Environmental protection fire retardation composite reinforced ABS material

A composite technology of ABS material and flame retardant, which is applied in the field of ABS material, can solve problems such as inconvenience, and achieve the effects of high gloss, good mechanical properties, and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

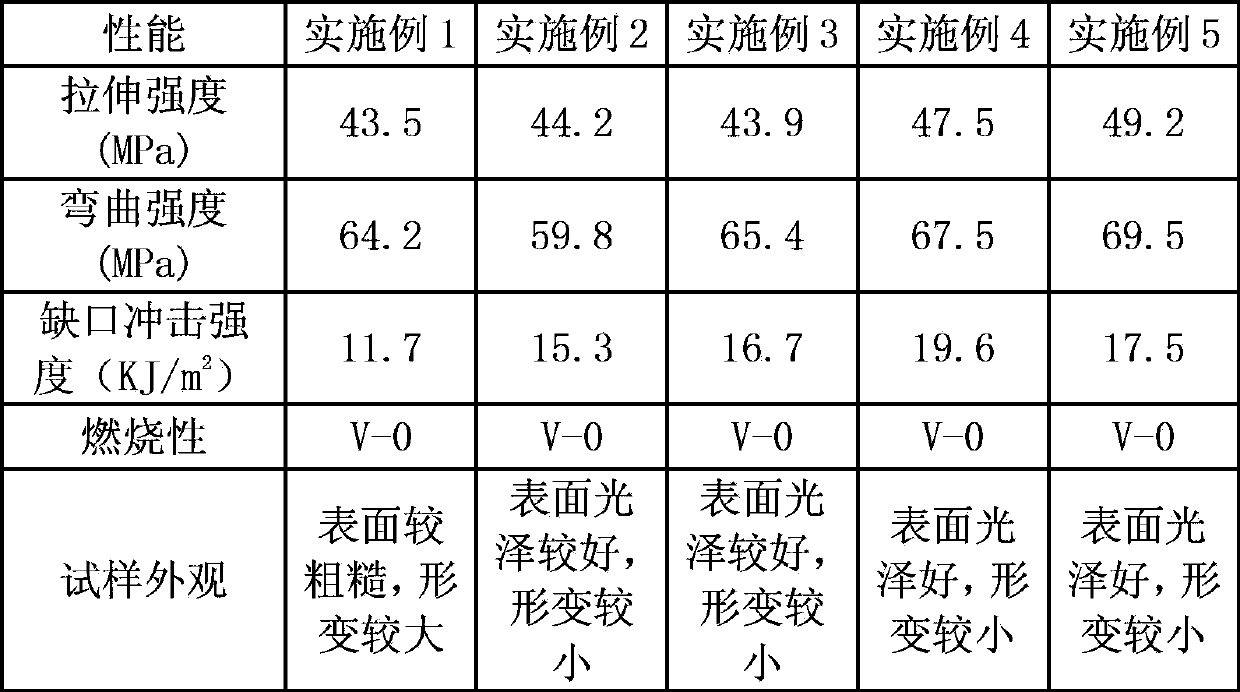

Examples

Embodiment 1

[0033] 70 parts of ABS resin,

[0034] 15 parts of styrene-acrylonitrile resin,

[0035] 2 parts of silicon flame retardant,

[0036] 2 parts of sulfonate flame retardant,

[0037] 10 parts of high aspect ratio inorganic filler,

[0038] Antioxidant 0.6 part,

[0039] Processing aid 0.4 parts,

[0040] Among them: ABS resin-based acrylonitrile-butadiene-styrene graft copolymer (ABS) is ABS PA-747 of Taiwan CHIMEI Company; styrene-acrylonitrile resin is produced by Taiwan Chemical Company, the brand is NF2200; silicon-based The flame retardant is a silicone flame retardant, the brand of the silicone flame retardant is B-338; the sulfonate flame retardant is a flame retardant FR-2025 produced by 3M Company in the United States; The diameter ratio inorganic fillers are high aspect ratio wollastonite and high aspect ratio whiskers, the particle size is ≤15μm, and the aspect ratio is ≥10:1; wollastonite is provided by Zhengzhou Institute of Comprehensive Utilization of Mineral Resources, Chi...

Embodiment 2

[0045] 60 parts of ABS resin,

[0046] 15 parts of styrene-acrylonitrile resin,

[0047] 2 parts of silicon flame retardant,

[0048] 2 parts of sulfonate flame retardant,

[0049] High aspect ratio inorganic filler 20 parts,

[0050] Antioxidant 0.6 part,

[0051] Processing aid 0.4 parts,

[0052] Wherein: the ABS resin is an acrylonitrile-ethylene propylene elastomer-styrene graft copolymer (AES); the silicon-based flame retardant is a siloxane flame retardant, the grade of the siloxane flame retardant It is X-40-9805; the antioxidant is the antioxidant 168 produced by Shanghai Ciba (CIBA) Fine Chemical Company.

[0053] The rest of this embodiment is the same as in embodiment 1.

Embodiment 3

[0055] 60 parts of ABS resin,

[0056] 10 parts of styrene-acrylonitrile resin,

[0057] 3 parts of silicone flame retardant,

[0058] 1 part of sulfonate flame retardant,

[0059] 25 parts of inorganic filler with high aspect ratio,

[0060] Antioxidant 0.5 part,

[0061] Processing aid 0.5 part,

[0062] Wherein: the ABS resin is a mixture of acrylonitrile-styrene-acrylic acid terpolymer (ASA) and methyl methacrylate-butadiene-styrene graft copolymer (MBS); the silicon-based flame retardant The siloxane flame retardant is a silicone flame retardant, and the brand name of the siloxane flame retardant is X-40-9805; the antioxidant is an antioxidant 168 produced by Shanghai Ciba (CIBA) Jinghua Company.

[0063] The rest of this embodiment is the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com