Non-halogen flame retardant PC (polycarbonate) /ABS (acrylonitrile butadiene styrene) alloy and preparation method thereof

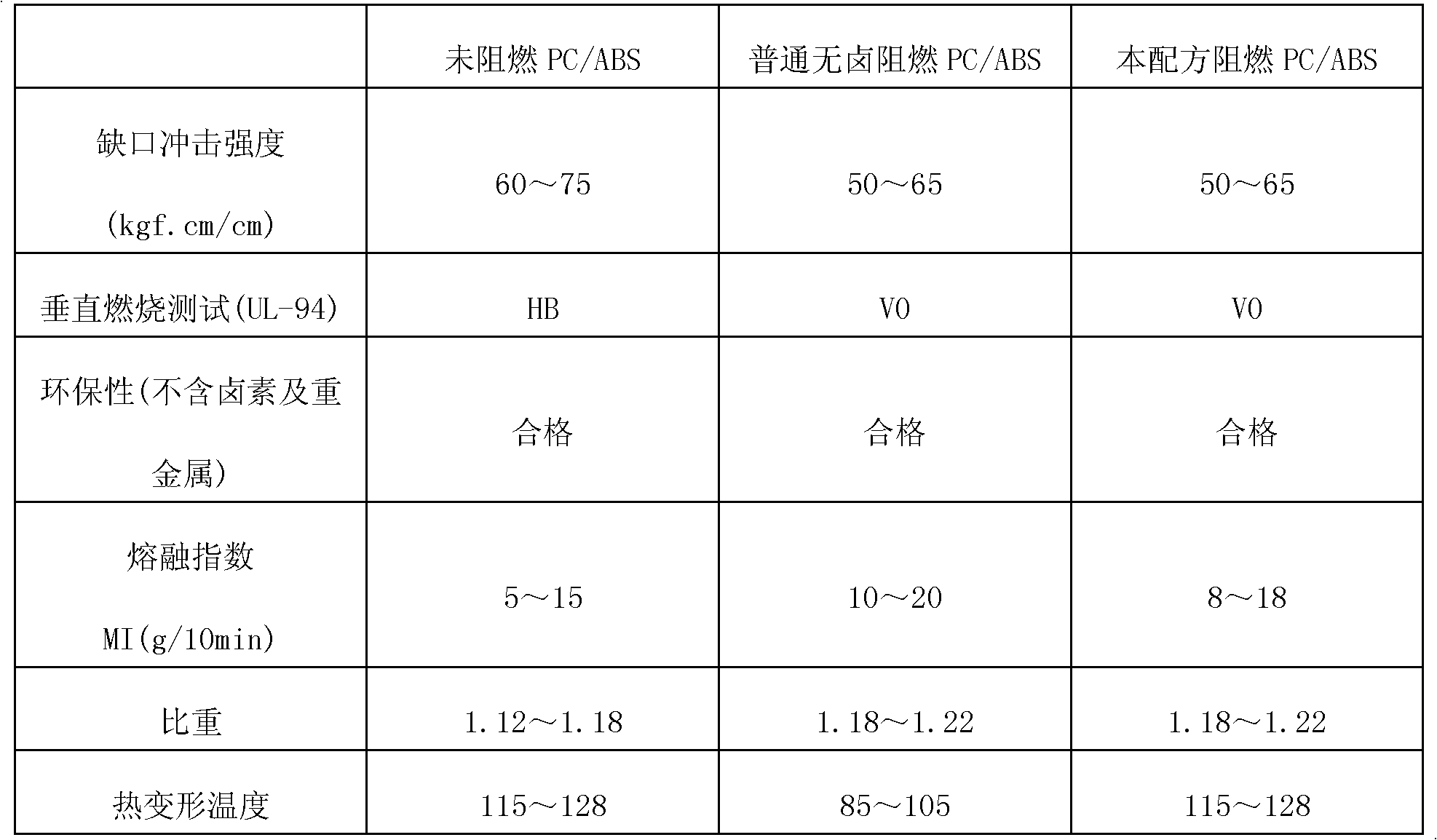

A technology of ABS resin and alloy, applied in the field of halogen-free flame retardant PC/ABS alloy, can solve problems such as adverse effects on the mechanical properties of PC/ABS alloy, and achieve the effect of improving the operating temperature range and reducing the thermal deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention will be further described in detail below.

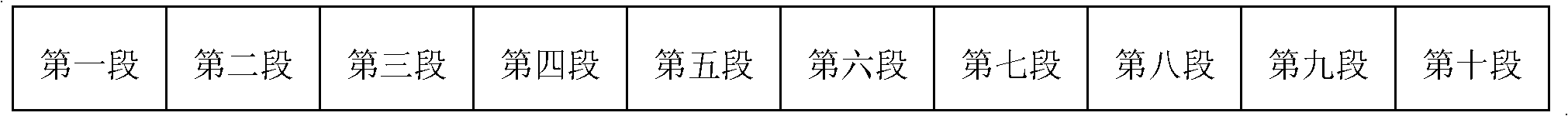

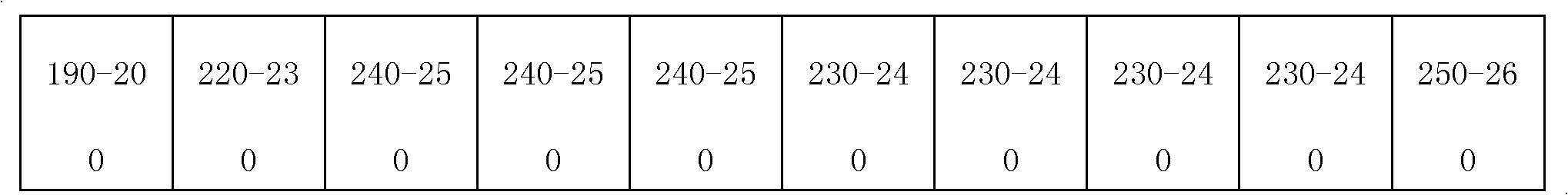

[0013] This halogen-free flame-retardant PC / ABS alloy includes 50-85 parts of PC resin, 3-25 parts of ABS resin, 3-8 parts of toughening agent, 8-20 parts of flame retardant, 0.3-1 part of antioxidant A, 0.3-1 part of antioxidant B, 0.3-0.8 part of anti-dripping agent, wherein said PC resin is bisphenol A type polycarbonate resin, said ABS resin is acrylonitrile-butadiene-styrene resin, said The toughening agent is a maleic anhydride grafted ABS resin blend, and the flame retardant is hydroxymethylphenyl phosphinate, methylphenyl phosphate, methylphenyl phosphate, methylphenyl phosphinate At least one of the phosphate esters, the antioxidant A is 1010, i.e. tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester, and the antioxidant B is 168, i.e. Tris(2.4-di-tert-butylphenyl) phosphite, anti-dripping agent is polytetrafluoroethylene resin.

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com