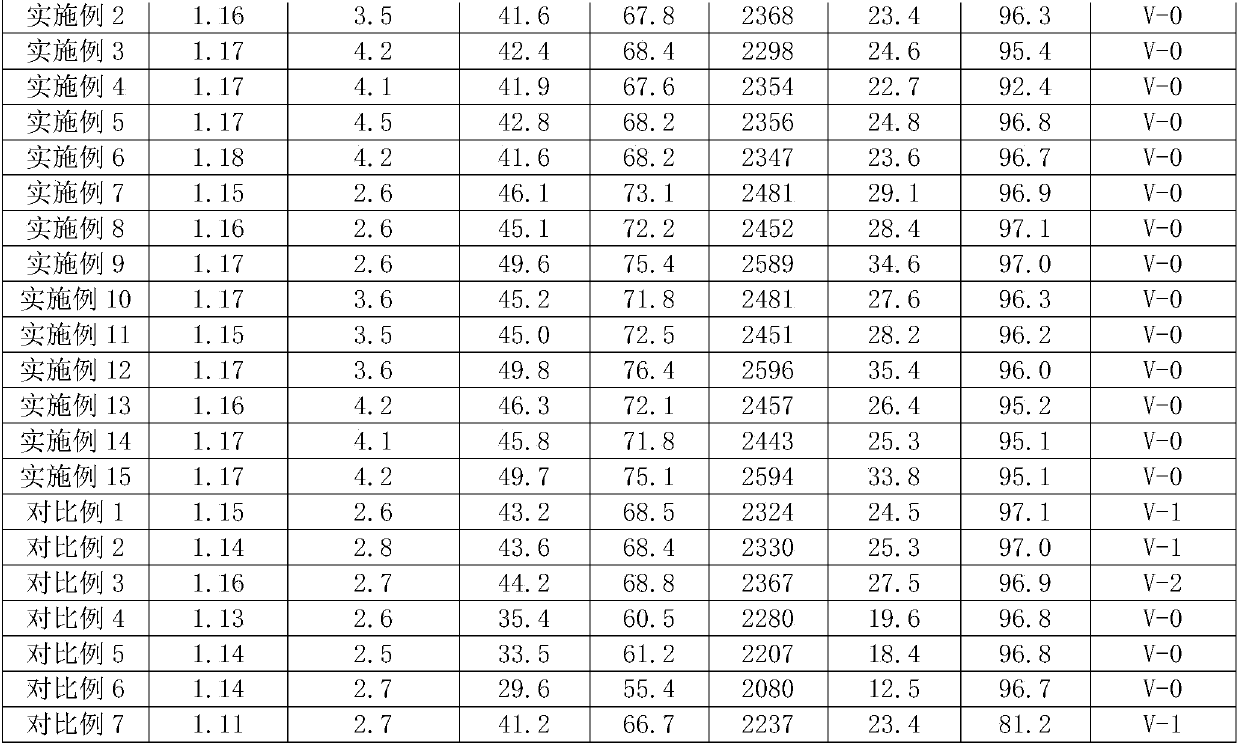

Flame-retardant and heat-resistant material for battery jar and preparation method thereof

The invention belongs to battery jar materials, and discloses a flame-retardant and heat-resistant material for a battery jar and a preparation method thereof. An acrylonitrile butadiene styrene (ABS) resin battery jar of the prior art cannot meet flame-retardant and heat-resistant requirements of a battery. The flame-retardant and heat-resistant material consists of the following materials in part by weight: 20 to 35 parts of ABS high glue powder, 35 to 60 parts of styrene-acrylonitrile resin, 5 to 20 parts of brominated epoxy flame retardant, 3 to 6 parts of antimony flame retardant, 2 to 6 parts of powdered butadiene-acrylonitrile rubber, 0.2 to 1 part of antioxidant, and 0.2 to 1 part of processing agent. The preparation method comprises the following steps of: adding the raw materials into a high-speed mixer for uniform mixing; delivering the mixture into a twin-screw extruder of which the length-diameter ratio is 32 to 40; and performing mixing, extruding, strip pulling, cooling, and chopping to obtain the flame-retardant and heat-resistant material. The flame-retardant and heat-resistant material has the advantages of high flame retardance and heat resistance to prolong the service life of the battery, high impact resistance and chemical corrosion resistance to meet working requirements of the battery, and simple preparation process which is easy to operate.

Owner:SHANGHAI KINGFA SCI & TECH +1

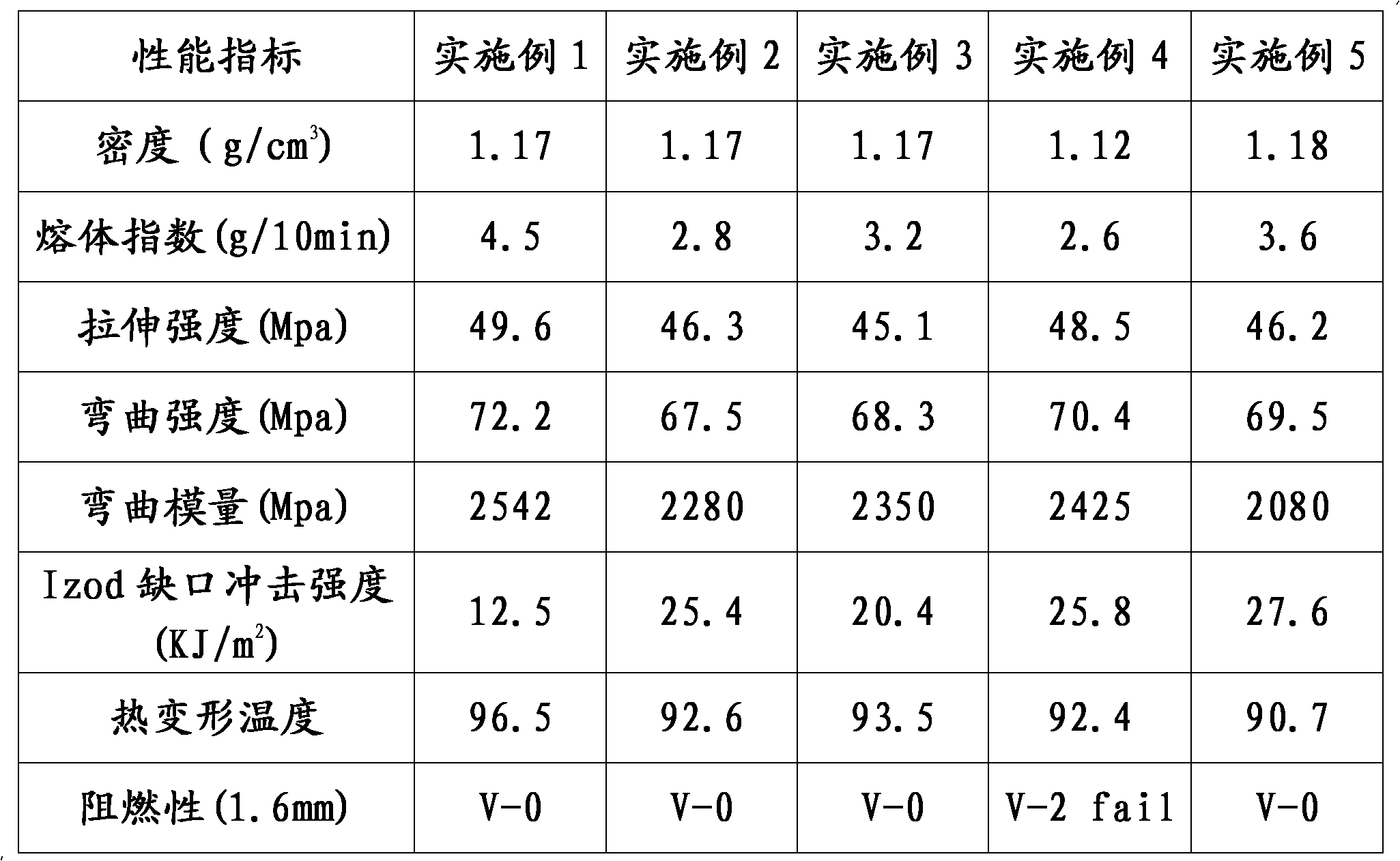

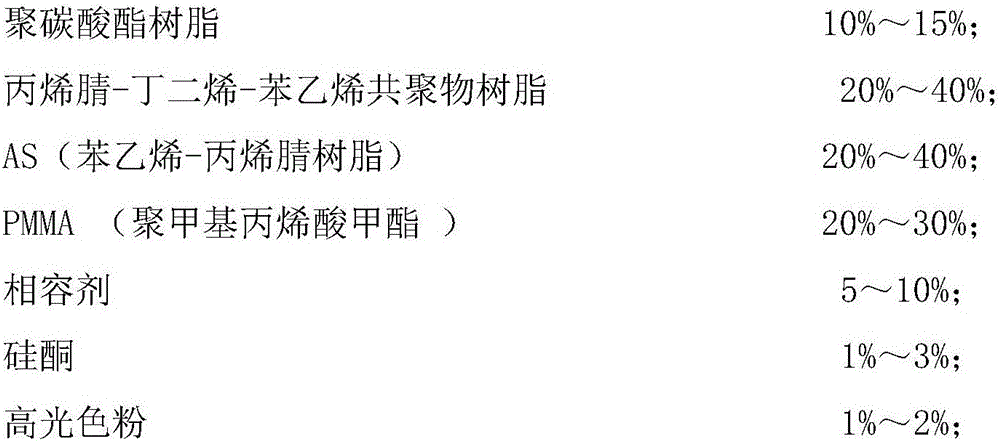

High-gloss high-hardness scraping-resistant ABS material

InactiveCN105802118ASignificant technological progressHigh hardnessStyrene-acrylonitrile resinPolymethyl methacrylate

The invention provides a high-gloss high-hardness scraping-resistant ABS material which comprises the following components in percentage by mass: 10-15% of polycarbonate resin, 20-40% of an acrylonitrile-butadiene-styrol copolymer, 20-40% of styrene-acrylonitrile resin, 20-30% of polymethyl methacrylate, 5-10% of a compatilizer, 1-3% of silicone, 1-2% of a high-gloss toner and 0.1-1% of an additive. The high-gloss high-hardness scraping-resistant ABS material provided by the invention has properties of good impact resistance, high gloss, high hardness, scraping resistance and the like, and moreover is low in cost and easy to prepare. In addition, the preparation method of the high-gloss high-hardness scraping-resistant ABS material adopts conventional equipment and is simple to operate and applicable to industrial production.

Owner:中广核俊尔(上海)新材料有限公司

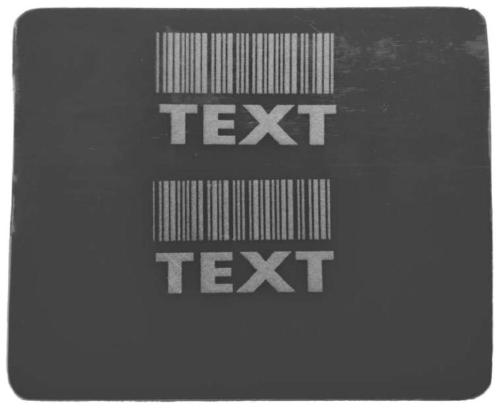

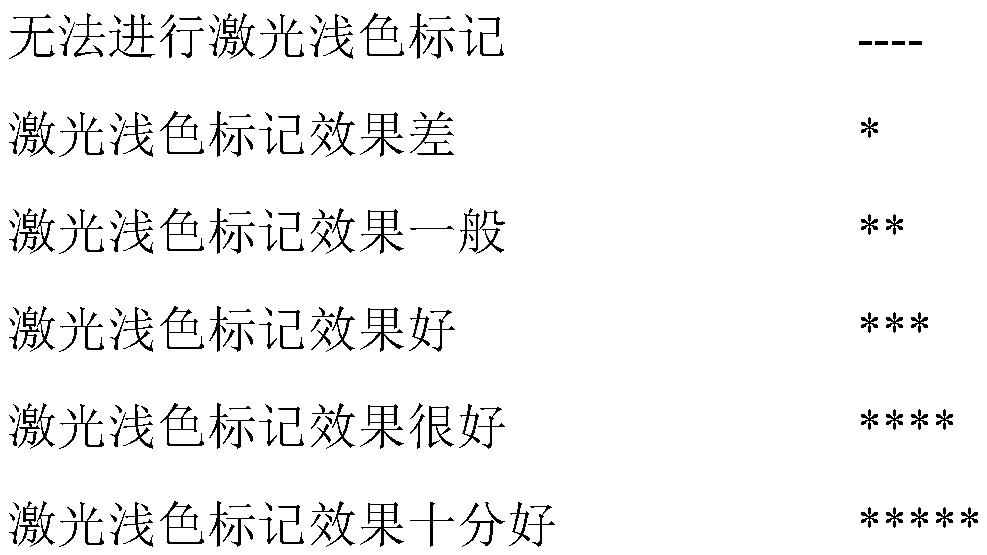

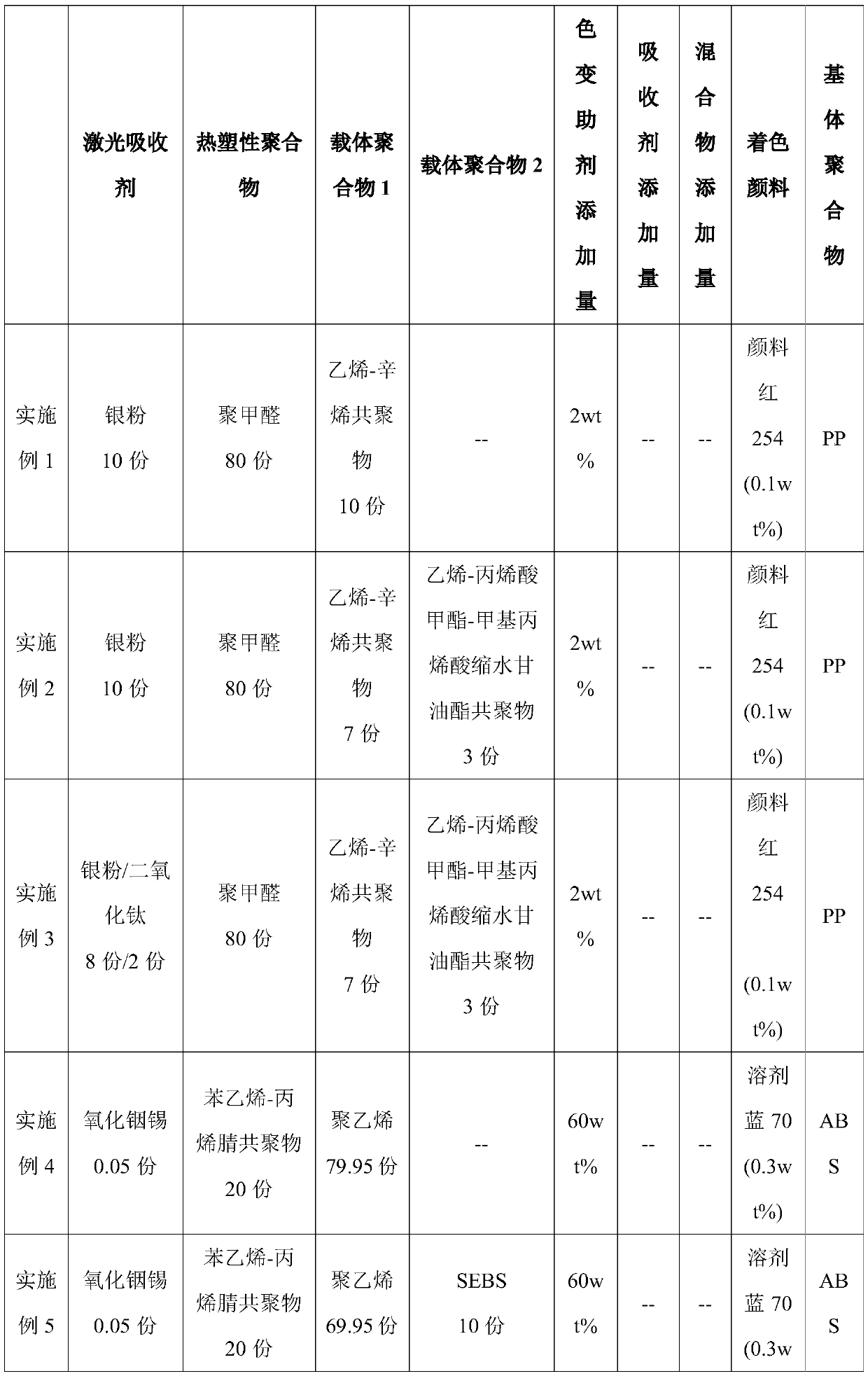

Color change aid used for preparing white or light-colored marks and preparation method thereof

ActiveCN110408165ASimple manufacturing processSimple and fast operationPolymer scienceStyrene-acrylonitrile resin

The invention discloses a color change aid. The color change aid is prepared from, by weight, 0.05-10.00 parts of a laser absorbent, 20.00-80.00 parts of a thermoplastic polymer and 10.00-79.95 partsof a carrier polymer, wherein the thermoplastic polymer is polyacrylate resin, polyoxymethylene resin, styrene-acrylonitrile resin, acrylate-styrene resin or ABS resin. The invention further disclosesthe use of the color change aid for performing marking on colored polymers. Experiments show that after a certain amount of the color change aid is added into the polymers of different colors, the light-colored to white marks can be efficiently marked on the polymers of different colors; the preparation method of the disclosed color change aid is simple, easy to operate, safe, environmentally friendly, low in energy consumption, and very suitable for large-scale production in industries, and has good economic benefits.

Owner:SICHUAN UNIV

Transparent high-hardness impact-resistant acrylonitrile butadiene styrene (ABS) plastic alloy composition

The invention discloses a transparent high-hardness impact-resistant acrylonitrile butadiene styrene (ABS) plastic alloy composition. The transparent high-hardness impact-resistant ABS plastic alloy composition comprises 30 to 50 weight parts of styrene-acrylonitrile resin, 30 to 50 weight parts of polymethacrylate resin and 10 to 30 weight parts of acrylic ester elastomer. The ABS plastic alloy composition prepared by the technical scheme has the advantages that: the ABS plastic alloy composition is transparent and has high toughness and high surface hardness; 2, the ABS plastic alloy composition is transparent and has high impact resistance and surface hardness, so surface coating can be saved; and 3, the ABS plastic alloy composition has high flowability, so filling formation of a large-sized die is facilitated. The ABS plastic alloy composition can be applied to shells of mobile phones, mobile digital video disc (DVD) electronic products, domestic appliances such as televisions, liquid crystal displays and the like and automobile instrument displays and the like.

Owner:SHANGHAI PRET COMPOSITES

Exterior component disposed on front surface of radar device of vehicle

InactiveUS20070210979A1Improve aestheticsLow costAntenna adaptation in movable bodiesRadiating element housingsAttenuation coefficientStyrene-acrylonitrile resin

An exterior vehicle component includes a proximity member disposed along an outer perimeter of an electromagnetic wave transmission member provided at a center of the component which is disposed in front of a radar device. The proximity member includes a chromium-plated portion formed on its front surface which reflects an electromagnetic wave. The proximity member is formed of an acrylate-styrene-acrylonitrile resin or a modified polyphenylene oxide resin having an attenuation coefficient for electromagnetic wave transmission, which is equal to or greater than a predetermined value.

Owner:HONDA MOTOR CO LTD

High-impact high-weather-resistance environmental-friendly brominated flame-retardant ASA material and preparation method and application thereof

ActiveCN103073809AAdd lessUniform mechanical propertiesStyrene-acrylonitrile resinWeather resistance

The invention discloses a high-impact high-weather-resistance environmental-friendly brominated flame-retardant ASA (Acrylonitrile-styrene-acrylate) material which comprises the following components in part by weight: 15 to 40 parts of ASA resin, 30 to 60 parts of styrene-acrylonitrile resin, 7 to 12 parts of environmental-friendly brominated flame retardant, 5 to 20 parts of chlorinated polyethylene and 2 to 6 parts of novel environmental-friendly flame-retardant synergist. The preparation method comprises the following steps: sequentially adding the components into a high-speed mixer to uniformly mix according to a certain proportion; and then adding the mixture into a double-screw extruder to carry out mixing, extrusion, bracing, water cooling and sized dicing to obtain the high-impact high-weather-resistance environmental-friendly brominated flame-retardant ASA material. According to the high-impact high-weather-resistance environmental-friendly brominated flame-retardant ASA material disclosed by the invention, the adding amount of the flame retardant is less than the use amounts of current other flame-retardant systems by over one third; and tests show that the flame retardant rating reaches UL94@3.0 to 1.0mmV-0, impact intensity is kept above 15kJ / m<2>, a melt index exceeds 20g / 10min, weather resistance is excellent, other various mechanical performances are balanced, a preparation method is simple and easy to operate, and the high-impact high-weather-resistance environmental-friendly brominated flame-retardant ASA material is easy to process and is suitable to popularize and apply in the fields of outdoor electronics and the like which require high impact and high weather resistance.

Owner:KINGFA SCI & TECH CO LTD +1

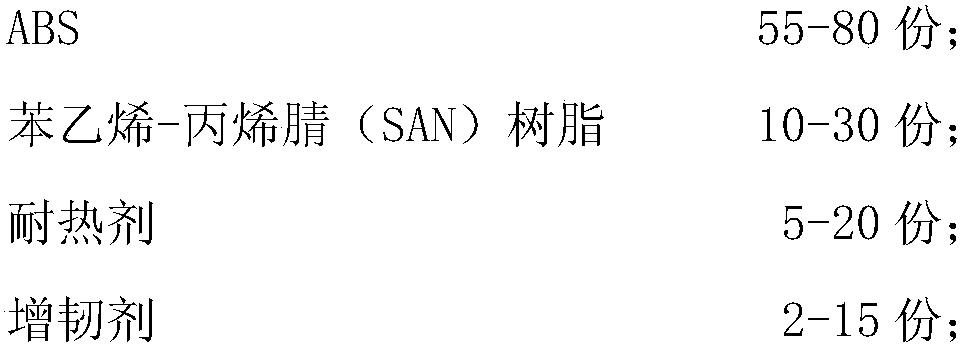

Microbubble injection moulding ABS composite material and preparation method thereof

The invention discloses a microbubble injection moulding ABS composite material and a preparation method thereof. The microbubble injection moulding ABS composite material comprises the following components in parts by weight: 95-98 parts of a high-fluidity high melt-strength ABS composite material, and 2-5 parts of foaming agent master batch; wherein the high-fluidity high melt-strength ABS composite material comprises the following components in parts by weight: 55-80 parts of ABS, 10-30 parts of styrene-acrylonitrile (SAN)resin, 5-20 parts of a heat-resistant agent, 2-15 parts of a flexibilizer, 0.05-1 part of a cross-linking agent, and 0.1-2 parts of an anti-oxidant. By adding the cross-linking agent, ABS is extruded to form a micro-crosslinking structure, ABS melt-strength is increased, and uniform compact micropores can be easily obtained. The high-fluidity SAN resin is added at a rear segment of a screw, melt strength is increased, fluidity of the composite material is increased, the material is in favor of moulding processing, and is in favor of obtaining the good member surface appearance. The raw material cost is saved, and the microbubble injection moulding ABS compositematerial having the characteristics of fine and uniformly compact bubble apertures as well as good mechanical properties can be obtained.

Owner:ZHEJIANG PRET NEW MATERIALS +4

Preparation method of toughened 3D (three-dimensional) printing consumables

InactiveCN104845032AHigh impact strengthImprove toughnessAdditive manufacturing apparatusStyrene-acrylonitrile resinPolymer science

The invention discloses a preparation method of toughened 3D (three-dimensional) printing consumables. According to the method, additives are added to ABS (acrylonitrile butadiene styrene) grafting powder and are mixed with SAN (styrene-acrylonitrile resin) particles, after the mixture is uniformly mixed, extrusion and palletizing are carried out, and products are obtained; the three raw materials have the proportion in parts by weight: 40 to 70 parts of ABS grafting powder, 5 to 10 parts of additives and 30 to 50 parts of SAN particles; the additives are mixtures of polyphenyl ether, polycarbonate and modified polyacrylic ester. The preparation method provided by the invention has the advantages that the reaction conditions are mild, the operation is simple, and the 3D printing consumables prepared by the method have high impact resistant intensity and good toughness.

Owner:JIANGSU HAOYU ELECTRONICS TECH

Environmental protection fire retardation composite reinforced ABS material

InactiveCN103865225AImprove flame retardant performanceGood mechanical propertiesEnvironmental resistanceStyrene-acrylonitrile resin

The invention relates to an environmental protection fire retardation composite reinforced ABS material, which is characterized by comprising, by weight, 45-70 parts of an ABS resin, 10-15 parts of a styrene-acrylonitrile resin, 1-3 parts of a silicon base fire retardation agent, 1-3 parts of a sulfonate fire retardation agent, 10-40 parts of a high length-diameter ratio inorganic filler, 0.4-0.6 part of an antioxidant, and 0.4-0.6 part of a processing auxiliary agent. The environmental protection fire retardation composite reinforced ABS material has advantage of excellent fire retardation and good mechanical property.

Owner:SHANGHAI KINGFA SCI & TECH +1

Low-cost high-flow weather-proof environment-friendly brominated flame retardant ASA material as well as preparation method and application thereof

The invention discloses a low-cost high-flow weather-proof environment-friendly brominated flame retardant ASA (acrylonitrile styrene acrylate) material, which comprises the following components in parts by weight: 15-40 parts of ASA resin, 30-60 parts of styrene-acrylonitrile resin, 8-12 parts of environment-friendly brominated flame retardant, 5-20 parts of chlorinated polyethylene and 2-6 parts of novel environment-friendly flame retardant synergist. A preparation method for the ASA material comprises the steps as follows: adding the components into a high-speed mixer in sequence according to the proportion for uniformly mixing, and adding a mixture into a double screw extruder for mixing, extruding, pulling, water-cooling and dicing to obtain the ASA material. According to the ASA material, the addition amount of the flame retardant is lower than that of other conventional flame-retardant system by more than 1 / 3; through the test, the flame retardant level reaches UL94@1.0-3.0 mm V-0, the impact intensity is kept more than 10 kJ / m<2>, the melting index exceeds 42 g / 10 min, the weather-proof performance is excellent, and the other mechanical performance is balanced; the preparation method is simple and easy to implement; and the ASA material is easy to process and is suitable for popularization and application in the fields of outdoor electronic products and the like.

Owner:KINGFA SCI & TECH CO LTD +1

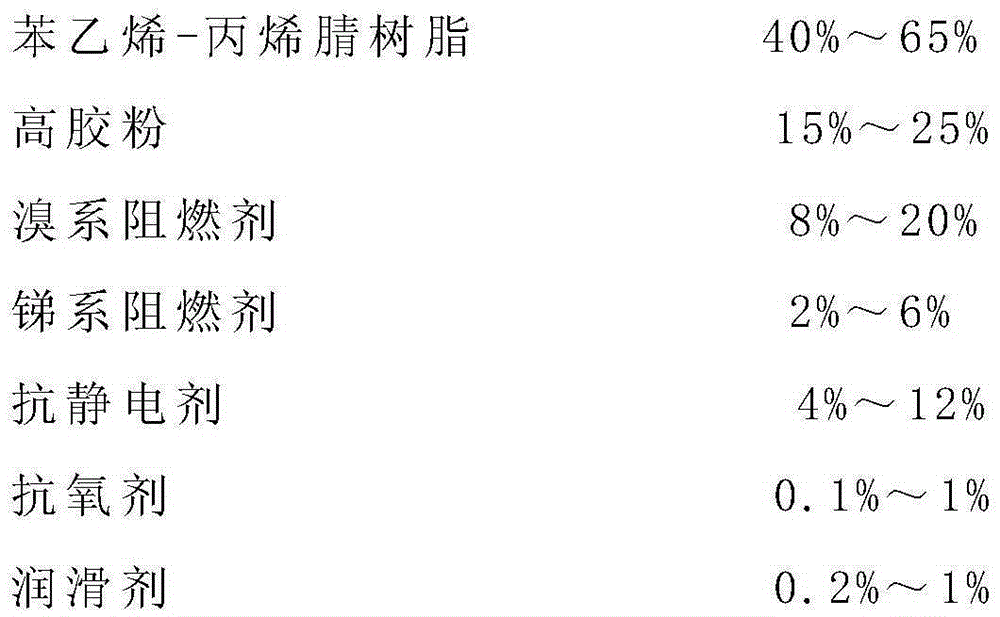

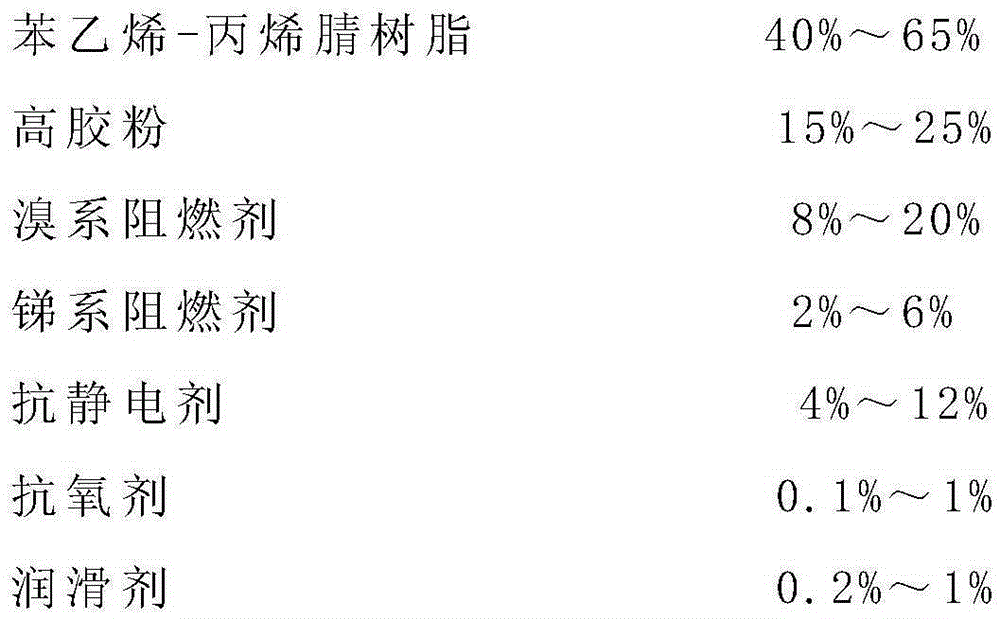

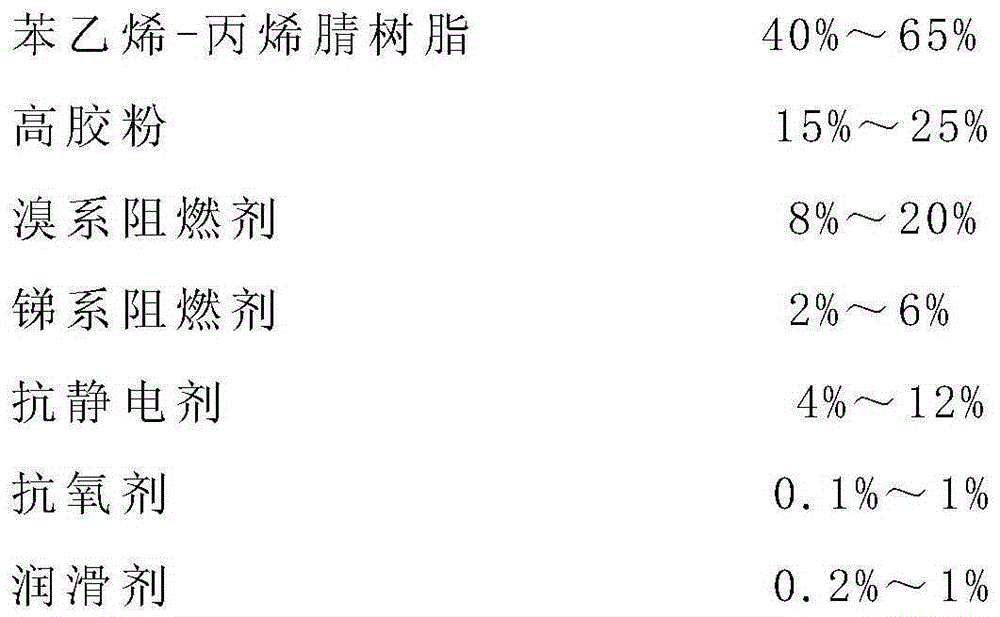

Permanent antistatic ABS (acrylonitrile butadiene styrene) flame-retardant material

InactiveCN105255037ARetain flame retardant effectStrong impact resistancePolymer scienceStyrene-acrylonitrile resin

The invention discloses a permanent antistatic ABS (acrylonitrile butadiene styrene) flame-retardant material. The material is characterized by comprising, in percentage by weight, 40%-65% of styrene-acrylonitrile resin, 15%-25% of high glue powder, 8%-20% of a brominated flame retardant, 2%-6% of an antimony flame retardant, 4%-12% of an antistatic agent, 0.1%-1% of an antioxidant and 0.2%-1% of a lubricant. The styrene-acrylonitrile resin is SAN (styrene acrylonitrile) resin with the melt flow index larger than 2.5. The good anti-impact performance of the ABS is guaranteed, and the material has a permanent antistatic effect.

Owner:昆山幻彩塑胶科技有限公司

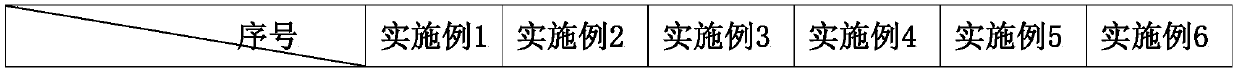

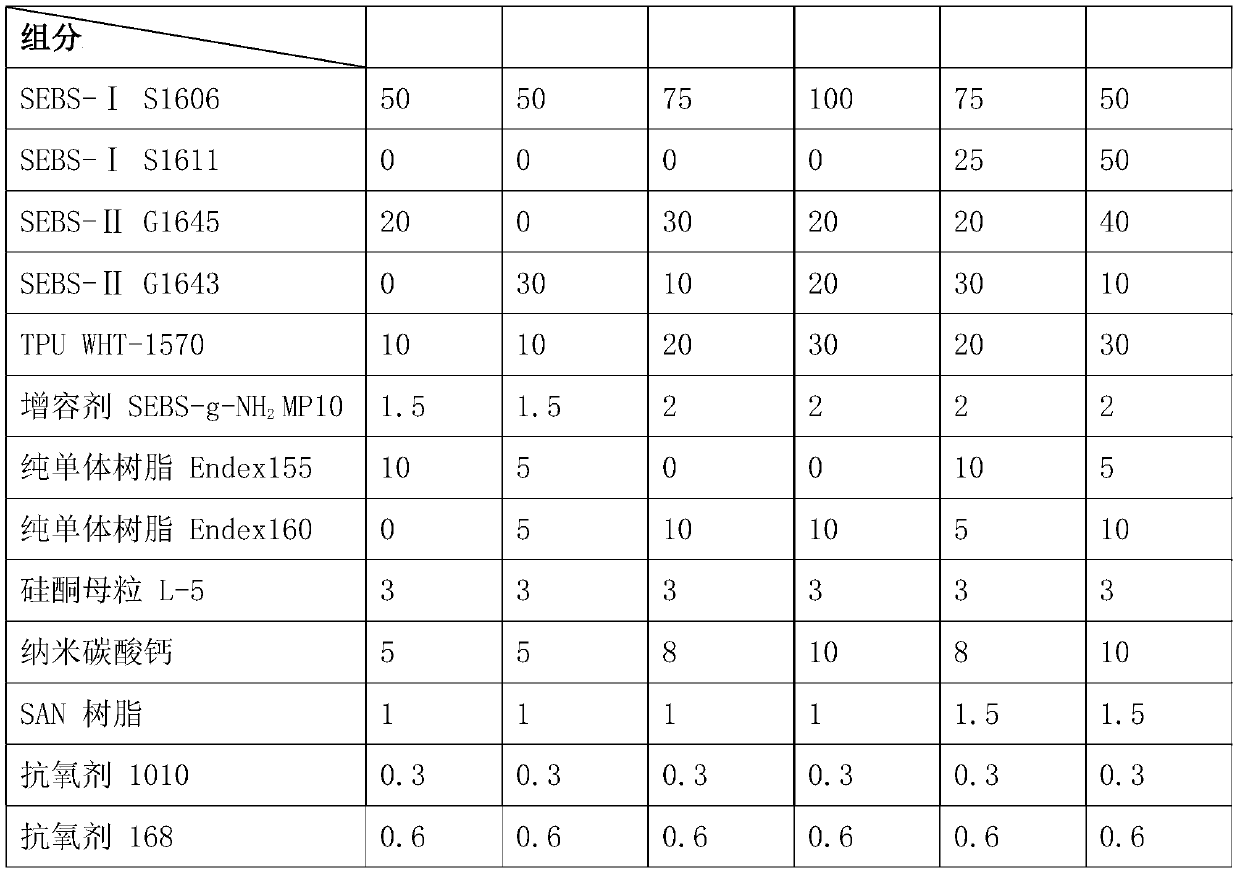

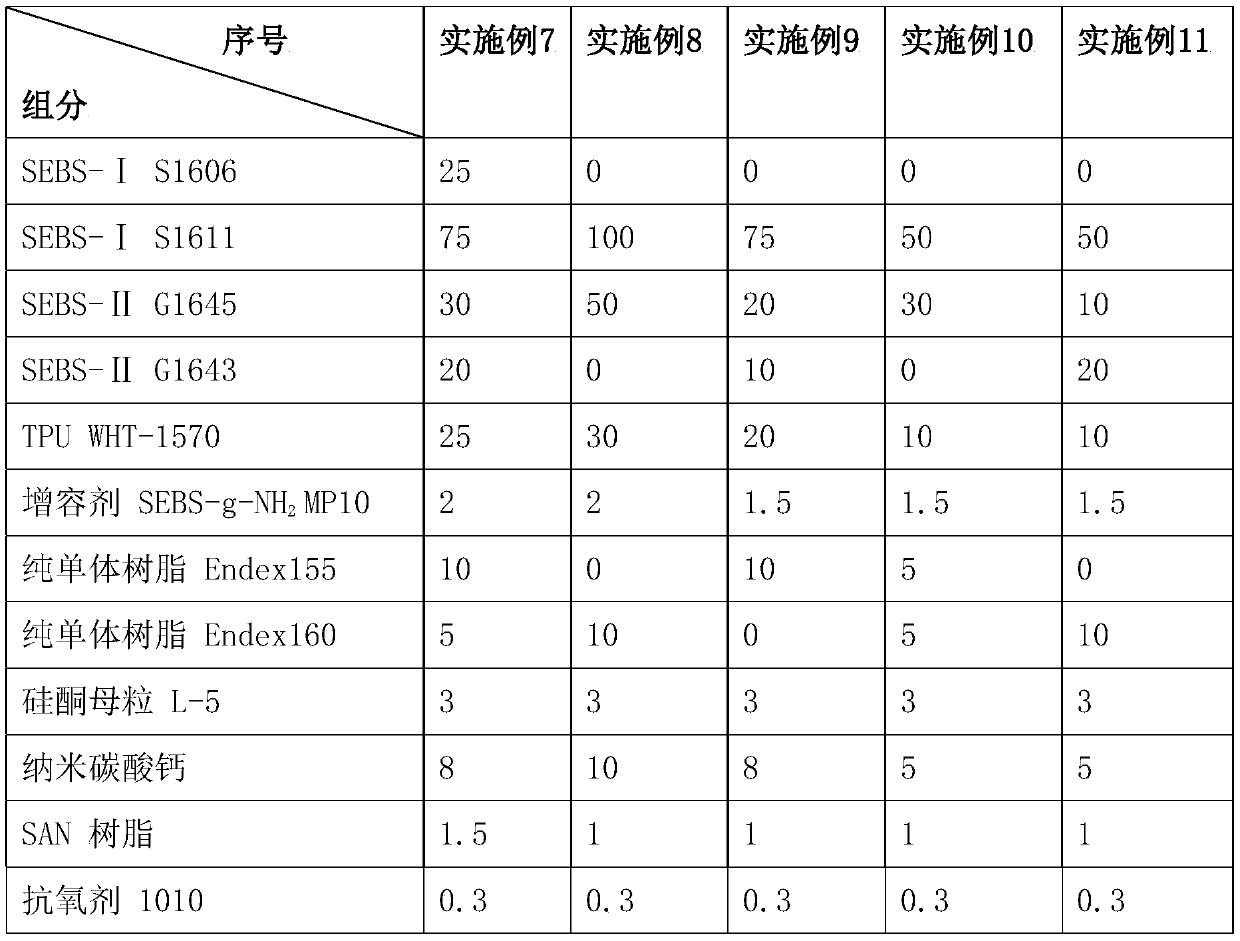

SEBS elastomer composite material for high-performance refrigerator sealing strip and preparation method thereof

ActiveCN111205585AGood flexibilityHigh tensile strengthChemical industryPolyurethane elastomerStyrene-acrylonitrile resin

The invention discloses an SEBS elastomer composite material for a high-performance refrigerator sealing strip and a preparation method thereof. The composition is prepared from the following raw materials in parts by weight: 50-100 parts of a special styryl thermoplastic elastomer I (SEBS-I); 20-50 parts of a special styryl thermoplastic elastomer II (SEBS-II); 10-30 parts of polyurethane elastomer, 1-3 parts of a compatibilizer, 10-15 parts of pure monomer resin, 2-4 parts of silicone master batch, 5-12 parts of nano calcium carbonate, 1-3 parts of styrene-acrylonitrile resin SAN and 0.1-2.0parts of an antioxidant. The prepared SEBS elastomer material for the refrigerator sealing strip has the characteristics of low hardness, high strength, easiness in welding, good weather resistance,no precipitation, the simple preparation process and the like, and is a high-performance refrigerator sealing strip material with excellent comprehensive performance.

Owner:NANTONG UNIVERSITY

Special heat-resistant, high-impact and flame-retardant resin for outer casing of storage battery

InactiveCN108752840AImprove corrosion resistanceHigh heat resistanceJackets/cases materialsTO-18Styrene-acrylonitrile resin

The invention discloses special heat-resistant, high-impact and flame-retardant resin for an outer casing of a storage battery. The special heat-resistant, high-impact and flame-retardant resin is prepared from the following raw materials and components in parts by mass: 30 to 50 parts of ABS (acrylonitrile butadiene styrene) powder, 40 to 60 parts of styrene-acrylonitrile resin, 10 to 30 parts ofbutadiene, 20 to 35 parts of heat-resistant agent, 10 to 18 parts of bromine flame retardant, 3 to 8 parts of antinomy flame retardant, 0.5 to 2 parts of antioxidant, and 0.1 to 1 part of anti-dripping agent. The special heat-resistant, high-impact and flame-retardant resin has the beneficial effects that the ABS with high-impact property is used as the main raw material, and is added with the bromine flame retardant, the antinomy flame retardant and the anti-dripping agent, so that the flame-retardant property is obviously improved; by adding the heat-resistant property, the heat-resistant temperature of the ABS material is obviously increased; by adding the antioxidant, the corrosion-resistant property of the outer casing of the storage battery is improved; the heat-resistant property,corrosion-resistant property, high-impact property and obvious fireproof property are realized; the ABS material has good shrinkage property, so that the expanded and deformed outer casing can be restored in the charging process.

Owner:信丰永冠塑电科技有限公司

Flame-retarded ASA (Acrylic ester-Styrene-Acrylonitrile) modified resin and preparation method thereof

The invention relates to flame-retarded resin, in particular to flame-retarded ASA (Acrylic ester-Styrene-Acrylonitrile) modified resin and a preparation method thereof. The flame-retarded ASA modified material in the prior art has the defects of low flame-retarded level, flammability and unsafe use in outdoor equipment, electric appliances, and the like. The flame-retarded ASA modified material comprises the following substances in weight ratio: 20-55 parts of acrylic ester-styrene-acrylonitrile-ternary graft copolymer, 25-55 parts of styrene-acrylonitrile resin, 12-20 parts of bromine flame retardant agents, 3-7 parts of stibium flame retardant agents, 0.1-1.5 parts of drip-proof additive, 0.2-1% of antioxidant, 0.3-1% of ultraviolet absorbent and 0.2-1% of processing agent. The preparation method comprises the following steps of: accurately weighing each component and placing into a high speed mixer for uniform mixing; introducing into a twin screw extruder with a long diameter; mixing and milling; extruding; pulling into strips; cooling; and cutting into granules and packaging. The invention has the advantages of satisfying the flame retarded property and having more balanceable thermal stability, processing liquidity and impact strength; and the preparation method is simple and easy for operation.

Owner:SHANGHAI KINGFA SCI & TECH +1

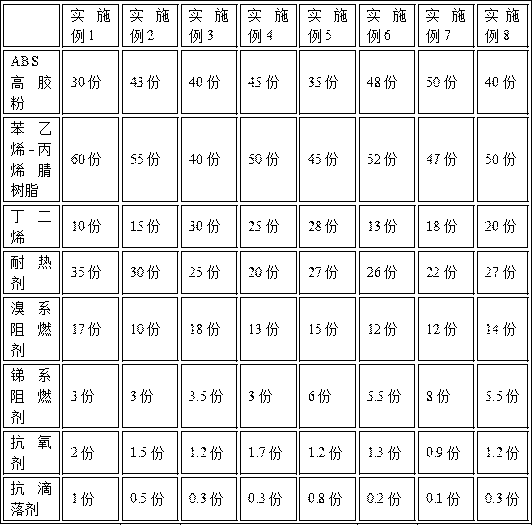

Special ABS material for storage battery case

InactiveCN107686609AAccelerated corrosionImprove heat resistanceStyrene-acrylonitrile resinAntioxidant

The invention discloses a special ABS material for a storage battery case. The material comprises the following ingredients by mass percentage: 20-35% of ABS high glue powder, 35-60% of styrene-acrylonitrile resin, 5-20% of a brominated flame retardant, 3-6% of an antimonic flame retardant, 2-6% of a flexibilizer and 0.2-1% of an antioxidant. The material has the following advantages and effects that: the styrene-acrylonitrile resin and the ABS high glue powder serve as the major raw materials; the flame resistance is significantly improved by adding the brominated flame retardant and the antimonic flame retardant; the corrosion resistance and heat resistance of the special ABS material for the storage battery case are improved by adding the antioxidant; when the special ABS material for the storage battery case is prepared into a storage battery, the material can meet operating requirements of the storage battery; a service life of the storage battery is prolonged.

Owner:台州市三鼎模塑有限公司

Flame retardant polymer compositions comprising stabilized hypophosphite salts

A flame retardant polymer composition is described. The composition can include at least one polymer and a hypophosphite salt, wherein the hypophosphite salt is heat stabilized so that when it is heated for 3 hours at 298° C. under a flow of argon flushing at rate 58 mL / min, it generates less than 0.5 mL of phosphine per gram of hypophosphite salt. The polymer can be an epoxy resin, a phenolic resin, an acrylonitrile-butadiene-styrene resin, a styrene-acrylonitrile resin, a mixture of high impact polystyrene and polyphenylene oxides, a styrene-butadiene rubber, a polylactic acid or a polyvinyl chloride.

Owner:RHODIA OPERATIONS SAS +1

ASA co-extruding material with flame resistance and high weather resistance

InactiveCN109233131AImprove anti-blocking performanceImprove surface propertiesWater basedHigh resistance

The invention provides an ASA co-extruding material with flame resistance and high weather resistance and relates to the technical field of macromolecules. The ASA co-extruding material with flame resistance and high weather resistance provided by the invention comprises the following components in parts by weight: 20-32 parts of ASA powder, 62-70 parts of medium flow styrene acrylonitrile resin,8-12 parts of low flow styrene acrylonitrile resin, 20-30 parts of ethylene ditetrabromide phthalimide, 6.2-9.3 parts of auxiliary fire retardant and 10-15 parts of water-based wear-resisting agent. The ASA co-extruding material has excellent flame resistance, high wearing resistance, high surface evenness and high heat stability; ASA powder, medium flow styrene acrylonitrile resin and low flow styrene acrylonitrile resin are compounded and prepared into a base stock resin, so that liquidity is moderate, impact property is excellent and melt strength is higher; an anti-flaming plasticizer is added, so that fire-resistant temperature and capacity of resisting against high-temperature corrosion deformation of the product are promoted; the water-based wear-resisting agent is added for obviously improving the surface performance of system, so that the wearing resistance, smoothness and anti-adhesion property of the coating can be obviously promoted.

Owner:ZHEJIANG HONGBO NEW BUILDING MATERIALS

Impact-resistant strong-adhesion type powder coating material and preparation method thereof

InactiveCN111440487AGood flexibilityHigh hardnessPowdery paintsEpoxy resin coatingsPolymer scienceStyrene-acrylonitrile resin

The invention relates to the technical field of powder coating materials, and discloses an impact-resistant strong-adhesion type powder coating material and a preparation method thereof, wherein 100 parts by weight of the impact-resistant strong-adhesion type powder coating material are prepared from 2 to 20 parts by weight of a modified epoxy resin, 12 to 15 parts by weight of a modified polyester resin, 13 to 15 parts by weight of a polycarbonic acid resin, 15 to 18 parts by weight of a styrene-acrylonitrile resin, 2 to 5 parts by weight of a curing agent, 3 to 5 parts by weight of a leveling agent and 35 to 40 parts by weight of a pigment. After the specific resin composition of the modified epoxy resin, the modified polyester resin, the polycarbonic acid resin and the styrene-acrylonitrile resin is combined with the curing agent, the leveling agent and the pigment according to a specific ratio, the obtained powder coating material is good in flexibility and high in hardness, and has super-strong impact resistance and excellent adhesive force.

Owner:浙江绿环新材料科技有限公司

Highly weather-proof environment-friendly high-molecular weight bromine flame-retardant ASA material and preparation method and application thereof

The invention discloses a highly weather-proof environment-friendly high-molecular weight bromine flame-retardant ASA material which comprises the following components in parts by weight: 15-40 parts of ASA resin, 30-60 parts of styrene-acrylonitrile resin, 8-12 parts of environment-friendly high-molecular weight brome flame retardant, 5-20 parts of chlorinated polyethylene and 2-6 parts of novel environment-friendly flame-retardant synergist. A preparation method comprises the following steps of: sequentially adding the components into a high-speed mixer according to the proportion and mixing uniformly; adding the mixture into a twin-screw extruder; and performing mixing, extrusion, drawing, water cooling and granulation to obtain the highly weather-proof environment-friendly high-molecular weight bromine flame-retardant ASA material. According to the highly weather-proof environment-friendly high-molecular weight bromine flame-retardant ASA material disclosed by the invention, the addition amount of the flame retardant is over 1 / 3 less than the dosage of other existing flame-retardant systems; through tests, the flame-retardant grade reaches UL94@1.0-3.0mmV-0, the impact strength is kept over 10kJ / m<2>, the weather-proof property is excellent, and other mechanical properties are balanced; and the preparation method is simple and easy to implement, and the material is easy to process; and therefore, the material and the preparation method of the method are suitable for popularization and application on the market.

Owner:KINGFA SCI & TECH CO LTD +1

Reactive extrusion matte agent, low gloss PC/ABS alloy and its preparation method

Owner:SHANGHAI KUMHO SUNNY PLASTICS

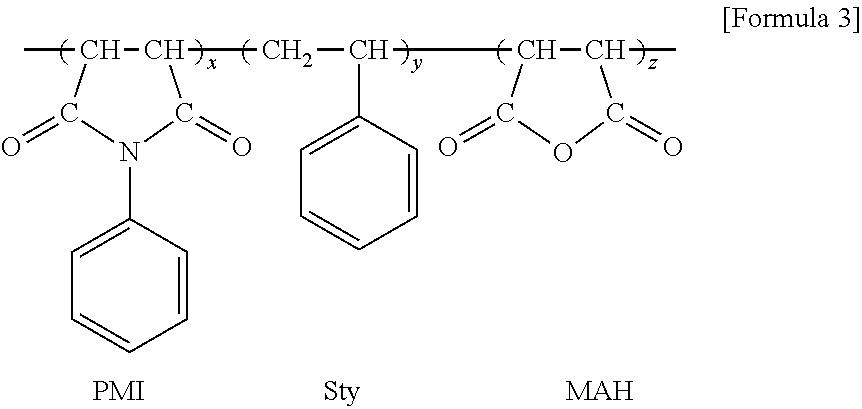

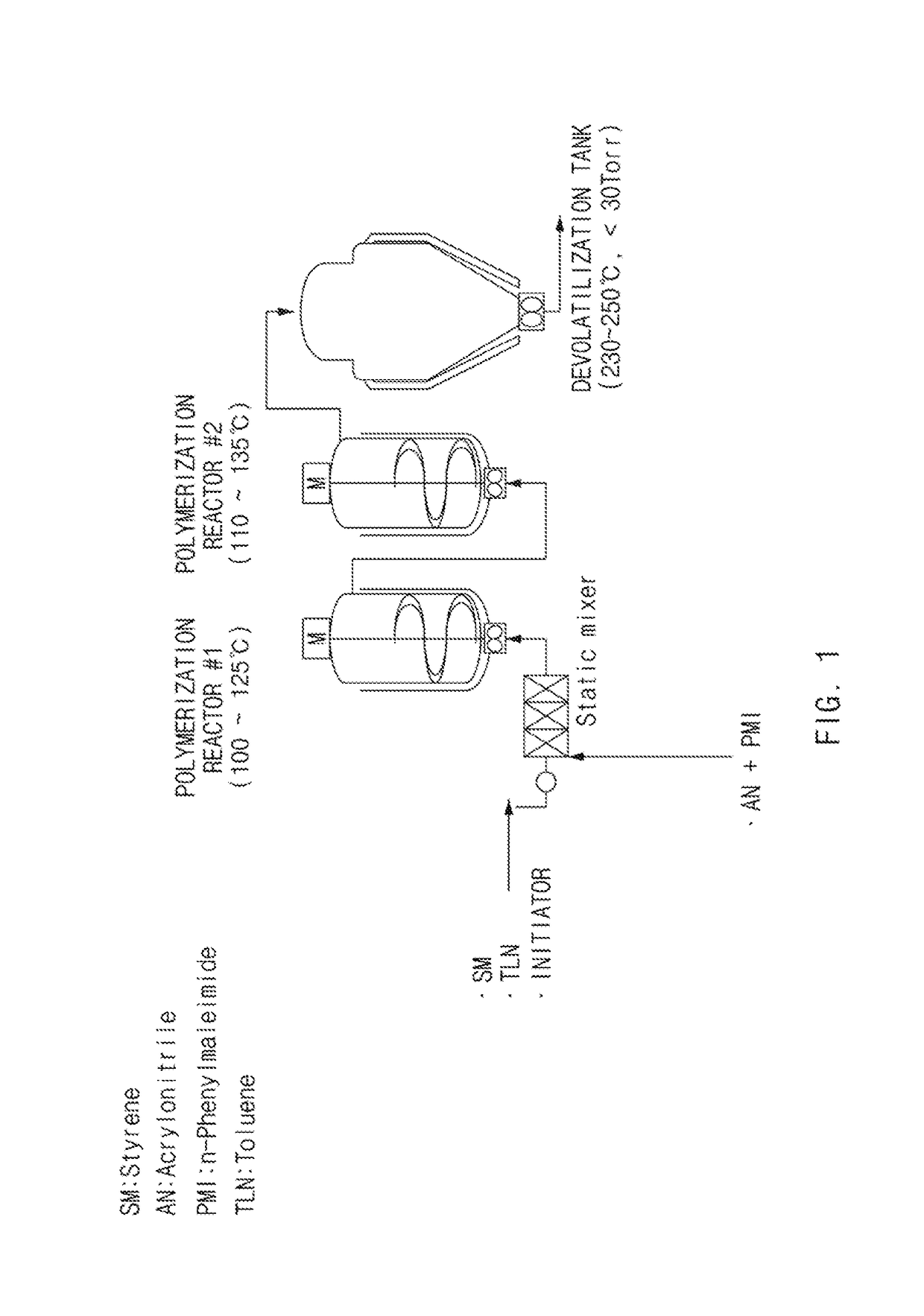

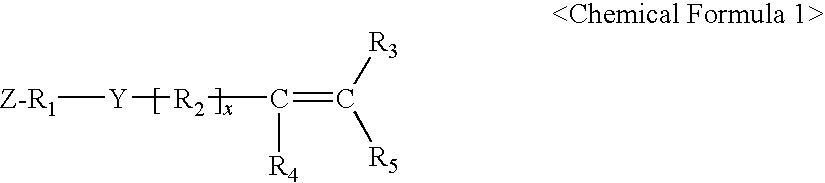

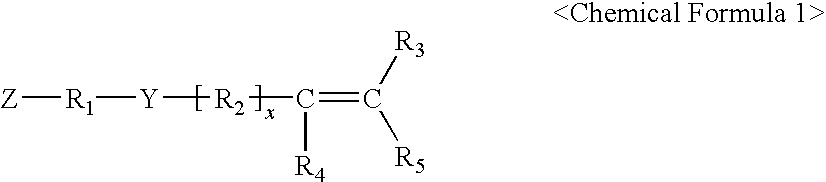

Styrene-acrylonitrile resin with high thermal resistance and method for producing the same

The present invention provides a styrene-acrylonitrile (SAN) resin that exhibits significantly improved thermal resistance and, at the same time, can be produced at high productivity and is highly processable and highly moldable; and a method of producing the same by preparing and storing the solution containing a mixture of an N-substituted maleimide monomer and an unsaturated nitrile monomer at a particular temperature, introducing the solution and a styrene polymer into the polymerization reactor separately, and maintaining the first polymerization reactor and the second polymerization reactor at particular respective temperatures, thereby significantly reducing the amounts of oligomers contained in the SAN resin.

Owner:LG CHEM LTD

Low-cost medium-flow high-weather-proof environment-friendly brominated flame retardant ASA material as well as preparation method and application thereof

The invention discloses a low-cost medium-flow high-weather-proof environment-friendly brominated flame retardant ASA (acrylonitrile styrene acrylate) material, which comprises the following components in parts by weight: 15-40 parts of ASA resin, 30-60 parts of styrene-acrylonitrile resin, 8-12 parts of environment-friendly brominated flame retardant, 5-20 parts of chlorinated polyethylene and 2-6 parts of novel environment-friendly flame retardant synergist. A preparation method for the ASA material comprises the steps as follows: adding the components into a high-speed mixer in sequence according to the proportion for uniformly mixing, and adding a mixture into a double screw extruder for mixing, extruding, pulling, water-cooling and dicing to obtain the ASA material. According to the ASA material, the addition amount of the flame retardant is lower than that of other conventional flame-retardant system by more than 1 / 3; through the test, the flame retardant level reaches UL94@3.0-1.0 mm V-0, the impact intensity is kept more than 10 kJ / m<2>, the melting index exceeds 35 g / 10 min, the weather-proof performance is excellent, and the other mechanical performance is balanced; the preparation method is simple and easy to implement; and the ASA material is easy to process and is suitable for popularization and application in the fields of outdoor electronic products and the like.

Owner:KINGFA SCI & TECH CO LTD +1

Halogen and phosphorus-free flame-retardant antistatic ABS resin and its preparation method

ActiveCN102936391AStrong impact resistanceImprove flame retardant performanceHalogenAntistatic agent

The invention relates to a halogen and phosphorus-free flame-retardant antistatic ABS (acrylonitrile-butadiene-styrene) resin, which comprises the following components by weight: 45%-75% of ABS resin; 20%-40% of styrene-acrylonitrile resin; 0.1%-5% of a silicone flame retardant; 0.1%-2% of a sulfonate flame retardant; 2%-8% of an antistatic agent; 0.1%-1% of an antioxidant; and 0.2%-1% of a processing aid. Compared with the prior art, on the basis of maintaining the intrinsic good impact resistance of ABS resin, the ABS resin provided in the invention also has excellent flame retardance and antistatic property, and has a simple preparation technology that is easy to operate, thus having broad application prospects.

Owner:SHANGHAI KINGFA SCI & TECH

High flow thermoplastic resin composition with excellent chemical resistance, impact resistance and gloss

The present invention provides a thermoplastic resin composition that can have excellent impact resistance, chemical resistance, fluidity and high gloss, which comprises about 1 to about 80 parts by weight of a styrene-acrylonitrile resin (A) including one or more functional groups capable of reacting with polyester; about 1 to about 98 parts by weight of an acrylonitrile-butadiene-styrene resin (B) including about 5 to about 40% by weight of a graft polymerized acrylonitrile-butadiene-styrene resin (B1) and about 60 to about 95% by weight of a styrene-acrylonitrile resin (B2) and including about 20% by weight or less of acrylonitrile; and about 1 to about 98 parts by weight of a polyester resin (C), wherein the resin composition comprises acrylonitrile in a total amount of about 1 to about 13% by weight.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Environmentally friendly thermoplastic ice non-slip sole and preparation method thereof

ActiveCN105802113AImprove skid resistanceImprove mechanical propertiesSolesPolymer scienceAntioxidant

The invention relates to the technical field of high polymer materials, and provides an environmentally friendly thermoplastic ice non-slip sole and a preparation method thereof. The environmentally friendly thermoplastic ice non-slip sole has a good non-slip effect on a snowfield, a frost ice surface, a dry ice surface, and a wet ice road surface, and good low temperature flexibility, and can be repeatedly recycled. The environmentally friendly thermoplastic ice non-slip sole is prepared from an epoxidized styrene-butadiene-styrene block copolymer (ESBS), styrene-acrylonitrile resin (SAN), chlorinated polyethylene resin, hemp fiber, white mineral oil, an antioxidant, zinc stearate, and nano calcium carbonate. The materials are premixed in a high speed mixer for 5 to 7 minutes, and then a premix is extruded and granulated by a twin screw extruder; and finally, the thermoplastic ice non-slip sole is obtained by injection molding at a temperature of 173 to 175 DEG C.

Owner:茂泰(福建)新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com