Patents

Literature

122 results about "Acrylonitrile-butadiene-styrene resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Styrene acrylonitrile resin is a copolymer plastic consisting of styrene and acrylonitrile. It is also known as SAN. It is widely used in place of polystyrene owing to its greater thermal resistance.

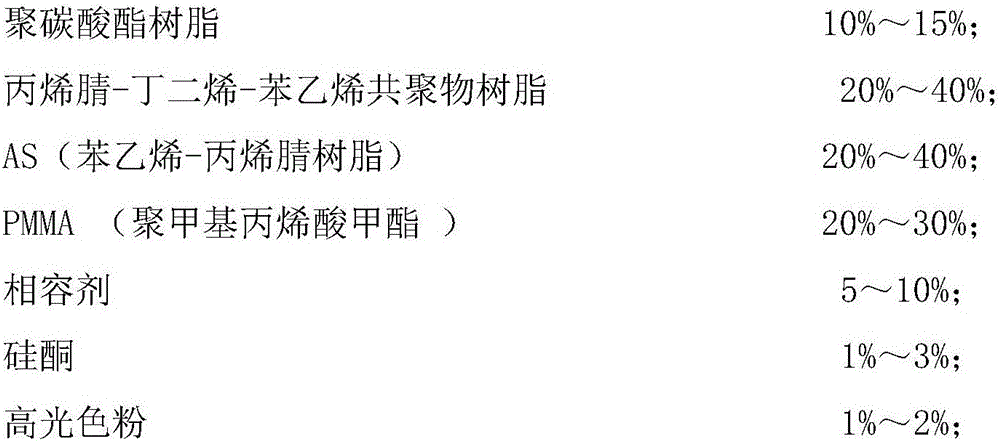

Low-gloss polycarbonate styreneresin composite and preparation method thereof

InactiveCN101787192AReasonable preparation processSolve technical problems with severe performance degradationStyrene-acrylonitrile resinAcrylonitrile-butadiene-styrene resin

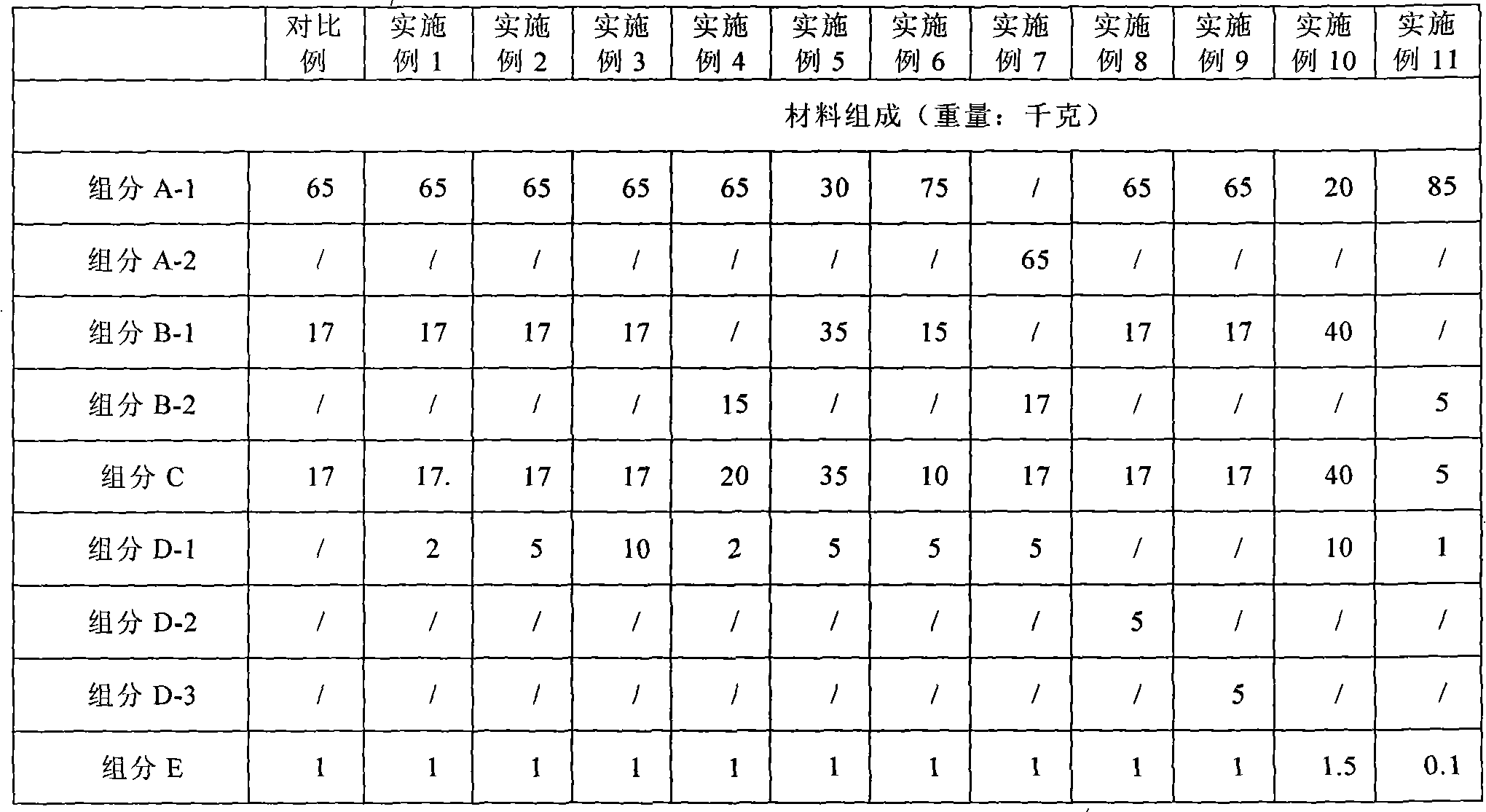

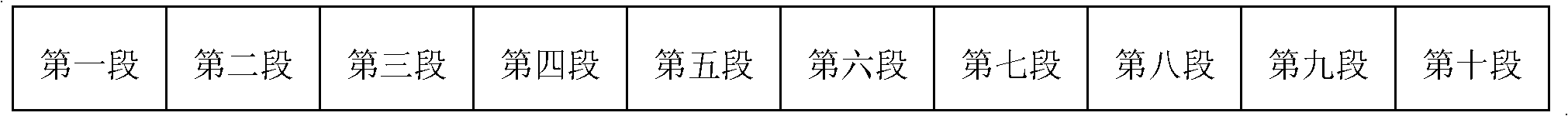

The invention relates to a low-gloss polycarbonate styreneresin composite and a preparation method thereof. The composite comprises the following components (by weight percent): 20-85wt% of polycarbonate resin, 5-50wt% of styrene flexibilizer, 5-40wt% of styrene-acrylonitrile resin,1-10wt% of specific matting agent, and 0.1-1.5wt% of processing agent; the materials are premixed for 3-10 minutes in a high speed mixer, then premix compound is subject to melt extrusion at 230-300 DEG C by a double screw extruding machine, and cooling and pelletizing are carried out, thus obtaining the low-gloss polycarbonate (PC) / styreneresin composite. Compared with the prior art, the invention has the advantages that preparation technology is reasonable and the technical problem of degradation of performance of products as matting efficiency of polycarbonate (PC) / styreneresin composite is low is solved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

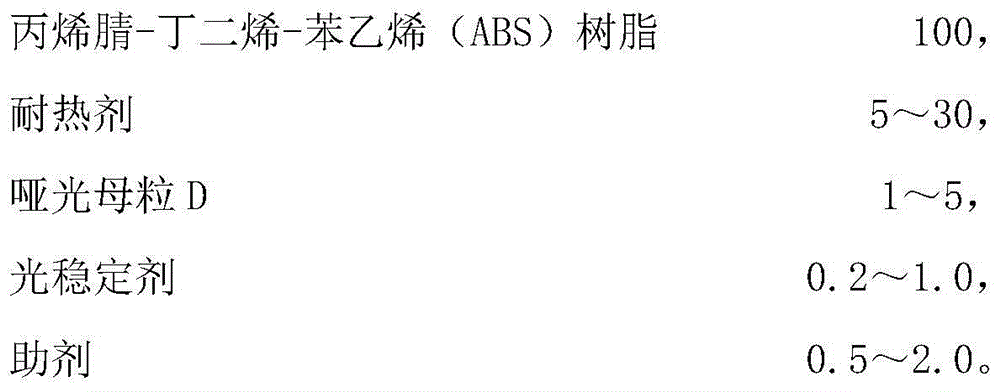

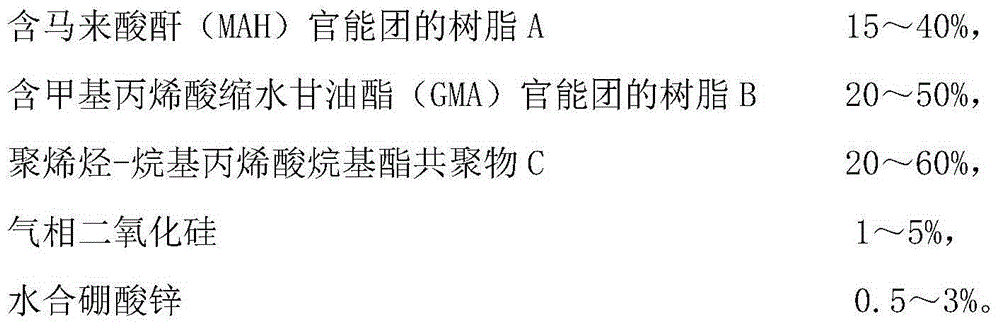

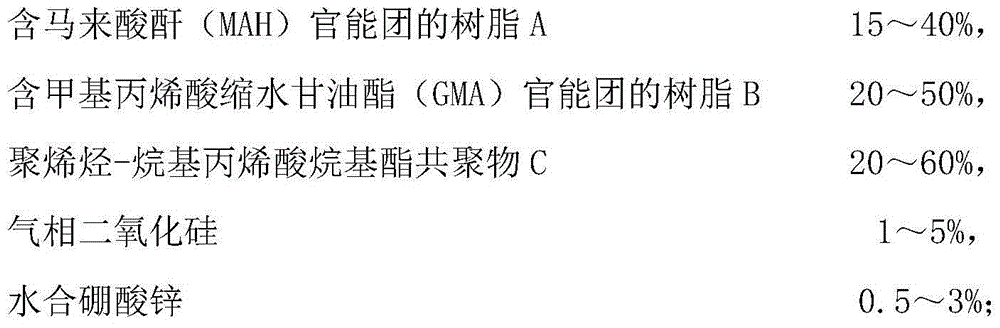

Low-gloss heat-resistant ABS resin composition and preparation method thereof

ActiveCN104559033AIncreased efficiency of catalyzed crosslinking reactionsRelieve extrusion swellingPolymer scienceAcrylonitrile-butadiene-styrene resin

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Nylon/acrylonitrile-butadiene-styrene resin mixing material

The invention discloses a nylon / acrylonitrile-butadiene-styrene resin blending material, which comprises the component of nylon, ABS resin, antioxidant and graft compatibilizer. The invention is characterized in that the graft compatibilizer is styrene-N- phenyl maleimide- maleic anhydride copolymer. The components are counted by weight: nylon 50 to 80 portions, the ABS resin 10 to 35 portions, the styrene-N- phenyl maleimide- maleic anhydride copolymer 4 to 15 portions and the antioxidant 0.1 portion. The nylon / acrylonitrile-butadiene-styrene resin blending material of the invention has the advantages of low density, good fluidity, fine hear resistance, chemical resistance and mechanical property, which can be used for making inner decorative parts, and used as the material for making an air exhaust grill and a defroster grill of a vehicle, vehicle door components and a motorcycle baffle.

Owner:CHONGQNG PRET NEW MATERIAL +2

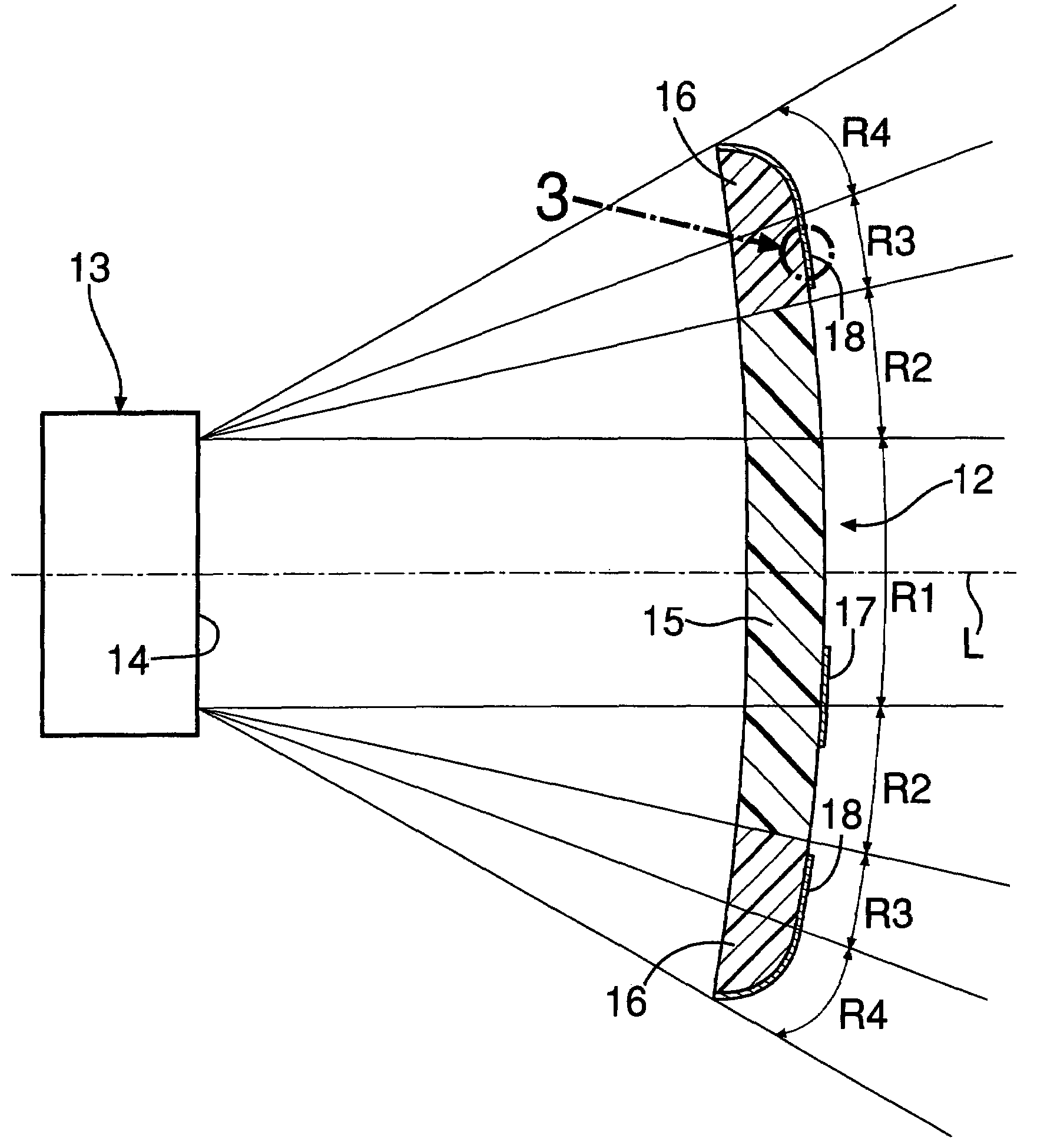

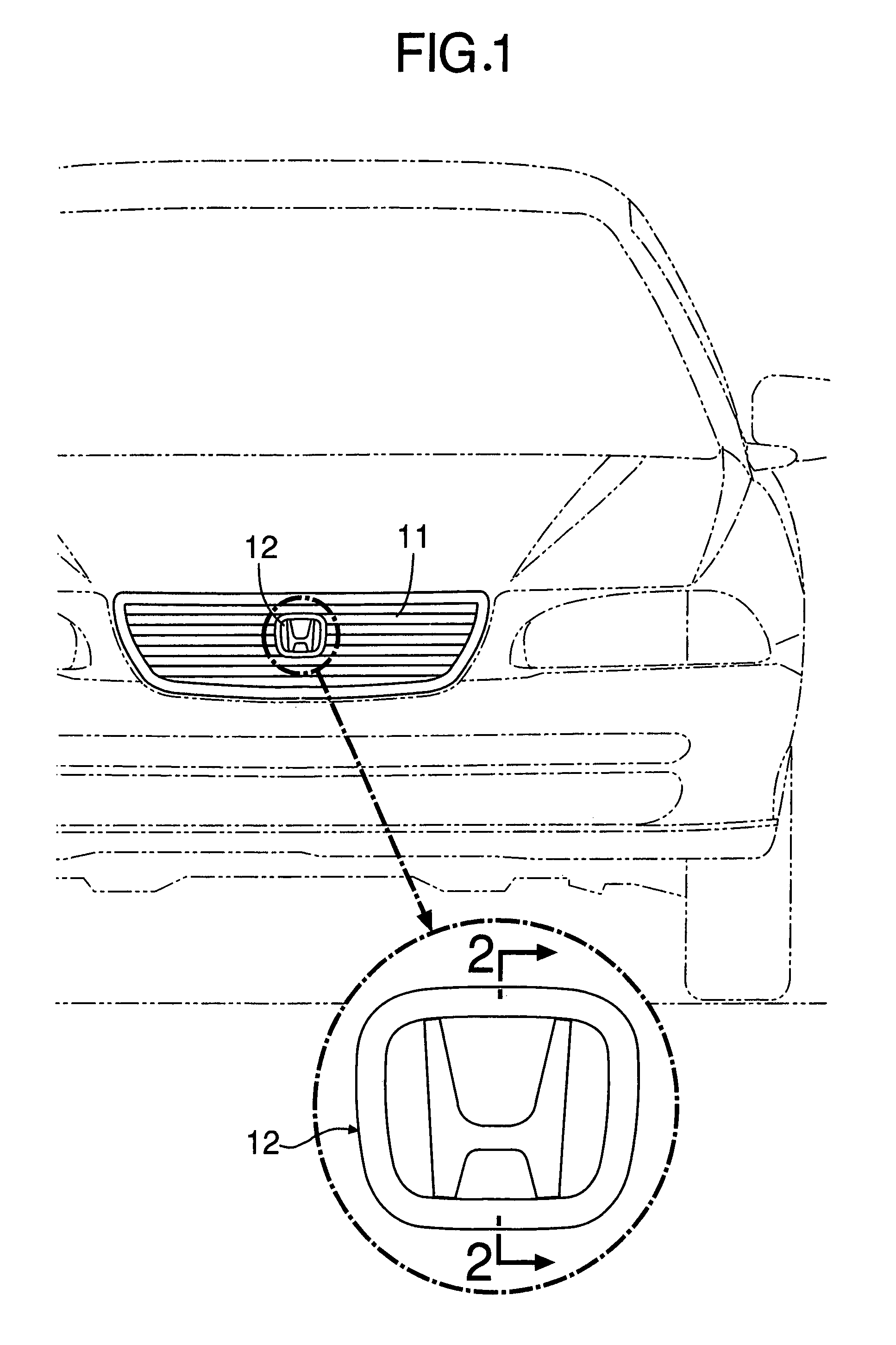

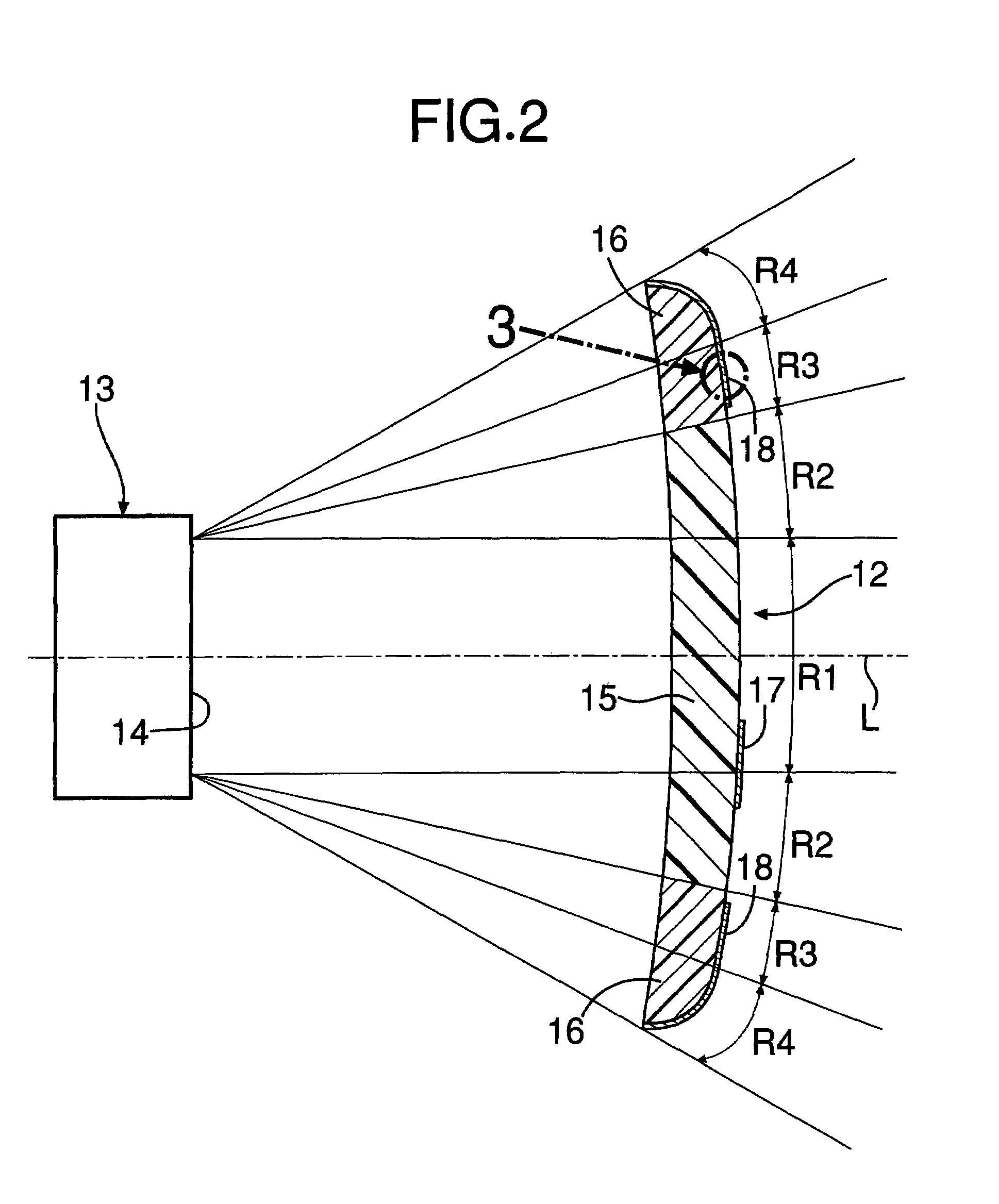

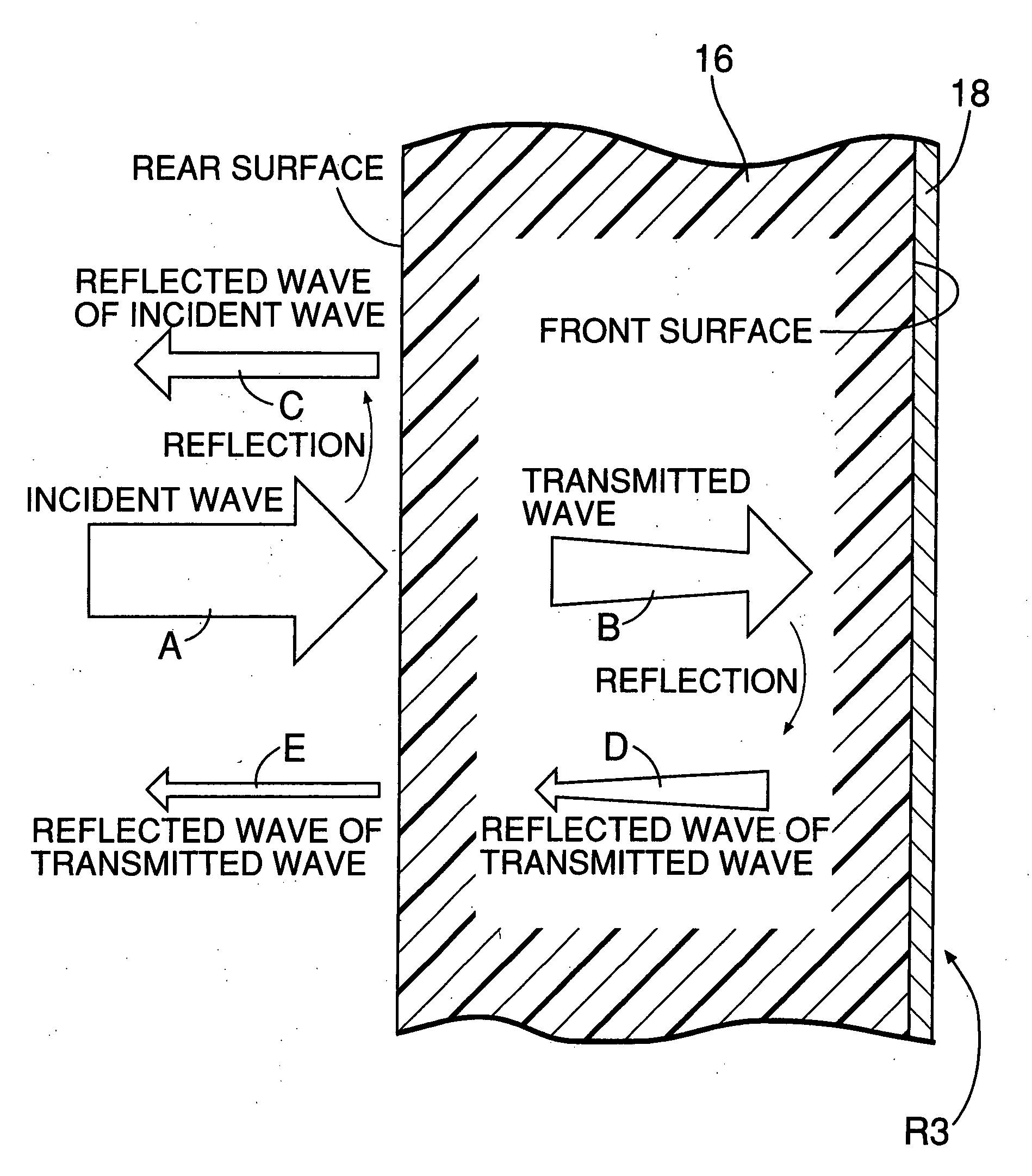

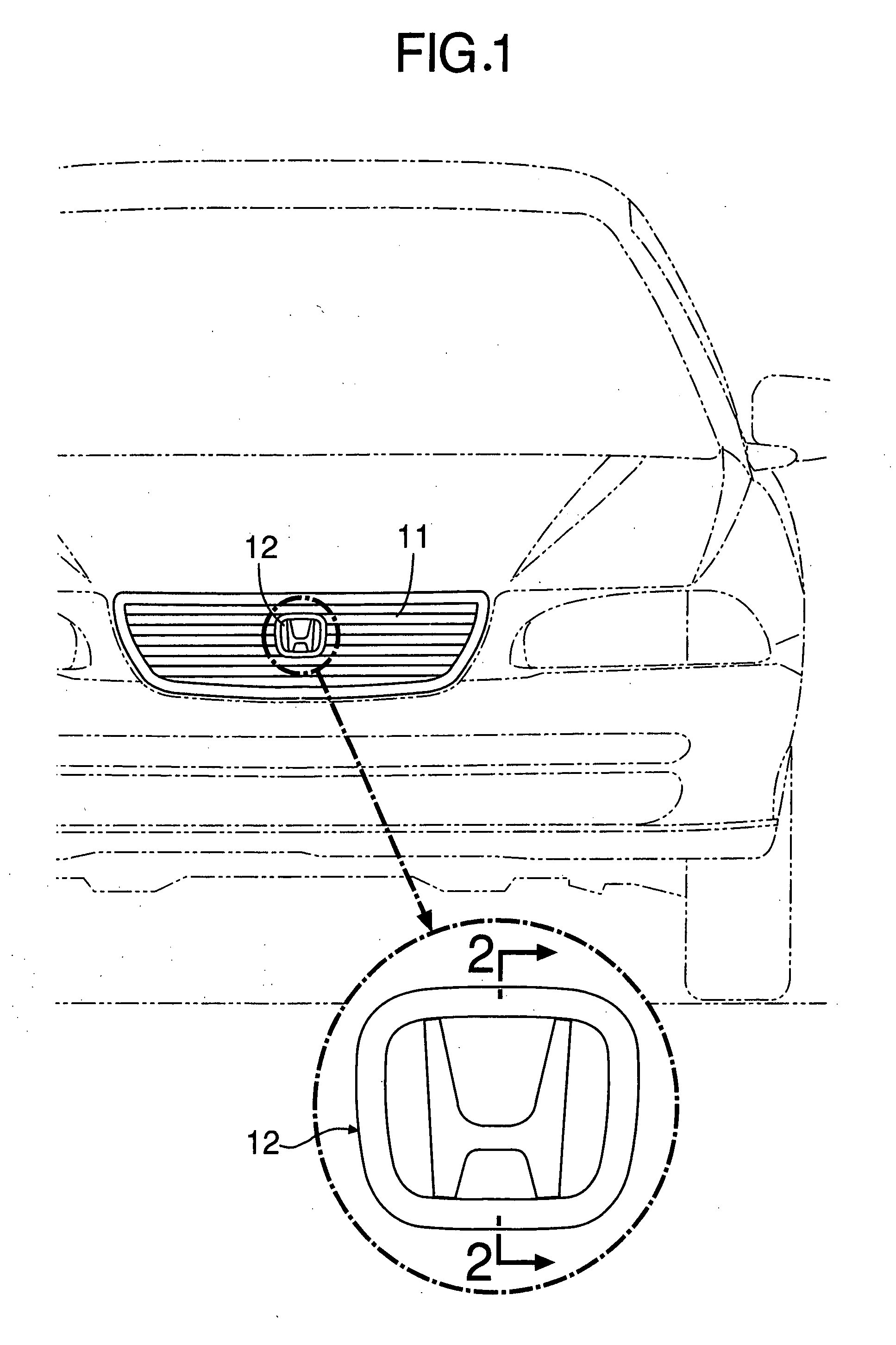

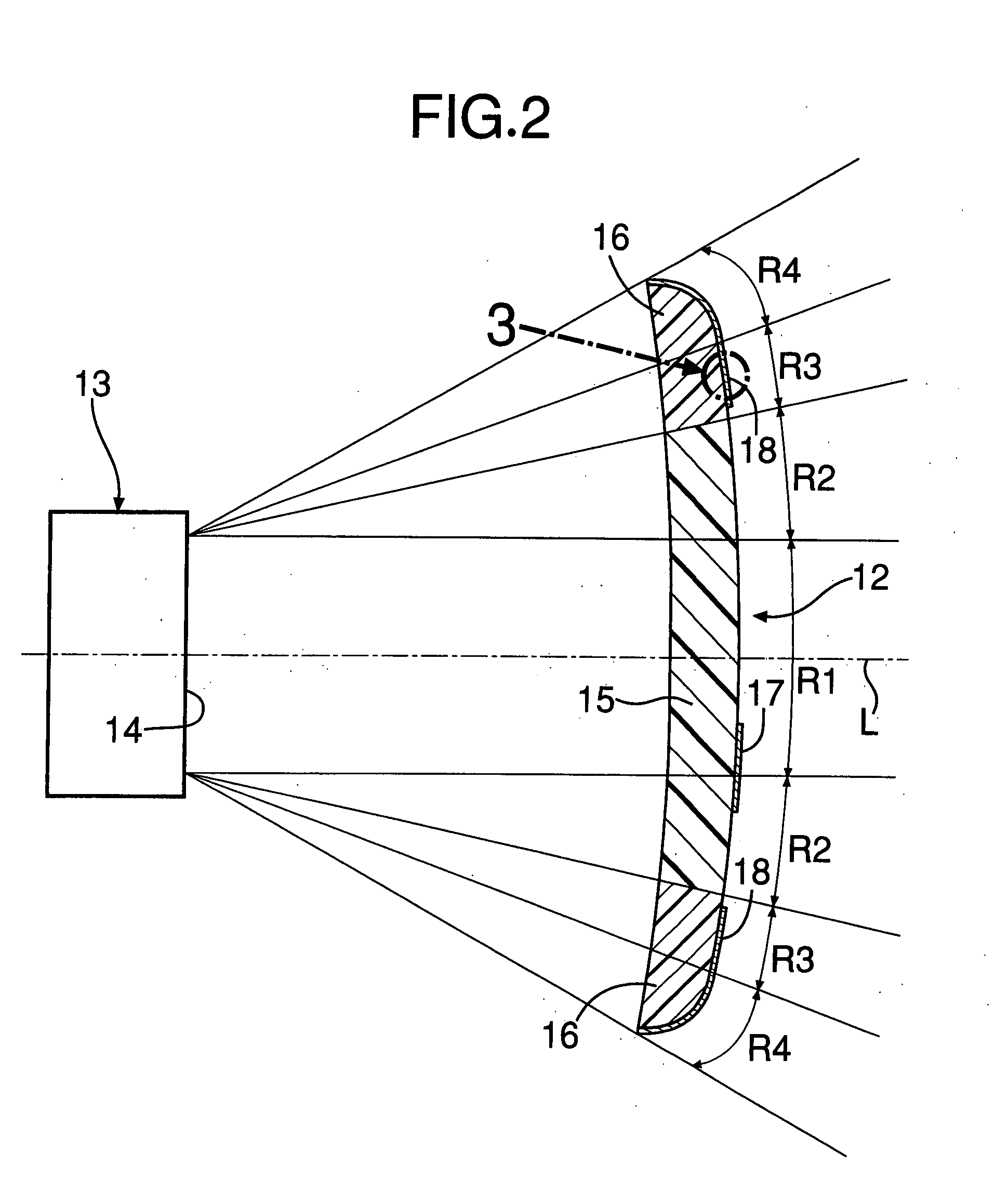

Exterior component disposed on front surface of radar device of vehicle

InactiveUS7508353B2Increase freedomLow costAntenna adaptation in movable bodiesRadiating element housingsAttenuation coefficientStyrene-acrylonitrile resin

An exterior vehicle component includes a proximity member disposed along an outer perimeter of an electromagnetic wave transmission member provided at a center of the component which is disposed in front of a radar device. The proximity member includes a chromium-plated portion formed on its front surface which reflects an electromagnetic wave. The proximity member is formed of an acrylate-styrene-acrylonitrile resin or a modified polyphenylene oxide resin having an attenuation coefficient for electromagnetic wave transmission, which is equal to or greater than a predetermined value.

Owner:HONDA MOTOR CO LTD

Non halogenic, low smoky fire retardant polycarbonate/resin of acrylonitrile butylbenzene and preparation method

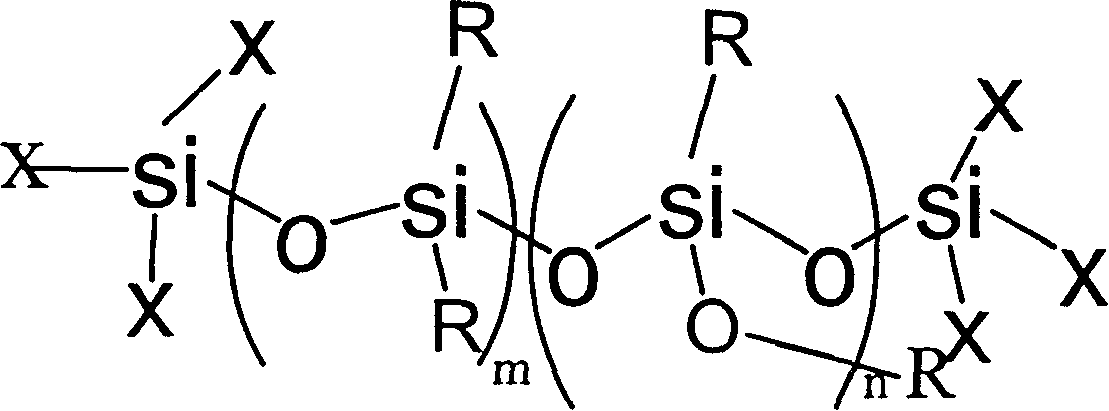

A non-halogen low-smoke flame-retarding polycarbonate / acrylonitrile butadiene-styrene resin is proportionally prepared from polycarbonate / acrylonitrile butadiene-styrene resin, non-halogen primary flame retardant, Si-type secondary flame retardant, efficient compatibilier, anti-impact modifier and machining assistant.

Owner:SHANGHAI KINGFA SCI & TECH

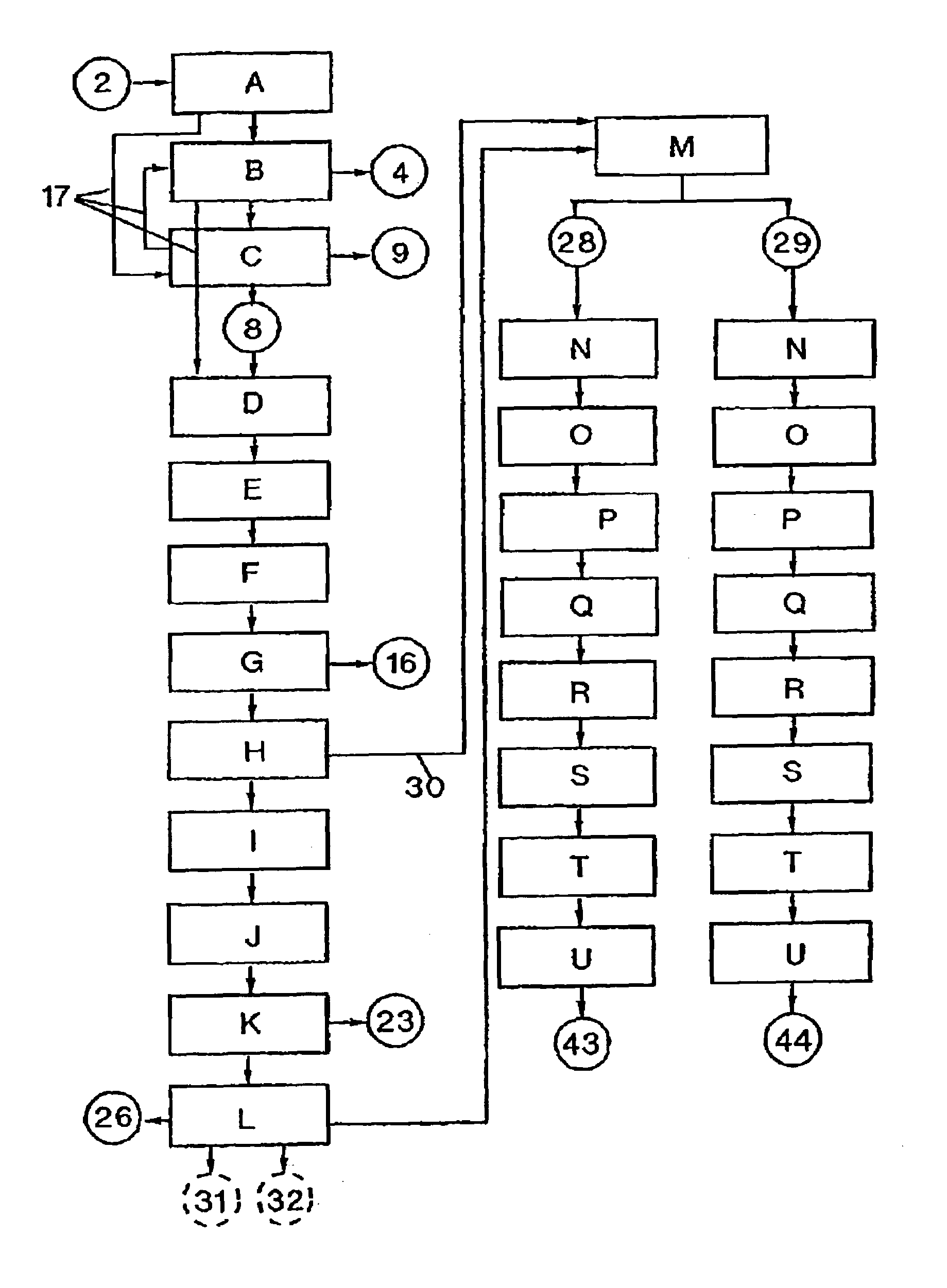

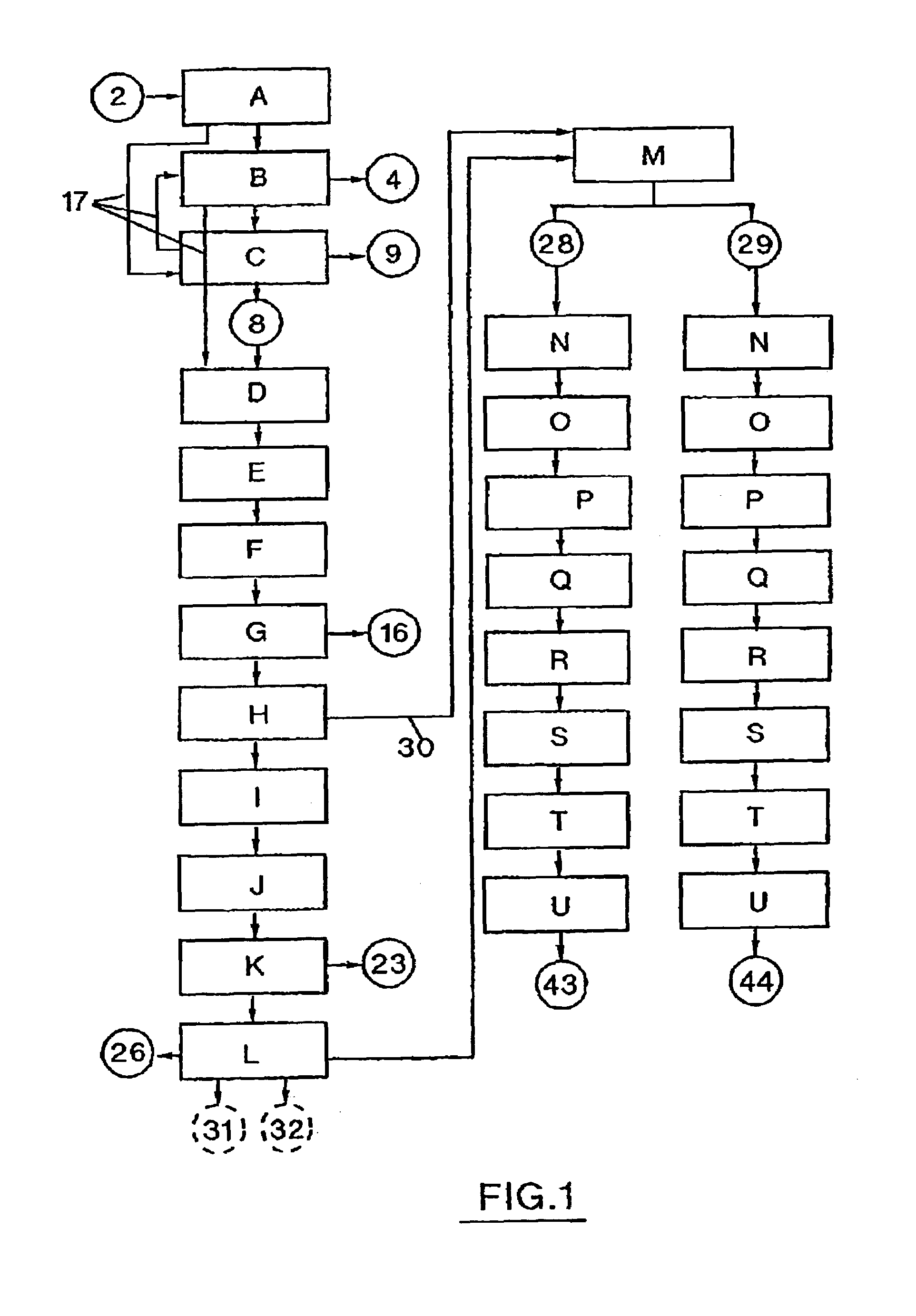

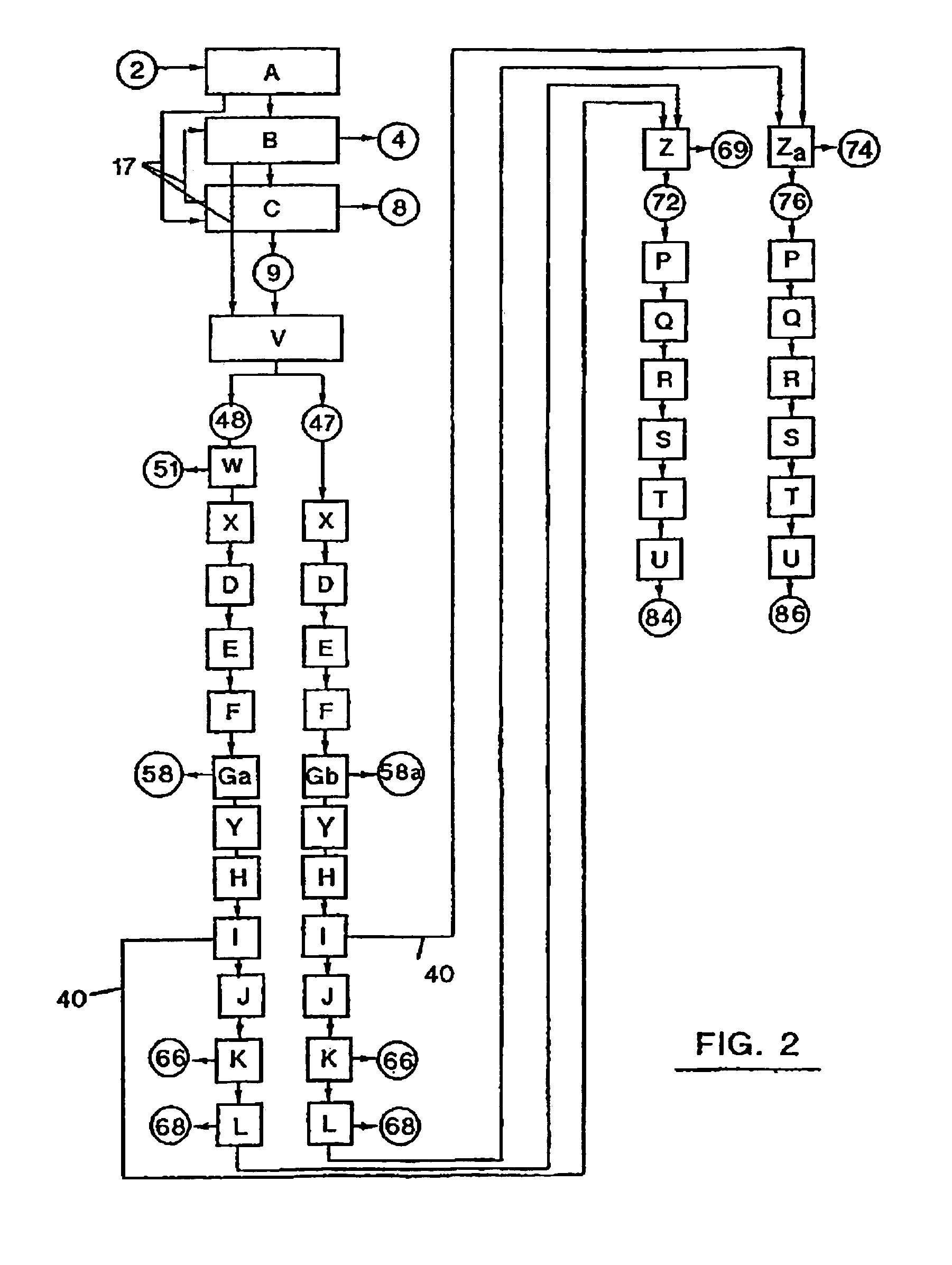

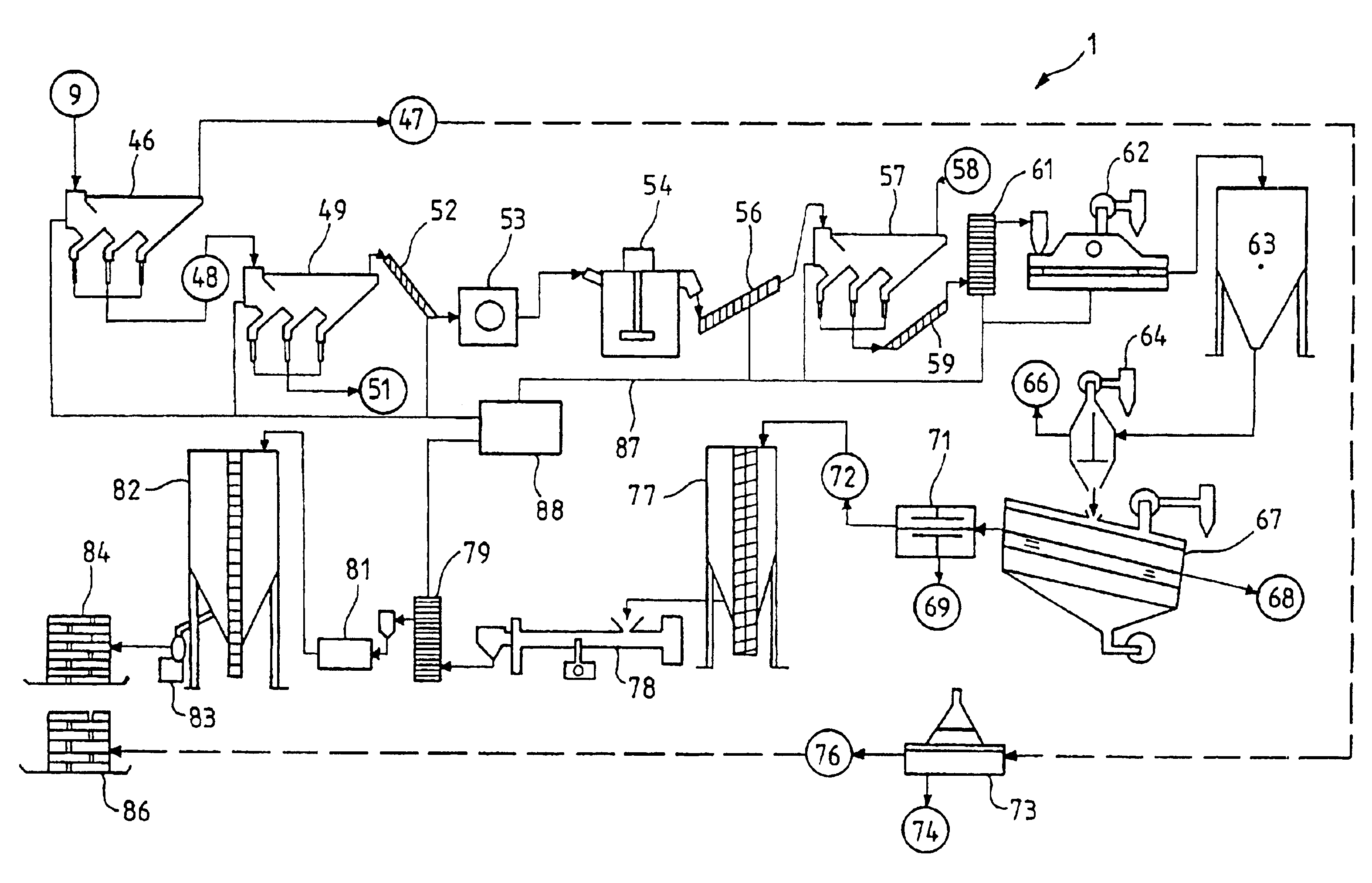

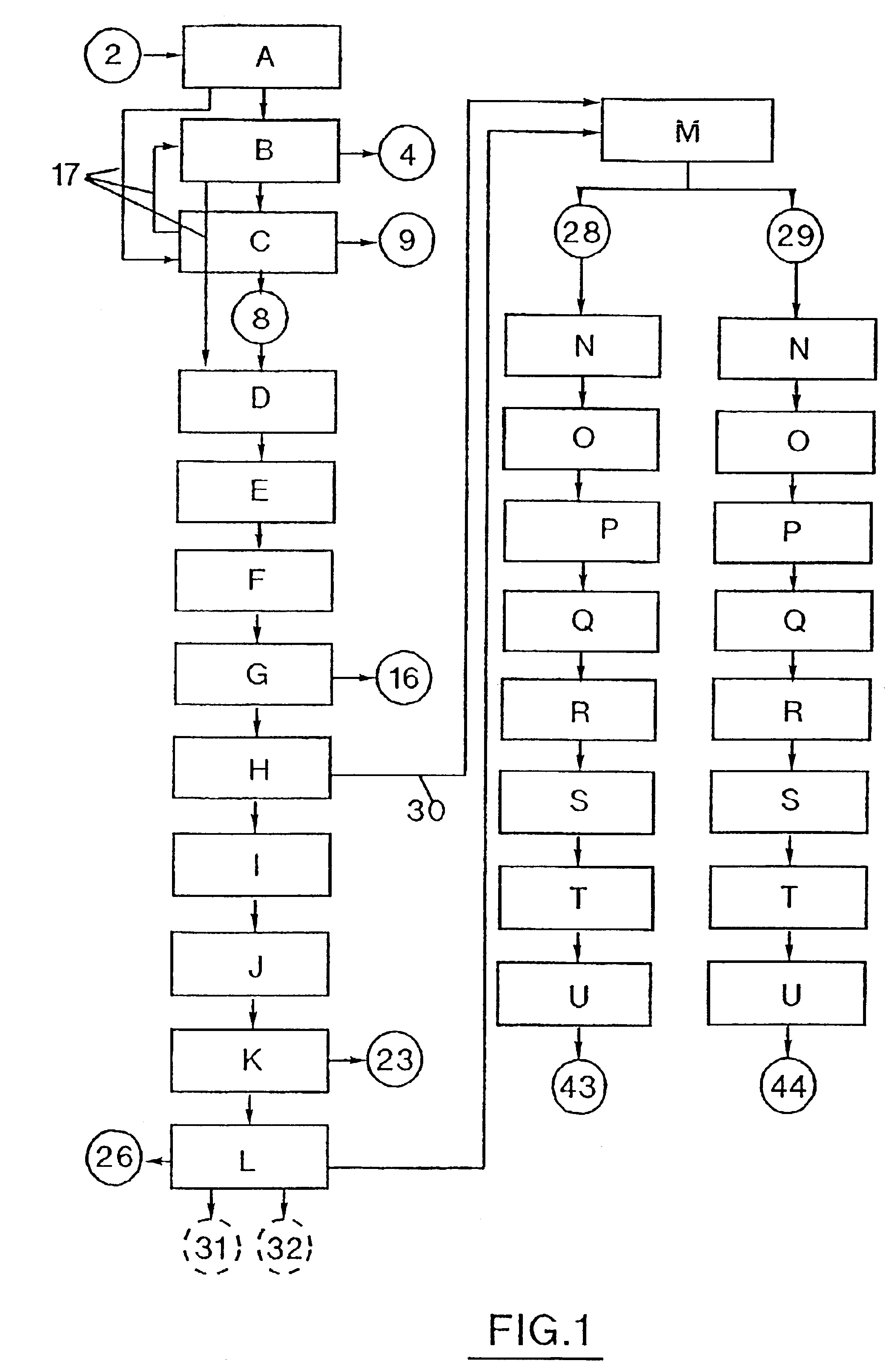

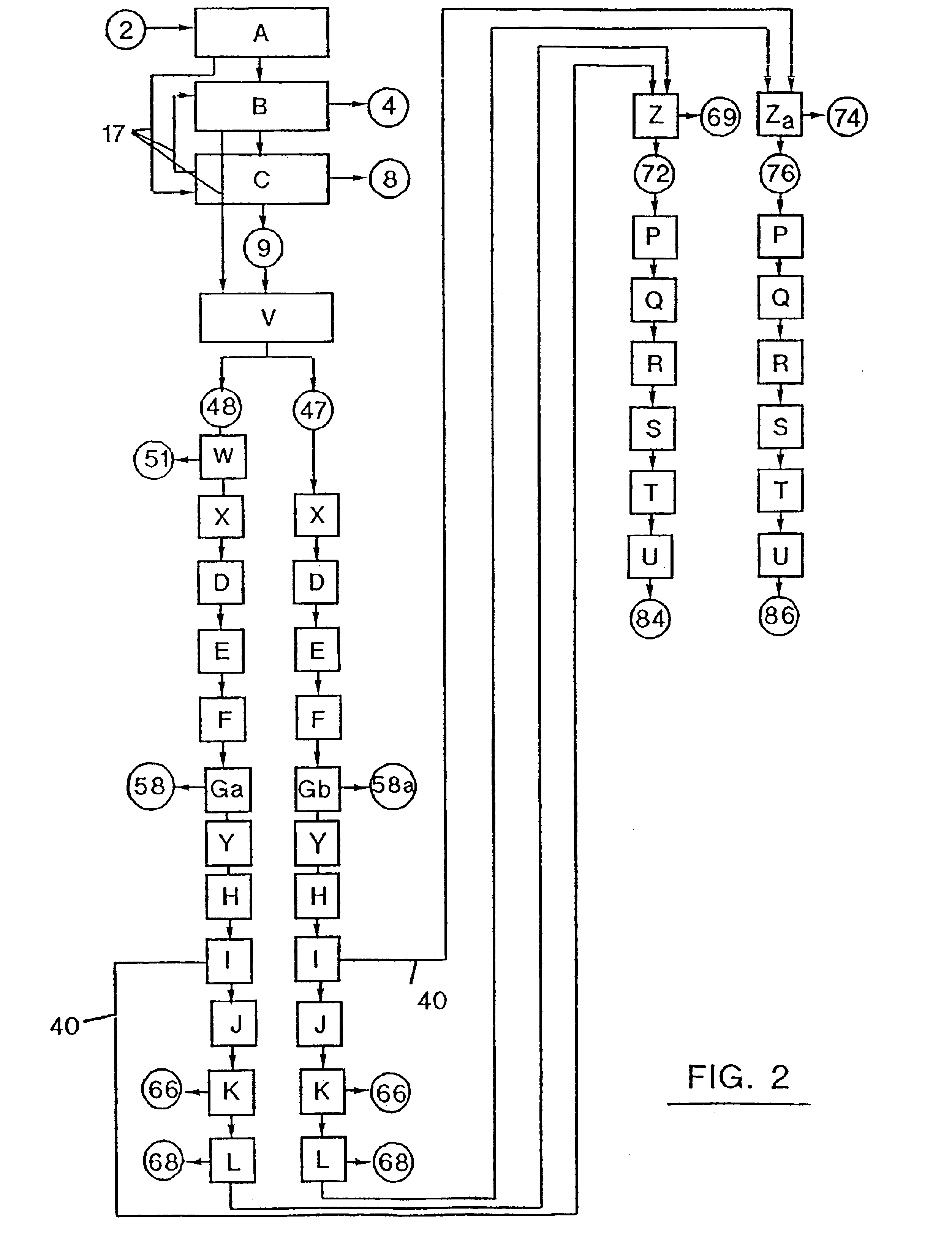

Method and plant for separating polymeric materials

A method for recycling polymeric materials, including a mechanical separation step (B), a first density separation step (C), an intensive cleaning step (E), and a second density separation step (G, V) is described. Additional separation steps, such as a third density separation step (M, W), and optionally a fourth density separation step (Ga, Gb). Further less essential steps such as wetting (A), grinding (D), air flow separation (K), drying (I), electrostatic sorting (Z) and optional sorting (Za) steps may also be carried out to achieve optimized and refined separation. Polymeric materials from refuse or crushed motor vehicles may thus be separated, and polyethylene, polypropylene, polystyrene and acrylonitrile-butadiene-styrene resins may be recycled.

Owner:VANDEPUTTE ANTOINE

Low-gloss and scratch-resistant nylon/acrylonitrile-butadiene-styrene resin blending material

ActiveCN102051042AGood scratch resistanceGood chemical resistanceN-phenylmaleimideBulk polymerization

The invention discloses a blending material, in particular to a low-gloss and scratch-resistant nylon / acrylonitrile-butadiene-styrene resin blending material. The blending material consists of the following components in part by weight: 35 to 75 parts of nylon, 0 to 35 parts of bulk polymerization acrylonitrile-butadiene-styrene (ABS) graft copolymer, 15 to 30 parts of ABS high glue powder, 3 to 10 parts of styrene-N-phenylmaleimide-maleic anhydride copolymer serving as compatibilizer, 2 to 10 parts of inorganic filler and the balance of antioxidant. The nylon / acrylonitrile-butadiene-styrene resin blending material prepared by the technical scheme has the characteristics of excellent scratch resistance, chemical resistance and mechanical property, low gloss, high liquidity and the like, and is very suitable for manufacturing automobile interior decorative materials of instrument boards, door sheets and the like.

Owner:SHANGHAI PRET COMPOSITES

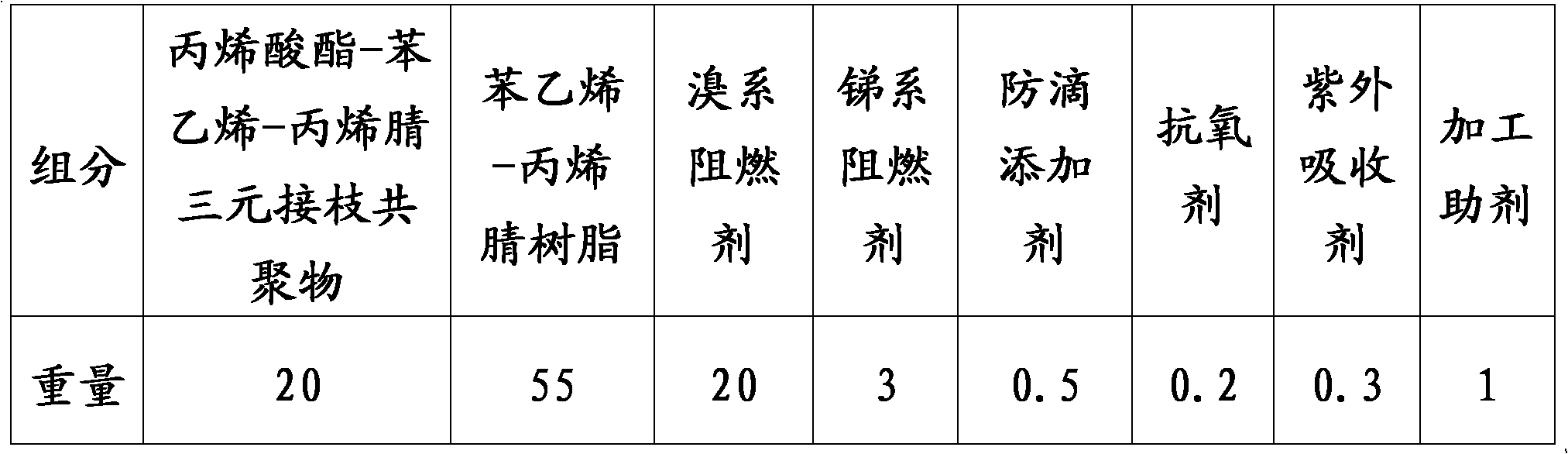

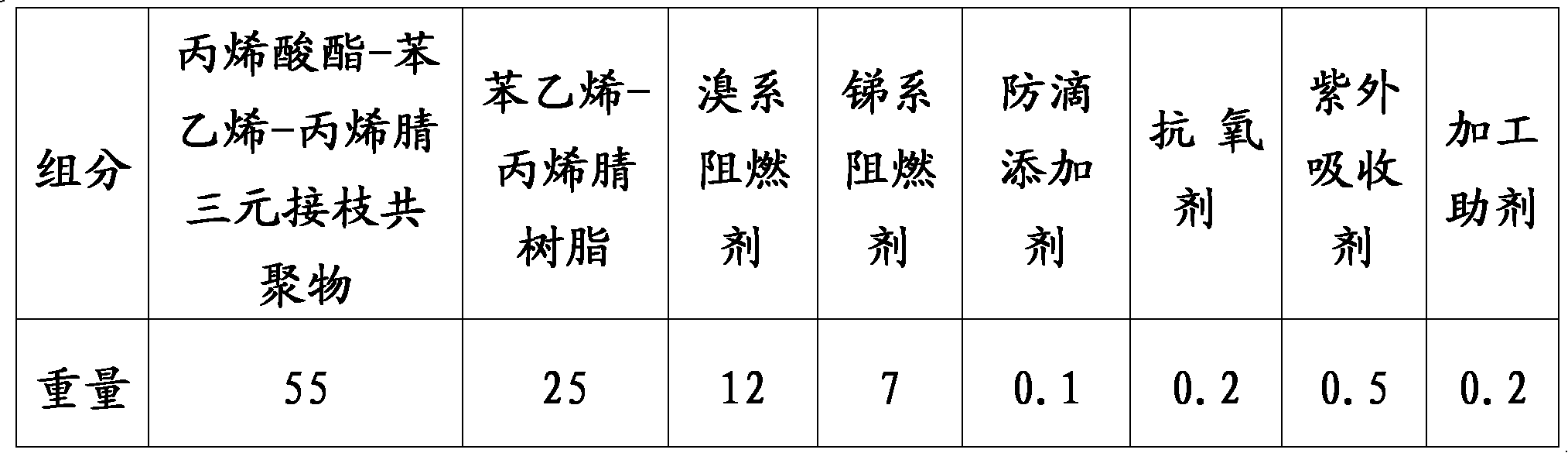

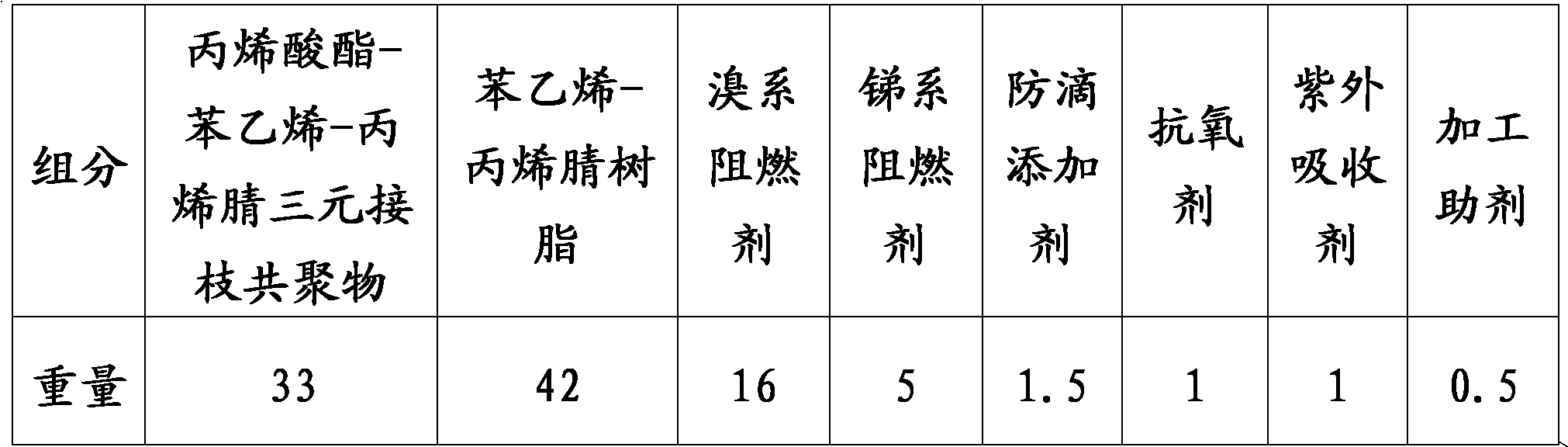

Flame-retarded ASA (Acrylic ester-Styrene-Acrylonitrile) modified resin and preparation method thereof

The invention relates to flame-retarded resin, in particular to flame-retarded ASA (Acrylic ester-Styrene-Acrylonitrile) modified resin and a preparation method thereof. The flame-retarded ASA modified material in the prior art has the defects of low flame-retarded level, flammability and unsafe use in outdoor equipment, electric appliances, and the like. The flame-retarded ASA modified material comprises the following substances in weight ratio: 20-55 parts of acrylic ester-styrene-acrylonitrile-ternary graft copolymer, 25-55 parts of styrene-acrylonitrile resin, 12-20 parts of bromine flame retardant agents, 3-7 parts of stibium flame retardant agents, 0.1-1.5 parts of drip-proof additive, 0.2-1% of antioxidant, 0.3-1% of ultraviolet absorbent and 0.2-1% of processing agent. The preparation method comprises the following steps of: accurately weighing each component and placing into a high speed mixer for uniform mixing; introducing into a twin screw extruder with a long diameter; mixing and milling; extruding; pulling into strips; cooling; and cutting into granules and packaging. The invention has the advantages of satisfying the flame retarded property and having more balanceable thermal stability, processing liquidity and impact strength; and the preparation method is simple and easy for operation.

Owner:SHANGHAI KINGFA SCI & TECH +1

Method and plant for separating polymeric materials

A method for recycling polymeric materials, including a mechanical separation step (B), a first density separation step (C), an intensive cleaning step (E), and a second density separation step (G, V) is described. Additional separation steps, such as a third density separation step (M, W), and optionally a fourth density separation step (Ga, Gb). Further less essential steps such as wetting (A), grinding (D), air flow separation (K), drying (I), electrostatic sorting (Z) and optional sorting (Za) steps may also be carried out to achieve optimized and refined separation. Polymeric materials from refuse or crushed motor vehicles may thus be separated, and polyethylene, polypropylene, polystyrene and acrylonitrile-butadiene-styrene resins may be recycled.

Owner:GALLOO PLASTICS

Flame-retardant and heat-resistant material for battery jar and preparation method thereof

The invention belongs to battery jar materials, and discloses a flame-retardant and heat-resistant material for a battery jar and a preparation method thereof. An acrylonitrile butadiene styrene (ABS) resin battery jar of the prior art cannot meet flame-retardant and heat-resistant requirements of a battery. The flame-retardant and heat-resistant material consists of the following materials in part by weight: 20 to 35 parts of ABS high glue powder, 35 to 60 parts of styrene-acrylonitrile resin, 5 to 20 parts of brominated epoxy flame retardant, 3 to 6 parts of antimony flame retardant, 2 to 6 parts of powdered butadiene-acrylonitrile rubber, 0.2 to 1 part of antioxidant, and 0.2 to 1 part of processing agent. The preparation method comprises the following steps of: adding the raw materials into a high-speed mixer for uniform mixing; delivering the mixture into a twin-screw extruder of which the length-diameter ratio is 32 to 40; and performing mixing, extruding, strip pulling, cooling, and chopping to obtain the flame-retardant and heat-resistant material. The flame-retardant and heat-resistant material has the advantages of high flame retardance and heat resistance to prolong the service life of the battery, high impact resistance and chemical corrosion resistance to meet working requirements of the battery, and simple preparation process which is easy to operate.

Owner:SHANGHAI KINGFA SCI & TECH +1

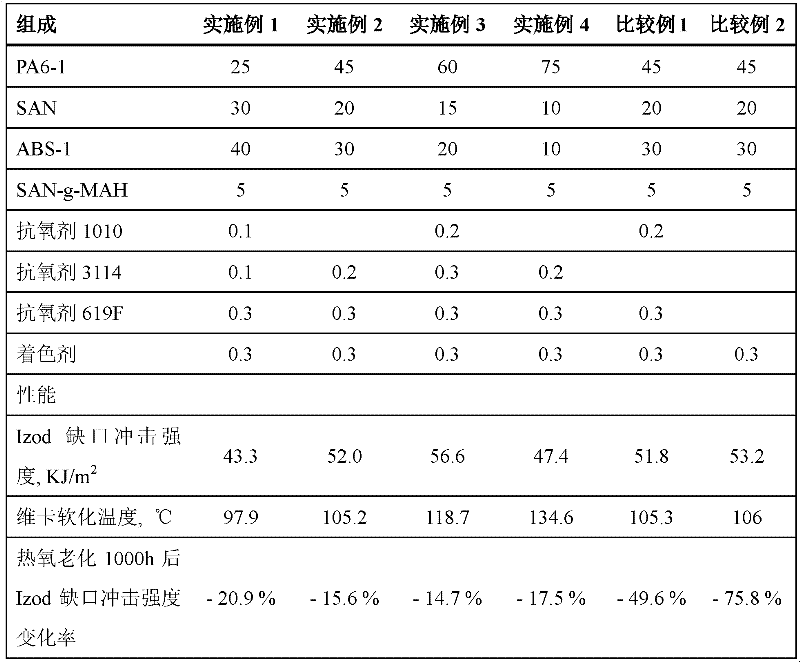

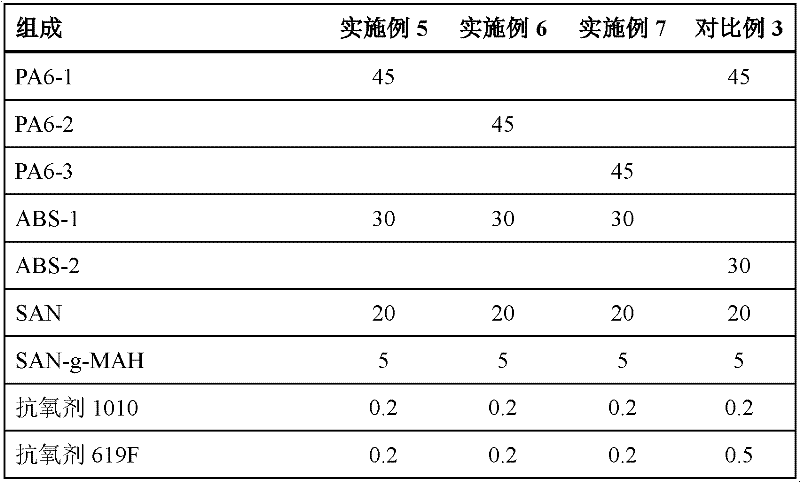

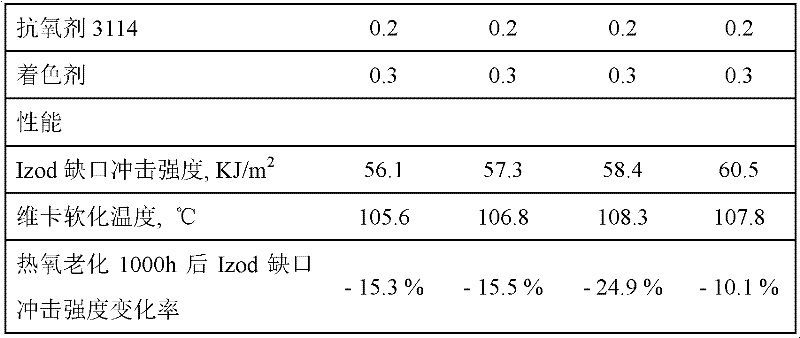

Thermo-oxidative ageing-resistant nylon/acrylonitrile-butadiene-styrene resin mixed material

ActiveCN102532874AExcellent thermal and oxidative aging resistanceImprove liquidityAntioxidantAging resistance

The invention discloses a thermo-oxidative ageing-resistant nylon / acrylonitrile-butadiene-styrene resin blending material. The thermo-oxidative ageing-resistant nylon / acrylonitrile-butadiene-styrene resin mixed material comprises the following components in part by weight: 25 to 75 parts of nylon resin, 10 to 30 parts of acrylonitrile-styrene copolymer, 10 to 40 parts of acrylonitrile-butadiene-styrene copolymer, 5 parts of maleic anhydride-grafted acrylonitrile-styrene copolymer compatibilizer, 0.2 to 0.5 part of main antioxidant and 0.2 to 0.5 part of auxiliary antioxidant. By adoption of the technical scheme, the thermo-oxidative ageing-resistant nylon / acrylonitrile-butadiene-styrene resin mixed material has the characteristics of excellent thermo-oxidative ageing resistance and high flowability, has a high notch impact property, chemical resistance and mechanical properties, can be used as manufacturing materials of shells of automobile accessories, electric tools, office equipment and the like.

Owner:SHANGHAI PRET COMPOSITES

Anti-flaming polycarbonate/acrylonitrile-butadiene-styrene resin mixing material and preparation method thereof

The present invention relates to blending polymer and the preparation method, and discloses a flame-retardant polycarbonate and acrylonitrile-butadiene-styrene resin blend and the manufacturing method. The components and weight shares include: 55 to 80 shares of polycarbonate, 10 to 30 shares of acrylonitrile-butadiene-styrene resin, 5 to 30 shares of flame retardant, 1 to 5 shares of flame retardant synergist, 5 to 30 shares of spherical inorganic particle, 0.3 to 10 shares of coupling agent, 0.1 to 2 shares of anti-dropping agent, and 0.1 to 1 share of antioxidant. The product of the present invention has the overall balance of the high mobility, high heat resistance, and high flame retardancy; the flame retardancy, mobility, modulus, and heat resistance of the product of the present invention are excellent, and can meet the requirements of such industries as the household electrical appliance, the electronics, and the auto part and so on. The method has the advantages of the simple process, the high production efficiency, the strong applicability, and so on.

Owner:SHANGHAI KINGFA SCI & TECH

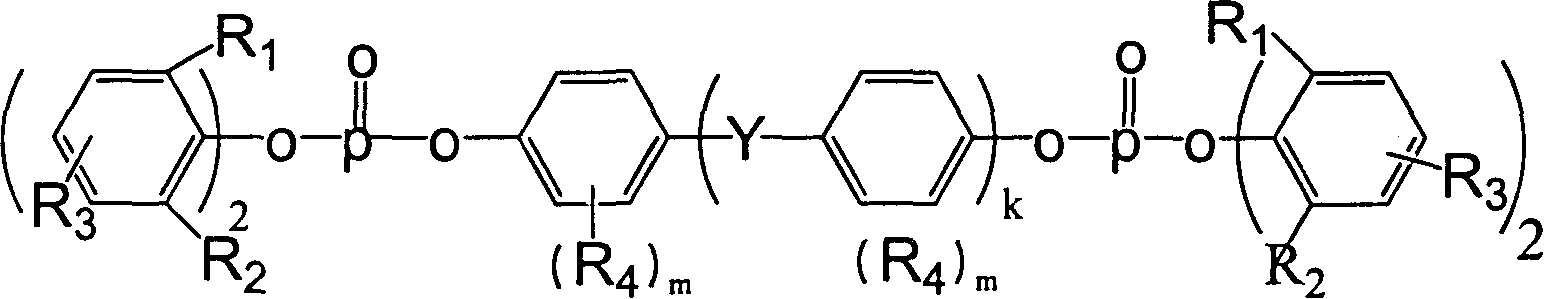

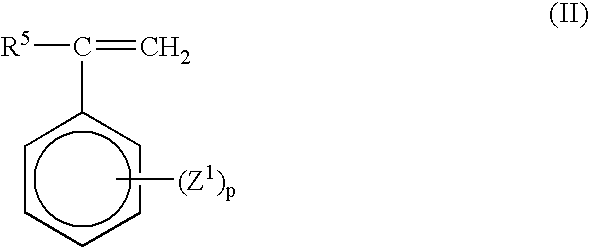

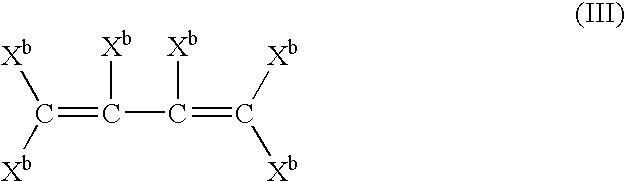

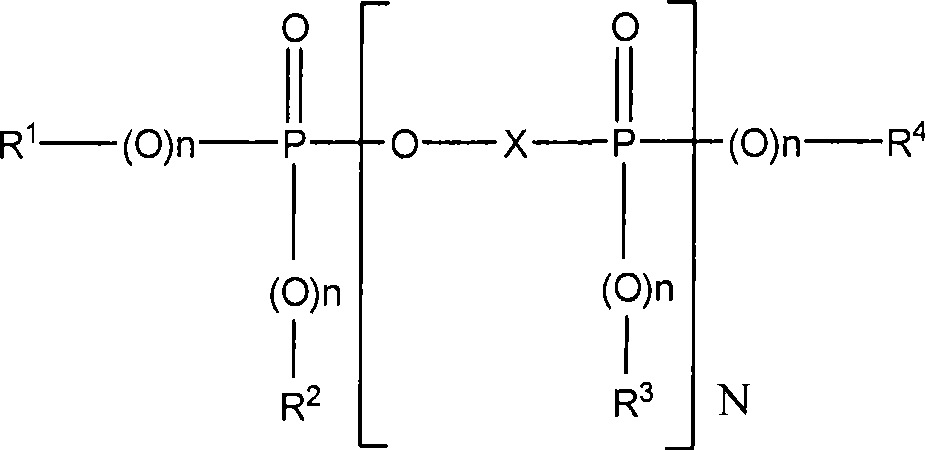

Flame retardant resin compositions

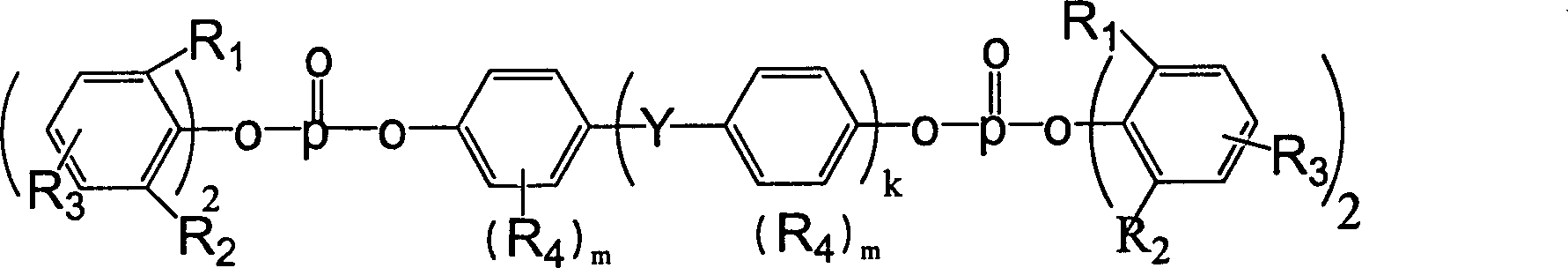

InactiveUS20040102549A1Improved flowabilityHigh strengthFireproof paintsPlastic/resin/waxes insulatorsAlcoholPhosphate

A flame retardant thermoplastic resin composition comprises a thermoplastic resin comprising a polyphenylene ether resin, a high impact polstyrene resin or an acrylonitrile-butadiene-styrene resin; an organo phosphate compound in an amount less than or equal to about 20 parts by weight for every 100 parts by weight of the thermoplastic resin; and a polyhydric alcohol compound in an amount of about 0.5 to about 5.0 parts for every 100 parts by weight of the thermoplastic resin. A method for the manufacture of the thermoplastic resin composition is also disclosed. The thermoplastic resin composition exhibits high flow characteristics and improved impact strength while providing effective flame retardance.

Owner:SABIC INNOVATIVE PLASTICS IP BV

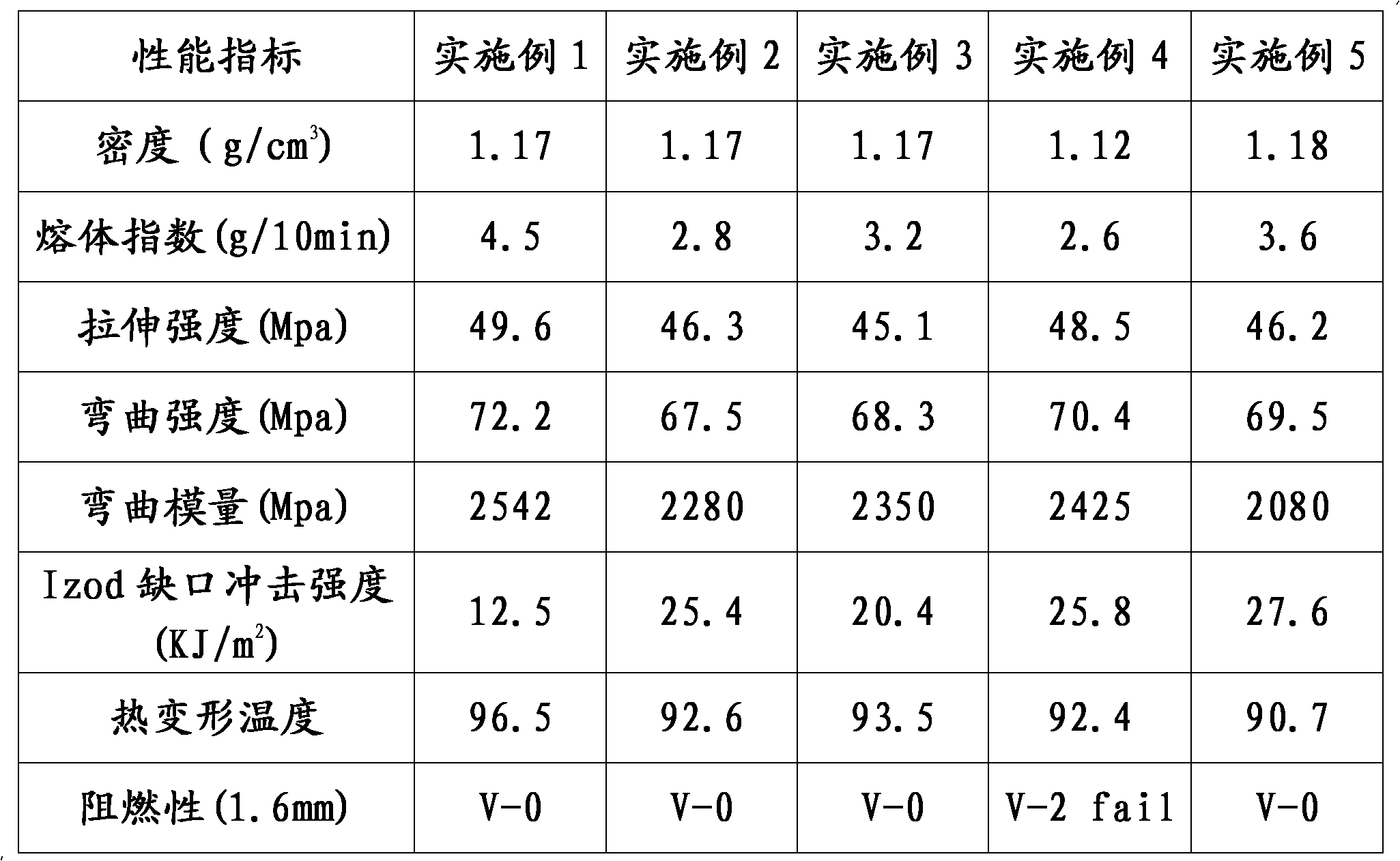

Flame-retardant and heat-resistant acrylonitrile butadiene styrene (ABS) composition and preparation method thereof

ActiveCN103013035AHigh glass transition temperatureImprove heat resistanceHeat deflection temperaturePolymer science

The invention relates to the technical field of preparation of acrylonitrile butadiene styrene (ABS), and in particular relates to a flame-retardant and heat-resistant ABS composition and a preparation method thereof, wherein the composition consists of the following raw materials in parts by weight: 45-70 parts of acrylonitrile-butadiene-styrene resin, 11-16 parts of fire retardant, 2-5 parts of flame-retardant synergist, 0.1-0.2 part of antioxidant A, 0.1-0.2 part of antioxidant B, 0.5-0.7 part of lubricant A, 0.2-0.5 part of lubricant B, 9-30 parts of heat-resistant agent and 2-4 parts of flexibilizer. The ABS composition disclosed by the invention can reach 99.9 DEG C in heat distortion temperature, excellent in flame-retardant performance and accordant with the UL-94VO grade standard; the product has excellent stability, high mechanical strength and good quality; and the preparation method disclosed by the invention is simple in process, low in production cost and favorable for general popularization and application.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

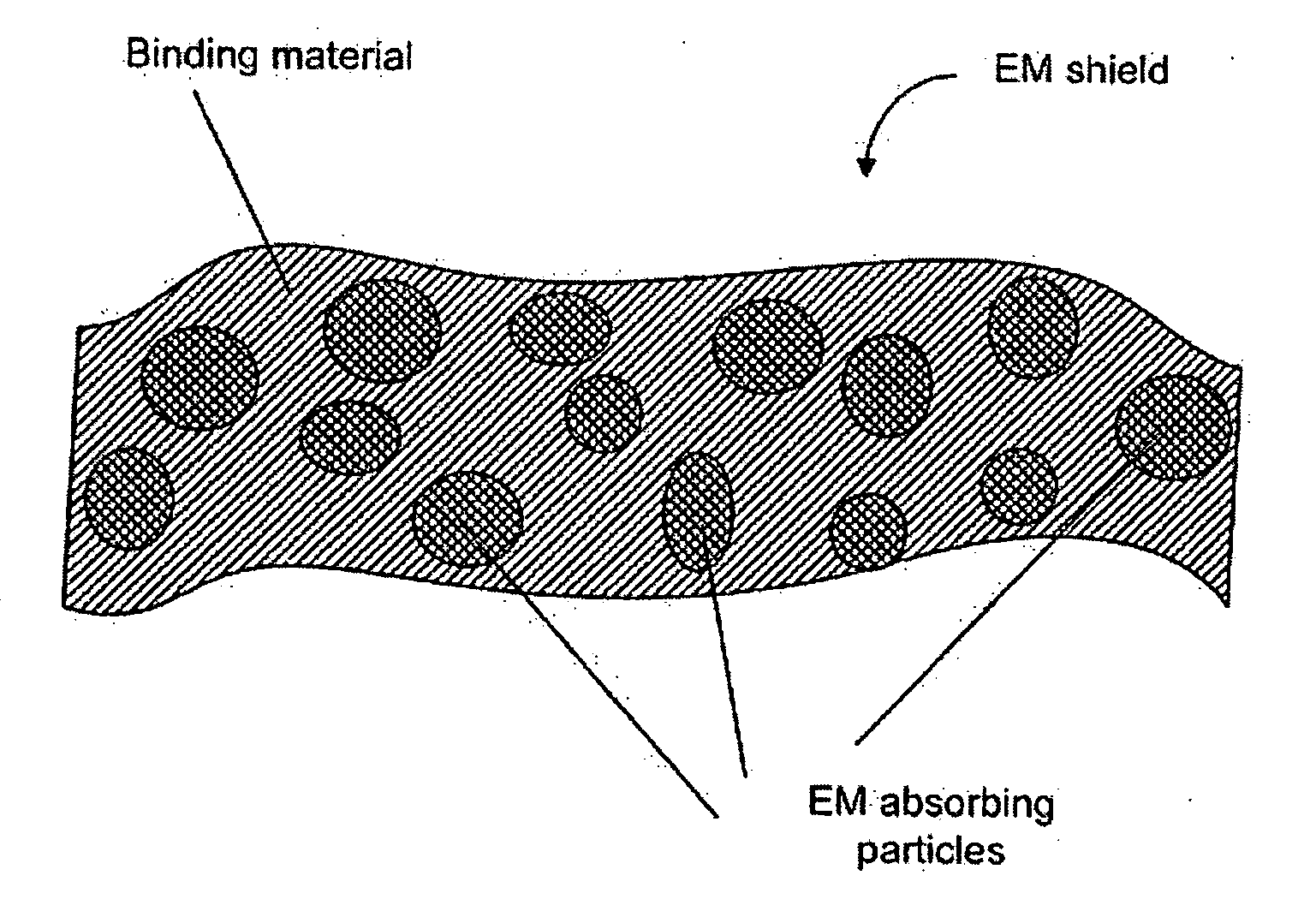

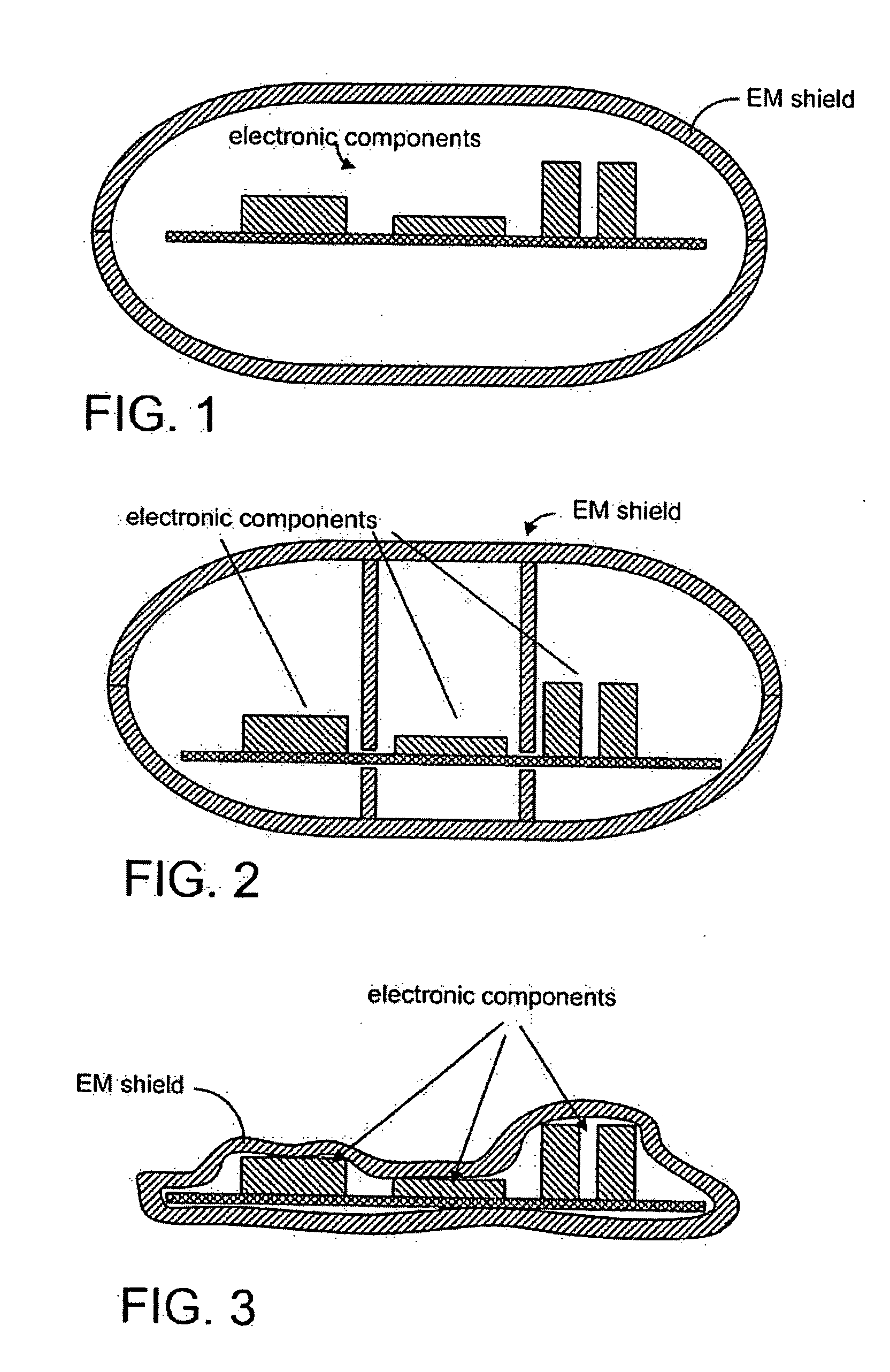

Shielding material for preventing from outleakage and penetration of electromagnetic waves

InactiveUS20050183871A1Effectively absorbs energy associated with electromagnetic waveReduce electromagnetic radiationMagnetic/electric field screeningRadiation-absorbing paintsEpoxyEthylene thiourea

An EM shielding material and an EM shielding contains a material composition comprising at least one EM absorbing element or compound in a discrete particle form and a binding compound to bind the discrete particles in a layer or paste. The discrete particles are made of one or more metals such as Fe, Ni, Cr and Mn or dielectric compounds having magnetic properties. The binding compounds can be selected from silicone, rubber, arcylonitrile butadiene styreneresin (ABS), polycarbonate (PC), epoxy, silica and polyurethane. The associated components can be selected from zinc oxide, magnesium oxide, ethylene thiourea, carbon black, and stearic acid. The material can also be used as the package material for the electronic components in an electronic product.

Owner:HOU PON WEI

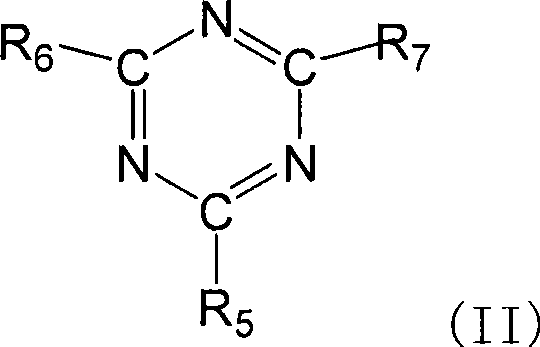

Non-halogen flame retardant PC (polycarbonate) /ABS (acrylonitrile butadiene styrene) alloy and preparation method thereof

InactiveCN102352096ALittle influence of heat distortion temperatureExtended operating temperature rangePhosphateAlloy

The invention discloses a non-halogen flame retardant PC (polycarbonate) / ABS (acrylonitrile butadiene styrene) alloy with high heat distortion temperature. The alloy comprises the following components in parts by weight: 50-85 parts of PC resin, 3-25 parts of ABS resin, 3-8 parts of toughening agent, 8-20 parts of flame retardant, 0.3-1 part of antioxidant A, 0.3-1 part of antioxidant B and 0.3-0.8 part of anti-dripping agent, wherein the PC resin is bisphenol A-type polycarbonate resin, the ABS resin is acrylonitrile-butadiene-styrene resin, the toughening agent is maleic anhydride grafted ABS resin blend, the flame retardant is at least one of hydroxymethylphenyl hypophosphite salt, methylphenyl phosphate salt, methylphenyl phosphate and methylphenyl phosphite, the antioxidant A is pentaerythrityl-tetra-[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate], the antioxidant B is tris(2,4-ditert-butylphenyl)phosphite and the anti-dripping agent is polytetrafluoethylene resin. The invention also provides a method for preparing the alloy.

Owner:苏州铧茂工程塑料有限公司

High weather resistant, halogen-free and flame retardant PC/ABS alloy material special for outdoor telecommunication box and preparation method thereof

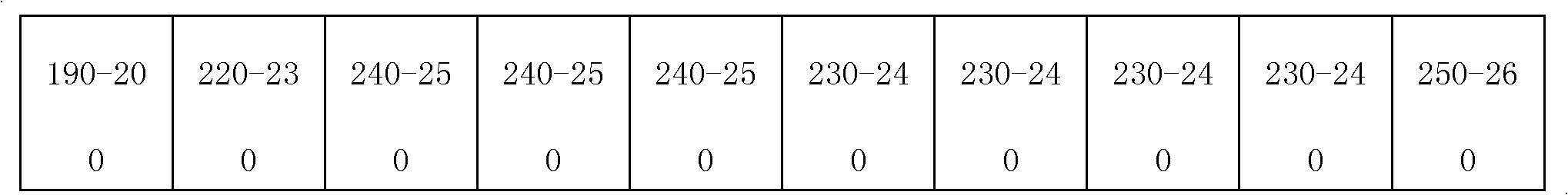

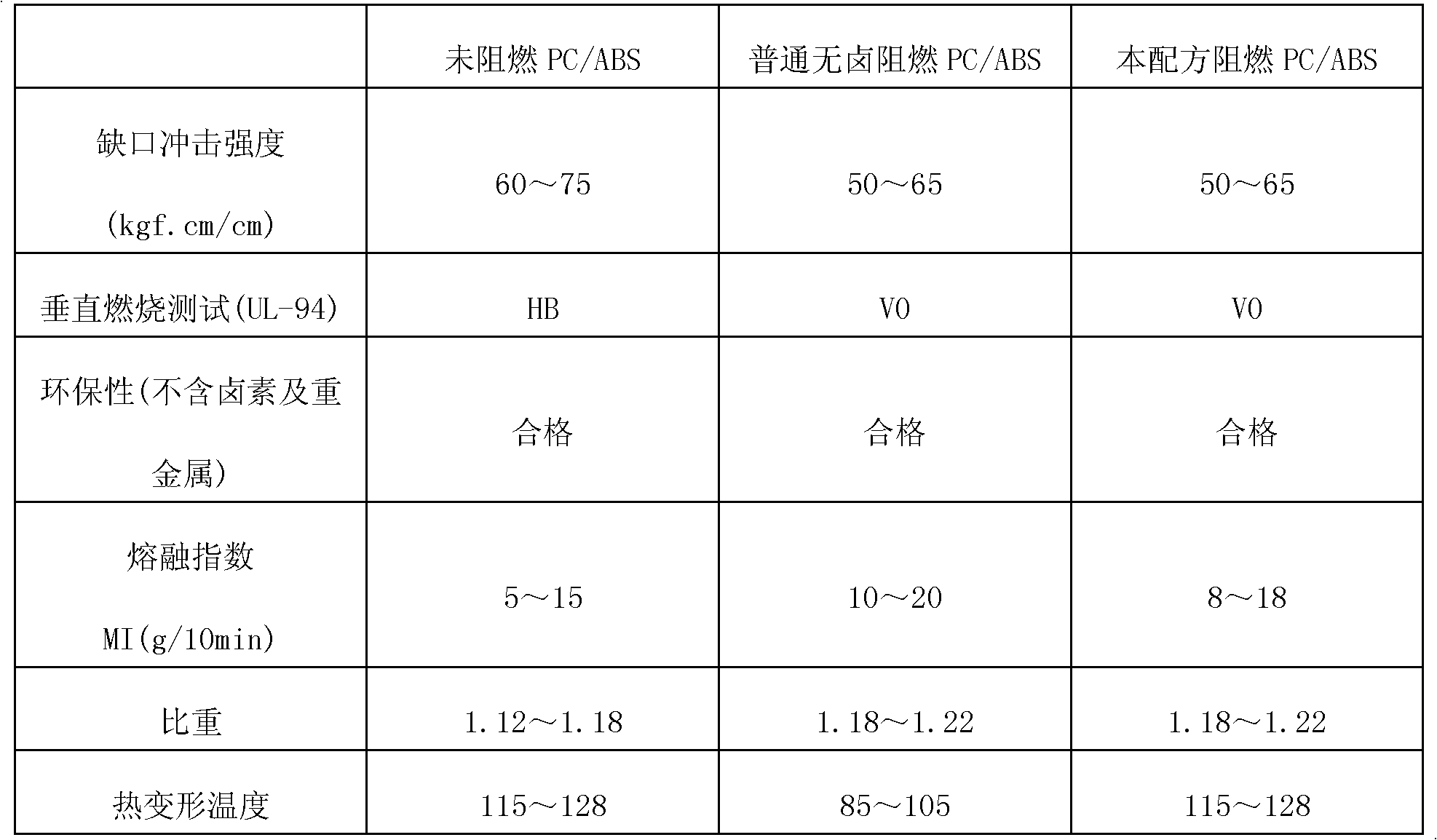

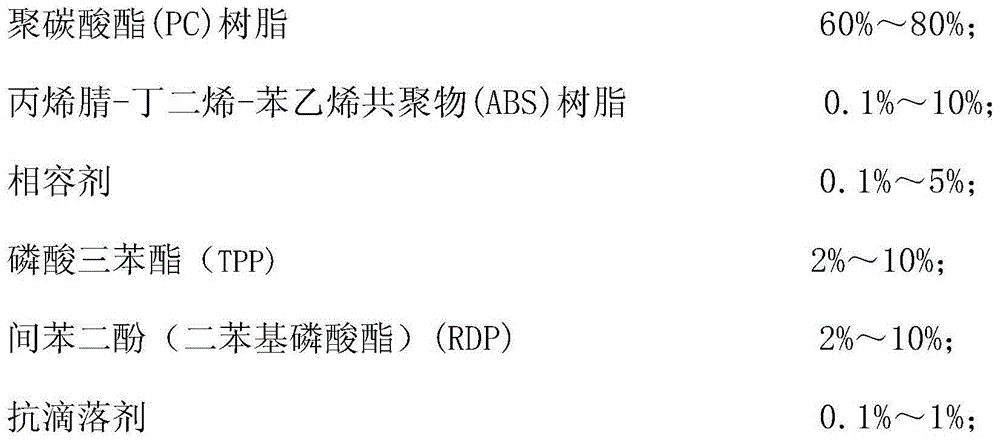

The invention discloses a high weather resistant, halogen-free and flame retardant PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material special for an outdoor telecommunication box and a preparation method thereof. The PC / ABS alloy material is prepared from the following raw materials by weight percentage: 60%-80% of polycarbonate resin; 0.1%-10% of acrylonitrile-butadiene-styrene resin; 0.1%-5% of a compatibilizer; 2%-10% of triphenyl phosphate; 2%-10% of resorcinol (diphenyl phosphate); 0.1%-1% of an anti-dripping agent; 0.1%-2% of a light stabilizer; and 0.1%-2% of assistants. According to the invention, the PC and ABS resin with good weather resistance are adopted as the matrix, and through synergy of the compatilizer, the halogen-free flame retardants and the light stabilizer, the halogen-free and flame retardant PC / ABS alloy material with high heat resistance and high performance can be obtained, and can be widely used in the communications industry, the automobile industry, building materials, decoration materials, cables and the electrical industry. The preparation method of the alloy material adopts existing equipment, is simple to operate, and is suitable for industrialized production.

Owner:SHANGHAI AUSELL CHEM TECH

Flame-retardant polycarbonate and acrylonitrile-butadiene-styrene resin compositions

InactiveCN101412843AImprove flame retardant and smoke suppression performanceNo harmToxic gasCombustion

The invention provides a composition of flame-retardant polycarbonate and acrylonitrile-butadiene-styrene resin. The composition comprises the following components and weight percentage (based on the total weight of the composition): 40 to 80 percent of polycarbonate, 5 to 45 percent of acrylonitrile-butadiene-styrene resin, 5 to 40 percent of halogen-free main flame retardant and 1 to 5 percent of boron-containing auxiliary flame retardant. The composition of flame-retardant polycarbonate and acrylonitrile-butadiene-styrene resin can not emit a large amount of dense smoke, corrosive gas or toxic gas during combustion, and improves the processability of materials.

Owner:SHANGHAI RES INST OF CHEM IND

High-gloss high-hardness scraping-resistant ABS material

InactiveCN105802118ASignificant technological progressHigh hardnessStyrene-acrylonitrile resinPolymethyl methacrylate

The invention provides a high-gloss high-hardness scraping-resistant ABS material which comprises the following components in percentage by mass: 10-15% of polycarbonate resin, 20-40% of an acrylonitrile-butadiene-styrol copolymer, 20-40% of styrene-acrylonitrile resin, 20-30% of polymethyl methacrylate, 5-10% of a compatilizer, 1-3% of silicone, 1-2% of a high-gloss toner and 0.1-1% of an additive. The high-gloss high-hardness scraping-resistant ABS material provided by the invention has properties of good impact resistance, high gloss, high hardness, scraping resistance and the like, and moreover is low in cost and easy to prepare. In addition, the preparation method of the high-gloss high-hardness scraping-resistant ABS material adopts conventional equipment and is simple to operate and applicable to industrial production.

Owner:中广核俊尔(上海)新材料有限公司

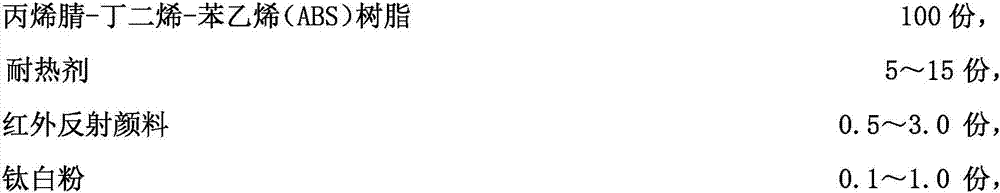

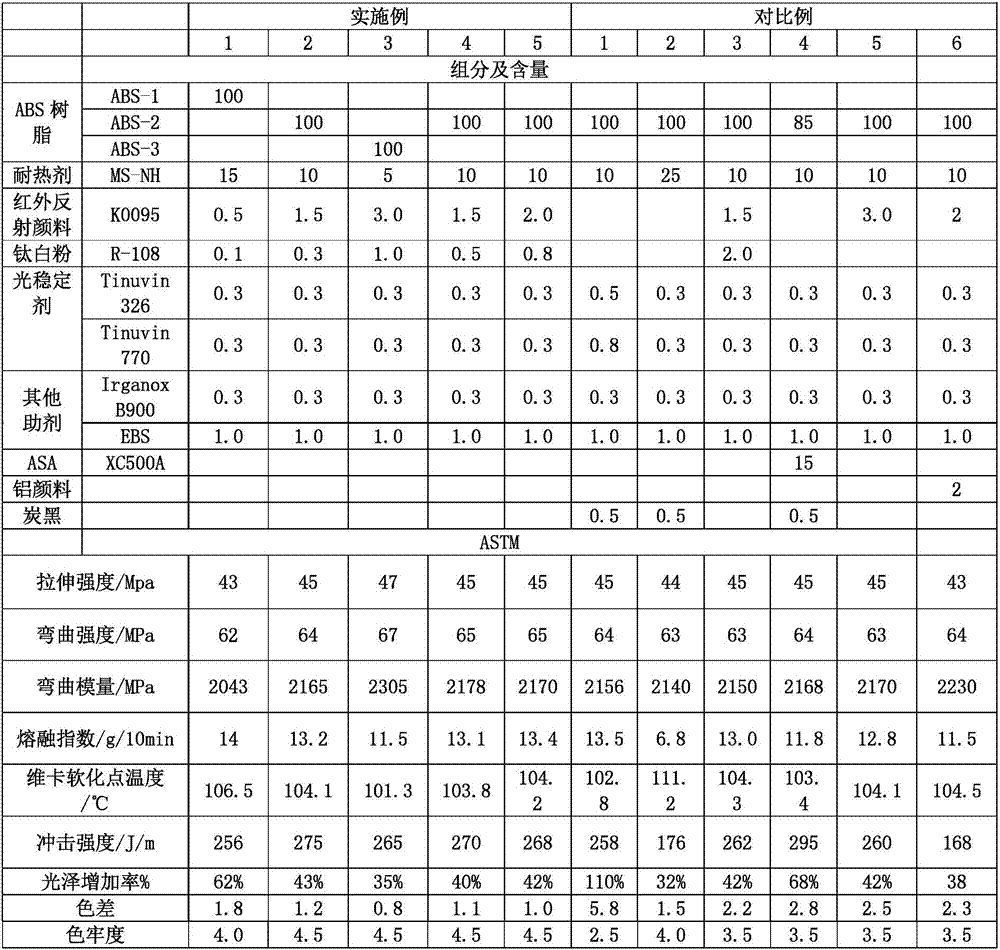

Deep-color heat-resistant ABS resin composition with improved weather resistance

ActiveCN107043516AImprove performanceGood weather resistanceWeather resistanceAcrylonitrile-butadiene-styrene resin

The invention discloses a deep-color heat-resistant ABS resin composition with improved weather resistance. The composition comprises the following components in parts by weight: 100 parts of acrylonitrile-butadiene-styrene resin, 1-5 parts of a heat resistant agent, 0.5-3.0 parts of an infrared reflection pigment, 0.1-1.0 part of titanium dioxide, 0.2-1.0 part of a light stabilizer and 0.5-2.0 parts of other auxiliary agents. The deep-color heat-resistant ABS resin composition with improved weather resistance is obtained by the steps of: fully stirring and mixing the raw materials in a high speed mixer; feeding the mixture into a twin-screw extruder through a metering device; melting and compounding the materials under conveyance, shearing and mixing of screws; and then performing extrusion, wire-bracing, cooling and dicing steps. The heat-resistant ABS resin composition disclosed by the invention not only has excellent weather resistance, but also has excellent mechanical properties, and is quite suitable for being applied to the field of automotive upholsteries.

Owner:SHANGHAI KUMHOSUNNY JINSHAN PLASTICS CO LTD

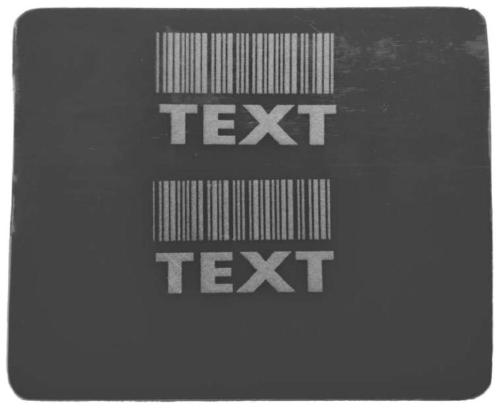

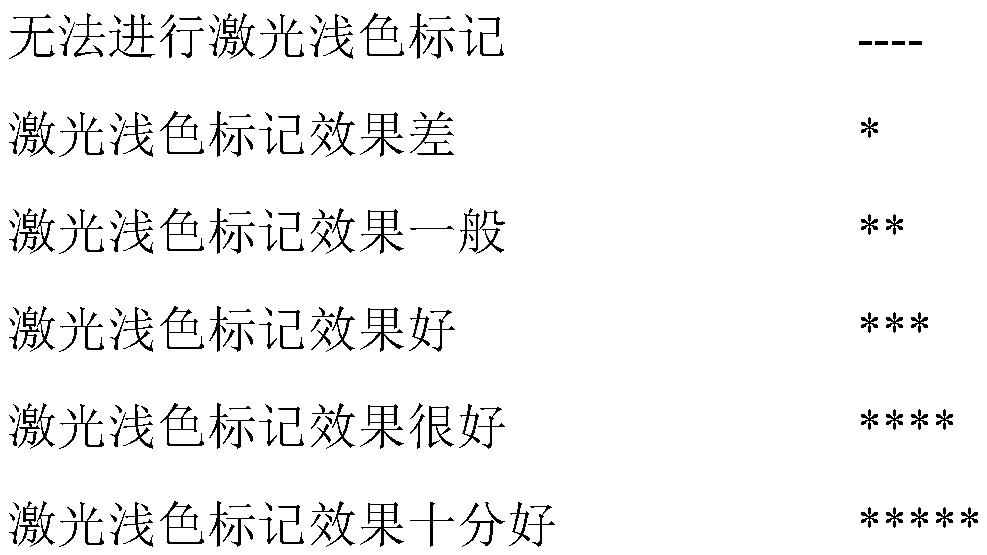

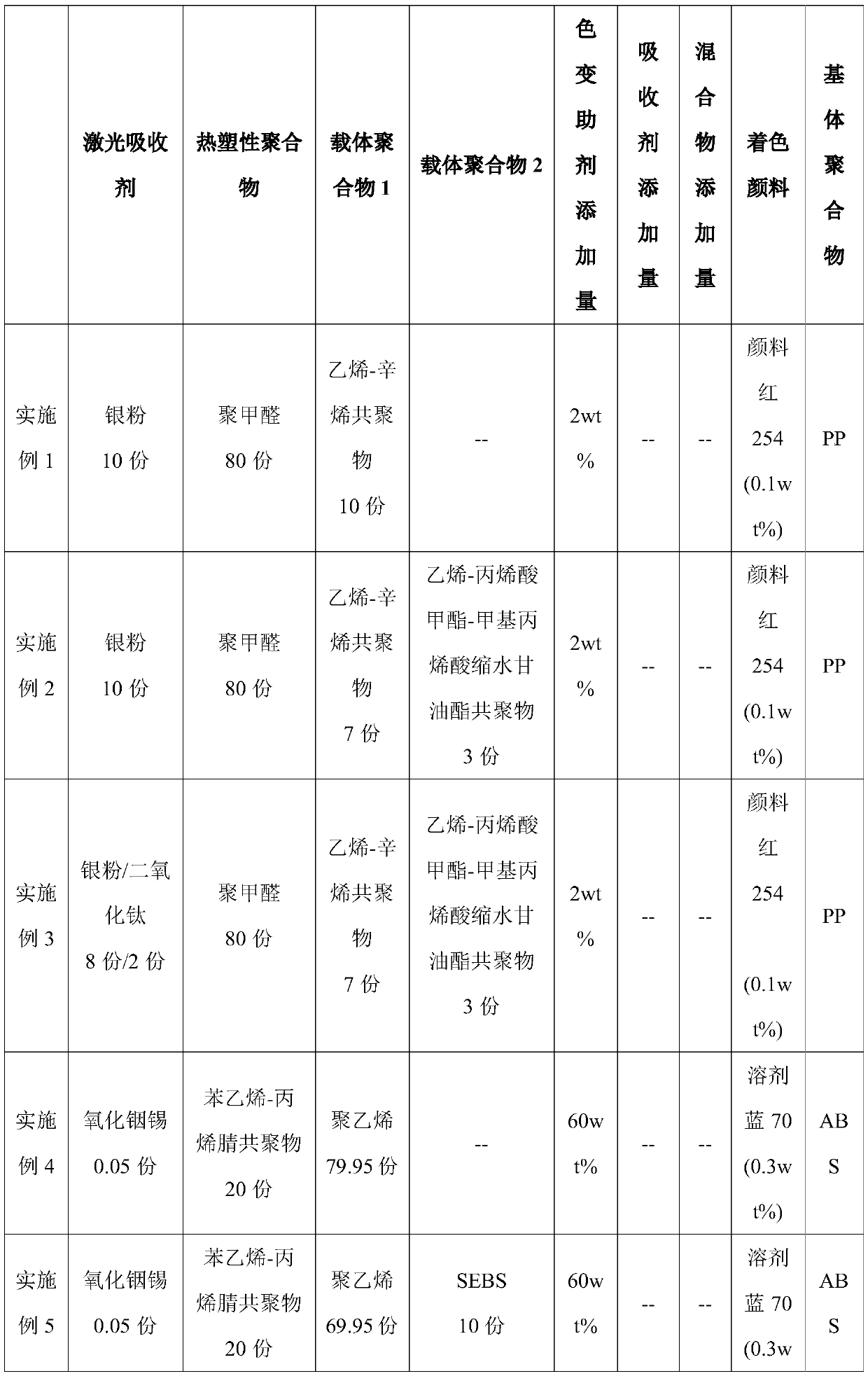

Color change aid used for preparing white or light-colored marks and preparation method thereof

ActiveCN110408165ASimple manufacturing processSimple and fast operationPolymer scienceStyrene-acrylonitrile resin

The invention discloses a color change aid. The color change aid is prepared from, by weight, 0.05-10.00 parts of a laser absorbent, 20.00-80.00 parts of a thermoplastic polymer and 10.00-79.95 partsof a carrier polymer, wherein the thermoplastic polymer is polyacrylate resin, polyoxymethylene resin, styrene-acrylonitrile resin, acrylate-styrene resin or ABS resin. The invention further disclosesthe use of the color change aid for performing marking on colored polymers. Experiments show that after a certain amount of the color change aid is added into the polymers of different colors, the light-colored to white marks can be efficiently marked on the polymers of different colors; the preparation method of the disclosed color change aid is simple, easy to operate, safe, environmentally friendly, low in energy consumption, and very suitable for large-scale production in industries, and has good economic benefits.

Owner:SICHUAN UNIV

Transparent high-hardness impact-resistant acrylonitrile butadiene styrene (ABS) plastic alloy composition

The invention discloses a transparent high-hardness impact-resistant acrylonitrile butadiene styrene (ABS) plastic alloy composition. The transparent high-hardness impact-resistant ABS plastic alloy composition comprises 30 to 50 weight parts of styrene-acrylonitrile resin, 30 to 50 weight parts of polymethacrylate resin and 10 to 30 weight parts of acrylic ester elastomer. The ABS plastic alloy composition prepared by the technical scheme has the advantages that: the ABS plastic alloy composition is transparent and has high toughness and high surface hardness; 2, the ABS plastic alloy composition is transparent and has high impact resistance and surface hardness, so surface coating can be saved; and 3, the ABS plastic alloy composition has high flowability, so filling formation of a large-sized die is facilitated. The ABS plastic alloy composition can be applied to shells of mobile phones, mobile digital video disc (DVD) electronic products, domestic appliances such as televisions, liquid crystal displays and the like and automobile instrument displays and the like.

Owner:SHANGHAI PRET COMPOSITES

Exterior component disposed on front surface of radar device of vehicle

InactiveUS20070210979A1Improve aestheticsLow costAntenna adaptation in movable bodiesRadiating element housingsAttenuation coefficientStyrene-acrylonitrile resin

An exterior vehicle component includes a proximity member disposed along an outer perimeter of an electromagnetic wave transmission member provided at a center of the component which is disposed in front of a radar device. The proximity member includes a chromium-plated portion formed on its front surface which reflects an electromagnetic wave. The proximity member is formed of an acrylate-styrene-acrylonitrile resin or a modified polyphenylene oxide resin having an attenuation coefficient for electromagnetic wave transmission, which is equal to or greater than a predetermined value.

Owner:HONDA MOTOR CO LTD

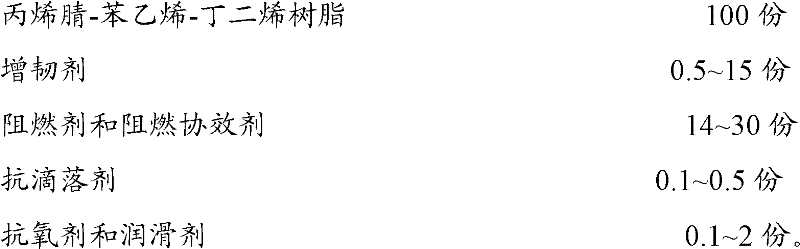

Flame-retardant acrylonitrile-butadiene-styrene resin composition and preparation method thereof

The invention relates to a flame-retardant acrylonitrile-butadiene-styrene resin composition, which comprises the following components in part by weight: 100 parts of acrylonitrile-butadiene-styrene resin, 0.5 to 15 parts of toughening agent, 14 to 30 parts of flame retardant and flame retardant synergist, 0.1 to 0.5 part of antifogging agent and 0.1 to 2 parts of antioxidant and lubricating agent. The flame retardant is added into the flame-retardant acrylonitrile-butadiene-styrene resin composition, the composition has excellent flame retardancy; in the formula, the components have better compatibility; meanwhile, due to the synergism of the lubricating agent and the antioxidant, the processing fluidity of the flame-retardant acrylonitrile-butadiene-styrene resin composition can be improved and the dispersion performance of the flame retardant in the composition can be improved; and the prepared flame-retardant acrylonitrile-butadiene-styrene resin composition has high impact strength, bending strength, tensile strength, flame retardancy and fluidity. In addition, the invention also relates to a method for preparing the flame-retardant acrylonitrile-butadiene-styrene resin composition.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

Artificial fish bait made by composite material and production method thereof

The invention relates to a composite artificial false fishing lure, and relative production. Wherein, said composite is formed by polycarbonate resin, polyethylene resin, acrylic nitrile- butadiene-styrene rein, added with silica dioxide nanometer powder; mixing and adding additive, injection molding, removing mould, cooling and shaping. The invention is lighter than wood production, with better flexibility and corrosion resistance, while it will not be degraded in long time service.

Owner:南京鸿耕展金属有限公司

Low-gloss flame-retardant alloy

The invention relates to a low-gloss flame-retardant alloy consisting of the following components in percentage by weight: 33.7-64.4% of polycarbonate, 15-30% of polyethylene glycol terephthalate or acrylonitrile-butadiene-styrene resin, 10-15% of a flame retardant, 3-7% of a flame-retardant synergistic agent, 5-8% of a toughening compatilizer, 2-5% of a matting agent, 0.3-0.5% of an antioxidant and 0.3-0.8% of a processing aid. The low-gloss flame-retardant alloy provided by the invention is excellent in alloy phase comprehensive performance, low in cost and high in cost performance, reaches a flame retardant grade of UL94-V0, and can be widely applied to automotive interior parts.

Owner:浙江精亮新材料科技有限公司

Highly weather-resistant colored polycarbonate-acrylonitrile-butadiene-styrene resin blending material and preparation method thereof

The invention discloses a highly weather-resistant colored polycarbonate-acrylonitrile-butadiene-styrene resin blending material and a preparation method thereof. The blending material is prepared from the following raw materials in parts by weight: 40-60 parts of polycarbonate resin, 35-55 parts of acrylonitrile-butadiene-styrene grafted copolymer, 0-5 parts of acrylonitrile-butadiene-styrene grafted maleic anhydride compatilizer, 0.1-2 parts of light absorber, 0.2-0.7 part of antioxidant and 0.1-1 part of coloring agent. By adoption of the highly weather-resistant colored polycarbonate (PC)-acrylonitrile-butadiene-styrene resin (ABS) blending material, when the PC / ABS material is prepared into different colors, the weather resistance data of the material is greatly improved by adjusting the toner proportion due to an experiment under the condition that a weather-resistant aid combination is optimized, and the blending material can be used for automobile interior and exterior parts, household appliances and the like.

Owner:SHANGHAI PRET COMPOSITES +2

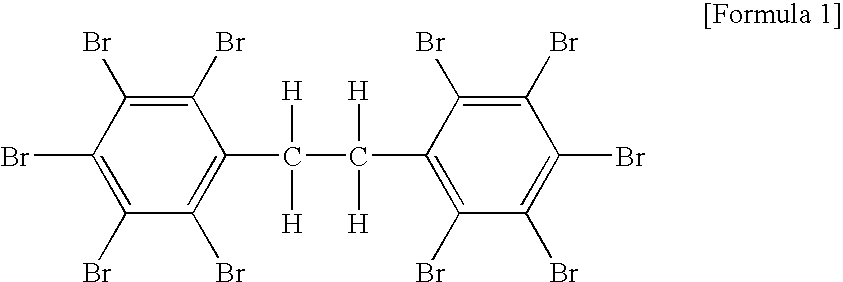

Acrylonitrile-butadiene-styrene resin composition having good weatherability and thermostability

ActiveUS20070142524A1Improve flame resistanceHigh mechanical strengthFibre treatmentOrganic dyesAcrylonitrileStearic acid

The present invention relates to an acrylonitrile-butadiene-styrene resin composition, and more precisely, an acrylonitrile-butadiene-styrene resin composition which is prepared by adding a brominated organic compound flame retardant, an antimony flame retardant auxiliary and one or more other compounds selected from a group consisting of metal stearate and stearamide compounds to a basic resin composed of acrylonitrile-butadiene-styrene copolymer and styrene-acrylonitrile copolymer.The acrylonitrile-butadiene-styrene resin composition of the present invention not only has excellent flame resistance but also has improved thermostability and weatherability.

Owner:LG CHEM LTD

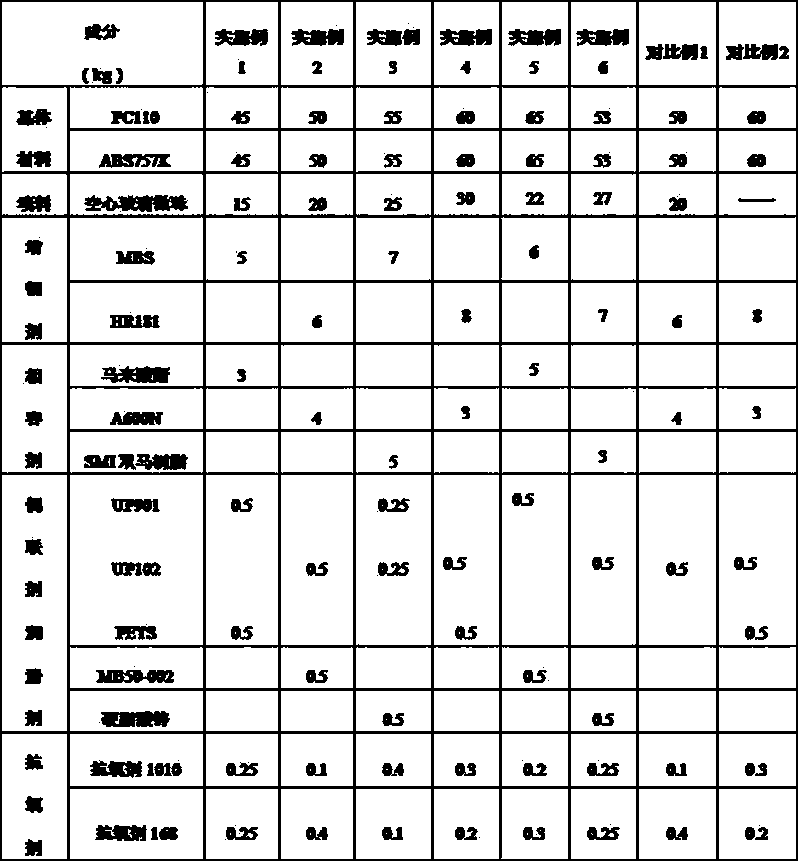

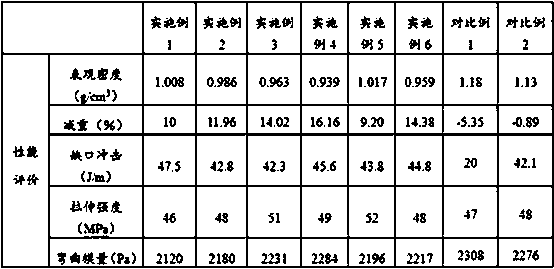

Lightweight PC/ABS weight loss composite material and preparation method thereof

ActiveCN109096725ALow densityHigh specific strengthPolycarbonateAcrylonitrile-butadiene-styrene resin

The invention discloses a lightweight PC / ABS weight loss composite material which comprises, by weight parts, 45-65 parts of polycarbonate (PC), 45-65 parts of acrylonitrile butadiene styrene resin (ABS), 15-30 parts of hollow glass beads, 5-8 parts of toughener, 3-5 parts of compatibilizer, 0.5 part of coupling agent, 0.5 part of lubricant, and 0.5 part of antioxidant. The invention also discloses a method for preparing the PC / ABS weight loss composite material. The hollow glass beads, the toughener, the coupling agent, the compatibilizer and the antioxidant are added and premixed and then added into a PC and ABS reaction system in a side feeding mode, so that the weight reduction effect of the composite material is obvious, and comprehensive mechanical properties are excellent.

Owner:江苏兆维塑料科技有限公司

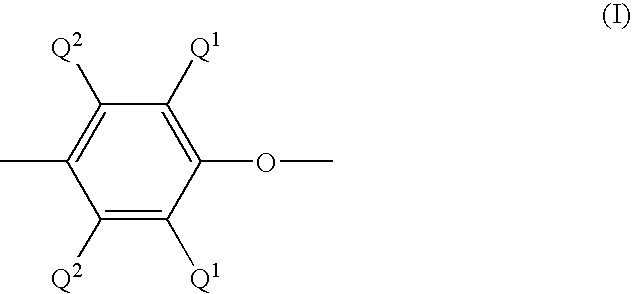

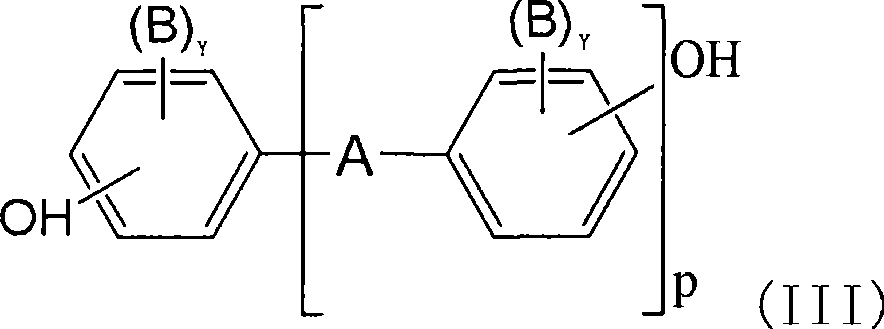

Preparation method of novel polyphenols antioxidant

InactiveCN107827713AGood compatibilityInhibition of oxidative degradationOrganic chemistryOrganic compound preparationPolystyreneEthyl acetate

The invention relates to the field of preparation of antioxidants, in particular to a preparation method of a novel polyphenols antioxidant. The preparation method comprises the following steps: preparing an intermediate which adopts 3,5-di-tert-butyl-4-hydroxy-benzyl alcohol: adding 7.27 g of paraformaldehyde, 1.08 g of potassium tert-butoxide and 100 mL of tertiary butanol into a round-bottom flask with the volume of 500 mL, heating the flask under a condition of 70 DEG C till the paraformaldehyde is depolymerized; adding 20 g of 2,6-di-tert-butylphenol into the reaction liquid for reactionunder a normal temperature condition for 3 h, then adding 200 mL of deionized water into the reaction liquid, adding 100 mL of an ethyl acetate extraction organic phase, drying the mixture with a drying agent for 2 h, and carrying out suction filtering to remove the drying agent. The preparation method is simple in process and convenient to operate; a product is relatively high in heat stability and oxidization resistance, is high in compatibility with a polymer, can inhibit oxidative degradation of polypropylene, polyethylene, acrylonitrile-butadiene-styrene resin and polystyrene, and also can be used for synthesizing natural rubber, plastic and lubricating oil.

Owner:SHAANXI QIYUAN TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com