Low-gloss polycarbonate styreneresin composite and preparation method thereof

A technology of styrene resin and polycarbonate resin, which is applied in the field of low-gloss polycarbonate styrene resin composition and preparation, can solve problems such as low efficiency, increased embossing links, and reduced physical and mechanical properties of molded products. To achieve a reasonable effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

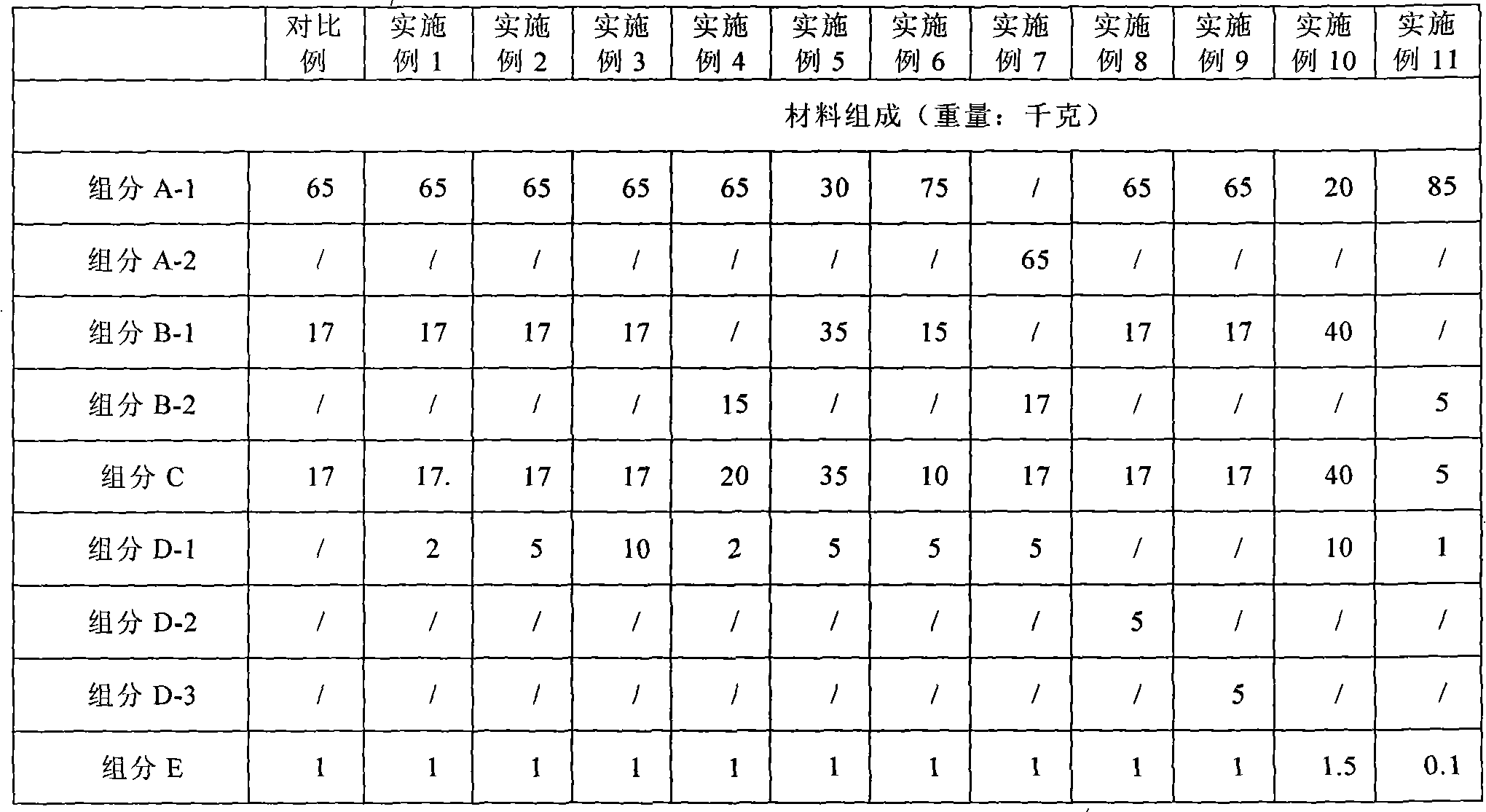

[0043] (1) Prepare materials according to the following components and content (wt%):

[0044] Component A: Polycarbonate resin (PC) accounts for 20-85%; Component B: styrene toughener accounts for 5-50%; Component C: styrene-acrylonitrile copolymer (SAN) accounts for 5- 40%, of which SAN contains 60-80% styrene, 20-40% acrylonitrile; component D: special matting agent accounts for 1%-10%; component E: processing aid accounts for 0.1-1.5%.

[0045] Among them, the polycarbonate (A) used in the present invention is well known to those skilled in the art to which the present invention belongs.

[0046] The polycarbonate resin used in the present invention is in the presence of a molecular weight modifier and a catalyst, by reacting dihydric phenol with phosgene or by transesterifying dihydric phenol with a carbonate prepolymer of diphenyl carbonate reaction to prepare.

[0047] The polycarbonate resin includes linear polycarbonate, branched polycarbonate and polyester carbonat...

Embodiment 10

[0085] (1) Prepare materials according to the following components and contents:

[0086] Polycarbonate resin 20kg, styrene toughening agent 50kg; styrene-acrylonitrile resin 40kg; special matting agent 10kg; processing aid 1.5kg, of which polycarbonate resin molecular weight 10000, styrene toughener is Styrene-butadiene-acrylonitrile, the molecular weight of styrene-acrylonitrile resin is 15000, wherein the content of styrene is 60wt%, and the content of acrylonitrile is 40wt%. The special matting agent is montmorillonite intercalated with organic matter. The organic matter is Long-chain alkanes containing at least two epoxyethyl groups and epoxypropyl groups. Montmorillonite is a silicate clay with a layered structure after organic modification. The average wafer thickness is less than 30nm. Processing aids include lubricants, anti- Oxygen agent, release agent, lubricant is pentaerythritol stearate, and antioxidant is commercially available 168 phosphite antioxidants, and ...

Embodiment 11

[0090] (1) Prepare materials according to the following components and content (wt%):

[0091] Polycarbonate resin 85kg, styrene toughening agent 5kg; styrene-acrylonitrile resin 5kg; special matting agent 1kg; processing aid 0.1kg, of which polycarbonate resin molecular weight 50000, styrene toughening agent is Styrene-butadiene-acrylate, styrene-acrylonitrile resin molecular weight is 20000, wherein styrene content is 80wt%, acrylonitrile content is 20wt%, special matting agent is the montmorillonite of intercalation organic matter, and organic matter is Long-chain alkanes containing at least two epoxyethyl groups and epoxypropyl groups. Montmorillonite is a silicate clay with a layered structure after organic modification. The average wafer thickness is less than 30nm. Processing aids include lubricants, anti- Oxygen, release agent and colorant, lubricant is pentaerythritol stearate, antioxidant is commercially available IRGANOX 1076 hindered phenolic antioxidant, release a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com