Flame-retardant and heat-resistant material for battery jar and preparation method thereof

A technology of heat-resistant materials and battery tanks, which is applied in the field of battery tank materials, can solve the problems that ABS materials have not been reported in literature, cannot be used in acidic battery tanks, and cannot be used in battery tank materials, and achieve easy operation, meet work requirements, and durability Effects of Chemical Corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

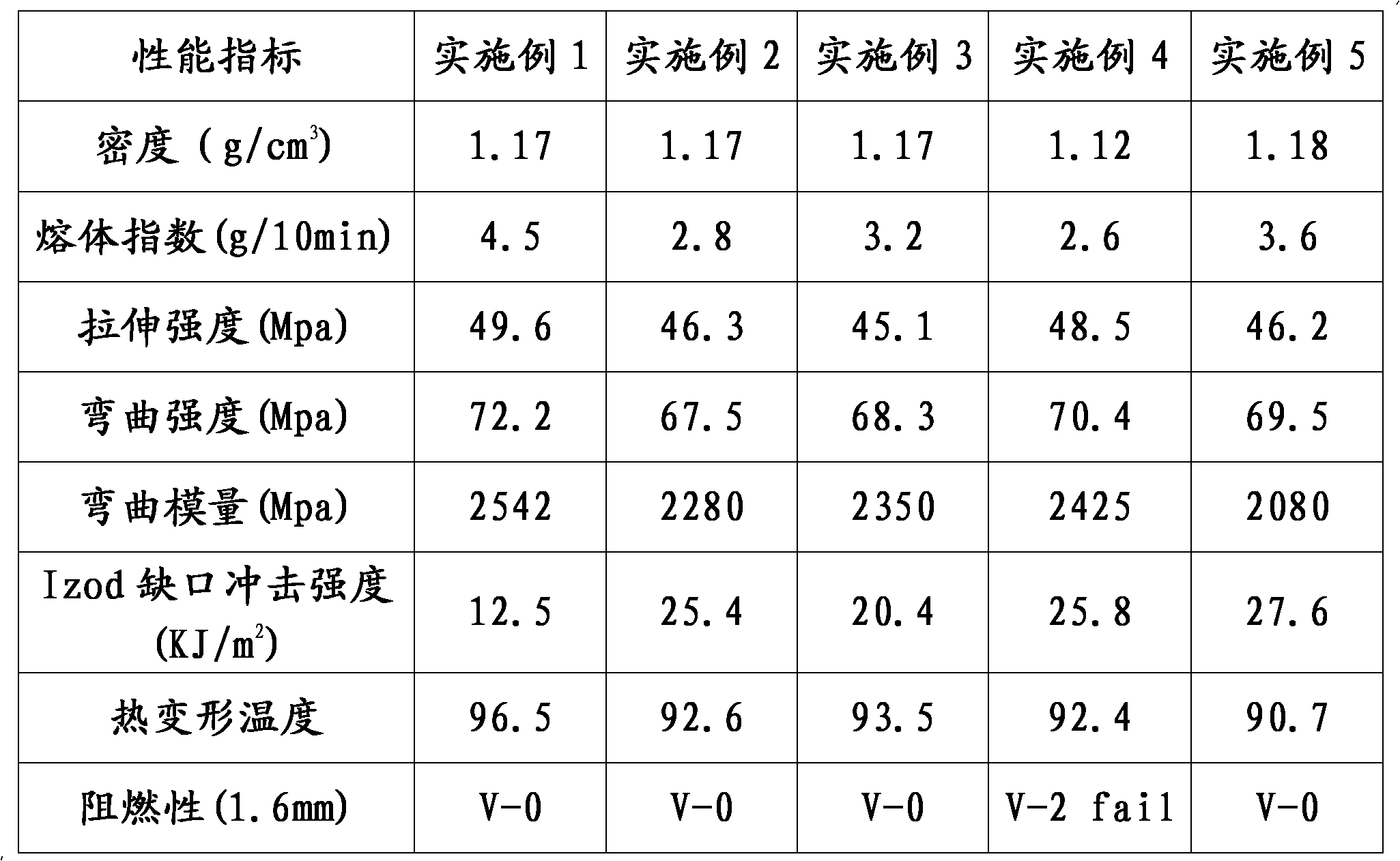

Examples

Embodiment 1

[0040] Accurately weigh 20 kg of ABS high rubber powder, 57.6 kg of styrene-acrylonitrile resin NF2200, 15 kg of brominated epoxy polymer F-3100, 5 kg of antimony trioxide, 2 kg of toughening agent P830, 0.2 kg of antioxidant agent, 0.2 kg of processing aid EB-G. Add the above-mentioned raw materials into a high-speed mixer for uniform mixing, and then feed the above-mentioned mixture into a twin-screw extruder through a precisely metered feeder for kneading, extrusion, drawing, cooling, and pelletizing to make a battery Flame-retardant and heat-resistant materials for tanks. The length-to-diameter ratio of the twin-screw extruder used in this example is 36:1, the temperature of each section of the twin-screw extruder is 190°C, 200°C, 200°C, 210°C, 210°C, and the head temperature is 210°C. °C; the screw speed is 400 rpm.

Embodiment 2

[0042] Accurately weigh 30 kg of ABS high rubber powder, 40 kg of styrene-acrylonitrile resin NF2200, 20 kg of brominated epoxy polymer F-3100, 3 kg of antimony trioxide, 6 kg of toughening agent P830, 0.5 kg of antioxidant agent, 0.5 kg of processing aid EB-G. Add the above-mentioned raw materials into a high-speed mixer for uniform mixing, and then feed the above-mentioned mixture into a twin-screw extruder through a precisely metered feeder for kneading, extrusion, drawing, cooling, and pelletizing to make a battery Flame-retardant and heat-resistant materials for tanks. The length-to-diameter ratio of the twin-screw extruder used in this example is 36:1, the temperature of each section of the twin-screw extruder is 190°C, 200°C, 200°C, 210°C, 210°C, and the head temperature is 210°C. °C; the screw speed is 400 rpm.

Embodiment 3

[0044] Accurately weigh 30 kg of ABS high rubber powder, 44 kg of styrene-acrylonitrile resin NF2200, 18 kg of brominated epoxy polymer F-3100, 4 kg of antimony trioxide, 3 kg of toughening agent P830, 0.5 kg of antioxidant agent, 0.5 kg of processing aid EB-G. Add the above-mentioned raw materials into a high-speed mixer for uniform mixing, and then feed the above-mentioned mixture into a twin-screw extruder through a precisely metered feeder for kneading, extrusion, drawing, cooling, and pelletizing to make a battery Flame-retardant and heat-resistant materials for tanks. The length-to-diameter ratio of the twin-screw extruder used in this example is 36:1, the temperature of each section of the twin-screw extruder is 190°C, 200°C, 200°C, 210°C, 210°C, and the head temperature is 210°C. °C; the screw speed is 400 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com