High-gloss high-hardness scraping-resistant ABS material

An ABS material, scratch-resistant technology, applied in the field of materials science, can solve problems such as poor scratch resistance, and achieve the effects of low cost, simple operation and easy processing

Inactive Publication Date: 2016-07-27

中广核俊尔(上海)新材料有限公司

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Aiming at the above-mentioned technical problems in the prior art, the present invention provides a high-gloss high-hardness scratch-resistant ABS material. The high-gloss high-hardness scratch-resistant ABS material is to solve the problem of high-gloss ABS in the prior art. Bad technical issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

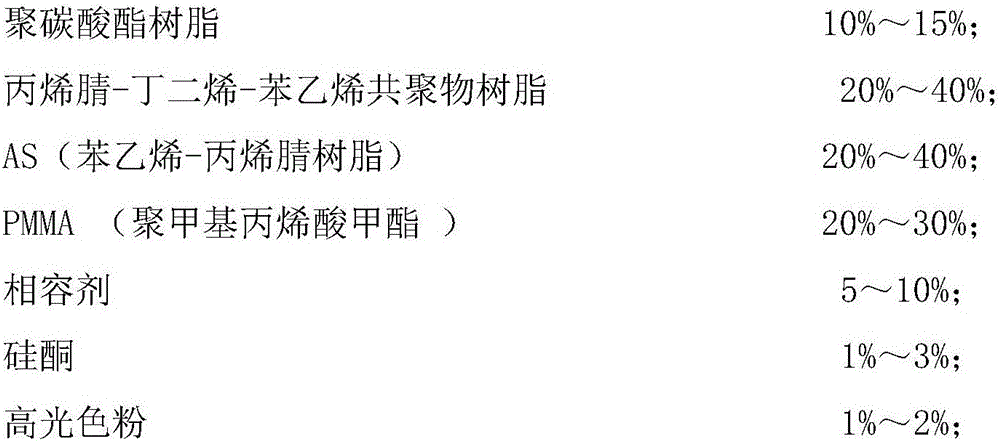

The invention provides a high-gloss high-hardness scraping-resistant ABS material which comprises the following components in percentage by mass: 10-15% of polycarbonate resin, 20-40% of an acrylonitrile-butadiene-styrol copolymer, 20-40% of styrene-acrylonitrile resin, 20-30% of polymethyl methacrylate, 5-10% of a compatilizer, 1-3% of silicone, 1-2% of a high-gloss toner and 0.1-1% of an additive. The high-gloss high-hardness scraping-resistant ABS material provided by the invention has properties of good impact resistance, high gloss, high hardness, scraping resistance and the like, and moreover is low in cost and easy to prepare. In addition, the preparation method of the high-gloss high-hardness scraping-resistant ABS material adopts conventional equipment and is simple to operate and applicable to industrial production.

Description

technical field [0001] The invention belongs to the field of material science, and relates to an ABS alloy, in particular to a high-gloss, high-hardness, scratch-resistant ABS material. Background technique [0002] ABS plastic is one of the five major synthetic plastics. It has good impact resistance, heat resistance, low temperature resistance, chemical resistance and excellent electrical properties. It also has the characteristics of easy processing, stable product size, and good surface gloss. Coating, coloring, and secondary processing such as surface metal spraying, electroplating, welding, hot pressing and bonding, etc., is a thermoplastic engineering plastic with a wide range of uses. [0003] ABS resin is widely used in industrial fields such as machinery, automobiles, electronic appliances, instrumentation, textiles and construction. The use in the automotive field includes automotive dashboards, body panels, interior trim panels, steering wheels, sound insulation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L55/02C08L25/12C08L33/12C08L69/00C08L83/04C08K3/04

CPCC08L55/02C08L25/12C08L33/12C08L2205/035C08L69/00C08L83/04C08K3/04

Inventor 杨燕黄志杰杨仓先顾伟

Owner 中广核俊尔(上海)新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com